ASTM F1233-98(2004)

(Test Method)Standard Test Method for Security Glazing Materials And Systems

Standard Test Method for Security Glazing Materials And Systems

SIGNIFICANCE AND USE

This test method is based on field experience rather than laboratory analysis. It provides a basis for the comparative evaluation of ballistic/forced entry/containment resistance of security glazings and systems and should not be used to establish or confirm the absolute prevention of forcible entries or forced exits. This test method defines three factors which determine the success or failure of any attempt to forcefully enter (or exit) the glazing or system. They are: (1) the tools employed, (2) the techniques and methods used by the attackers, and (3) the total time available to effect the entry or exit. This test method defines two of the three factors (tools and techniques) and allows the third (duration) to vary in order to establish levels of forced entry or exit resistance.

SCOPE

1.1 This test method sets forth procedures whose purpose is limited to the evaluation of the resistance of security glazing materials and systems against the following threats:

1.1.1 Ballistic Impact,

1.1.2 Blunt Tool Impacts,

1.1.3 Sharp Tool Impacts,

1.1.4 Thermal Stress and

1.1.5 Chemical Deterioration.

Note 1—Specifically exempted from this test method are the use of power (motor or engine-driven) tools or devices, explosives, military ordinance (excepting small arms) and tools, processes or devices requiring more than two persons to transport and operate.

1.2 The values stated in inch-pounds are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For a specific warning statement, see Warning in 9.1.1.6.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F 1233–98(Reapproved 2004)

Standard Test Method for

Security Glazing Materials And Systems

This standard is issued under the fixed designation F 1233; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope (SAAMI)—Ammunition

United States Military Ammunition Specifications—

1.1 This test method sets forth procedures whose purpose is

Ammunition

limited to the evaluation of the resistance of security glazing

Federal Specification GGG-313U—Cold Chisel

materials and systems against the following threats:

American Iron and Steel Institute M-1020—Structural

1.1.1 Ballistic Impact,

Steel

1.1.2 Blunt Tool Impacts,

UL 10BC—Fire Extinguisher

1.1.3 Sharp Tool Impacts,

1.1.4 Thermal Stress, and

3. Terminology

1.1.5 Chemical Deterioration.

3.1 Definitions:

NOTE 1—Specifically exempted from this test method are the use of

3.1.1 test director—theindividualidentifiedbytheindepen-

power (motor or engine-driven) tools or devices, explosives, military

dent testing laboratory as being responsible to complete the

ordinance(exceptingsmallarms)andtools,processesordevicesrequiring

specified tests as required and to document the results.

more than two persons to transport and operate.

1.2 The values stated in inch-pounds are to be regarded as

4. Summary of Test Method

the standard. The values given in parentheses are for informa-

4.1 Forced entry shall be determined by resistance of the

tion only.

glazing material or system to the following:

1.3 This standard does not purport to address all of the

4.1.1 Ballistics attack only.

safety concerns, if any, associated with its use. It is the

4.1.2 Physical attack only to include blunt tool impacts,

responsibility of the user of this standard to establish appro-

sharp tool impacts, thermal stress, and chemical deterioration.

priate safety and health practices and determine the applica-

4.1.3 Ballisticsattackfollowedby,andincombinationwith,

bility of regulatory limitations prior to use. For a specific

physical attack.

warning statement, see Warning in 9.1.1.6.

5. Significance and Use

2. Referenced Documents

5.1 Thistestmethodisbasedonfieldexperienceratherthan

2.1 ASTM Standards:

laboratory analysis. It provides a basis for the comparative

A36/A36M Specification for Carbon Structural Steel

evaluation of ballistic/forced entry/containment resistance of

A53/A53M Specification for Pipe, Steel, Black and Hot-

security glazings and systems and should not be used to

Dipped, Zinc-Coated, Welded and Seamless

establish or confirm the absolute prevention of forcible entries

A 574 Specification for Alloy Steel Socket-Head Cap

or forced exits. This test method defines three factors which

Screws

determine the success or failure of any attempt to forcefully

F1029 Guide for Selection of Physical Security Measures

enter (or exit) the glazing or system. They are: (1) the tools

for a Facility

employed, (2) the techniques and methods used by the attack-

2.2 Other Documents:

ers, and (3) the total time available to effect the entry or exit.

Sporting Arms and Ammunition Manufacturer’s Institute

Available from Sporting Arms and Ammunition Manufacturers’ Association

This test method is under the jurisdiction of Committee F12 on Security (SAAMI), Box 1075, Riverside, CT 06878.

Systems and Equipment and is the direct responsibility of Subcommittee F12.10 on Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Systems Products and Services. Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098

Current edition approved April 1, 2004. Published April 2004. Originally Available from General Services Adm., 7th and D Sts. SW, Washington, DC

approved in 1989. Last previous edition approved in 1998 as F1233–98. 20407.

2 6

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American Iron and Steel Institute (AISI), 1101 17th St., NW,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Suite 1300, Washington, DC 20036.

Standards volume information, refer to the standard’s Document Summary page on Available from Underwriters Laboratories (UL), Corporate Progress, 333

the ASTM website. Pfingsten Rd., Northbrook, IL 60062.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1233–98 (2004)

This test method defines two of the three factors (tools and 6.3.1 Aluminumfoil,kitchenfoil,orequivalent,0.00094in.

techniques) and allows the third (duration) to vary in order to (.024 mm) 610% thick. Alloy may be 8111 or 1100, “0”

establish levels of forced entry or exit resistance. temper.

6.4 Instrumentation:

6.4.1 Photosensitive Triggering Screens,

6. Apparatus (Ballistics)

6.4.2 Chronograph,

6.1 Ballistic Firing Devices—Firearms or test barrels suit-

6.4.3 Thermometer—Temperature range from +120 to

able for use with the following calibers of ammunition pro-

−30°F (+49 to −16°C).

ducing minimum velocities as required:

6.5 Test Frame and Stand:

6.1.1 .38 Special, 158 grain (10.2g), lead,

6.5.1 Samples of glazing submitted for testing shall be in

6.1.2 .357 Magnum, 158 grain (10.2g), jacketed soft point,

sizes that would be encountered during normal use, but in no

6.1.3 9mm, 124 grain (8.0g), full metal casing,

casesmallerthan12by12in.(30by30cm)orlargerthan29 ⁄4

6.1.4 .44 Magnum, 240 grain (15.6g), lead gas check,

by 29 ⁄4 in. (75 by 75 cm). The size and configuration of each

6.1.5 .223 (5.56 mm, M193 Ball),55grain(3.6g),fullmetal

sample will be such that it can be mounted in a structurally

casing,

sound,rigidtestfixturecapableofaccommodatingavarietyof

6.1.6 .30–’06, 180 grain (11.7g), soft point,

sizes of rectangular samples. The framing must be affixed to

6.1.7 .308 Winchester (7.62 mm, M80 Ball), 147 grain

the glazing sample in a manner which does not enhance or

(9.5g), full metal casing,

detract from the ballistic resistance of any portion of the

6.1.8 .30–’06, 164 grain (10.6g), M2-AP (armor piercing),

sample to be ballistically impacted. For testing of glazing

6.1.9 12 gage, 3 in. Magnum, 00 Buckshot, 15 pellets, and

materials only, the mounting method is not subject to any tests

6.1.10 12 gage, 1 oz. (437.5 grain, 28.3g), rifled slug.

herein.

6.2 Ammunition/Standard Specification Ballistic Protection

6.6 Test Set-Up:

Levels—All ammunition used in conducting tests within this

6.6.1 The sample shall be mounted rigidly (bolted) to the

test method shall be manufactured in compliance with current

test fixture to produce a zero degree (63 degrees (estimated))

configurations and standards established by the SportingArms

obliquity (ZDO) to the path of the bullet. Photosensitive

andAmmunition Manufacturer’s Institute (SAAMI) or United

triggering screens shall be positioned 5 and 15 ft (1.5 and 4.5

States Military Specifications as applicable, except as may be

m) from the threat side of the sample which, in conjunction

notedwithinthistestmethod.Thistestmethodshallbedefined

with an elapsed time counter or direct reading chronograph,

by the following ballistic threat levels:

shallbeusedtodeterminebulletvelocities10ft(3m)fromthe

6.2.1 Caliber 9 mm Parabellum/Submachine Gun—

strike face of the sample. The test weapon shall be rigidly

Ammunition conforming to U.S. Military specifications for

mounted at a distance of 25 ft (7.5 m) from the muzzle to the

caliber 9 mm NATO 124 grain copper jacket producing

targetareaofthetestassembly.Thetestweaponshallbeaimed

velocities of 1400 (650) ft per s (425 (615) m pers) at 15 ft

to produce a zero degree obliquity trajectory to the target area

(4.5 m) from the muzzle.

within the tolerances of this test method.

6.2.2 Caliber .44 Magnum/Handgun—Ammunition con-

6.6.2 The witness material shall be securely positioned

formingtoSAAMIspecificationsforcaliber.44Magnum,240

parallel to, and no more than 6 in. (15 cm) behind (protected

grain, soft point producing velocities of 1450 (650) ft per s

side), the target area of the test assembly. Curvilinear features

(425 (615) m pers) at 15 ft (4.5 m) from the muzzle.

of the target area shall therefore have the witness contoured to

6.2.3 Caliber .38 Super/Handgun—Ammunition conform-

parallel these features. The witness material shall be stretched

ing to SAAMI Specifications for caliber .38 super, 130 grain,

taut.

metal case producing, velocities of 1280 (650) ft. per s (390

6.6.3 Should there be reason to suspect bullet flight stabili-

(615) m pers) at 15 ft (4.5 m) from the muzzle.

ties, the test director is obligated to implement a paper witness

6.2.4 Caliber 7.62 mm Steel Jacketed NATO/Rifle—

panel, positioned 3 ft (91 cm) in front of the target area. This

Ammunition conforming to U.S. Military specifications for

witnesspanelshallbeinspectedfollowingeachtestfiringasto

caliber7.62mmNATO,M80ballproducingvelocitiesof2800

indication of a yawed projectile. Evidence of a yawed or

(650) ft per s (850 (615) m per s) at 15 ft (4.5 m) from the

unstable projectile shall constitute an unfair hit, and shall

muzzle.

require retesting.

6.2.5 Caliber .30–’06 Armor Piercing/Rifle (AP)—

6.6.4 The number and location of ballistic impacts required

Ammunition conforming to U.S. Military specifications for

of this specification are minimum requirements. Further, the

caliber .30–’06, M2AP producing velocities of 2775 (650) ft

testdirectorshallbeobligatedtoconductzerodegreeobliquity

per s (845 (615) m per s) at 15 ft (4.5 m) from the muzzle.

orobliquefirings(asrequiredbydesign)intothetestspecimen

6.2.6 Shotshell 12-gage 3 in. Magnum/Shotgun—

features that have design features passing completely or

Ammunition conforming to SAAMI specifications for Shot-

partially through the thickness of the glazing to examine all

shell12-gage,3in.Magnum,00Buckshotproducingvelocities

of 1315 (650) ft per s (400 (615) m per s) at 15 ft (4.5 m)

The sole source of supply of the apparatus known to the committee at this time

from the muzzle. The 12-gage ballistic threat is to be used as

is Oehler Research, P.O. Box 9135, Austin, TX 78766. If you are aware of

a confirmatory test of assemblies. Glazing materials are not to

alternative suppliers, please provide this information to ASTM International

be tested or rated against this threat.

Headquarters.Your comments will receive careful consideration at a meeting of the

6.3 Witness Material: responsible technical committee , which you may attend.

F 1233–98 (2004)

possible penetration paths. Not only shall the primary weapon/

ammunition be used, but the 12-gage shotgun (as defined

within this test method as an adjunct to the primary test) as

well. The 12-gage ballistic threat is to be used as a confirma-

torytestofassemblies.Glazingmaterialsarenottobetestedor

rated against this threat.

6.6.4.1 Due to chronograph/triggering screen accessibility,

thetestdirectormayelectnottoelectronicallymeasuremuzzle

velocities of certain oblique firings.

7. Apparatus (Physical Attack)

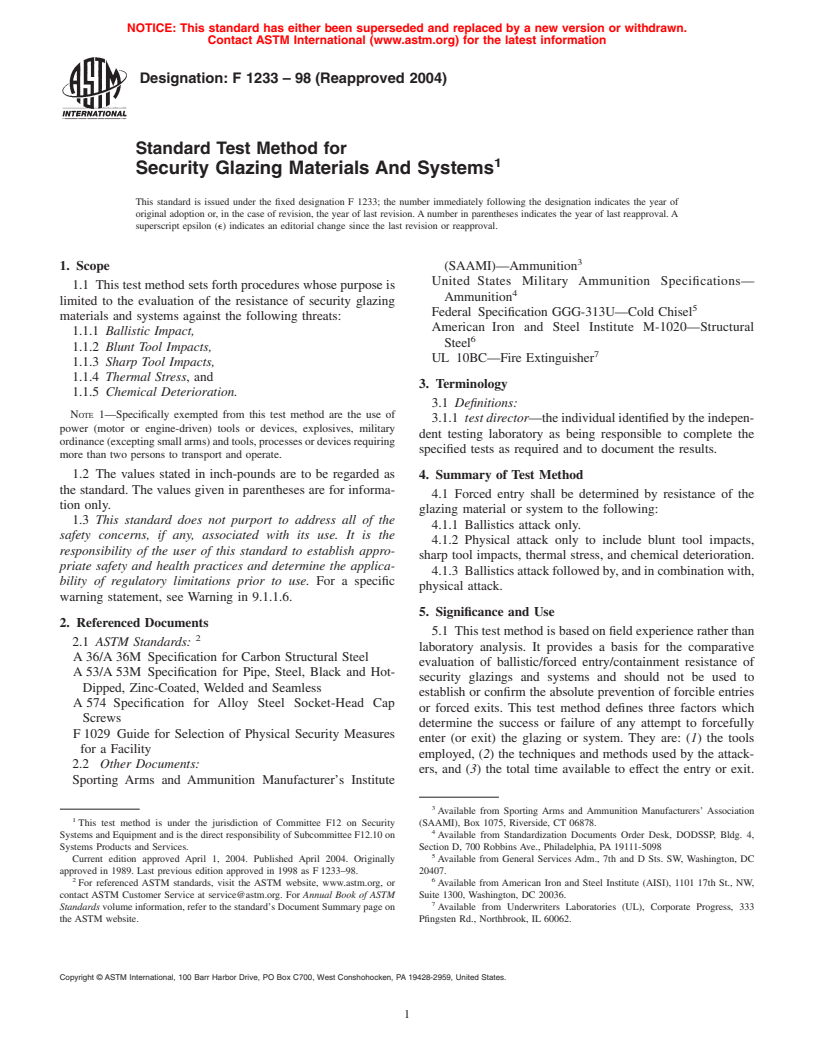

7.1 TestStand—Thetestglazingsampleswillbemountedin

a vertical test stand of rigid, 6 in. (15 cm) steel wide flange

beams as in Fig. 1. The wide flange beam stand will be

anchored in, or rigidly fixed to, a substantial concrete structure

at each of its four corners (minimum requirements), and no

linear dimension between supports of the test will exceed 8 ft

FIG. 2 Glazing Material Test Frame

(2.5 m).

7.2 Test Frame:

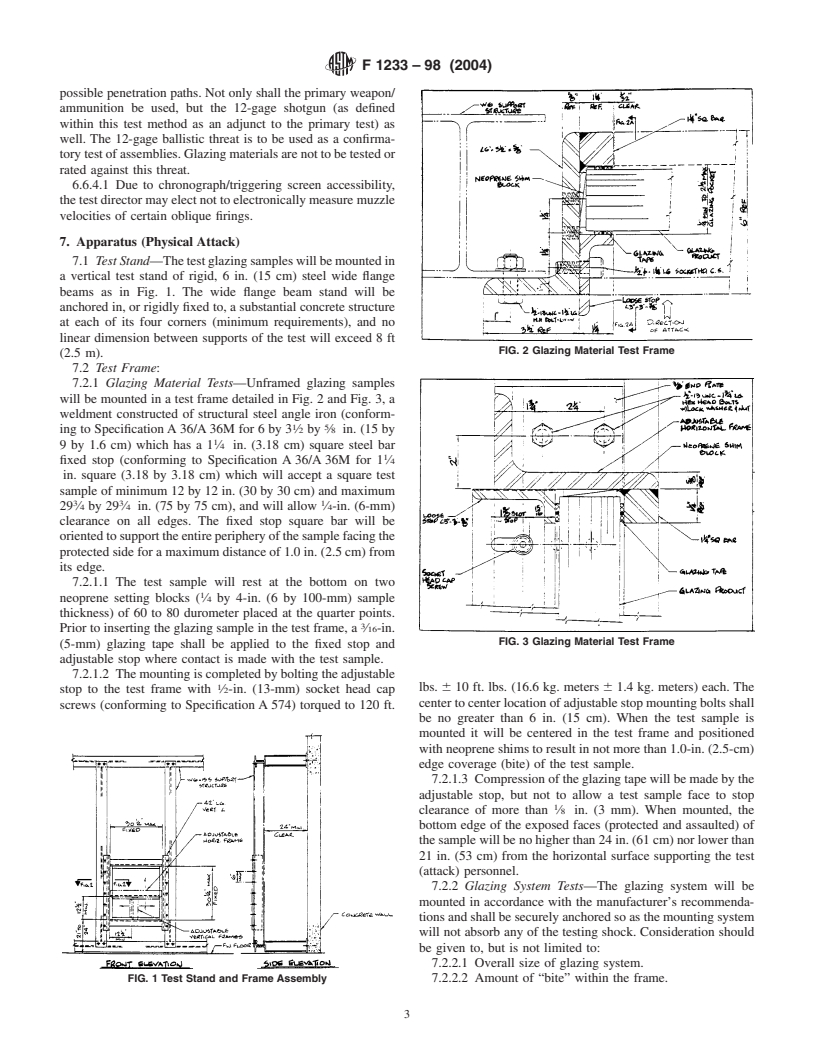

7.2.1 Glazing Material Tests—Unframed glazing samples

will be mounted in a test frame detailed in Fig. 2 and Fig. 3, a

weldment constructed of structural steel angle iron (conform-

1 5

ing to SpecificationA36/A36M for 6 by 3 ⁄2 by ⁄8 in. (15 by

9 by 1.6 cm) which has a 1 ⁄4 in. (3.18 cm) square steel bar

fixed stop (conforming to Specification A36/A36M for 1 ⁄4

in. square (3.18 by 3.18 cm) which will accept a square test

sample of minimum 12 by 12 in. (30 by 30 cm) and maximum

3 3 1

29 ⁄4 by 29 ⁄4 in. (75 by 75 cm), and will allow ⁄4-in. (6-mm)

clearance on all edges. The fixed stop square bar will be

orientedtosupporttheentireperipheryofthesamplefacingthe

protectedsideforamaximumdistanceof1.0in.(2.5cm)from

its edge.

7.2.1.1 The test sample will rest at the bottom on two

neoprene setting blocks ( ⁄4 by 4-in. (6 by 100-mm) sample

thickness) of 60 to 80 durometer placed at the quarter points.

Prior to inserting the glazing sample in the test frame, a ⁄16-in.

FIG. 3 Glazing Material Test Frame

(5-mm) glazing tape shall be applied to the fixed stop and

adjustable stop where contact is made with the test sample.

7.2.1.2 Themountingiscompletedbyboltingtheadjustable

lbs. 610 ft. lbs. (16.6 kg. meters 61.4 kg. meters) each. The

stop to the test frame with ⁄2-in. (13-mm) socket head cap

centertocenterlocationofadjustablestopmountingboltsshall

screws (conforming to Specification A574) torqued to 120 ft.

be no greater than 6 in. (15 cm). When the test sample is

mounted it will be centered in the test frame and positioned

withneopreneshimstoresultinnotmorethan1.0-in.(2.5-cm)

edge coverage (bite) of the test sample.

7.2.1.3 Compressionoftheglazingtapewillbemadebythe

adjustable stop, but not to allow a test sample face to stop

clearance of more than ⁄8 in. (3 mm). When mounted, the

bottom edge of the exposed faces (protected and assaulted) of

thesamplewillbenohigherthan24in.(61cm)norlowerthan

21 in. (53 cm) from the horizontal surface supporting the test

(attack) personnel.

7.2.2 Glazing System Tests—The glazing system will be

mounted in accordance with the manufacturer’s recommenda-

tionsandshallbesecurelyanchoredsoasthemountingsystem

will not absorb any of the testing shock. Consideration should

be given to, but is not limited to:

7.2.2.1 Overall size of glazing system.

FIG. 1 Test Stand and Frame Assembly 7.2.2.2 Amount of “bite” within the frame.

F 1233–98 (2004)

7.2.2.3 Integrity of the frame. 7.8.1 Six males, muscular (180 to 250 lb (82 to 113 kg)), in

7.2.2.4 Strength of base material. good health, who carry out an enthusiastic assault.

7.2.2.5 Size of removable stop. 7.8.2 No less than two members of the test team will be

7.2.2.6 Removable stop fastener. left-handed, and no less than two shall be right-handed.

7.2.2.7 Interface between glazing and frame. 7.9 Test Specimens:

7.2.2.8 Integrity of anchorage of glazing system to adjoin- 7.9.1 Number of Samples—All testing is done on a single

ing architectural features. sample. Replicate testing is to be specified by the purchaser.

7.3 Blunt Impacting Tools: 7.9.2 Size of Samples:

7.3.1 Sledge Hammer, 12-lb (5.5-kg), double-face

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.