ASTM B393-09

(Specification)Standard Specification for Niobium and Niobium Alloy Strip, Sheet, and Plate

Standard Specification for Niobium and Niobium Alloy Strip, Sheet, and Plate

ABSTRACT

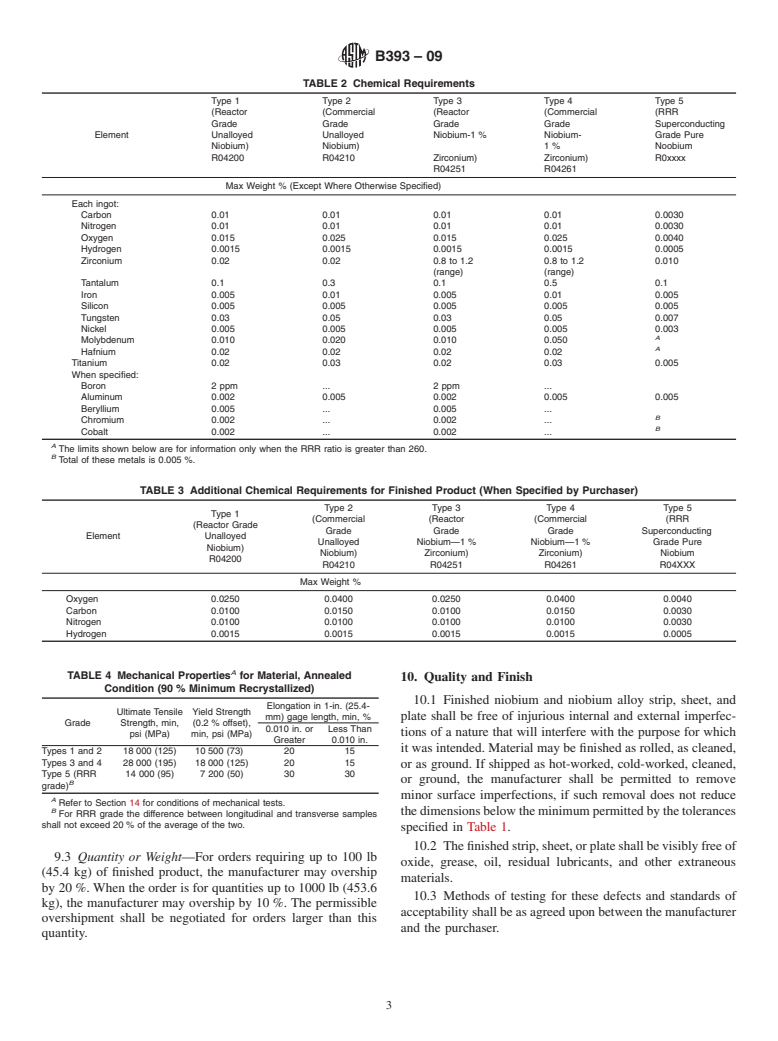

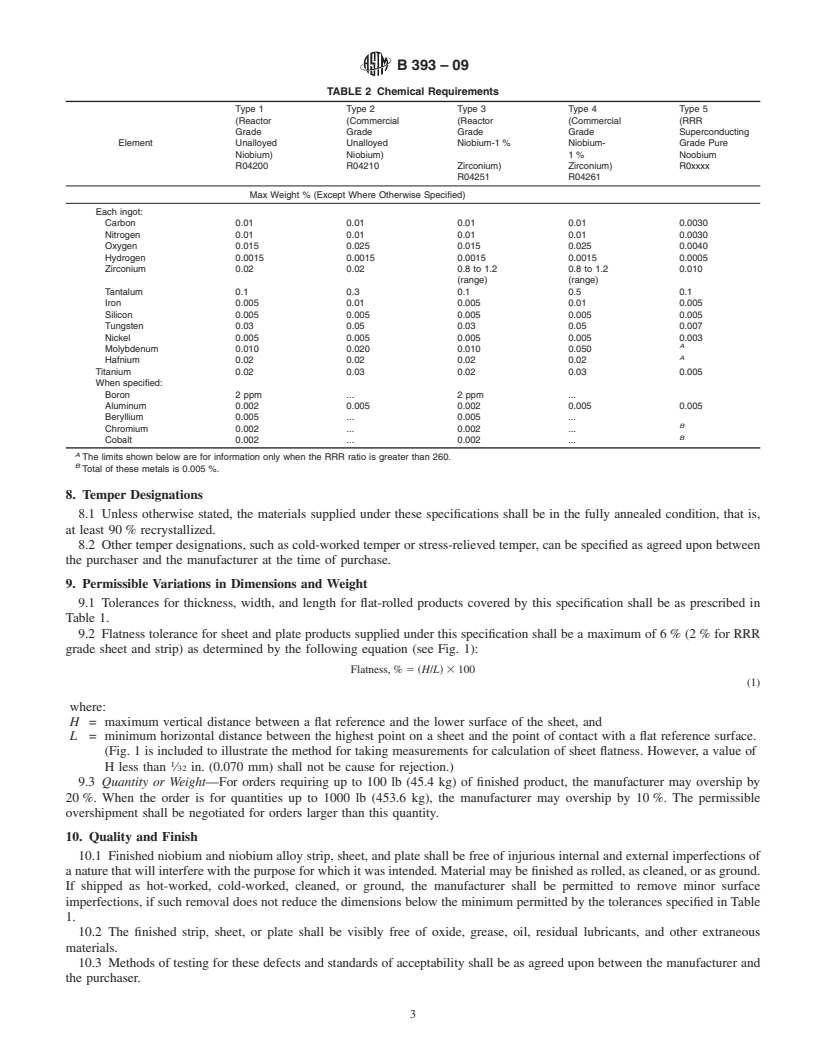

This specification covers five grades of wrought niobium and niobium alloy strip, sheet, and plate. These are reactor grade unalloyed niobium (R04200-Type 1), commercial grade unalloyed niobium (R04210-Type 2), reactor grade niobium alloy containing 1% zirconium (R04251-Type 3), commercial grade niobium alloy containing 1% zirconium (R04261-Type 4), and RRR grade pure niobium (R0xxxx-Type 5). The RRR grade pure niobium is used in superconducting applications that require ultra high purity, making it conducive to very large grains that can adversely affect formability. It is therefore not recommended for other applications. The materials shall be made from ingots produced by vacuum or plasma arc welding, vacuum electron-beam melting, or a combination of these three methods. The various niobium mill products covered by this specification are formed with the conventional extrusion, forging, swaging, rolling, and drawing equipment normally available in metal working plants. Samples for chemical and tension testing shall be taken from the finished material after the metallurgical processing to determine conformity to this specification. The samples may be taken prior to final inspection and minor surface conditioning by abrasion and pickling shall be representative of the finished product.

SIGNIFICANCE AND USE

For the purposes of determining compliance with the specified limits for requirements of the properties listed in this specification, an observed value or a calculated value shall be rounded as indicated in accordance with the rounding method of Practice E29.

SCOPE

1.1 This specification covers five grades of wrought niobium and niobium alloy strip, sheet, and plate as follows:

1.1.1 R04200-Type 1—Reactor grade unalloyed niobium,

1.1.2 R04210-Type 2—Commercial grade unalloyed niobium,

1.1.3 R04251-Type 3—Reactor grade niobium alloy containing 1 % zirconium, and

1.1.4 R04261-Type 4—Commercial grade niobium alloy containing 1 % zirconium.

1.1.5 R0xxxx-Type 5—RRR grade pure niobium.

Note 1—This grade of niobium is used in superconducting applications that require the ultra high purity. Because of the high purity the product is conducive to very large grains that can adversely affect formability. It is not recommended for other applications.

1.2 Except for dimensional tolerances in Table 1, the values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 The following precautionary caveat pertains only to the test methods portion of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B393 – 09

Standard Specification for

1

Niobium and Niobium Alloy Strip, Sheet, and Plate

This standard is issued under the fixed designation B393; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E29 Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications

1.1 This specification covers five grades of wrought nio-

E2626 Guide for Spectrometric Analysis of Reactive and

bium and niobium alloy strip, sheet, and plate as follows:

Refractory Metals

1.1.1 R04200-Type 1—Reactor grade unalloyed niobium,

1.1.2 R04210-Type 2—Commercial grade unalloyed nio-

3. Terminology

bium,

3.1 Definitions of Terms Specific to This Standard:

1.1.3 R04251-Type 3—Reactor grade niobium alloy con-

3.1.1 lot, n—alotshallconsistofallmaterialproducedfrom

taining 1 % zirconium, and

the same ingot at one time, with the same cross section,

1.1.4 R04261-Type 4—Commercial grade niobium alloy

processed with the same nominal metallurgical parameters and

containing 1 % zirconium.

heat treated at the same conditions.

1.1.5 R0xxxx-Type 5—RRR grade pure niobium.

3.1.2 plate, n—a flat product 6 in. (152.4 mm) or more in

NOTE 1—Thisgradeofniobiumisusedinsuperconductingapplications

3

width and greater than ⁄16 in. (4.76 mm) in thickness.

that require the ultra high purity. Because of the high purity the product is

3.1.3 sheet, n—a flat product 6 in. (152.4 mm) or more in

conducive to very large grains that can adversely affect formability. It is

3

width and from 0.005 in. (0.13 mm) to ⁄16 in. (4.76 mm) in

not recommended for other applications.

thickness.

1.2 Except for dimensional tolerances in Table 1, the values

3.1.4 strip, n—aflatproduct,whichmaybesuppliedincoil,

stated in inch-pound units are to be regarded as standard. The

less than 6 in. (152.4 mm) in width and from 0.005 in. (0.13

values given in parentheses are mathematical conversions to SI

3

mm) to ⁄16 in. (4.76 mm) in thickness.

units that are provided for information only and are not

considered standard.

4. Ordering Information

1.3 The following precautionary caveat pertains only to the

4.1 Orders for materials under this specification shall in-

test methods portion of this specification. This standard does

clude the following information as applicable:

not purport to address all of the safety concerns, if any,

4.1.1 Type and grade (Section 1),

associated with its use. It is the responsibility of the user of this

4.1.2 ASTM designation and year of issue,

standard to establish appropriate safety and health practices

4.1.3 Quantityinweight,numberofpieces,anddimensions,

and determine the applicability of regulatory limitations prior

4.1.4 Chemistry (6.3),

to use.

4.1.5 Temper designation (Section 8),

4.1.6 Permissible overshipment (9.3),

2. Referenced Documents

4.1.7 Quality and finish (10.3),

2

2.1 ASTM Standards:

4.1.8 Sampling (11.2),

B391 Specification for Niobium and Niobium Alloy Ingots

4.1.9 Inspection (Section 15),

E8 Test Methods for Tension Testing of Metallic Materials

4.1.10 Required reports (Section 17),

4.1.11 Marking (Section 18), and

1

4.1.12 Additions to the specification and supplementary

This specification is under the jurisdiction of ASTM Committee B10 on

Reactive and Refractory Metals and Alloys and is the direct responsibility of

requirements, as required.

Subcommittee B10.03 on Niobium and Tantalum.

Current edition approved Oct. 1, 2009. Published December 2009. Originally

5. Materials and Manufacture

approved in 1999. Last previous edition approved in 2005 as B393 - 05. DOI:

5.1 Material covered by this specification shall be made

10.1520/B0393-09.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

from ingots that conform to Specification B391 and that are

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

produced by vacuum or plasma arc melting, vacuum electron-

Standards volume information, refer to the standard’s Document Summary page on

beam melting, or a combination of these three methods.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B393 – 09

TABLE 1 Dimensional Tolerances for Niobium Flat-Rolled Products

A B

Tolerance on Thickness plus or Tolerance on Width (slit) plus or

Tolerance on Sheared Lengths, in. (mm)

minus, in. (mm) in lower table minus, in.(mm) in lower table

Thickness of Material,

Length 12 in. or 304.8 mm

Width6to24in. Width6to24in.

in. (mm) in lower table Length over 12 in. or 304.8 mm

Width under 6 i

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B393–05 Designation: B 393 – 09

Standard Specification for

1

Niobium and Niobium Alloy Strip, Sheet, and Plate

This standard is issued under the fixed designation B 393; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers five grades of wrought niobium and niobium alloy strip, sheet, and plate as follows:

Note1—Committee B10 has adopted “niobium” as the designation for Element No. 41, formerly named “columbium.”

1.1.1 R04200-Type 1—Reactor grade unalloyed niobium,

1.1.2 R04210-Type 2—Commercial grade unalloyed niobium,

1.1.3 R04251-Type 3—Reactor grade niobium alloy containing 1 % zirconium, and

1.1.4 R04261-Type 4—Commercial grade niobium alloy containing 1 % zirconium.

1.1.5 R0xxxx-Type 5—RRR grade pure niobium.

NOTE2—This 1—Thisgradeofniobiumisusedinsuperconductingapplicationsthatrequiretheultrahighpurity.Becauseofthehighpuritytheproduct

is conducive to very large grains that can adversely affect formability. It is not recommended for other applications.

1.2 Except for dimensional tolerances in Table 1, the values stated in inch-pound units are to be regarded as the standard. The

values given in parentheses are for information only. , the values stated in inch-pound units are to be regarded as standard. The

values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered

standard.

1.3 The following precautionary caveat pertains only to the test methods portion of this specification. This standard does not

purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to

establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

B 391 Specification for Niobium and Niobium Alloy Ingots

E8 Test Methods for Tension Testing of Metallic Materials

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications Practice for Using

Significant Digits in Test Data to Determine Conformance with Specifications

E 2626 Guide for Spectrometric Analysis of Reactive and Refractory Metals

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 lot, n—a lot shall consist of all material produced from the same ingot at one time, with the same cross section, processed

with the same nominal metallurgical parameters and heat treated at the same conditions.

3

3.1.2 plate, n—a flat product 6 in. (152.4 mm) or more in width and greater than ⁄16 in. (4.76 mm) in thickness.

3

3.1.3 sheet, n—a flat product 6 in. (152.4 mm) or more in width and from 0.005 in. (0.13 mm) to ⁄16 in. (4.76 mm) in thickness.

3.1.4 strip, n—a flat product, which may be supplied in coil, less than 6 in. (152.4 mm) in width and from 0.005 in. (0.13 mm)

3

to ⁄16 in. (4.76 mm) in thickness.

4. Ordering Information

4.1 Orders for materials under this specification shall include the following information as applicable:

4.1.1 Type and grade (Section 1),

4.1.2 ASTM designation and year of issue,

1

This specification is under the jurisdiction of ASTM Committee B10 on Reactive and Refractory Metals and Alloys and is the direct responsibility of Subcommittee

B10.03 on Niobium and Tantalum.

Current edition approved MayOct. 1, 2005.2009. Published June 2005.October 2009. Originally approved in 1999. Last previous edition approved in 20032005 as

B 393 - 035.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B393–09

TABLE 1 Dimensional Tolerances for Niobium Flat-Rolled Products

A B

Tolerance on Thickness plus or Tolerance on Width (slit) plus or

Tolerance on Sheared Lengths, in. (mm)

minus, in. (mm) in lower table minus, in.(mm) in lower table

Thickness of Material,

Length 12 in. or 304.8 mm

Width6to24in. Width6to24in.

in. (mm) in lower table Length over 12 in. or 304.8 mm

Width under 6 in. Width under

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.