ASTM A501-01

(Specification)Standard Specification for Hot-Formed Welded and Seamless Carbon Steel Structural Tubing

Standard Specification for Hot-Formed Welded and Seamless Carbon Steel Structural Tubing

SCOPE

1.1 This specification covers black and hot-dipped galvanized hot-formed welded and seamless carbon steel square, round, rectangular, or special shape structural tubing for welded, riveted, or bolted construction of bridges and buildings, and for general structural purposes.

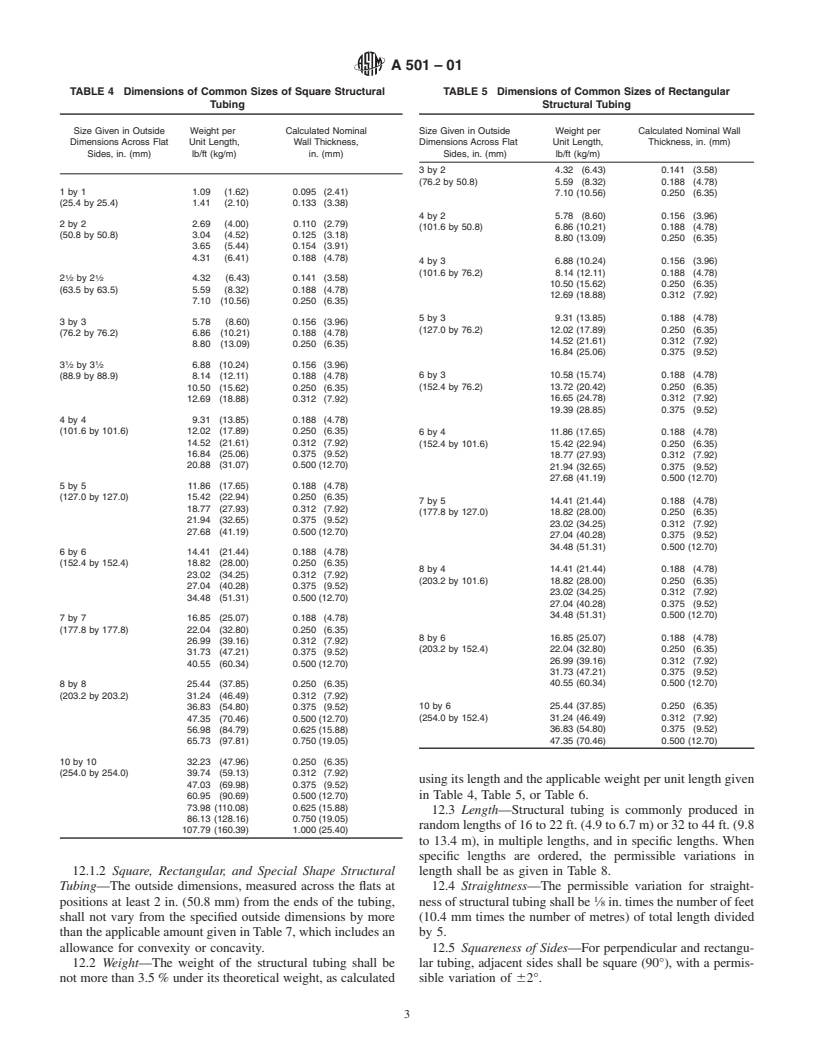

1.2 Square and rectangular tubing is furnished in sizes 1 to 10 in. (25.4 to 254 mm) across flat sides with wall thicknesses 0.095 to 1.000 in. (2.41 to 25.40 mm), dependent upon size; round tubing is furnished in NPS 1/2 to NPS 24 (see Note 0) inclusive, with nominal (average) wall thicknesses 0.109 to 1.000 in. (2.77 to 25.40 mm), dependent upon size. Special shape tubing and tubing with other dimensions is permitted to be furnished, provided that such tubing complies with all other requirements of this specification.

Note 1--The dimensionless designator NPS (nominal pipe size) has been substituted in this standard for such traditional terms as "nominal diameter," "size," and "nominal size."

1.3 The following precautionary statement pertains only to the test method portion of this specification: This standard does not purport to address all the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are mathematical conversions of the values in inch-pound units to SI units.

1.5 The text of this specification contains notes and footnotes that provide explanatory material. Such notes and footnotes, excluding those in tables and figures, do not contain any mandatory requirements.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 501 – 01

Standard Specification for

Hot-Formed Welded and Seamless Carbon Steel Structural

1

Tubing

This standard is issued under the fixed designation A 501; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope A 53/A 53M Specification for Pipe, Steel, Black and Hot-

2

Dipped, Zinc-Coated, Welded and Seamless

1.1 This specification covers black and hot-dipped galva-

A 370 Test Methods and Definitions for MechanicalTesting

nized hot-formed welded and seamless carbon steel square,

3

of Steel Products

round, rectangular, or special shape structural tubing for

A 700 Practices for Packaging, Marking, and Loading

welded, riveted, or bolted construction of bridges and build-

4

Methods for Steel Products for Domestic Shipment

ings, and for general structural purposes.

A 751 Test Methods, Practices, and Terminology for

1.2 Square and rectangular tubing is furnished in sizes 1 to

3

Chemical Analysis of Steel Products

10 in. (25.4 to 254 mm) across flat sides with wall thicknesses

A 941 Terminology Relating to Steel, Stainless Steel, Re-

0.095 to 1.000 in. (2.41 to 25.40 mm), dependent upon size;

2

lated Alloys, and Ferroalloys

1

round tubing is furnished in NPS ⁄2 to NPS 24 (see Note 1)

2.2 AIAG Standard:

inclusive, with nominal (average) wall thicknesses 0.109 to

5

B-1 Bar Code Symbology Standard

1.000 in. (2.77 to 25.40 mm), dependent upon size. Special

shape tubing and tubing with other dimensions is permitted to

3. Terminology

be furnished, provided that such tubing complies with all other

3.1 Definitions—For definitions of terms used in this speci-

requirements of this specification.

fication, refer to Terminology A 941.

NOTE 1—The dimensionless designator NPS (nominal pipe size) has

been substituted in this standard for such traditional terms as “nominal

4. Ordering Information

diameter,” “size,” and “nominal size.”

4.1 Orders for material under this specification shall contain

1.3 The following precautionary statement pertains only to

information concerning as many of the following items as are

thetestmethodportionofthisspecification: This standard does

required to describe the desired material adequately:

not purport to address all the safety concerns, if any, associ-

4.1.1 Quantity (feet or number of lengths),

ated with its use. It is the responsibility of the user of this

4.1.2 Name of material (hot-formed tubing),

standard to establish appropriate safety and health practices

4.1.3 Method of manufacture (seamless or welded) (see

and determine the applicability of regulatory limitations prior

Section 6),

to use.

4.1.4 Finish (black or galvanized),

1.4 The values stated in inch-pound units are to be regarded

4.1.5 Size (outside diameter and calculated nominal wall

asthestandard.Thevaluesgiveninparenthesesaremathemati-

thickness for round tubing and the outside dimensions and

cal conversions of the values in inch-pound units to SI units.

calculated nominal wall thickness for square and rectangular

1.5 The text of this specification contains notes and foot-

tubing (Section 11),

notes that provide explanatory material. Such notes and foot-

4.1.6 Length (random, multiple, or specific; see 12.3),

notes, excluding those in tables and figures, do not contain any

4.1.7 End condition (see 17.3),

mandatory requirements.

4.1.8 Burr removal (see 17.3),

4.1.9 Certification (see Section 19),

2. Referenced Documents

4.1.10 ASTM specification designation and year of issue,

2.1 ASTM Standards:

4.1.11 End use,

1 2

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Annual Book of ASTM Standards, Vol 01.01.

3

Stainless Steel, and RelatedAlloys, and is the direct responsibility of Subcommittee Annual Book of ASTM Standards, Vol 01.03.

4

A01.09 on Carbon Steel Tubular Products. Annual Book of ASTM Standards, Vol 01.05.

5

Current edition approved Mar. 10, 2001. Published May 2001. Originally Available from Automotive Industry Action Group, 26200 Lahser Road, Suite

published as A 501 – 64. Last previous edition A 501 – 99. 200, Southfield, MI 48034.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A501–01

TABLE 2 Tensile Requirements

4.1.12 Special requirements, and

4.1.13 Bar coding (see 20.3). Tensile strength, min, psi (MPa) 58 000 (400)

Yield strength, min, psi (MPa) 36 000 (250)

Elongation in 2 in. (50.8 mm), min, % 23

5. Process

5.1 The steel shall be made by one or more of the follow

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.