ASTM D1506-15(2020)

(Test Method)Standard Test Methods for Carbon Black—Ash Content

Standard Test Methods for Carbon Black—Ash Content

SIGNIFICANCE AND USE

4.1 The ash content of a carbon black is the amount of non-carbon components present after combustion. Primary contributants to ash are the manufacturing process water and the catalyst in the feedstock.

SCOPE

1.1 These test methods cover the determination of the ash content of carbon black.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements see Sections 6 and 13.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1506 − 15 (Reapproved 2020)

Standard Test Methods for

1

Carbon Black—Ash Content

This standard is issued under the fixed designation D1506; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 4. Significance and Use

1.1 These test methods cover the determination of the ash 4.1 The ash content of a carbon black is the amount of

content of carbon black.

non-carbon components present after combustion. Primary

contributants to ash are the manufacturing process water and

1.2 The values stated in SI units are to be regarded as

the catalyst in the feedstock.

standard. No other units of measurement are included in this

standard.

Method A—Muffle Furnace Method

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5. Apparatus

responsibility of the user of this standard to establish appro-

5.1 Muffle Furnace, capable of temperature regulation of

priate safety, health, and environmental practices and deter-

625°C at 550°C.

mine the applicability of regulatory limitations prior to use.

5.2 Crucibles:

For specific precautionary statements see Sections 6 and 13.

1.4 This international standard was developed in accor- 5.2.1 Porcelain Crucible, high-form, size O, rim 35 mm,

3

height 29 mm, capacity 15 cm , with cover size E.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the 5.2.2 Porous Quartz Fiber Crucible, 20, 50, and 100 mL

3

Development of International Standards, Guides and Recom- with optional disk inserts and lids.

mendations issued by the World Trade Organization Technical

5.3 Analytical Balance, having a sensitivity of 0.1 mg.

Barriers to Trade (TBT) Committee.

5.4 Desiccator.

2. Referenced Documents

5.5 Oven, gravity-convection type, capable of temperature

2

2.1 ASTM Standards:

regulation within 61°C at 125°C and temperature uniformity

D1799 Practice for Carbon Black—Sampling Packaged

within 65°C.

Shipments

D1900 Practice for Carbon Black—Sampling Bulk Ship-

6. Hazards

ments

6.1 Precautions:

D4483 Practice for Evaluating Precision for Test Method

6.1.1 Keep the door of the furnace open about 6 mm to

Standards in the Rubber and Carbon Black Manufacturing

admit air to support the combustion of organic material.

Industries

6.1.2 Exert care in removing ashed sample from furnace to

3. Summary of Test Method

desiccator.

6.1.3 Always keep the cover on the crucible when transfer-

3.1 A pre-dried sample (1 h at 125°C) is weighed before and

ring it to and from the desiccator to prevent the loss of ash due

after combustion for 16 h at 550°C. The remaining ash is

to air currents.

weighed and calculated as a percent of the dried sample.

6.1.4 After the sample has cooled in the desiccator, admit air

1 slowly to avoid loss of ash from the crucible.

These test methods are under the jurisdiction of ASTM Committee D24 on

Carbon Black and are the direct responsibility of Subcommittee D24.31 on

Non-Carbon Black Components of Carbon Black.

Current edition approved Nov. 1, 2020. Published December 2020. Originally

3

approved in 1957. Last previous edition approved in 2015 as D1506 – 15. DOI: The sole source of supply of the apparatus (quartz ashing dishes, Part Number

10.1520/D1506-15R20. 303040) known to the committee at this time is CEM Corporation, P.O. Box 200,

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Matthews, NC 28106. If you are aware of alternative suppliers, please provide this

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM information to ASTM International Headquarters. Your comments will receive

1

Standards volume information, refer to the standard’s Document Summary page on careful consideration at a meeting of the responsible technical committee, which

the ASTM website. you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1506 − 15 (2020)

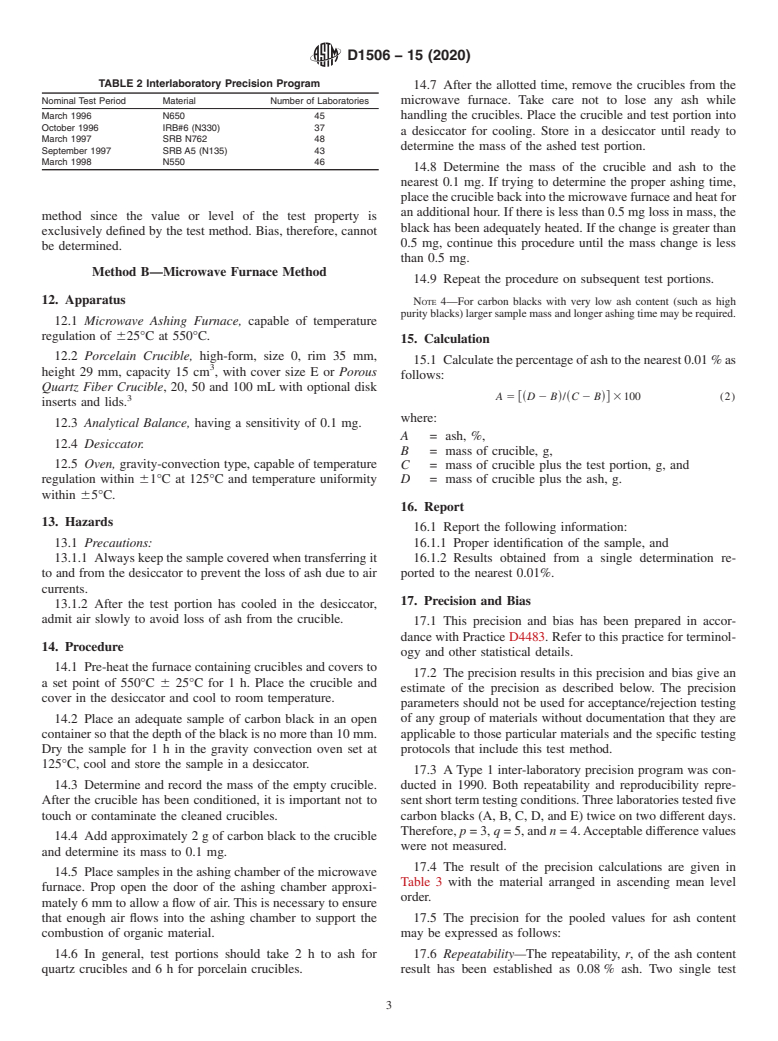

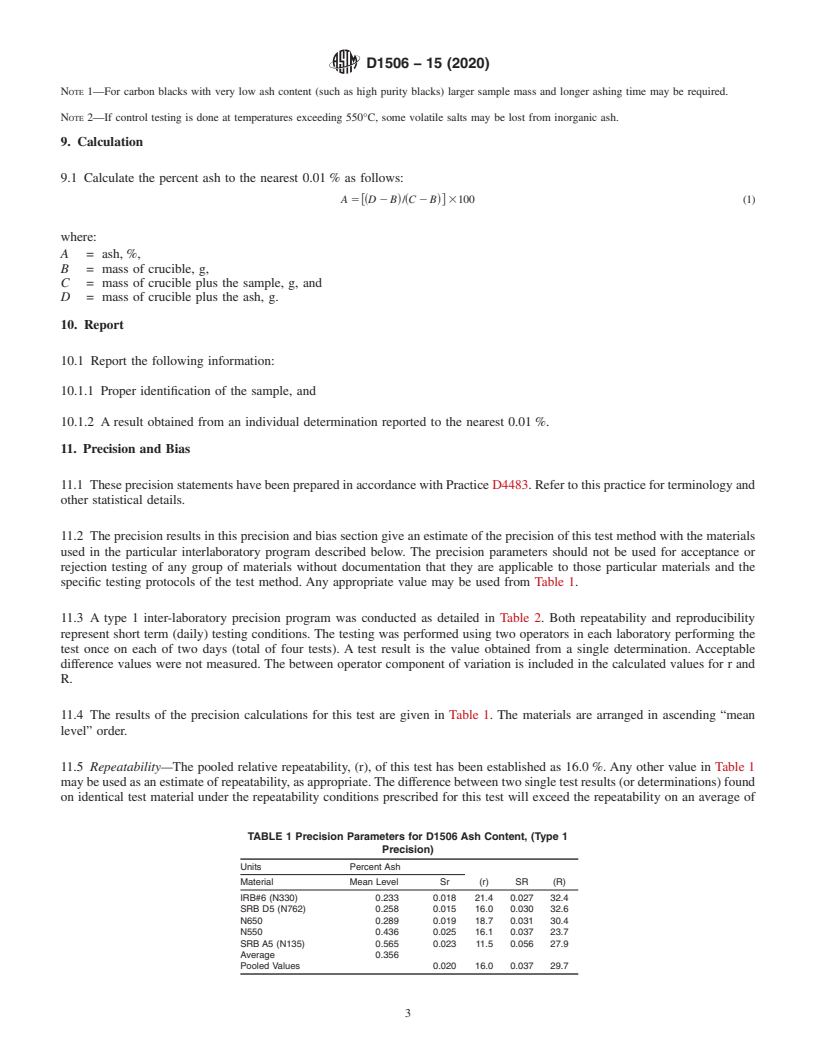

7. Sampling ticular materials and the specific testing protocols of the test

method. Any appropriate value may be used from Table 1.

7.1 Samples shall be taken in accordance with Practices

D1799 or D1900. 11.3 A type 1 inter-laboratory precision program was con-

ducted as detailed in Table 2. Both repeatability and reproduc-

8. Procedure

ibility represent short term (daily) testing conditions. The

testing was performed using two operators in eac

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D1506 − 15 D1506 − 15 (Reapproved 2020)

Standard Test Methods for

1

Carbon Black—Ash Content

This standard is issued under the fixed designation D1506; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 These test methods cover the determination of the ash content of carbon black.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use. For specific precautionary statements see Sections 6 and 13.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D1799 Practice for Carbon Black—Sampling Packaged Shipments

D1900 Practice for Carbon Black—Sampling Bulk Shipments

D4483 Practice for Evaluating Precision for Test Method Standards in the Rubber and Carbon Black Manufacturing Industries

3. Summary of Test Method

3.1 A pre-dried sample (1 h at 125°C) is weighed before and after combustion for 16 h at 550°C. The remaining ash is weighed

and calculated as a percent of the dried sample.

4. Significance and Use

4.1 The ash content of a carbon black is the amount of non-carbon components present after combustion. Primary contributants

to ash are the manufacturing process water and the catalyst in the feedstock.

1

These test methods are under the jurisdiction of ASTM Committee D24 on Carbon Black and are the direct responsibility of Subcommittee D24.31 on Non-Carbon Black

Components of Carbon Black.

Current edition approved June 1, 2015Nov. 1, 2020. Published July 2015December 2020. Originally approved in 1957. Last previous edition approved in 20132015 as

D1506 – 99 (2013).D1506 – 15. DOI: 10.1520/D1506-15.10.1520/D1506-15R20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1506 − 15 (2020)

Method A—Muffle Furnace Method

5. Apparatus

5.1 Muffle Furnace, capable of temperature regulation of 625°C at 550°C.

5.2 Crucibles:

3

5.2.1 Porcelain Crucible, high-form, size O, rim 35 mm, height 29 mm, capacity 15 cm , with cover size E.

3

5.2.2 Porous Quartz Fiber Crucible, 20, 50, and 100 mL with optional disk inserts and lids.

5.3 Analytical Balance, having a sensitivity of 0.1 mg.

5.4 Desiccator.

5.5 Oven, gravity-convection type, capable of temperature regulation within 61°C at 125°C and temperature uniformity within

65°C.

6. Hazards

6.1 Precautions:

6.1.1 Keep the door of the furnace open about 6 mm to admit air to support the combustion of organic material.

6.1.2 Exert care in removing ashed sample from furnace to desiccator.

6.1.3 Always keep the cover on the crucible when transferring it to and from the desiccator to prevent the loss of ash due to air

currents.

6.1.4 After the sample has cooled in the desiccator, admit air slowly to avoid loss of ash from the crucible.

7. Sampling

7.1 Samples shall be taken in accordance with Practices D1799 or D1900.

8. Procedure

8.1 Porous quartz fiber crucibles and optional disks should be ignited in the furnace at 550 6 25°C for at least 15 min. Porcelain

crucibles should be ignited with cover in the muffle furnace at 550 6 25°C for 1 h. Place the crucible and cover in the desiccator.

Cool to room temperature and weigh to nearest 0.1 mg.

8.2 Dry an adequate sample of carbon black for 1 h in the gravity-convection oven set at 125°C in an open

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.