ASTM A989/A989M-98(2002)e1

(Specification)Standard Specification for Hot Isostatically-Pressed Alloy Steel Flanges, Fittings, Valves, and Parts for High Temperature Service

Standard Specification for Hot Isostatically-Pressed Alloy Steel Flanges, Fittings, Valves, and Parts for High Temperature Service

SCOPE

1.1 This specification covers hot isostatically-pressed, powder metal, alloy steel piping components for use in pressure systems. Included are flanges, fittings, valves, and similar parts made to specified dimensions or to dimensional standards, such as in ASME Specification B16.5.

1.2 Several grades of alloy steels are included in this specification.

1.3 Supplementary requirements are provided for use when additional testing or inspection is desired. These shall apply only when specified individually by the purchaser in the order.

1.4 This specification is expressed in both inch-pound units and in SI units. Unless the order specifies the applicable "M" specification designation (SI units), however, the material shall be furnished to inch-pound units.

1.5 The values stated in either inch-pound units or SI units are to be regarded separately as the standard. Within the text, the SI units are shown in parentheses. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.6 The following safety hazards caveat pertains only to test methods portions 8.1, 8.2, and 9.5-9.7 of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

e1

Designation: A 989/A 989M – 98 (Reapproved 2002)

Standard Specification for

Hot Isostatically-Pressed Alloy Steel Flanges, Fittings,

Valves, and Parts for High Temperature Service

This standard is issued under the fixed designationA 989/A 989M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—The title was changed to a dual designation editorially to reflect the existing measurements in the standard

in September 2004.

1. Scope A 370 Test Methods and Definitions for MechanicalTesting

of Steel Products

1.1 This specification covers hot isostatically-pressed, pow-

A 751 Test Methods, Practices, and Terminology for

der metal, alloy steel piping components for use in pressure

Chemical Analysis of Steel Products

systems. Included are flanges, fittings, valves, and similar parts

E 165 Test Method for Liquid Penetrant Examination

madetospecifieddimensionsortodimensionalstandards,such

E 340 Test Method for Macroetching Metals and Alloys

as in ASME Specification B16.5.

E 606 Practice for Strain-Controlled Fatigue Testing

1.2 Several grades of alloy steels are included in this

2.2 MSS Standard:

specification.

SP 25 Standard Marking System for Valves, Fittings,

1.3 Supplementary requirements are provided for use when

Flanges, and Unions

additional testing or inspection is desired. These shall apply

2.3 ASME Specifications and Boiler and Pressure Vessel

only when specified individually by the purchaser in the order.

Codes:

1.4 This specification is expressed in both inch-pound units

B16.5 Dimensional Standards for Steel Pipe Flanges and

and in SI units. Unless the order specifies the applicable “M”

Flanged Fittings

specification designation (SI units), however, the material shall

2.4 ASME Section IX Welding Qualifications:

be furnished to inch-pound units.

SFA-5.5 Specification for Low-Alloy Steel Covered Arc-

1.5 The values stated in either inch-pound units or SI units

Welding Electrodes

are to be regarded separately as the standard. Within the text,

theSIunitsareshowninparentheses.Thevaluesstatedineach

3. Terminology

system are not exact equivalents; therefore, each system must

3.1 Definitions of Terms Specific to This Standard:

be used independently of the other. Combining values from the

3.1.1 can, n—the container used to encapsulate the powder

two systems may result in nonconformance with the specifi-

during the pressure consolidation process that is removed

cation.

partially or fully from the final part.

1.6 The following safety hazards caveat pertains only to test

3.1.2 compact, n—the consolidated powder from one can

methods portions, 8.1, 8.2, and 9.5-9.7 of this specification:

that may be used to make one or more parts.

This standard does not purport to address all of the safety

3.1.3 consolidation, n—the bonding of adjacent powder

concerns, if any, associated with its use. It is the responsibility

particles in a compact under pressure by heating to a tempera-

of the user of this standard to establish appropriate safety and

ture below the melting point of the powder.

health practices and to determine the applicability of regula-

3.1.4 fill stem, n—thepartofthecompactusedtofillthecan

tory limitations prior to use.

that usually is not integral to the part produced.

2. Referenced Documents 3.1.5 hot isostatic-pressing, n—a process for simulta-

neously heating and forming a compact in which the powder is

2.1 ASTM Standards:

contained in a sealed formable enclosure usually made from

A 275/A 275M Test Method for Magnetic Particle Exami-

nation of Steel Forgings

Annual Book of ASTM Standards, Vol 01.03.

1 4

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Annual Book of ASTM Standards, Vol 03.03.

Stainless Steel, and RelatedAlloys and is the direct responsibility of Subcommittee Annual Book of ASTM Standards, Vol 03.01.

A01.22 onSteelForgingsandWroughtFittingsforPipingApplicationsandBolting AvailablefromManufacturersStandardizationSocietyoftheValveandFittings

Materials for Piping and Special Purpose Applications. Industry (MSS), 127 Park St., NE, Vienna, VA 22180-4602.

Current edition approved Mar. 10, 1998. Published September 1998. Available from American Society of Mechanical Engineers (ASME), ASME

Annual Book of ASTM Standards, Vol 01.05. International Headquarters, Three Park Ave., New York, NY 10016-5990.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

e1

A 989/A 989M – 98 (2002)

metal and the so-contained powder is subjected to equal 5.1.2 Thepowdershallbeprealloyedandmadebyamelting

pressure from all directions at a temperature high enough to method capable of producing the specified chemical composi-

permit plastic deformation and consolidation of the powder tion,suchasbutnotlimitedtoairorvacuuminductionmelting,

particles to take place. followed by gas atomization.

3.1.6 lot, n—a number of parts produced from a single 5.1.3 When powder from more than one heat is used to

powder blend following the same manufacturing conditions. make a blend, the heats shall be mixed thoroughly to ensure

3.1.7 part, n—a single item coming from a compact, either homogeneity.

prior to or after machining. 5.1.4 The compact shall be sectioned and the microstructure

3.1.8 powder blend, n—a homogeneous mixture of powder examined to check for porosity and other internal imperfec-

from one or more heats of the same grade. tionsandshallmeettherequirementsof8.1.3.Thesampleshall

3.1.9 rough part, n—the part prior to final machining. betakenfromthefillstemorfromalocationinapartasagreed

upon by the manufacturer and purchaser.

4. Ordering Information

5.1.5 Unless otherwise specified in the purchase order, the

4.1 It is the responsibility of the purchaser to specify in the

manufacturer shall remove the can material from the surfaces

purchase order all requirements that are necessary for material of the consolidated compacts by chemical or mechanical

ordered under this specification. Such requirements may in- methods, such as by pickling or machining. This may be done

clude, but are not limited to, the following: before or after heat treatment at the option of the manufacturer

4.1.1 Quantity (weight or number of parts). (see Note 1).

4.1.2 Name of material or UNS number.

NOTE 1—Often, it is advantageous to leave the can material in place

4.1.3 ASTM designation and year of issue.

until after heat treatment or further thermal processing of the consolidated

4.1.4 Dimensions (tolerances and surface finishes).

compact.

4.1.5 Microstructure examination, if required (5.1.4).

6. Chemical Composition

4.1.6 Inspection (14.1).

4.1.7 Whether rough part or finished machined (8.2.2). 6.1 The steel both as a blend and as a part shall conform to

4.1.8 Supplementary requirements, if any. the requirements for chemical composition prescribed in Table

4.1.9 Additional requirements (see 7.2.1 and 16.1). 1. Test Methods, Practices, and Terminology of A 751 shall

4.1.10 Requirement, if any, that the manufacturer shall apply.

submit drawings for approval showing the shape of the rough 6.1.1 Each blend of powder shall be analyzed by the

part before machining and the exact location of test specimen manufacturer to determine the percentage of elements pre-

material (see 9.3.1). scribed in Table 1. This analysis shall be made using a

representative sample of the powder. The blend shall conform

5. Materials and Manufacture

to the chemical composition requirements prescribed in Table

5.1 Manufacturing Practice: 1.

5.1.1 Compacts shall be manufactured by placing a single 6.1.2 When required by the purchaser, the chemical com-

powderblendintoacan,evacuatingthecan,andsealingit.The position of a sample from one part from each lot of parts shall

can material shall be selected to ensure that it has no deleteri- be determined by the manufacturer. The composition of the

ous effect on the final product. The entire assembly shall be sample shall conform to the chemical composition require-

heated at a temperature and placed under sufficient pressure for ments prescribed in Table 1.

a sufficient period of time to ensure that the final consolidated 6.2 Addition of lead, selenium, or other elements for the

part meets the density requirements of 8.1.2.1. One or more purpose of rendering the material free-machining shall not be

parts shall be machined from a single compact. permitted.

TABLE 1 Chemical Requirements

Composition, %

UNS

Columbium

Grade

Phosphorus, Sulfur, Tantalum,

Designation

Carbon Manganese Silicon Nickel Chromium Molybdenum plus Titanium

max max max

Tantalum

Alloy Steels

K90941 9 % chromium 0.15 max 0.30–0.60 0.030 0.030 0.50–1.00 . . . 8.0–10.0 0.90–1.10 . . . . . . . . .

K91560 9 % chromium, 1 % 0.08-0.12 0.30–0.60 0.020 0.010 0.20–0.50 0.40 max 8.0–9.5 0.85–1.05 Other Elements

molybdenum, 0.2 % Cb 0.06–0.10

vanadium plus N 0.03–0.07

columbium and Al 0.04 max

nitrogen V 0.18–0.25

K31545 chromium-molybdenum 0.05–0.15 0.30–0.60 0.040 0.040 0.50 max . . . 2.7–3.3 0.80–1.06 . . . . . . . . .

K21590 chromium-molybdenum 0.05–0.15 0.30–0.60 0.040 0.040 0.50 max . . . 2.00–2.50 0.87–1.13 . . . . . . . . .

Class 1

K21590 chromium-molybdenum 0.05–0.15 0.30–0.60 0.040 0.040 0.50 max . . . 2.00–2.50 0.87–1.13 . . . . . . . . .

Class 3

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

e1

A 989/A 989M – 98 (2002)

6.3 The steel shall not contain an unspecified element, for 8.1.2.3 At the option of the producer, the density shall be

the ordered grade, to the extent that the steel conforms to the compared to the room temperature density typical of wrought

requirements of another grade for which that element is a alloy steels or to the density of a wrought reference sample of

specified element having a required minimum content. the same grade heat treated in accordance with the require-

ments of Table 2 (see Note 2). The typical density for alloy

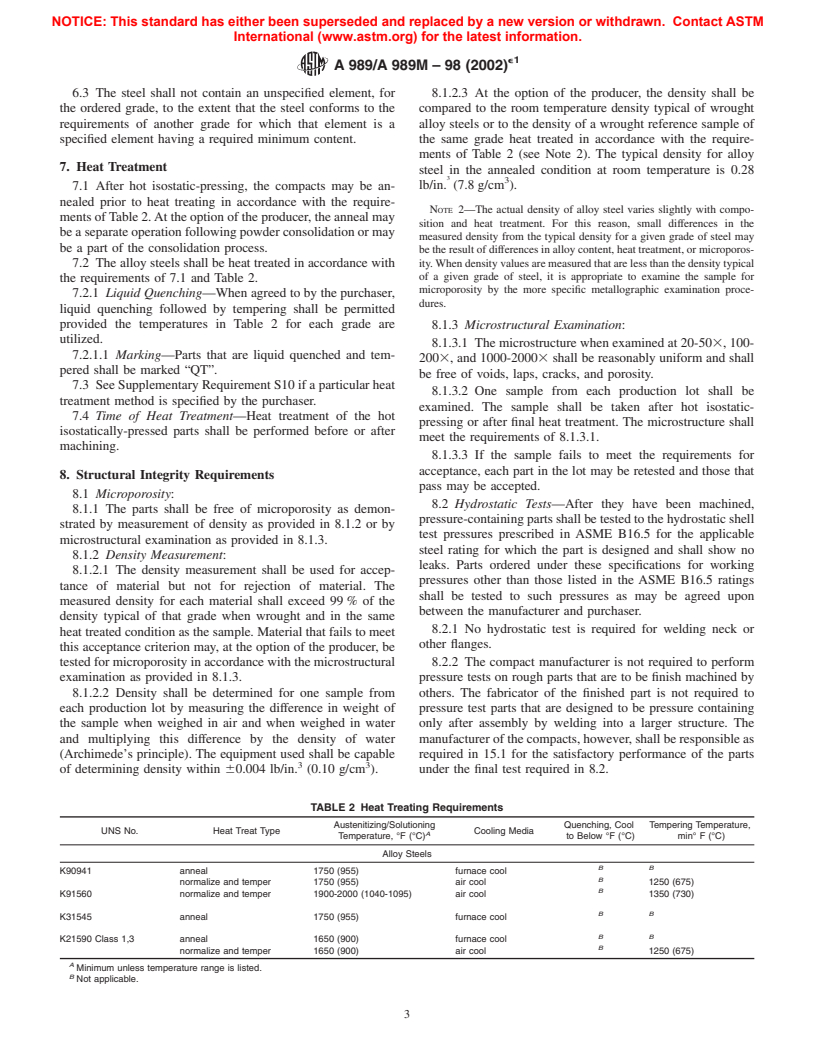

7. Heat Treatment

steel in the annealed condition at room temperature is 0.28

lb/in. (7.8 g/cm ).

7.1 After hot isostatic-pressing, the compacts may be an-

nealed prior to heat treating in accordance with the require-

NOTE 2—The actual density of alloy steel varies slightly with compo-

ments ofTable 2.At the option of the producer, the anneal may

sition and heat treatment. For this reason, small differences in the

be a separate operation following powder consolidation or may

measured density from the typical density for a given grade of steel may

be a part of the consolidation process.

be the result of differences in alloy content, heat treatment, or microporos-

ity.Whendensityvaluesaremeasuredthatarelessthanthedensitytypical

7.2 The alloy steels shall be heat treated in accordance with

of a given grade of steel, it is appropriate to examine the sample for

the requirements of 7.1 and Table 2.

microporosity by the more specific metallographic examination proce-

7.2.1 Liquid Quenching—When agreed to by the purchaser,

dures.

liquid quenching followed by tempering shall be permitted

provided the temperatures in Table 2 for each grade are 8.1.3 Microstructural Examination:

utilized.

8.1.3.1 The microstructure when examined at 20-503, 100-

7.2.1.1 Marking—Parts that are liquid quenched and tem-

2003, and 1000-20003 shall be reasonably uniform and shall

pered shall be marked “QT”.

be free of voids, laps, cracks, and porosity.

7.3 See Supplementary Requirement S10 if a particular heat

8.1.3.2 One sample from each production lot shall be

treatment method is specified by the purchaser.

examined. The sample shall be taken after hot isostatic-

7.4 Time of Heat Treatment—Heat treatment of the hot

pressing or after final heat treatment. The microstructure shall

isostatically-pressed parts shall be performed before or after

meet the requirements of 8.1.3.1.

machining.

8.1.3.3 If the sample fails to meet the requirements for

acceptance, each part in the lot may be retested and those that

8. Structural Integrity Requirements

pass may be accepted.

8.1 Microporosity:

8.2 Hydrostatic Tests—After they have been machined,

8.1.1 The parts shall be free of microporosity as demon-

pressure-containingpartsshallbetestedtothehydrostaticshell

strated by measurement of density as provided in 8.1.2 or by

test pressures prescribed in ASME B16.5 for the applicable

microstructural examination as provided in 8.1.3.

steel rating for which the part is designed and shall show no

8.1.2 Density Measurement:

leaks. Parts ordered under these specifications for working

8.1.2.1 The density measurement shall be used for accep-

pressures other than those listed in the ASME B16.5 ratings

tance of material but not for rejection of material. The

shall be tested to such pressures as may be agreed upon

measured density for each material shall exceed 99 % of the

between the manufacturer and purchaser.

density typical of that grade when wrought and in the same

8.2.1 No hydrostatic test is required for welding neck or

heat treated condition as the sample. Material that fails to meet

other flanges.

this acceptance criterion may, at the option of the producer, be

tested for microporosity in accordance with the microstructural 8.2.2 The compact manufacturer is not required to perform

examination as provided in 8.1.3. pressure tests on rough parts that are to be finish machined by

8.1.2.2 Density shall be determined for one sample from others. The fabricator of the finished part is not required to

each production lot by measuring the difference in weight of pressure test parts that are designed to be pressure containing

the sample when weighed in air and when weighed in water only after assembly by welding into a larger structure. The

and multiplying this difference by the density of water manufacturer of the compacts, however, shall be responsible as

(Archimede’s principle). The equipment used shall be capable required in 15.1 for the satisfactory performance of the parts

3 3

of determining density within 60.004 lb/in. (0.10 g/cm ). under the final test required in 8.2.

TABLE 2 Heat Treating Requirements

Austenitizing/Solutioning Quenching, Cool Tempering Temperature,

UNS No. Heat Treat Type Cooling Media

A

Temperature, °F (°C) to Below °F (°C) min° F (°C)

Alloy Steels

BB

K90941 anneal 1750 (955) furnace co

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.