ASTM D4404-84(1998)e1

(Test Method)Standard Test Method for Determination of Pore Volume and Pore Volume Distribution of Soil and Rock by Mercury Intrusion Porosimetry

Standard Test Method for Determination of Pore Volume and Pore Volume Distribution of Soil and Rock by Mercury Intrusion Porosimetry

SCOPE

1.1 This test method covers the determination of the pore volume and the pore volume distributions of soil and rock by the mercury intrusion porosimetry method. The range of apparent diameters of pores for which this test method is applicable is fixed by the operant pressure range of the testing instrument. This range is typically between apparent pore entrance diameters of about 100 [mu]m and 2.5 nm (0.0025 [mu]m). Larger pores must be measured by another method.

1.2 Mercury intrusion porosimetry is useful only for measuring pores open to the outside of a soil or rock fragment; mercury intrusion porosimetry will not give the volume of any pores completely enclosed by surrounding solids. This test method will give only the volume of intrudable pores that have an apparent diameter corresponding to a pressure within the pressurizing range of the testing instrument.

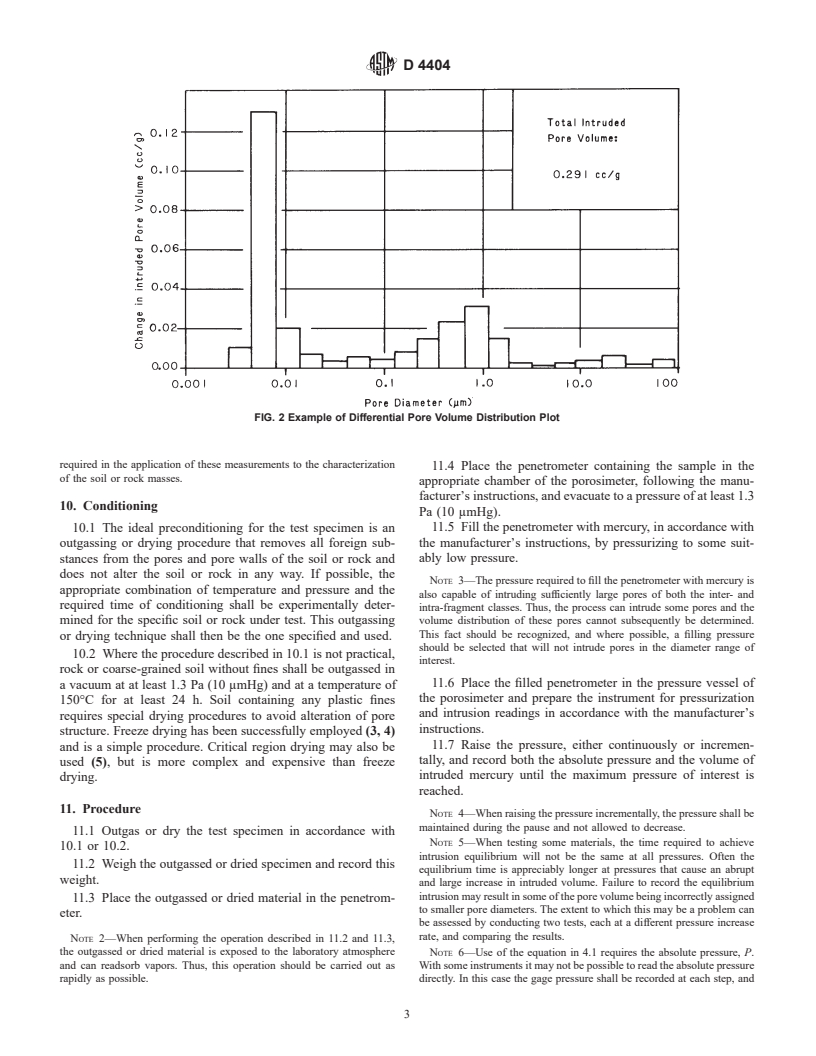

1.3 The intrusion process proceeds from the outside of a fragment toward its center. Comparatively large interior pores can exist that have smaller pores as the only means of access. Mercury intrusion porosimetry will incorrectly register the entire volume of these "ink-bottle" pores as having the apparent diameter of the smaller access pores. In a test sample, inter-fragment pores can exist in addition to intra-fragment pores (see Section 3 for definitions). The inter-fragment pores will vary in size and volume depending on the size and shape of the soil or rock fragments and on the manner in which the fragments are packed together. It is possible that some inter-fragment pores can have the same apparent diameter as some intra-fragment pores. When this occurs this test method cannot distinguish between them. Thus, the test method yields an intruded pore volume distribution that is in part dependent upon the packing of multifragment samples. However, most soils and rocks have intra-fragment pores much smaller than the inter-fragment pores. This situation leads to a bi-modal pore size distribution and the distinction between the two classes of pores can then be made (see Figs. 1 and 2).

1.4 Mercury intrusion may involve the application of high pressures to the sample. This may result in a temporary, or permanent, or temporary and permanent alteration in the pore geometry. Generally, soils and rocks are composed of comparatively strong solids and are less subject to these alterations than certain other materials. However, the possibility remains that the use of this test method may alter the natural pore volume distribution that is being measured.

1.5 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to consult and establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precaution statements, see Section 8.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: D 4404 – 84 (Reapproved 1998)

Standard Test Method for

Determination of Pore Volume and Pore Volume Distribution

of Soil and Rock by Mercury Intrusion Porosimetry

This standard is issued under the fixed designation D 4404; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Keywords were added editorially in December 1998.

1. Scope 1.4 Mercury intrusion may involve the application of high

pressures to the sample. This may result in a temporary, or

1.1 This test method covers the determination of the pore

permanent, or temporary and permanent alteration in the pore

volume and the pore volume distributions of soil and rock by

geometry. Generally, soils and rocks are composed of com-

the mercury intrusion porosimetry method. The range of

paratively strong solids and are less subject to these alterations

apparent diameters of pores for which this test method is

than certain other materials. However, the possibility remains

applicable is fixed by the operant pressure range of the testing

that the use of this test method may alter the natural pore

instrument. This range is typically between apparent pore

volume distribution that is being measured.

entrance diameters of about 100 μm and 2.5 nm (0.0025 μm).

1.5 This standard does not purport to address all of the

Larger pores must be measured by another method.

safety concerns, if any, associated with its use. It is the

1.2 Mercury intrusion porosimetry is useful only for mea-

responsibility of the user of this standard to consult and

suring pores open to the outside of a soil or rock fragment;

establish appropriate safety and health practices and deter-

mercury intrusion porosimetry will not give the volume of any

mine the applicability of regulatory limitations prior to use.

pores completely enclosed by surrounding solids. This test

For specific precaution statements, see Section 8.

method will give only the volume of intrudable pores that have

an apparent diameter corresponding to a pressure within the

2. Referenced Documents

pressurizing range of the testing instrument.

2.1 ASTM Standards:

1.3 The intrusion process proceeds from the outside of a

C 699 Methods for Chemical, Mass Spectrometric, and

fragment toward its center. Comparatively large interior pores

Spectrochemical Analysis of, and Physical Tests on, Be-

can exist that have smaller pores as the only means of access.

ryllium Oxide Powder

Mercury intrusion porosimetry will incorrectly register the

entire volume of these “ink-bottle” pores as having the

3. Terminology

apparent diameter of the smaller access pores. In a test sample,

3.1 Definitions:

inter-fragment pores can exist in addition to intra-fragment

3.1.1 apparent pore diameter—the diameter of a pore that is

pores (see Section 3 for definitions). The inter-fragment pores

assumed to be cylindrical and that is intruded at a pressure, P,

will vary in size and volume depending on the size and shape

given by the equation in 4.1.

of the soil or rock fragments and on the manner in which the

3.1.2 inter-fragment pores—those pores between fragments

fragments are packed together. It is possible that some inter-

when they are packed together and that are intruded during the

fragment pores can have the same apparent diameter as some

test.

intra-fragment pores. When this occurs this test method cannot

3.1.3 intra-fragment pores—those pores lying within the

distinguish between them. Thus, the test method yields an

exterior outlines of the individual soil and rock fragments.

intruded pore volume distribution that is in part dependent

3.1.4 intruded pore volume—the corrected volume of mer-

upon the packing of multifragment samples. However, most

cury intruded during the test.

soils and rocks have intra-fragment pores much smaller than

the inter-fragment pores. This situation leads to a bi-modal

4. Summary of Test Method

pore size distribution and the distinction between the two

4.1 When a liquid does not wet a porous solid, it will not

classes of pores can then be made (see Fig. 1 and Fig. 2).

enter the pores in the solid by capillary action. The non-wetting

liquid (mercury in this test method) can be forced into the pores

by the application of external pressure. The size of the pores

This test method is under the jurisdiction of ASTM Committee D-18 on Soil

and Rock and is the direct responsibility of Subcommittee D18.14 on Geotechnics

of Waste Management.

Current edition approved Aug. 31, 1984. Published October 1984. Annual Book of ASTM Standards, Vol 12.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 4404

FIG. 1 Example of Cumulative Pore Volume Distribution Plot

that are intruded is inversely proportional to the applied surrounding the test specimen with mercury at a low pressure,

pressure. When a cylindrical pore model is assumed, the a pressure generator to cause intrusion, pressure transducers,

relationship between pressure and size is given as follows: capable of measuring the intruding pressure with an accuracy

of at least 61 % throughout the range of pressures over which

d 524g~cosu!/P (1)

the pores of interest are being intruded, and a means of

where: measuring intruded mercury volumes to an accuracy of at least

3 −3 3

d 5 apparent pore diameter being intruded,

61mm (610 cm ).

g5 surface tension of the mercury,

6.2 Vacuum Pump, if not part of the porosimeter, to evacuate

u5 contact angle between the mercury and the pore wall,

the sample holder.

−7

and

6.3 Analytical Balance, with an accuracy of at least 610

P 5 absolute pressure causing the intrusion.

kg (60.1 mg).

Any set of convenient and compatible units may be used.

4.2 The volume of the intruded pores is determined by

7. Reagent

measuring the volume of mercury forced into them at various

7.1 Triple-Distilled Mercury.

pressures. A single determination involves increasing the

pressure, either continuously or step-wise, and recording the

8. Safety Precautions

measured intruded volume at various pressures.

8.1 Mercury is a hazardous substance that can cause illness

and death. Store mercury in closed containers to control its

5. Significance and Use

evaporation and use only in well ventilated rooms. Mercury

5.1 This test method is intended for use in determining the

can also be absorbed through the skin so avoid direct contact.

volume and the volume distribution of pores in soil and rock

Wash hands immediately after any operation involving mer-

with respect to the apparent diameter of the entrances of the

cury; the use of gloves is advocated. Exercise extreme care to

pores. In general, both the size and volume of the pores affects

avoid spilling mercury. Clean up any spills immediately using

the soil or rock performance. Thus, the pore volume distribu-

procedures recommended explicitly for mercury. Handle in-

tion is useful in understanding soil and rock performance and

truded samples with great care and dispose of in a safe and

in identifying a material that can beexpected to perform in a

environmentally acceptable manner immediately after comple-

particular manner (1, 2).

tion of the test.

6. Apparatus

9. Sampling, Test Specimens, and Test Units

6.1 Mercury Intrusion Porosimeter— This shall be

9.1 The material from which the test sample is drawn shall

equipped with a sample holder capable of containing one or

be representative of the soil or rock. The test sample shall be as

several soil or rock fragments. This sample holder is frequently

large as practicable considering the test apparatus.

called a penetrometer. The porosimeter shall have a means of

NOTE 1—Sample size is limited by the pore-measuring capacity of the

penetrometer, which is currently (1984) slightly more than 1 cm . The

small sample size may prevent the measurement of porosity represented

The boldface numbers in parentheses refer to the list of references appended to

this standard. by relatively large cracks and fissures in the material. Judgement is

D 4404

FIG. 2 Example of Differential Pore Volume Distribution Plot

required in the application of these measurements to the characterization

11.4 Place the penetrometer containing the sample in the

of the soil or rock masses.

appropriate chamber of the porosimeter, following the manu-

facturer’s instructions, and evacuate to a pressure of at least 1.3

10. Conditioning

Pa (10 μmHg).

10.1 The ideal preconditioning for the test specimen is an 11.5 Fill the penetrometer with mercury, in accordance with

the manufacturer’s instructions, by pressurizing to some suit-

outgassing or drying procedure that removes all foreign sub-

ably low pressure.

stances from the pores and pore walls of the soil or rock and

does not alter the soil or rock in any way. If possible, the

NOTE 3—The pressure required to fill the penetrometer with mercury is

appropriate combination of temperature and pressure and the

also capable of intruding sufficiently large pores of both the inter- and

required time of conditioning shall be experimentally deter-

intra-fragment classes. Thus, the process can intrude some pores and the

mined for the specific soil or rock under test. This outgassing volume distribution of these pores cannot subsequently be determined.

This fact should be recognized, and where possible, a filling pressure

or drying technique shall then be the one specified and used.

should be selected that will not intrude pores in the diameter range of

10.2 Where the procedure described in 10.1 is not practical,

interest.

rock or coarse-grained soil without fines shall be outgassed in

11.6 Place the filled penetrometer in the pressure vessel of

a vacuum at at least 1.3 Pa (10 μmHg) and at a temperature of

the porosimeter and prepare the instrument for pressurization

150°C for at least 24 h. Soil containing any plastic fines

and intrusion readings in accordance with the manufacturer’s

requires special drying procedures to avoid alteration of pore

instructions.

structure. Freeze drying has been successfully employed (3, 4)

11.7 Raise the pressure, either continuously or incremen-

and is a simple procedure. Critical region drying may also be

tally, and record both the absolute pressure and the volume of

used (5), but is more complex and expensive than freeze

intruded mercury until the maximum pressure of interest is

drying.

reached.

11. Procedure

NOTE 4—When raising the pressure incrementally, the pressure shall be

maintained during the pause and not allowed to decrease.

11.1 Outgas or dry the test specimen in accordance with

NOTE 5—When testing some materials, the time required to achieve

10.1 or 10.2.

intrusion equilibrium will not be the same at all pressures. Often the

11.2 Weigh the outgassed or dried specimen and record this

equilibrium time is appreciably longer at pressures that cause an abrupt

weight.

and large increase in intruded volume. Failure to record the equilibrium

intrusion may result in some of the pore volume being incorrectly assigned

11.3 Place the outgassed or dried material in the penetrom-

to smaller pore diameters. The extent to which this may be a problem can

eter.

be assessed by conducting two tests, each at a different pressure increase

rate, and comparing the results.

NOTE 2—When performing the operation described in 11.2 and 11.3,

the outgassed or dried material is exposed to the laboratory atmosphere NOTE 6—Use of the equation in 4.1 requires the absolute pressure, P.

and can readsorb vapors. Thus, this operation should be carried out as With some instruments it may not be possible to read the absolute pressure

rapidly as possible. directly. In this case the gage pressure shall be recorded at each step, and

D 4404

the absolute pressures subsequently calculated.

13.2.2 The contact angle enters the equation as a cosine

NOTE 7—The choice of pressure intervals at which data are to be

function, and it is more important to know the value of the

recorded is left to the judgment of the operator. Normally, at least 10 to 15

angle accurately for the material under test. The contact angle

intervals will be required to adequately define the pore volume distribu-

of mercury has been measured on a variety of solids by several

tion. In selecting these pressure intervals, a rough idea of the expected

different techniques; references to some of these measurements

distribution is helpful, since the pressure interval can be larger in regions

are given in Appendix X1. This appendix also lists references

where little or no intrusion occurs and should be smaller in regions where

for several methods of contact-angle measurement that have

a large volume of intrusion is expected. It is not necessary to continue the

process up to the maximum pressurizing capability of the instrument if all been found useful. The ideal value for reducing the data is the

of the pores of interest in a particular test specimen have been intruded at

one that has been determined for the material under test. If

a lesser pressure.

direct measurement is impractical, the use of an assumed value

is customary. If mercury intrusion is being used for the

11.8 Upon completion of the pressuring cycle, reduce the

comparison of similar materials for quality control purposes,

pressure and disassemble and clean the instrument in accor-

then an assumed value is satisfactory, however, when different

dance with the manufacturer’s instructions.

materials are being compared, the assumption of a single value

for the contact angle may lead to errors.

12. Blank Test for Corrections

13.3 The next step in the calculations is the correction of the

12.1 An intrusion test on a nonporous sample is required to

intruded volume readings. Corrections fall into two categories:

obtain values to use in correcting intrusion data for compress-

low-pressure corrections and high-pressure corrections.

ibilities and temperature changes.

13.3.1 Low-pressure corrections account for the fact that

12.2 Select a nonporous material that has approximately the

part of the apparent intrusion recorded at the lowest pressures

same compressibility and bulk volume as the soil or rock

is actually the compression of the air trapped in the penetrom-

sample that is to be tested.

eter when it was filled with mercury. This correction is

12.3 Test the nonporous sample in exactly the same manner

important only when the distribution of large pores must be

as outlined in Section 11. Raise the pressure in the same steps

meas

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.