ASTM A633/A633M-01

(Specification)Standard Specification for Normalized High-Strength Low-Alloy Structural Steel Plates

Standard Specification for Normalized High-Strength Low-Alloy Structural Steel Plates

SCOPE

1.1 This specification covers normalized high-strength low-alloy structural steel plates for welded, riveted, or bolted construction.

1.2 This material is particularly suited for service at low ambient temperatures of -50oF [-45oC] and higher where notch toughness better than that expected in as-rolled material of a comparable strength level is desired.

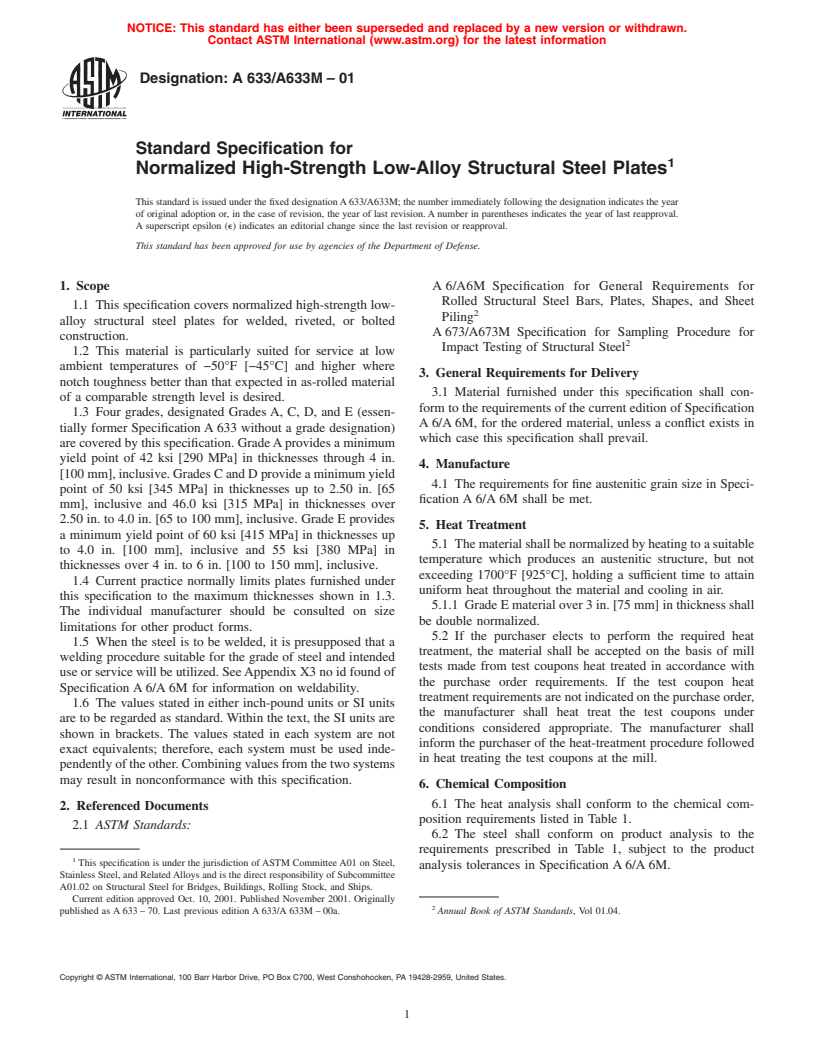

1.3 Four grades, designated Grades A, C, D, and E (essentially former Specification A633 without a grade designation) are covered by this specification. Grade A provides a minimum yield point of 42 ksi [290 MPa] in thicknesses through 4 in. [100 mm], inclusive. Grades C and D provide a minimum yield point of 50 ksi [345 MPa] in thicknesses up to 2.50 in. [65 mm], inclusive and 46.0 ksi [315 MPa] in thicknesses over 2.50 in. to 4.0 in. [65 to 100 mm], inclusive. Grade E provides a minimum yield point of 60 ksi [415 MPa] in thicknesses up to 4.0 in. [100 mm], inclusive and 55 ksi [380 MPa] in thicknesses over 4 in. to 6 in. [100 to 150 mm], inclusive.

1.4 Current practice normally limits plates furnished under this specification to the maximum thicknesses shown in 1.3. The individual manufacturer should be consulted on size limitations for other product forms.

1.5 When the steel is to be welded, it is presupposed that a welding procedure suitable for the grade of steel and intended use or service will be utilized. See Appendix X3 of Specification A6/A6M for information on weldability.

1.6 The values stated in either inch-pound units or SI units are to be regarded as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with this specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 633/A633M – 01

Standard Specification for

1

Normalized High-Strength Low-Alloy Structural Steel Plates

This standard is issued under the fixed designationA633/A633M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope A 6/A6M Specification for General Requirements for

Rolled Structural Steel Bars, Plates, Shapes, and Sheet

1.1 This specification covers normalized high-strength low-

2

Piling

alloy structural steel plates for welded, riveted, or bolted

A673/A673M Specification for Sampling Procedure for

construction.

2

Impact Testing of Structural Steel

1.2 This material is particularly suited for service at low

ambient temperatures of −50°F [−45°C] and higher where

3. General Requirements for Delivery

notch toughness better than that expected in as-rolled material

3.1 Material furnished under this specification shall con-

of a comparable strength level is desired.

form to the requirements of the current edition of Specification

1.3 Four grades, designated Grades A, C, D, and E (essen-

A6/A6M, for the ordered material, unless a conflict exists in

tially former SpecificationA633 without a grade designation)

which case this specification shall prevail.

arecoveredbythisspecification.GradeAprovidesaminimum

yield point of 42 ksi [290 MPa] in thicknesses through 4 in.

4. Manufacture

[100mm],inclusive.GradesCandDprovideaminimumyield

4.1 The requirements for fine austenitic grain size in Speci-

point of 50 ksi [345 MPa] in thicknesses up to 2.50 in. [65

fication A 6/A 6M shall be met.

mm], inclusive and 46.0 ksi [315 MPa] in thicknesses over

2.50 in. to 4.0 in. [65 to 100 mm], inclusive. Grade E provides

5. Heat Treatment

a minimum yield point of 60 ksi [415 MPa] in thicknesses up

5.1 Thematerialshallbenormalizedbyheatingtoasuitable

to 4.0 in. [100 mm], inclusive and 55 ksi [380 MPa] in

temperature which produces an austenitic structure, but not

thicknesses over 4 in. to 6 in. [100 to 150 mm], inclusive.

exceeding 1700°F [925°C], holding a sufficient time to attain

1.4 Current practice normally limits plates furnished under

uniform heat throughout the material and cooling in air.

this specification to the maximum thicknesses shown in 1.3.

5.1.1 GradeEmaterialover3in.[75mm]inthicknessshall

The individual manufacturer should be consulted on size

be double normalized.

limitations for other product forms.

5.2 If the purchaser elects to perform the required heat

1.5 When the steel is to be welded, it is presupposed that a

treatment, the material shall be accepted on the basis of mill

welding procedure suitable for the grade of steel and intended

tests made from test coupons heat treated in accordance with

useorservicewillbeutilized.SeeAppendixX3noidfoundof

the purchase order requirements. If the test coupon heat

Specification A6/A6M for information on weldability.

treatmentrequirementsarenotindicatedonthepurchaseorder,

1.6 The values stated in either inch-pound units or SI units

the manufacturer shall heat treat the test coupons under

are to be regarded as standard. Within the text, the SI units are

conditions considered appropriate. The manufacturer shall

shown in brackets. The values stated in each system are not

inform the purchaser of the heat-treatment procedure followed

exact equivalents; therefore, each system must be used inde-

in heat treating the test coupons at the mill.

pendentlyoftheother.Combiningvaluesfromthetwosystems

may result in nonconformance with this specification.

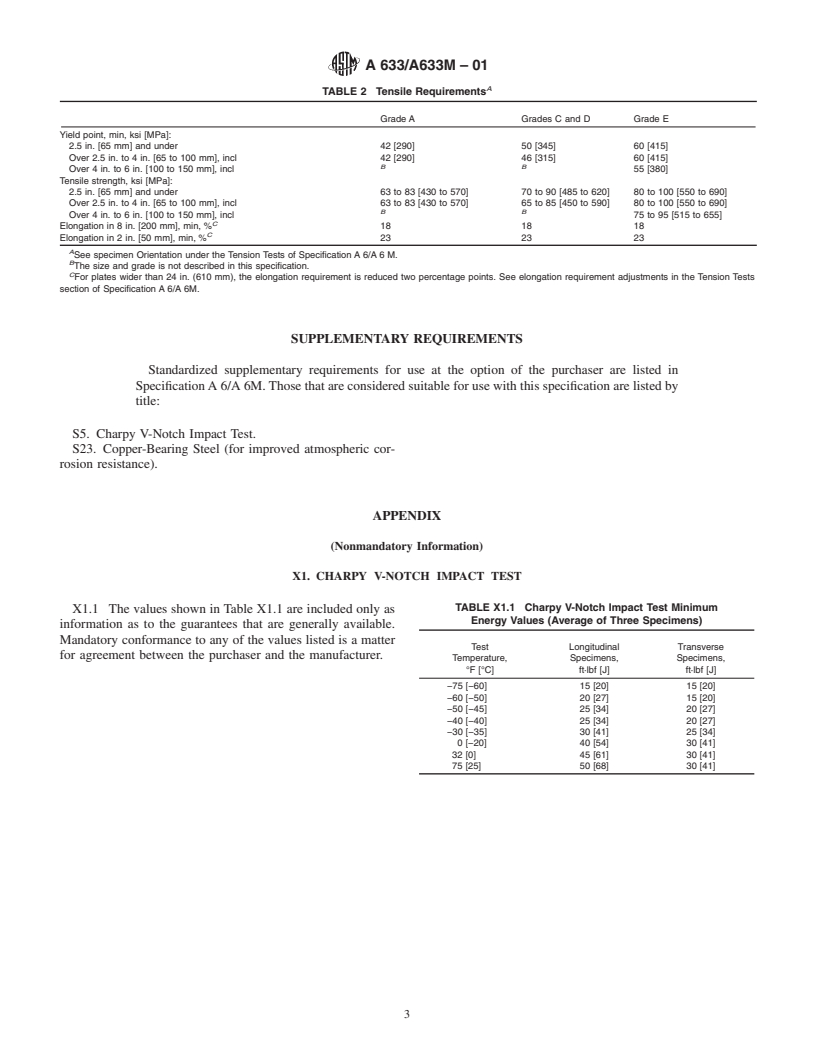

6. Chemical Composition

6.1 The heat analysis shall conform to the chemical com-

2. Referenced Documents

position requirements listed in Table 1.

2.1 ASTM Standards:

6.2 The steel shall conform on product analysis to the

requirements prescribed in Table 1, subject to the product

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel,

analysis tolerances in Specification A6/A6M.

Stainless Steel, and RelatedAlloys and is the direct responsibility of Subcommittee

A01.02 on Structural Steel for Bridges, Buildings, Rolling Stock, and Ships.

Current edition approved Oct. 10, 2001. Published November 2001. Originally

2

published as A633–70. Last previous edition A633/A633M–00a. Annual Book of ASTM Standards, Vol 01.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A 633/A633M – 01

TABLE 1 Chemical Requirements

NOTE—Where “.” appears in this table, there is no requirement.

A

Element Grade A, % Grade C, % G

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.