ASTM C964-19

(Guide)Standard Guide for Lock-Strip Gasket Glazing

Standard Guide for Lock-Strip Gasket Glazing

SIGNIFICANCE AND USE

3.1 This guide provides information and guidelines for the design of lock-strip gasket glazing systems. For related standards, see Specifications C542, C716, and C963.

SCOPE

1.1 This guide covers the use of lock-strip gaskets in compliance with Specification C542 in walls of buildings not over 15° from a vertical plane. The prime performance considerations are weathertightness against air and water infiltration, and structural integrity under wind loads. Included are terminology, design considerations, and fabrication tolerances when using lock-strip gaskets in glazing applications.

1.2 The values stated in SI units are to be regarded as the standard. The inch-pound units in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C964 − 19

Standard Guide for

1

Lock-Strip Gasket Glazing

This standard is issued under the fixed designation C964; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E283 Test Method for Determining Rate of Air Leakage

Through Exterior Windows, Skylights, Curtain Walls, and

1.1 This guide covers the use of lock-strip gaskets in

Doors Under Specified Pressure Differences Across the

compliance with Specification C542 in walls of buildings not

Specimen

over 15° from a vertical plane. The prime performance

E330 Test Method for Structural Performance of Exterior

considerations are weathertightness against air and water

Windows, Doors, Skylights and CurtainWalls by Uniform

infiltration, and structural integrity under wind loads. Included

Static Air Pressure Difference

are terminology, design considerations, and fabrication toler-

E331 Test Method for Water Penetration of Exterior

ances when using lock-strip gaskets in glazing applications.

Windows, Skylights, Doors, and Curtain Walls by Uni-

1.2 The values stated in SI units are to be regarded as the

form Static Air Pressure Difference

standard. The inch-pound units in parentheses are for informa-

tion only.

3. Significance and Use

1.3 This standard does not purport to address all of the

3.1 This guide provides information and guidelines for the

safety concerns, if any, associated with its use. It is the

design of lock-strip gasket glazing systems. For related

responsibility of the user of this standard to establish appro-

standards, see Specifications C542, C716, and C963.

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

4. Comparison to Other Standards

1.4 This international standard was developed in accor-

4.1 Thecommitteewithjurisdictionoverthisstandardisnot

dance with internationally recognized principles on standard-

aware of any comparable standards published by other orga-

ization established in the Decision on Principles for the

nizations.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

DESIGN CONSIDERATIONS

Barriers to Trade (TBT) Committee.

5. General

2. Referenced Documents

5.1 Structural integrity and watertightness of a gasket glaz-

2

2.1 ASTM Standards:

ing system is dependent on interaction of the several compo-

C542 Specification for Lock-Strip Gaskets

nents involved. These systems should be carefully designed

C716 Specification for Installing Lock-Strip Gaskets and

and built.

Infill Glazing Materials

C864 Specification for Dense Elastomeric Compression Seal

6. Components

Gaskets, Setting Blocks, and Spacers

6.1 The major components of lock-strip gasket glazing and

C963 Specification for Packaging, Identification, Shipment,

paneling systems are:

and Storage of Lock-Strip Gaskets

6.1.1 The supporting frame of metal, concrete, or other

C1036 Specification for Flat Glass

structural building materials,

6.1.2 Lock-strip gasket, serving as an elastomeric mechani-

cal seal and as a retainer for panel or glass, and

1

ThisguideisunderthejurisdictionofASTMCommitteeC24onBuildingSeals

and Sealants and is the direct responsibility of Subcommittee C24.73 on Compres- 6.1.3 Glass or panel infill.

sion Seal and Lock Strip Gaskets.

6.1.4 The design of these components and their accessories

Current edition approved Aug. 1, 2019. Published September 2019. Originally

are interrelated and the total system must be compatible.

approved in 1981. Last previous edition approved in 2012 as C964 – 07 (2012).

DOI: 10.1520/C0964-19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 7. Supporting Frames

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

7.1 Supporting frames are made of many materials, of

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. which the more common are aluminum, steel, and concrete.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

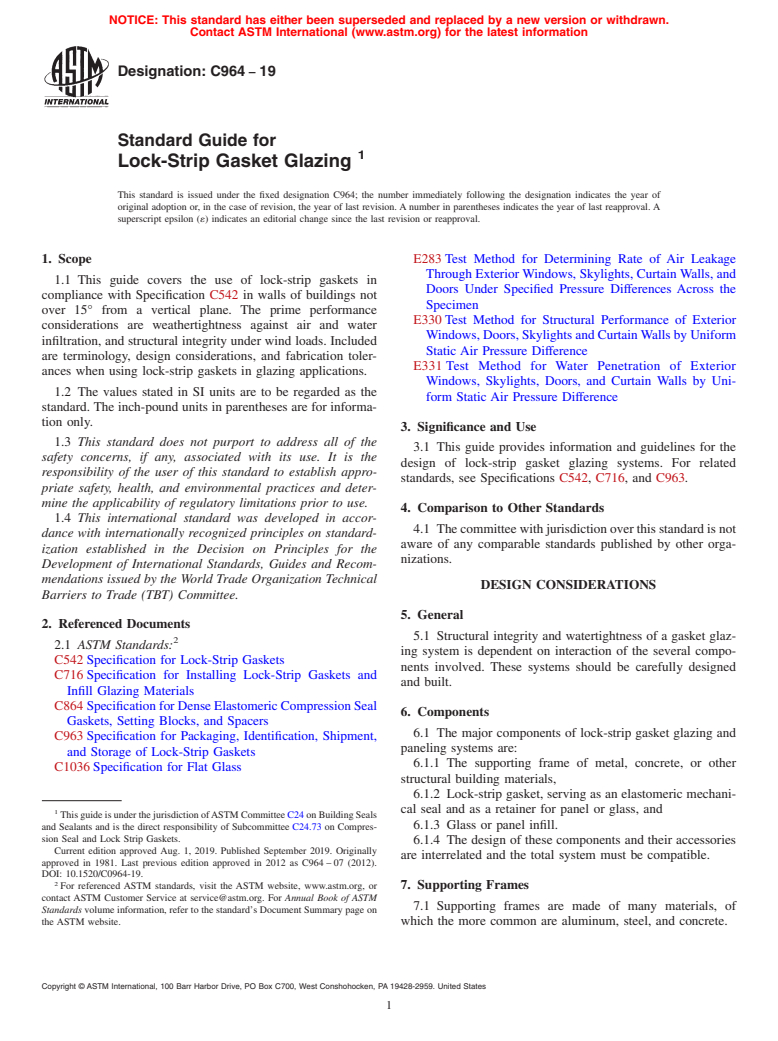

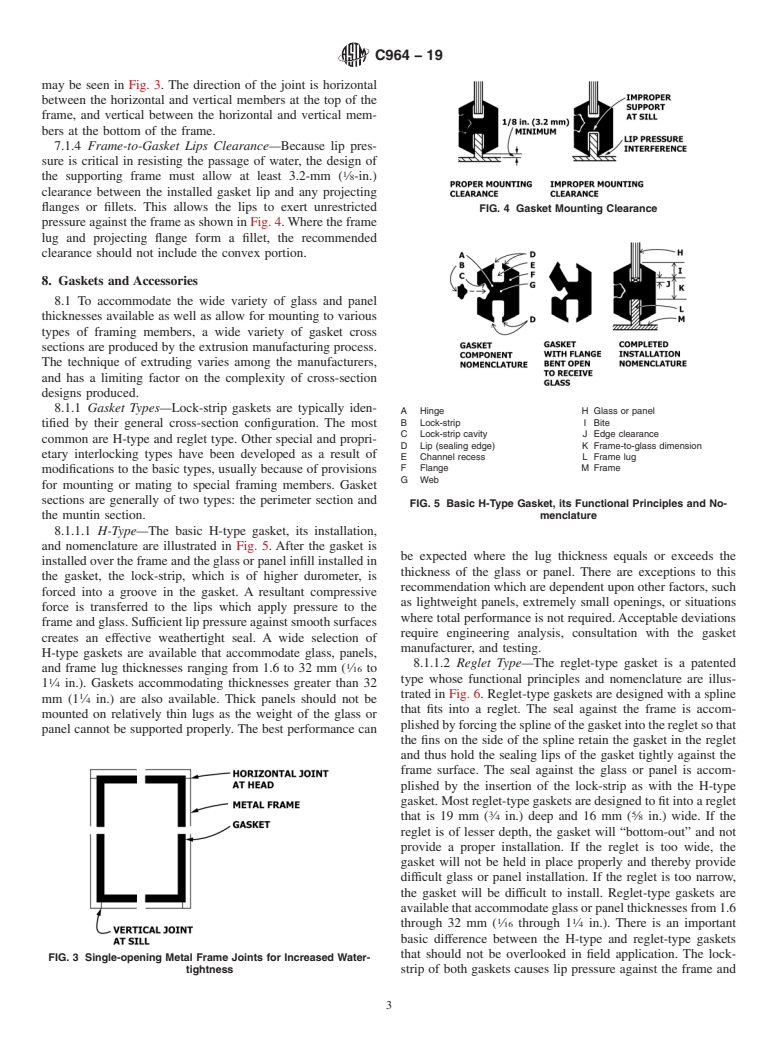

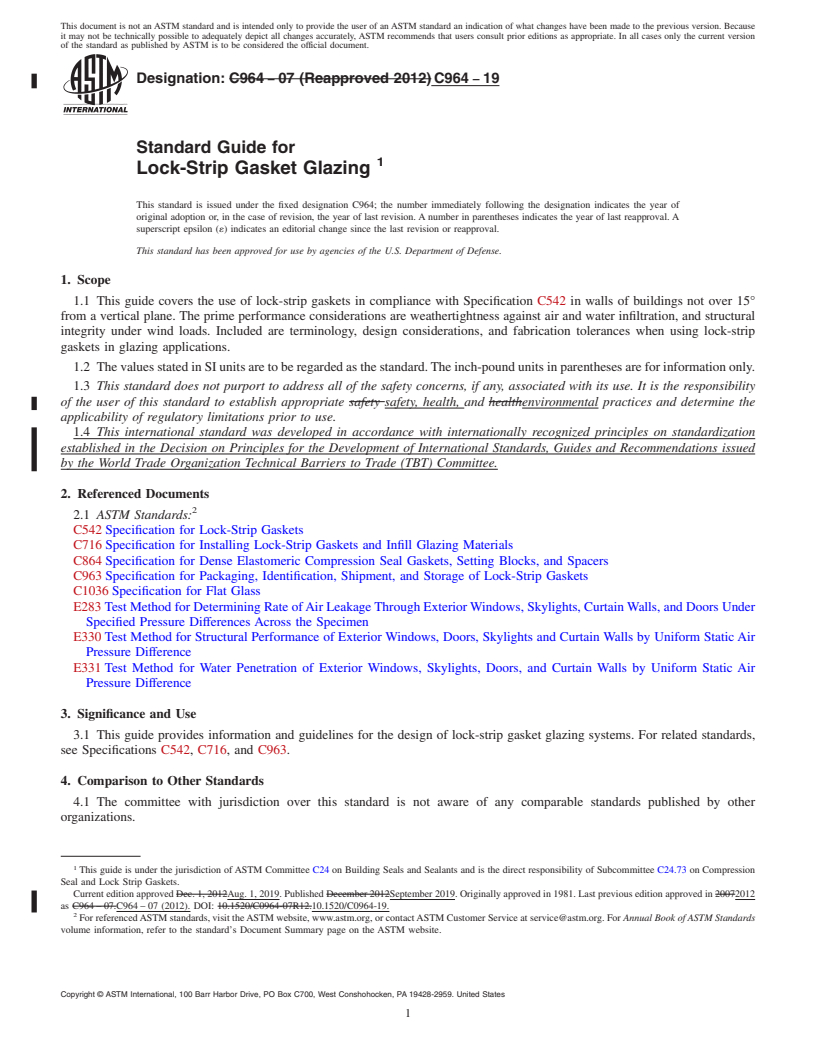

C964 − 19

7.1.1 Metal—Die marks, ridges, offsets, and scratches in be solidly cast into the concrete without any voids or honey-

metal frames in contact with the gasket lips that could cause combing at the leading edge of the flange because water could

leakage should be avoided. Metal in contact with any part of enter the interface between the flange and the concrete into

the gasket should have sharp edges and burrs removed to avoid which it is cast.

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C964 − 07 (Reapproved 2012) C964 − 19

Standard Guide for

1

Lock-Strip Gasket Glazing

This standard is issued under the fixed designation C964; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This guide covers the use of lock-strip gaskets in compliance with Specification C542 in walls of buildings not over 15°

from a vertical plane. The prime performance considerations are weathertightness against air and water infiltration, and structural

integrity under wind loads. Included are terminology, design considerations, and fabrication tolerances when using lock-strip

gaskets in glazing applications.

1.2 The values stated in SI units are to be regarded as the standard. The inch-pound units in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C542 Specification for Lock-Strip Gaskets

C716 Specification for Installing Lock-Strip Gaskets and Infill Glazing Materials

C864 Specification for Dense Elastomeric Compression Seal Gaskets, Setting Blocks, and Spacers

C963 Specification for Packaging, Identification, Shipment, and Storage of Lock-Strip Gaskets

C1036 Specification for Flat Glass

E283 Test Method for Determining Rate of Air Leakage Through Exterior Windows, Skylights, Curtain Walls, and Doors Under

Specified Pressure Differences Across the Specimen

E330 Test Method for Structural Performance of Exterior Windows, Doors, Skylights and Curtain Walls by Uniform Static Air

Pressure Difference

E331 Test Method for Water Penetration of Exterior Windows, Skylights, Doors, and Curtain Walls by Uniform Static Air

Pressure Difference

3. Significance and Use

3.1 This guide provides information and guidelines for the design of lock-strip gasket glazing systems. For related standards,

see Specifications C542, C716, and C963.

4. Comparison to Other Standards

4.1 The committee with jurisdiction over this standard is not aware of any comparable standards published by other

organizations.

1

This guide is under the jurisdiction of ASTM Committee C24 on Building Seals and Sealants and is the direct responsibility of Subcommittee C24.73 on Compression

Seal and Lock Strip Gaskets.

Current edition approved Dec. 1, 2012Aug. 1, 2019. Published December 2012September 2019. Originally approved in 1981. Last previous edition approved in 20072012

as C964 – 07.C964 – 07 (2012). DOI: 10.1520/C0964-07R12.10.1520/C0964-19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

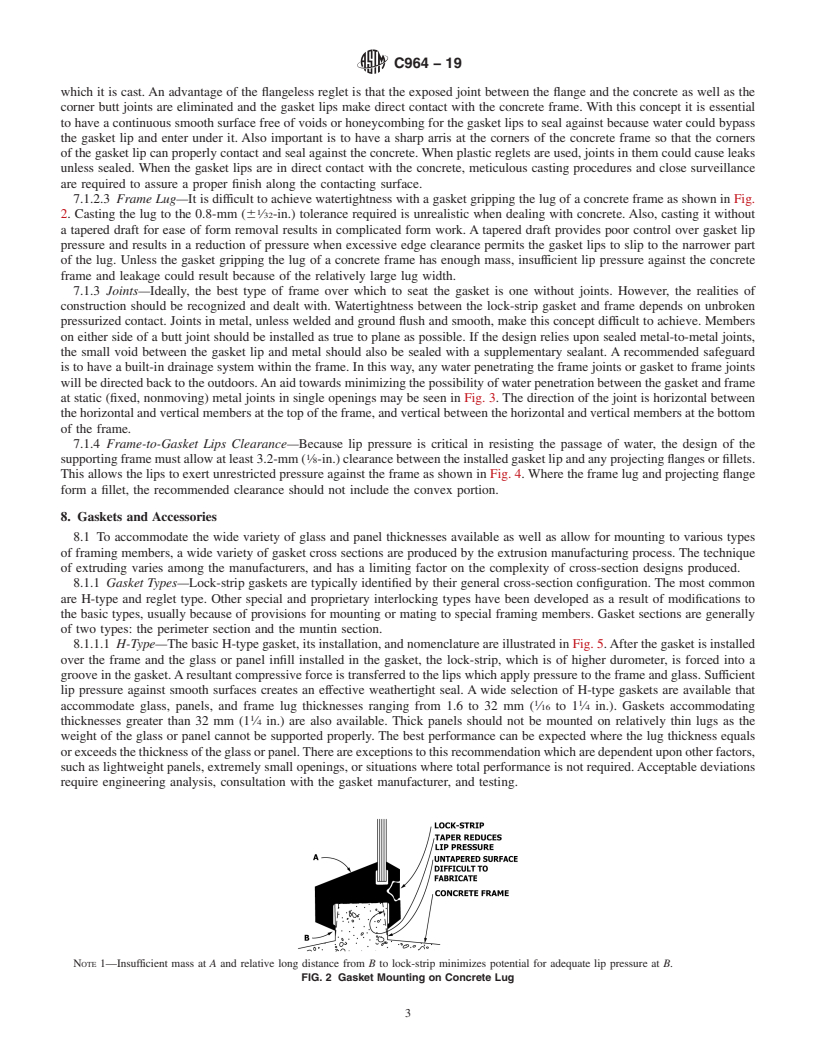

C964 − 19

DESIGN CONSIDERATIONS

5. General

5.1 Structural integrity and watertightness of a gasket glazing system is dependent on interaction of the several components

involved. These systems should be carefully designed and built.

6. Components

6.1 The major components of lock-strip gasket glazing and paneling systems are:

6.1.1 The supporting frame of metal, concrete, or other structural building materials,

6.1.2 Lock-strip gasket, serving as an elastomeric mechanical seal and as a retainer for panel or glass, and

6.1.3 Glass or panel infill.

6.1.4 The design of these components and their accessories are interrelated and the total system must be compatible.

7. Supporting Frames

7.1 Supporting frames are made of many materials, of which the more common are aluminum, st

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.