ASTM B584-11

(Specification)Standard Specification for Copper Alloy Sand Castings for General Applications

Standard Specification for Copper Alloy Sand Castings for General Applications

ABSTRACT

This specification covers requirements for copper alloy sand castings for general applications. The components part casting may be manufactured in advance and supplied from stock. The castings shall conform to the compositional requirements for named elements specified. Mechanical properties of copper alloys such as tensile strength, yield strength, and elongation shall be determined. The castings shall not be repaired, plugged, welded, or burned in.

SCOPE

1.1 This specification covers requirements for copper alloy sand castings for general applications. Nominal compositions of the alloys defined by this specification are shown in Table 1. This is a composite specification replacing former documents as shown in Table 1.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B584 −11

StandardSpecification for

1

Copper Alloy Sand Castings for General Applications

This standard is issued under the fixed designation B584; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* B67 Specification for Car and Tender Journal Bearings,

Lined

1.1 This specification covers requirements for copper alloy

B148 Specification for Aluminum-Bronze Sand Castings

sand castings for general applications. Nominal compositions

B176 Specification for Copper-Alloy Die Castings

of the alloys defined by this specification are shown in Table

2 B208 Practice for Preparing Tension Test Specimens for

1. This is a composite specification replacing former docu-

Copper Alloy Sand, Permanent Mold, Centrifugal, and

ments as shown in Table 1.

Continuous Castings

NOTE 1—Other copper alloy castings are included in the following

B271 Specification for Copper-BaseAlloy Centrifugal Cast-

ASTM specifications: B22, B61, B62, B66, B67, B148, B176, B271,

ings

B369, B427, B505/B505M, B763, B770, and B806.

B369 Specification for Copper-Nickel Alloy Castings

1.2 Component part castings produced to this specification

B427 Specification for Gear Bronze Alloy Castings

may be manufactured in advance and supplied from stock. In

B505/B505M Specification for Copper Alloy Continuous

such cases the manufacturer shall maintain a general quality

Castings

certification of all castings without specific record or date of

B763 Specification for Copper Alloy Sand Castings for

casting for a specific casting.

Valve Applications

B770 Specification for Copper-Beryllium Alloy Sand Cast-

1.3 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical ings for General Applications

B806 Specification for CopperAlloy Permanent Mold Cast-

conversions to SI units that are provided for information only

and are not considered standard. ings for General Applications

B824 Specification for General Requirements for Copper

Alloy Castings

2. Referenced Documents

B846 Terminology for Copper and Copper Alloys

3

2.1 ASTM Standards:

E255 Practice for Sampling Copper and Copper Alloys for

B22 Specification for Bronze Castings for Bridges and

the Determination of Chemical Composition

Turntables

E527 Practice for Numbering Metals and Alloys in the

B61 Specification for Steam or Valve Bronze Castings

Unified Numbering System (UNS)

B62 Specification for Composition Bronze or Ounce Metal

2.2 ASME Code:

Castings

4

ASME Boiler and Pressure Vessel Code

B66 Specification for Bronze Castings for Steam Locomo-

tive Wearing Parts

3. Terminology

3.1 Definitions of terms relating to copper alloys can be

found in Terminology B846.

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

and Copper Alloys and is the direct responsibility of Subcommittee B05.05 on

4. General Requirements

Castings and Ingots for Remelting.

4.1 The following sections of Specification B824 form a

Current edition approved April 1, 2011. Published May 2011. Originally

approved in 1973. Last previous edition approved in 2009 as B584 – 09a. DOI:

part of this specification. In the event of a conflict between this

10.1520/B0584-11.

specification and Specification B824, the requirements of this

2

The UNS system for copper and copper alloys (see Practice E527) is a simple

specification shall take precedence.

expansion of the former standard designation system accomplished by the addition

of a prefix “C” and a suffix “00”. The suffix can be used to accommodate 4.1.1 Terminology,

composition variations of the base alloy.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from American Society of Mechanical Engineers (ASME), ASME

Standards volume information, refer to the standard’s Document Summary page on International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

the ASTM website. www.asme.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B584−11

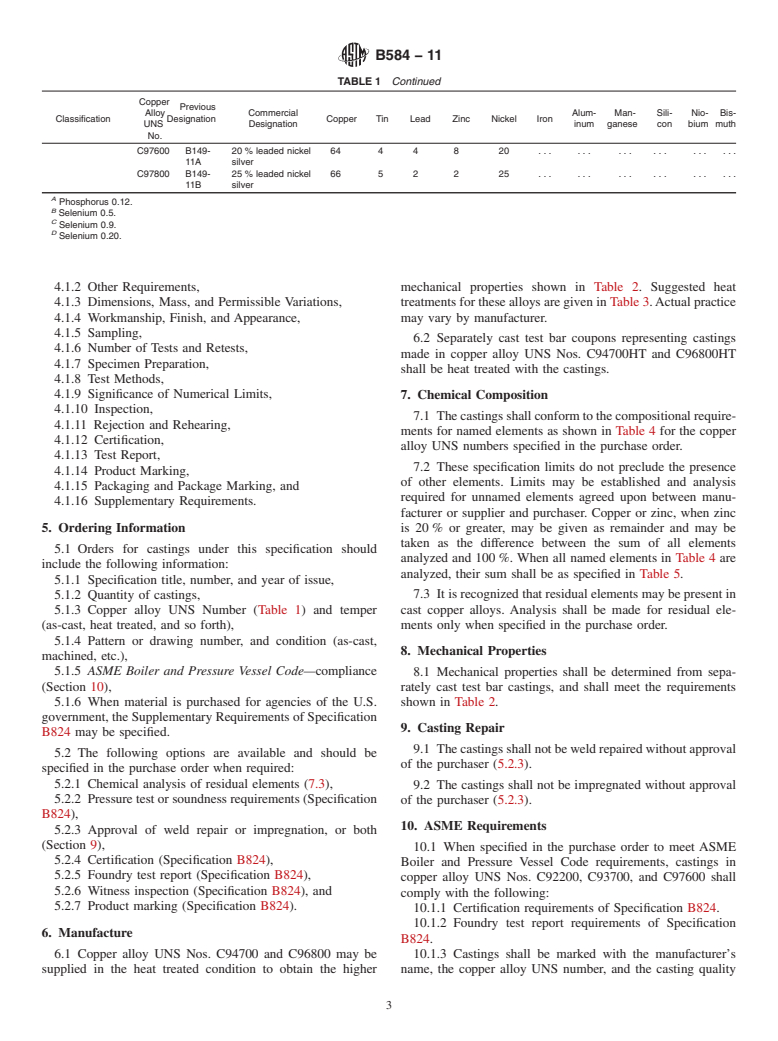

TABLE 1 Nominal Compositions

Copper

Previous

Alloy Commercial Alum- Man- Sili- Nio- Bis-

Classification Designation Copper Tin Lead Zinc Nickel Iron

UNS Designation inum ganese con bium muth

No.

1 1

Leaded red brass C83450 . . . . . . 88 2 ⁄2 26 ⁄2 1 . . . . . .

C83600 B145-4A 85-5-5-5 or No. 1 85 5

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B584–09a Designation: B584 – 11

Standard Specification for

1

Copper Alloy Sand Castings for General Applications

This standard is issued under the fixed designation B584; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This specification covers requirements for copper alloy sand castings for general applications. Nominal compositions of the

2

alloys defined by this specification are shown in Table 1. This is a composite specification replacing former documents as shown

in Table 1.

NOTE 1—Other copper alloy castings are included in the followingASTM specifications: B22, B61, B62, B66, B67, B148, B176, B271, B369, B427,

B505/B505M, B763, B770, and B806.

1.2 Component part castings produced to this specification may be manufactured in advance and supplied from stock. In such

cases the manufacturer shall maintain a general quality certification of all castings without specific record or date of casting for

a specific casting.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

2. Referenced Documents

3

2.1 ASTM Standards:

B22 Specification for Bronze Castings for Bridges and Turntables

B61 Specification for Steam or Valve Bronze Castings

B62 Specification for Composition Bronze or Ounce Metal Castings

B66 Specification for Bronze Castings for Steam Locomotive Wearing Parts

B67 Specification for Car and Tender Journal Bearings, Lined

B148 Specification for Aluminum-Bronze Sand Castings

B176 Specification for Copper-Alloy Die Castings

B208 Practice for Preparing Tension Test Specimens for Copper Alloy Sand, Permanent Mold, Centrifugal, and Continuous

Castings

B271 Specification for Copper-Base Alloy Centrifugal Castings

B369 Specification for Copper-Nickel Alloy Castings

B427 Specification for Gear Bronze Alloy Castings

B505/B505M Specification for Copper Alloy Continuous Castings

B763 Specification for Copper Alloy Sand Castings for Valve Applications

B770 Specification for Copper-Beryllium Alloy Sand Castings for General Applications

B806 Specification for Copper Alloy Permanent Mold Castings for General Applications

B824 Specification for General Requirements for Copper Alloy Castings

B846 Terminology for Copper and Copper Alloys

E255 Practice for Sampling Copper and Copper Alloys for the Determination of Chemical Composition

E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

2.2 ASME Code:

1

This specification is under the jurisdiction ofASTM Committee B05 on Copper and CopperAlloys and is the direct responsibility of Subcommittee B05.05 on Castings

and Ingots for Remelting.

Current edition approved Nov. 15, 2009.April 1, 2011. Published December 2009.May 2011. Originally approved in 1973. Last previous edition approved in 2009 as

B584 – 09a. DOI: 10.1520/B0584-09a.10.1520/B0584-11.

2

The UNS system for copper and copper alloys (see Practice E527) is a simple expansion of the former standard designation system accomplished by the addition of a

prefix “C” and a suffix “00”. The suffix can be used to accommodate composition variations of the base alloy.

3

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B584 – 11

TABLE 1 Nominal Compositions

Copper

Alloy Previous Alum- Man- Sili- Nio- Bis-

Classification Commercial Designation Copper Tin Lead Zinc Nickel Iron

UNS Designation inum ganese con bium muth

No.

1 1

Leaded red brass C83450 . . . . . . 88 2 ⁄226 ⁄2 1 . . . . . .

C83600 B145-4A 85-5-5-5 or No. 1 composition 85 5 5 5 . . . . . . . . . . . . . . . . . . . . .

C83800 B145-4B commercial red brass, 83-4-6-7 83 4 6 7 . . . . . .

C83800 B145-4B commercial red brass, 83-4-6-7 83 4 6 7 . . . . . .

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.