ASTM D3803-91(2009)

(Test Method)Standard Test Method for Nuclear-Grade Activated Carbon

Standard Test Method for Nuclear-Grade Activated Carbon

SIGNIFICANCE AND USE

The results of this test method give a conservative estimate of the performance of nuclear-grade activated carbon used in all nuclear power plant HVAC systems for the removal of radioiodine.

SCOPE

1.1 This test method is a very stringent procedure for establishing the capability of new and used activated carbon to remove radio-labeled methyl iodide from air and gas streams. The single test method described is for application to both new and used carbons, and should give test results comparable to those obtained from similar tests required and performed throughout the world. The conditions employed were selected to approximate operating or accident conditions of a nuclear reactor which would severely reduce the performance of activated carbons. Increasing the temperature at which this test is performed generally increases the removal efficiency of the carbon by increasing the rate of chemical and physical absorption and isotopic exchange, that is, increasing the kinetics of the radioiodine removal mechanisms. Decreasing the relative humidity of the test generally increases the efficiency of methyl iodide removal by activated carbon. The water vapor competes with the methyl iodide for adsorption sites on the carbon, and as the amount of water vapor decreases with lower specified relative humidities, the easier it is for the methyl iodide to be adsorbed. Therefore, this test method is a very stringent test of nuclear-grade activated carbon because of the low temperature and high relative humidity specified. This test method is recommended for the qualification of new carbons and the quantification of the degradation of used carbons.

1.1.1 Guidance for testing new and used carbons using conditions different from this test method is offered in Annex A1.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3803 − 91 (Reapproved 2009)

Standard Test Method for

Nuclear-Grade Activated Carbon

This standard is issued under the fixed designation D3803; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method is a very stringent procedure for 2.1 ASTM Standards:

establishing the capability of new and used activated carbon to D1193Specification for Reagent Water

D2652Terminology Relating to Activated Carbon

remove radio-labeled methyl iodide from air and gas streams.

Thesingletestmethoddescribedisforapplicationtobothnew D2854Test Method for Apparent Density of Activated

Carbon

and used carbons, and should give test results comparable to

those obtained from similar tests required and performed E300Practice for Sampling Industrial Chemicals

E691Practice for Conducting an Interlaboratory Study to

throughout the world. The conditions employed were selected

to approximate operating or accident conditions of a nuclear Determine the Precision of a Test Method

2.2 Code of Federal Regulations:

reactor which would severely reduce the performance of

activatedcarbons.Increasingthetemperatureatwhichthistest CFR Title 49,Section 173.34, “Qualification, Maintenance,

is performed generally increases the removal efficiency of the and Use of Cylinders’’

carbon by increasing the rate of chemical and physical absorp- CFR Title 49,Part 178, Subpart C, “Specifications for

tion and isotopic exchange, that is, increasing the kinetics of Cylinders’’

the radioiodine removal mechanisms. Decreasing the relative 2.3 Military Standards:

humidityofthetestgenerallyincreasestheefficiencyofmethyl MIL-F-51068D Filter, Particulate High Efficiency, Fire

iodideremovalbyactivatedcarbon.Thewatervaporcompetes Resistant

with the methyl iodide for adsorption sites on the carbon, and MIL-F-51079A Filter, Medium Fire Resistant, High Effi-

as the amount of water vapor decreases with lower specified ciency

relative humidities, the easier it is for the methyl iodide to be MIL-STD-45662 Calibration Systems Requirements

adsorbed.Therefore, this test method is a very stringent test of 2.4 Other Standards:

nuclear-grade activated carbon because of the low temperature ANSI/ASME N45.2.6 Qualifications of Inspection,

Examination, and Testing Personnel for Nuclear Power

and high relative humidity specified. This test method is

recommended for the qualification of new carbons and the Plants

quantification of the degradation of used carbons.

3. Terminology

1.1.1 Guidance for testing new and used carbons using

3.1 Definitions of Terms Specific to This Standard:

conditions different from this test method is offered in Annex

3.1.1 counter effıciency (CE)—the fraction of the actual

A1.

number of disintegrations of a radioactive sample that is

1.2 The values stated in SI units are to be regarded as

recorded by a nuclear counter.

standard. No other units of measurement are included in this

3.1.2 effıciency (E)—the percentage of the contaminant

standard.

removed from a gas stream by an adsorption bed; expressed

1.3 This standard does not purport to address all of the

mathematically as E = 100 − P, where E and P are given in

safety concerns, if any, associated with its use. It is the

percent.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

bility of regulatory limitations prior to use.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Published by the General Service Administration, 18th and “F”’ St., N. W.,

This test method is under the jurisdiction of ASTM Committee D28 on Washington, DC 20405.

Activated Carbon and is the direct responsibility of Subcommittee D28.04 on Gas Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Phase Evaluation Tests. Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

Current edition approved April 1, 2009. Published May 2009. Originally dodssp.daps.dla.mil.

approved in 1979. Last previous edition approved in 2004 as D3803–91 (2004). Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

DOI: 10.1520/D3803-91R09. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3803 − 91 (Reapproved 2009)

3.1.3 penetration (P)—the percentage of the contaminant to a depth of 50 6 1 mm, or they may be assembled from two

(CH I) which passes through the equilibrated test bed of separate units each capable of containing carbon to a depth of

standard depth, and is collected on the backup beds during the 25 mm.Two backup canisters, each of 50 6 1 mm total depth,

feed and elution periods under specified conditions. are required. Canisters may be reused after being decontami-

nated to remove residual radioactivity. An acceptable bed

3.1.4 relative humidity (RH)—for the purpose of this test

construction is shown in Fig. 1 with critical dimensions noted.

method, relative humidity is defined as the ratio of the partial

6.2.2 Clamping assemblies are needed for sample and

pressure of water in the gas to the saturation vapor pressure of

backup beds. The only requirements for these assemblies are

water at the gas temperature and pressure. At temperatures

that they provide a smooth sealing face, uniform alignment of

below 100°C, this is the normal definition and relative humid-

bedcanisters,andsufficientclampingforcesothattheleaktest

ity can range from 0 to 100%.

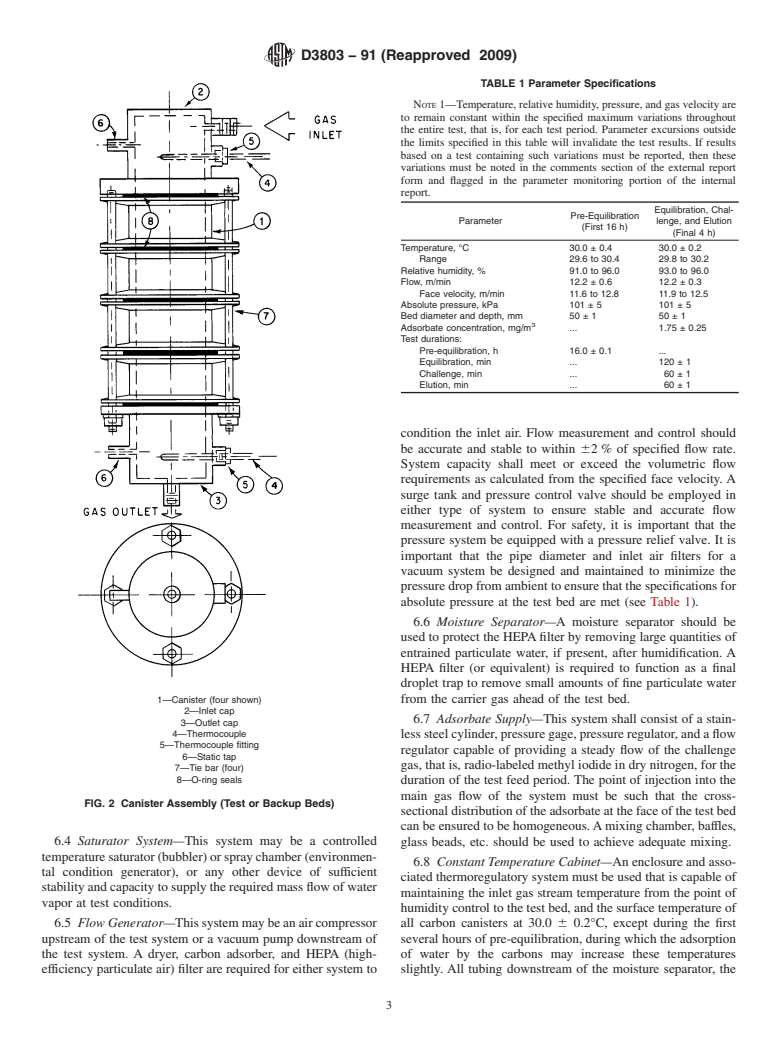

in10.2canbemet.Asuggesteddesignforclampingassemblies

3.2 Definitions—for additional terms relating to this stan-

is shown in Fig. 2.

dard, see Terminology D2652.

6.3 A schematic of a generalized test system is shown in

Fig. 3. This system is designed to operate at approximately

4. Summary of Test Method

30°Cand95%relativehumidity,withagasflowof24.7L/min

4.1 Both new and used carbons are first exposed to humid

at atmospheric pressure. If test conditions which differ signifi-

air (pressure, approximately 1 atm; temperature, 30.0°C; rela-

cantly from these are required, then separate calibrations or

tive humidity, 95%) for a pre-equilibration period of 16 h.

instrumentation, or both, may be required.

Duringthispre-equilibrationperiod,thetestsystemmayberun

unattended with the required parameter monitoring and ad-

equate control devices. Following pre-equilibration, the air

flow is continued for a two-hour equilibration period, during

which the acceptable variability of all parameters is reduced.

The test system must be closely monitored and controlled

during the final four hours of the test. Qualification of

personnel to perform this testing must meet or exceed ANSI/

ASMEN45.2.6—1978,LevelII,whichrequiresacombination

of education and actual test system operation experience.

During the challenge or feed period, radio-labeled methyl

iodideatamassconcentrationof1.75mg/m ofhumidairflow

is passed through the beds for a period of 60 min. Following

the feed period, humid air flow without test adsorbate is

continued at the same conditions for a 60-min elution period.

Throughout the entire test, the effluent from the sample bed

passes through two backup beds containing carbon having a

known high efficiency for methyl iodide.The two backup beds

trap essentially all the radio-labeled methyl iodide that passes

the test bed and provide a differential indication of their

efficiency.At the end of the elution period, the gamma activity

of I in the test and backup beds is measured by a gamma

counter,andthepercentofadsorbatepenetratingthetestbedis

determined.

5. Significance and Use

5.1 The results of this test method give a conservative

estimate of the performance of nuclear-grade activated carbon

used in all nuclear power plant HVAC systems for the removal

of radioiodine.

6. Apparatus

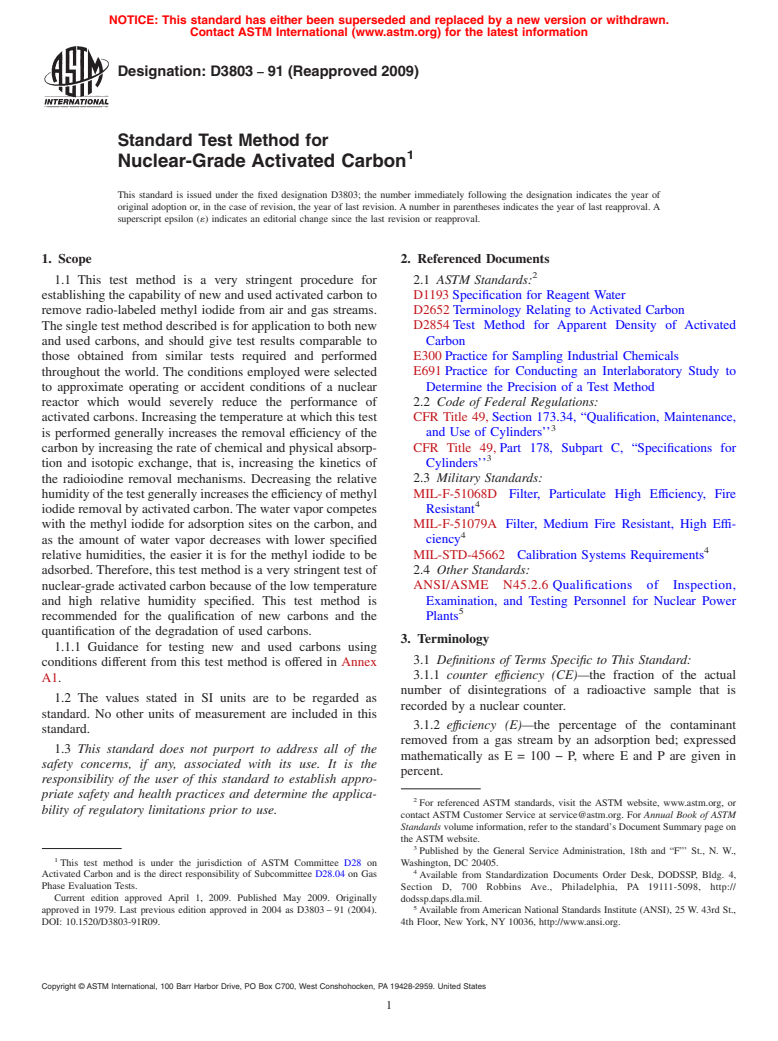

* Standard canister dimension may be used in multiples if desired.

6.1 Sample Preparation Apparatus:

Single test canisters of full depth may be used.

6.1.1 Riffle Sampler, in accordance with 32.5.2 of Practice

1—Bed holder

E300. 2—Adsorption media

3—O-ring gland

6.1.2 Feed Funnel and Vibrator, in accordance with the

4—Perforated screen (both ends)

Procedure Section of Test Method D2854.

5—Retaining snap ring (both ends)

6—Baffle (both ends)

6.2 Sample and Backup Bed Assemblies:

7—Holes for assembly tie-rods (four)

6.2.1 The sample bed canister and backup bed canisters

must each be either a single unit capable of containing carbon FIG. 1 Adsorption Media Test Bed Holder (Canister)

D3803 − 91 (Reapproved 2009)

TABLE 1 Parameter Specifications

NOTE 1—Temperature, relative humidity, pressure, and gas velocity are

to remain constant within the specified maximum variations throughout

the entire test, that is, for each test period. Parameter excursions outside

the limits specified in this table will invalidate the test results. If results

based on a test containing such variations must be reported, then these

variations must be noted in the comments section of the external report

form and flagged in the parameter monitoring portion of the internal

report.

Equilibration, Chal-

Pre-Equilibration

Parameter lenge, and Elution

(First 16 h)

(Final 4 h)

Temperature, °C 30.0 ± 0.4 30.0 ± 0.2

Range 29.6 to 30.4 29.8 to 30.2

Relative humidity, % 91.0 to 96.0 93.0 to 96.0

Flow, m/min 12.2 ± 0.6 12.2 ± 0.3

Face velocity, m/min 11.6 to 12.8 11.9 to 12.5

Absolute pressure, kPa 101 ± 5 101 ± 5

Bed diameter and depth, mm 50 ± 1 50 ± 1

Adsorbate concentration, mg/m . 1.75 ± 0.25

Test durations:

Pre-equilibration, h 16.0 ± 0.1 .

Equilibration, min . 120 ± 1

Challenge, min . 60 ± 1

Elution, min . 60 ± 1

condition the inlet air. Flow measurement and control should

be accurate and stable to within 62% of specified flow rate.

System capacity shall meet or exceed the volumetric flow

requirements as calculated from the specified face velocity. A

surge tank and pressure control valve should be employed in

either type of system to ensure stable and accurate flow

measurement and control. For safety, it is important that the

pressure system be equipped with a pressure relief valve. It is

important that the pipe diameter and inlet air filters for a

vacuum system be designed and maintained to minimize the

pressuredropfromambienttoensurethatthespecificationsfor

absolute pressure at the test bed are met (see Table 1).

6.6 Moisture Separator—A moisture separator should be

used to protect the HEPAfilter by removing large quantities of

entrained particulate water, if present, after humidification. A

HEPA filter (or equivalent) is required to function as a final

droplet trap to remove small amounts of fine particulate water

1—Canister (four shown) from the carrier gas ahead of the test bed.

2—Inlet cap

6.7 Adsorbate Supply—This system shall consist of a stain-

3—Outlet cap

4—Thermocouple

lesssteelcylinder,pressuregage,pressureregulator,andaflow

5—Thermocouple fitting

regulator capable of providing a steady flow of the challenge

6—Static tap

gas,thatis,radio-labeledmethyliodideindrynitrogen,forthe

7—Tie bar (four)

8—O-ring seals

duration of the test feed period. The point of injection into the

main gas flow of the system must be such that the cross-

FIG. 2 Canister Assembly (Test or Backup Beds)

sectionaldistributionoftheadsorbateatthefaceofthetestbed

canbeensuredtobehomogeneous.Amixingchamber,baffles,

6.4 Saturator System—This system may be a controlled glass beads, etc. should be used to achieve adequate mixing.

temperaturesaturator(bubbler)orspraychamber(environmen-

6.8 ConstantTemperatureCabinet—Anenclosureandasso-

tal condition generator), or any other device of sufficient

ciatedthermoregulatorysystemmustbeusedthatiscapableof

stabilityandcapacitytosupplytherequiredmassflowofwater

maintaining the inlet gas stream temperature from the point of

vapor at test conditions.

humiditycontroltothetestbed,andthesurfacetemperatureof

6.5 FlowGenerator—Thissystemmaybeanaircompressor all carbon canisters at 30.0 6 0.2°C, except during the first

upstream of the test system or a vacuum pump downstream of several hours of pre-equilibration, during which the adsorption

the test system. A dryer, carbon adsorber, and HEPA (high- of water by the carbons may increase these temperatures

efficiencyparticulateair)filterarerequiredforeithersystemto slightly. All tubing downstream of the moisture separator, the

D3803 − 91 (Reapproved 2009)

FIG. 3 Schematic of Activated Carbon Test System

carbon bed canisters and holders, temperature and pressure surement system calibration to 60.2°C are required for the

ports and measurement devices upstream and downstream of measurement of test bed inlet air temperature and dew point.

the test bed, and an upstream port and tubing to the dew point The placement of the air temperature RTD must be such that it

sensor all must be included within the temperature controlled isnotsubjecttoradiativeheatingfromthetestbed.Itiscritical

enclosure. In addition, it is highly recommended that a bypass to the exact measurement of relative humidity that the chilled

line be included around the sample bed assembly to avoid mirror RTD and the inlet air temperature RTD be matched

exposing the sample to start-up conditions possibly outside exactly(60.1°C)orthatdifferencesareexactlycorrectedforin

those specified. relative humidity calculations.

6.9 FlowMeasurementandControl—Massflowcontrollers,

6.12 Pressure Measurement Devices—Absolute pressure

control valve and orifice meter, rotameter or any other device

measuring devices must be accurate to within 61% of the

with adequate stability and demonstrated measurement system

reading at standard atmospheric pressure and be capable of

accuracy of 62% of specified flow rate at the test conditions.

digital or analog output to meet the specified recording

All flow measuring devices must use correction factors for

requirements. The sensors and output devices must be cali-

interpretation and application to actual test conditions. These

brated as a unit to ensure system accuracy. The differential

factors must be carefully predetermined and documented. No

pressure device required for measurements across the test bed

flow measuring device should be located directly downstream

mustbecapableofdetectinga0.25kPapressure

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.