ASTM A739-90a(2000)

(Specification)Standard Specification for Steel Bars, Alloy, Hot-Wrought, for Elevated Temperature or Pressure-Containing Parts, or Both

Standard Specification for Steel Bars, Alloy, Hot-Wrought, for Elevated Temperature or Pressure-Containing Parts, or Both

SCOPE

1.1 This specification covers hot-wrought, ferritic alloy steel bars for elevated temperature or pressure-containing parts suitable for fusion welding or both.

1.2 The bars are furnished in the following grades:

Grade B 11: 1.25% chromium, 0.55% molybdenum

Grade B 22: 2.25% chromium, 1.00% molybdenum

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 739 – 90a (Reapproved 2000)

Standard Specification for

Steel Bars, Alloy, Hot-Wrought, for Elevated Temperature or

Pressure-Containing Parts, or Both

This standard is issued under the fixed designation A 739; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

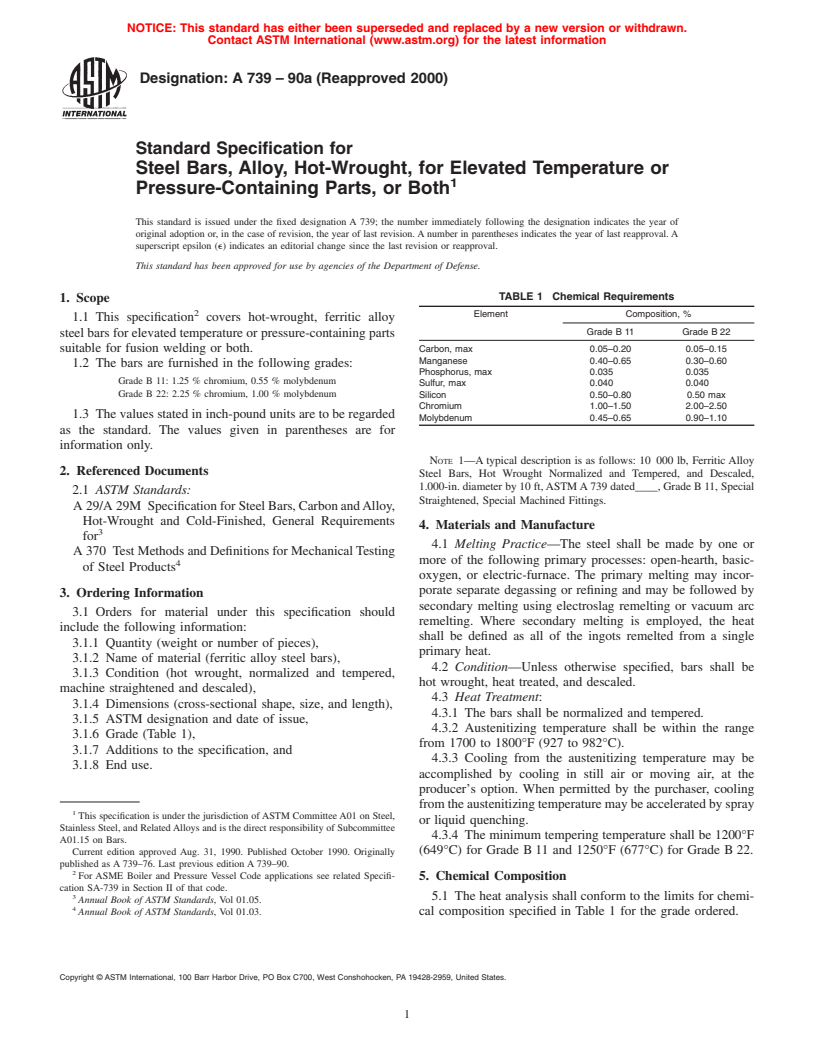

TABLE 1 Chemical Requirements

1. Scope

2 Element Composition, %

1.1 This specification covers hot-wrought, ferritic alloy

Grade B 11 Grade B 22

steel bars for elevated temperature or pressure-containing parts

suitable for fusion welding or both.

Carbon, max 0.05–0.20 0.05–0.15

Manganese 0.40–0.65 0.30–0.60

1.2 The bars are furnished in the following grades:

Phosphorus, max 0.035 0.035

Grade B 11: 1.25 % chromium, 0.55 % molybdenum

Sulfur, max 0.040 0.040

Grade B 22: 2.25 % chromium, 1.00 % molybdenum Silicon 0.50–0.80 0.50 max

Chromium 1.00–1.50 2.00–2.50

1.3 The values stated in inch-pound units are to be regarded

Molybdenum 0.45–0.65 0.90–1.10

as the standard. The values given in parentheses are for

information only.

NOTE 1—A typical description is as follows: 10 000 lb, Ferritic Alloy

2. Referenced Documents

Steel Bars, Hot Wrought Normalized and Tempered, and Descaled,

1.000-in. diameter by 10 ft,ASTMA 739 dated____, Grade B 11, Special

2.1 ASTM Standards:

Straightened, Special Machined Fittings.

A 29/A 29M SpecificationforSteelBars,CarbonandAlloy,

Hot-Wrought and Cold-Finished, General Requirements

4. Materials and Manufacture

for

4.1 Melting Practice—The steel shall be made by one or

A 370 Test Methods and Definitions for MechanicalTesting

more of the following primary processes: open-hearth, basic-

of Steel Products

oxygen, or electric-furnace. The primary melting may incor-

porate separate degassing or refining and may be followed by

3. Ordering Information

secondary melting using electroslag remelting or vacuum arc

3.1 Orders for material under this specification should

remelting. Where secondary melting is employed, the heat

include the following information:

shall be defined as all of the ingots remelted from a single

3.1.1 Quantity (weight or number of pieces),

primary heat.

3.1.2 Name of material (ferritic alloy steel bars),

4.2 Condition—Unless otherwise specified, bars shall be

3.1.3 Condition (hot wrought, normalized and tempered,

hot wrought, heat treated, and descaled.

machine straightened and descaled),

4.3 Heat Treatment:

3.1.4 Dimensions (cross-sectional shape, size, and length),

4.3.1 The bars shall be normalized and tempered.

3.1.5 ASTM designation and date of issue,

4.3.2 Austenitizing temperature shall be within the range

3.1.6 Grade (Table 1),

from 1700 to 1800°F (927 to 982°C).

3.1.7 Additions to the specification, and

4.3.3 Cooling from the austenitizing temperature may be

3.1.8 End use.

accomplished by cooling in still air or moving air, at the

producer’s option. When permitted by the purchaser, cooling

fromtheaustenitizingtemperaturemaybeacceleratedbyspray

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

or liquid quenching.

Stainless Steel, and RelatedAlloys and is the direct responsibility of Subcommittee

4.3.4 The minimum tempering temperature shall be 1200°F

A01.15 on Bars.

(649°C) for Grade B 11 and 1250°F (677°C) for Grade B 22.

Current edition approved Aug. 31, 1990. Published October 1990. Originally

published as A 739–76. Last previous edition A 739–90.

For ASME Boiler and Pressure Vessel Code applications see related Specifi-

5. Chemical Composition

cation SA-739 in Section II of that code.

3 5.1 The heat analysis shall conform to the limits for chemi-

Annual Book of ASTM Standards, Vol 01.05.

Annual Book of ASTM Standards, Vol 01.03. cal composition specified in Table 1 for the grade ordered.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.