ASTM D6481-99

(Test Method)Standard Test Method for Determination of Phosphorus, Sulfur, Calcium, and Zinc in Lubrication Oils by Energy Dispersive X-ray Fluorescence Spectroscopy

Standard Test Method for Determination of Phosphorus, Sulfur, Calcium, and Zinc in Lubrication Oils by Energy Dispersive X-ray Fluorescence Spectroscopy

SCOPE

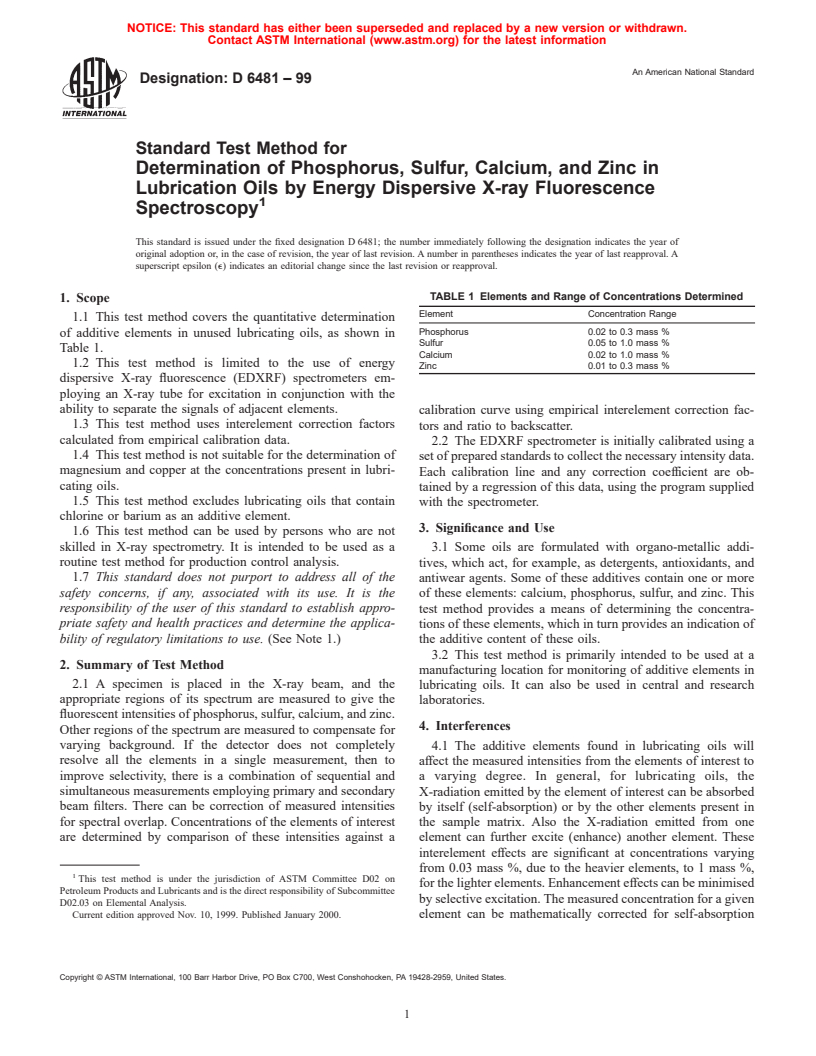

1.1 This test method covers the quantitative determination of additive elements in unused lubricating oils, as shown in Table 1.

1.2 This test method is limited to the use of energy dispersive X-ray fluorescence (EDXRF) spectrometers employing an X-ray tube for excitation in conjunction with the ability to separate the signals of adjacent elements.

1.3 This test method uses interelement correction factors calculated from empirical calibration data.

1.4 This test method is not suitable for the determination of magnesium and copper at the concentrations present in lubricating oils.

1.5 This test method excludes lubricating oils that contain chlorine or barium as an additive element.

1.6 This test method can be used by persons who are not skilled in X-ray spectrometry. It is intended to be used as a routine test method for production control analysis.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations to use. (See Note 1.)

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 6481 – 99

Standard Test Method for

Determination of Phosphorus, Sulfur, Calcium, and Zinc in

Lubrication Oils by Energy Dispersive X-ray Fluorescence

Spectroscopy

This standard is issued under the fixed designation D 6481; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

TABLE 1 Elements and Range of Concentrations Determined

1. Scope

Element Concentration Range

1.1 This test method covers the quantitative determination

Phosphorus 0.02 to 0.3 mass %

of additive elements in unused lubricating oils, as shown in

Sulfur 0.05 to 1.0 mass %

Table 1.

Calcium 0.02 to 1.0 mass %

1.2 This test method is limited to the use of energy

Zinc 0.01 to 0.3 mass %

dispersive X-ray fluorescence (EDXRF) spectrometers em-

ploying an X-ray tube for excitation in conjunction with the

ability to separate the signals of adjacent elements.

calibration curve using empirical interelement correction fac-

1.3 This test method uses interelement correction factors

tors and ratio to backscatter.

calculated from empirical calibration data.

2.2 The EDXRF spectrometer is initially calibrated using a

1.4 This test method is not suitable for the determination of

set of prepared standards to collect the necessary intensity data.

magnesium and copper at the concentrations present in lubri-

Each calibration line and any correction coefficient are ob-

cating oils.

tained by a regression of this data, using the program supplied

1.5 This test method excludes lubricating oils that contain

with the spectrometer.

chlorine or barium as an additive element.

3. Significance and Use

1.6 This test method can be used by persons who are not

skilled in X-ray spectrometry. It is intended to be used as a 3.1 Some oils are formulated with organo-metallic addi-

routine test method for production control analysis.

tives, which act, for example, as detergents, antioxidants, and

1.7 This standard does not purport to address all of the antiwear agents. Some of these additives contain one or more

safety concerns, if any, associated with its use. It is the

of these elements: calcium, phosphorus, sulfur, and zinc. This

responsibility of the user of this standard to establish appro-

test method provides a means of determining the concentra-

priate safety and health practices and determine the applica- tions of these elements, which in turn provides an indication of

bility of regulatory limitations to use. (See Note 1.)

the additive content of these oils.

3.2 This test method is primarily intended to be used at a

2. Summary of Test Method

manufacturing location for monitoring of additive elements in

2.1 A specimen is placed in the X-ray beam, and the

lubricating oils. It can also be used in central and research

appropriate regions of its spectrum are measured to give the

laboratories.

fluorescent intensities of phosphorus, sulfur, calcium, and zinc.

4. Interferences

Other regions of the spectrum are measured to compensate for

varying background. If the detector does not completely

4.1 The additive elements found in lubricating oils will

resolve all the elements in a single measurement, then to affect the measured intensities from the elements of interest to

improve selectivity, there is a combination of sequential and

a varying degree. In general, for lubricating oils, the

simultaneous measurements employing primary and secondary X-radiation emitted by the element of interest can be absorbed

beam filters. There can be correction of measured intensities

by itself (self-absorption) or by the other elements present in

for spectral overlap. Concentrations of the elements of interest the sample matrix. Also the X-radiation emitted from one

are determined by comparison of these intensities against a

element can further excite (enhance) another element. These

interelement effects are significant at concentrations varying

from 0.03 mass %, due to the heavier elements, to 1 mass %,

This test method is under the jurisdiction of ASTM Committee D02 on

for the lighter elements. Enhancement effects can be minimised

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

by selective excitation. The measured concentration for a given

D02.03 on Elemental Analysis.

Current edition approved Nov. 10, 1999. Published January 2000. element can be mathematically corrected for self-absorption

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 6481

and for interelement effects by other elements present in the 6. Reagents and Materials

sample matrix. If an element is present at significant concen-

6.1 Reagent grade chemicals shall be used in all tests.

trations and an inter-element correction for that element is not

Unless otherwise indicated, it is intended that all reagents

employed, the results can be low due to absorption or high due

conform to the specifications of the Committee on Analytical

to enhancement.

Reagents of the American Chemical Society where such

4.2 If a sample containing barium as an additive above 0.03

specifications are available. Other grades can be used, pro-

mass % is measured against a calibration derived from stan-

vided it is first ascertained that the reagent is of sufficiently

dards without barium, then results will be low.

high purity to permit its use without lessening the accuracy of

4.3 If a sample containing chlorine as an impurity above

the determination.

0.03 mass % is measured against a calibration derived from

6.2 Helium, at least 99.5 % purity, for the optical path of the

standards without chlorine, then the results can be affected.

spectrometer.

4.4 There can be spectral overlap of one element onto

6.3 Diluent Solvent, a suitable solvent free of metals,

another, especially for phosphorus on sulfur, and the instru-

phosphorus, and chlorine and containing less than 10 ppm of

ment must include correction procedures for any such overlaps.

sulfur (for example, deodorized kerosene, white oil, or mineral

oil).

5. Apparatus

6.4 Calibration Standard Materials:

5.1 Energy Dispersive X-ray Fluorescent Analyzer—Any 6.4.1 Certified concentration solutions of liquid organo-

metallic salts, each containing calcium or zinc, or both. The

energy dispersive X-ray fluorescent analyzer can be used if its

design incorporates at least the following features. solutions shall be sulfur free or the certificate shall state the

concentration of sulfur. Alternatively, the following standard

5.1.1 Source of X-ray Excitation, X-ray tube with palla-

dium, silver, or rhodium target programmable between 4 and at materials can be used.

6.4.1.1 Calcium 2-Ethylhexanoate, approximately 12.3

least 25 keV for preferential excitation to simplify the sample

spectra. (Warning—Operation of an analyzer using an X-ray mass % calcium, with a certified value.

6.4.1.2 Zinc Cyclohexanebutyrate, approximately 16.2 mass

tube source is to be conducted in accordance with the manu-

facturer’s safety instructions and federal, state, and local % zinc, with a certified value.

6.4.2 Bis(2-Ethylhexyl)Hydrogen Phosphate, 97 % purity

regulations)

5.1.2 X-ray Detector, gas filled proportional counter with (9.62 mass % phorphorus).

6.4.3 Di-n-butyl Sulfide, 97 % purity, (21.9 mass % sulfur).

high sensitivity and a resolution value not to exceed 1300 eV

at 5.9 keV. 6.4.4 Stabilizers, 2-ethylhexanoic acid, 2-ethylamine. Also,

proprietary stabilizer/chelating solutions are available commer-

NOTE 1—The limited data from instruments with solid state detectors in

cially. Stabilizers shall be free of the additive element.

the inter-laboratory precision study did not support their inclusion in the

method.

NOTE 2—In addition to the calibration standard materials identified in

6.4.1-6.4.3, single or multielement calibration standards can also be

5.1.3 Primary Beam Filters, to make the excitation more

prepared from materials similar to the samples being analyzed, provided

selective.

the calibration standards to be used have previously been characterized by

5.1.4 Secondary Beam Filters—When a proportional

independent primary (for example, gravimetric or volumetric) analytical

counter is used, these are necessary as a means of discriminat-

techniques to establish the elemental concentration mass % levels.

ing between an analyte’s X-rays and other analytes and the

7. Preparation of Calibration Standards

spectrum from the X-ray tube.

5.1.5 Multi-channel Analyzer, for discrimination between

7.1 To ensure complete solution of all components, prepare

an analyte’s X rays and background X rays.

calibration standards by precisely weighing the organo-

5.1.6 Optional Helium Purgeable Optical Path.

metallic solutions and phosphorus and sulfur solutions with the

5.2 Sample Cells, providing a depth of at least 6 mm and

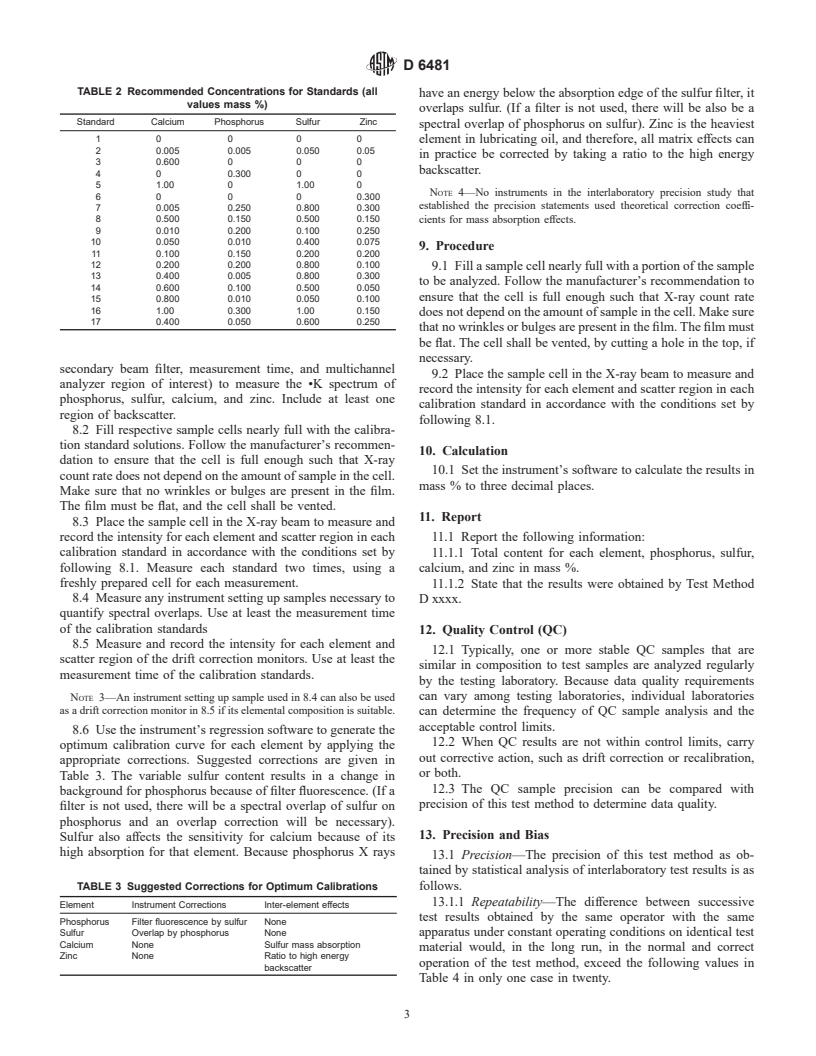

diluent solvent along with the appropriate stabilizer. Table 2

equipped with replaceable X-ray transparent film. Suitable

lists suggested concentrations when determining empirical

films include polypropylene and polycarbonate with thickness

influence coefficients. Complete sets of standards based on

from 3.5 to 8 μm.

Table 2 are commercially available.

5.3 Instrument Setting Up Samples (Elemental Reference

8. Calibration

Samples), to quantify spectral overlaps. These are required

when the instrument’s software does not include reference

8.1 Spectrometer Settings—Follow the manufacturer’s rec-

spectra to deconvolute spectra.

ommendations and set up a series of measurement conditions,

5.4 Drift Correction Monitors, to correct for instrumental

(X-ray tube voltage, X-ray tube current, primary beam filter,

drift. A

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.