ASTM D1413-99

(Test Method)Standard Test Method for Wood Preservatives by Laboratory Soil-Block Cultures

Standard Test Method for Wood Preservatives by Laboratory Soil-Block Cultures

SCOPE

1.1 This test method covers determination of the minimum amount of preservative that is effective in preventing decay of selected species of wood by selected fungi under optimum laboratory conditions.

1.2 The requirements for preparation of the material for testing and the test procedure appear in the following order: Section Summary of Method 3 Apparatus 4 Reagents 5 Wood and Test Blocks 6 Test Fungi 7 Culture Media 8 Preparation of Test Cultures 9 Preparation and Impregnation of Test Blocks 10 Conditioning of Treated Blocks 11 Preservative Permanence: Weathering Procedure 12 Stabilization of Treated Test Blocks and Place- 13 ment in Culture Bottles Incubation and Duration of Test 14 Handling Test Blocks After Exposure to Test 15 Fungi Calculation of Weight Losses 16 Evaluation of Test Results 17 Refining the Threshold 18 Report 19

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1413–99

Standard Test Method for

Wood Preservatives by Laboratory Soil-Block Cultures

This standard is issued under the fixed designation D1413; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope M-1-66 Method to Determine the Comparative Leachabil-

ity of Wood Preservatives

1.1 This test method covers determination of the minimum

amount of preservative that is effective in preventing decay of

3. Summary of Test Method

selected species of wood by selected fungi under optimum

3.1 Conditioned blocks of wood are impregnated with

laboratory conditions.

solutions of a preservative in water or suitable organic solvent

1.2 The requirements for preparation of the material for

to form one or more series of gradient retentions of the

testing and the test procedure appear in the following order:

preservative in the blocks. After periods of conditioning or

Section

weathering,theimpregnatedblocksareexposedtooneormore

Summary of Test Method 3

Apparatus 4

strains of wood-destroying fungi, one fungus for each test

Reagents 5

series. The minimum amount of preservative that in the

Wood and Test Blocks 6

prescribed testing protects the impregnated blocks against

Test Fungi 7

Culture Media 8

decay by a given test fungus is defined as the threshold

Preparation of Test Cultures 9

retention for that organism. Failure to protect is evidenced by

Preparation and Impregnation of Test Blocks 10

loss of wood from the treated wood blocks, as indicated by a

Conditioning of Treated Blocks 11

Preservative Permanence: Weathering Procedure 12

loss in weight.

Stabilization of Treated Test Blocks and Placement in Culture 13

3.2 Provision must be made for coordinated preparation of

Bottles

the test cultures and for impregnation, conditioning, or weath-

Incubation and Duration of Test 14

Handling Test Blocks After Exposure to Test Fungi 15

ering and conditioning, of the test blocks.

Calculation of Weight Losses 16

Evaluation of Test Results 17

4. Apparatus

Refining the Threshold 18

Report 19

4.1 Conditioning Chamber or Room, maintained at a se-

lected temperature between 20 and 30°C (68 and 86°F) and a

1.3 This standard does not purport to address all of the

selected relative humidity between 25 and 75%. The selected

safety concerns, if any, associated with its use. It is the

temperature shall not vary more than 61°C (62°F) and the

responsibility of the user of this standard to establish appro-

selected humidity not more than 62%.

priate safety and health practices and determine the applica-

4.2 Incubation Room or Incubation Cabinet,maintainedata

bility of regulatory limitations prior to use.

selected temperature between 25 and 27°C (77 and 81°F) and

2. Referenced Documents

a relative humidity between 65 and 75%. The selected

temperature shall not vary more than 61°C (62°F) and the

2.1 ASTM Standards:

selected humidity percentage not more than 2.

D841 Specification for Nitration Grade Toluene

4.3 Drying Oven—Asuitable, vented oven, maintained at a

D1193 Specification for Reagent Water

temperature of 105 6 2°C (220 6 4°F).

E11 Specification for Wire-Cloth Sieves for Testing Pur-

4.4 Steam Sterilizer.

poses

4.5 Balances, fast-acting types preferred, sensitive and ac-

2.2 AWPA Standard:

curate to 0.01 g.

4.6 Vacuum Pump or Water Suction Pump, capable of

reducing pressure to 100 mm (3.94 in.) Hg, or less.

This test method is under the jurisdiction of ASTM Committee D07 on Wood

4.7 Impregnation Apparatus—A suitable desiccator or bell

and is the direct responsibility of Subcommittee D07.06 on Treatments for Wood

jarshieldedtoprotectpersonnelineventofbreakage,provided

Products.

Current edition approved April 10, 1999. Published July 1999. Originally

published as D1413–49. Last previous edition D1413–76(1994)e1.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or American Wood Preservatives Assn., 1625 Eye St., N.W. Washington, DC

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 20006.

Standards volume information, refer to the standard’s Document Summary page on Scheffer, T. C., “Humidity Controls for Conditioning Rooms,” Forest Products

the ASTM website. Laboratory Report No. 2048, U.S. Forest Service, 4 pp., 5 Figs., January 1956.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D1413–99

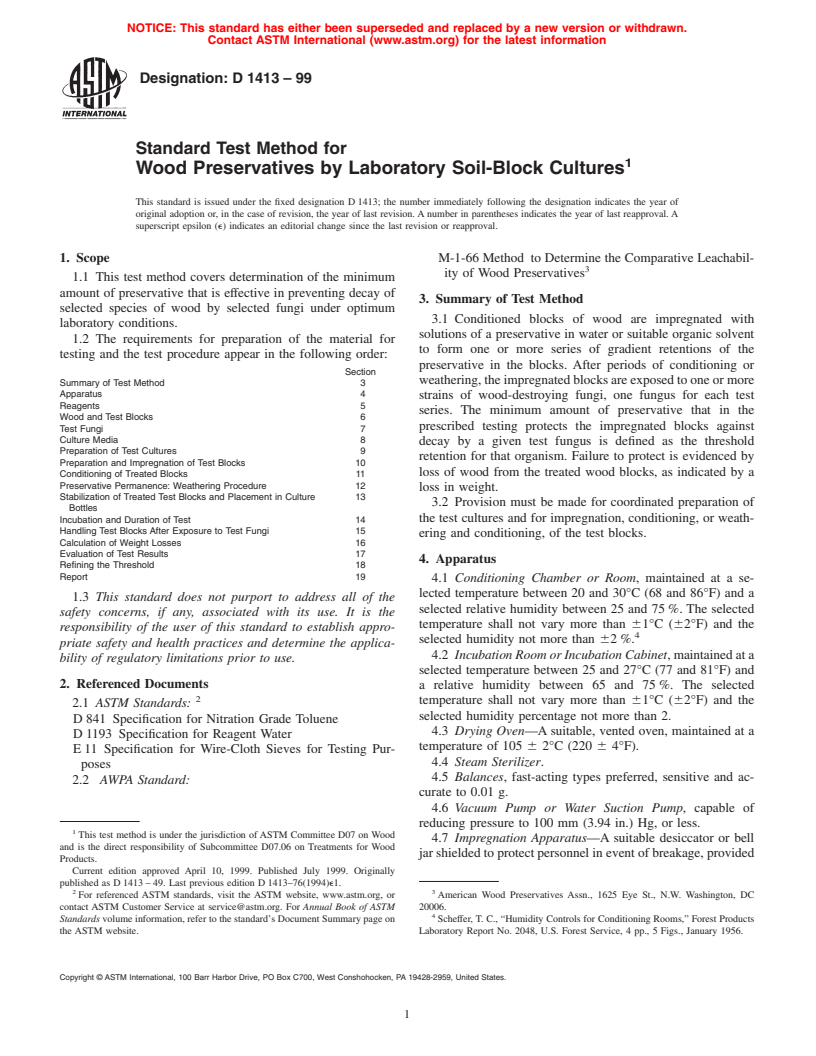

with suitable separatory funnel or auxiliary flask for holding

the treating solution and vacuum gage or manometer (Fig. 1).

4.8 Trays or Racks, or Pin Bars—Traysorracksmadefrom

suitable screening to permit free air movement around each

block during initial drying and for convenient handling of the

test blocks. Pin bars facilitate handling (see 6.2).

4.9 Weathering Apparatus:

4.9.1 Forced Draft Oven.

4.9.2 Apparatus designed for weathering salts-treated

A—Wood cubes, 19-mm or 0.75-in.

B—Test fungus growing over feeder block.

blocks is described in AWPA Method M-1-66.

C—Wood feeder block.

4.10 CultureBottles,cylindricalorsquare(Note1),capacity

D—Soil.

nominal 225 or 450 cm (8 or 16 oz), fitted with screw caps

FIG. 2 French Square and Cylindrical 225 cm (8 oz) and

without liners (Fig. 2).

cylindrical 450-mm (16-oz) Culture Bottles with Metal Screw Lids

NOTE 1—Culture Bottles:

(1) 225-cm (8-oz) French square, for use with one block only.

(2) 225-cm (8-oz) cylindrical, for use with one or two blocks.

of sufficiently high purity to permit its use without lessening

(3) 450-cm (16-oz) cylindrical, for use with two blocks only.

the accuracy of the determination.

4.11 Soil Sieves—U.S. No. 6 sieve in accordance with

5.2 Purity of Water—Unlessotherwiseindicated,references

Specification E11.

towatershallbeunderstoodtomeanreagentwaterconforming

to Type IV of Specification D1193.

5. Reagents

5.3 Toluene, conforming to Specification D841.

5.1 Purity of Reagents—Reagent grade chemicals shall be

6. Wood

used in all tests. Unless otherwise indicated, it is intended that

all reagents shall conform to the Specifications of the Com-

6.1 General Properties—Pine sapwood, free of knots and

mittee on Analytical Reagents of the American Chemical

visible concentration of resins, and showing no visible evi-

Society, where such specifications are available. Other grades

dence of infection by mold, stain, or wood-destroying fungi,

may be used, provided it is first ascertained that the reagent is 1

with 2 ⁄2 to 4 rings/cm (6 to 10 rings/in.) should be used for

standardcomparativetestsintendedtoshowcomparativewood

preserving values of preservatives under test. If southern pine

is used, it should be 40 to 50% summerwood. Whenever

Blue M Model OV 490 A.

practicable, selection of the wood for the test blocks should

“Reagent Chemicals,American Chemical Society Specifications,”Am. Chemi-

begin at the sawmill. Quartersawed boards are preferable.

cal Soc., Washington, DC. For suggestions on the testing of reagents not listed by

Newly cut boards, nominally (25 mm) (1 in.) thick, that are

theAmericanChemicalSociety,see“ReagentChemicalsandStandards,”byJoseph

Rosin, D. Van Nostrand Co., Inc., New York, NY, and the “United States

immediately kiln dried without antistain treatment provide

Pharmacopeia.

A—Vacuum desiccator, internal diameter 250 mm.

B—Plastic or glass treatment beaker.

C—Test wood blocks.

D—Glass or other suitable weight.

E—Treating solution.

F—Polyethylene tubing.

G—Three-way stopcock with TFE-fluorocarbon plug.

H—Flask containing treating solution.

I—Glass joint with O-ring leading to either vacuum gage or mercury manometer.

J—Glass joint with O-ring.

K—Flask for vacuum trap.

L—Stopcock to atmosphere.

M—Line to source of vacuum.

FIG. 1 Apparatus for Vacuum Impregnation

D1413–99

chemical-free wood that has had minimum opportunity for 7.2.3 Poria placenta (Fr.)Cook=[Poria monticolorMurr.]

fungus infection or deterioration before use in the soil-block (Madison 698, ATCC No. 11538)—A fungus particularly

culture test. tolerant to copper and zinc compounds. Suggested for testing

mercury compounds.

6.1.1 Sapwood Identification—When the boundary between

7.3 Fungus Species for Hardwood Sapwoods:

heartwood and sapwood is difficult to recognize, use a color

7.3.1 The three fungi listed in 7.2.

test to distinguish between the two. Uneven absorptions may

7.3.2 Coriolus versicolor (L.) Quél.=[Polyporus versi-

be caused by the presence of heartwood.

color L. ex. Fr.] (Madison 697,ATCC No. 12679), a white-rot

6.1.2 Conditioning of Parent Boards—Open-stack the

fungus prevalent on hardwood products.

boards under shelter and permit.

6.2 Test Blocks (Note 2), should be cubes milled as accu-

8. Culture Media

rately as possible to 19 mm (0.75 in.). If desired (for example,

for convenience in handling), blocks may be drilled through 8.1 Malt Agar Substrate—For both stock test-tube and petri

thecenterofatangentialfacewitha3-mmdrill(approximately dish cultures of the test fungi use a nutrient medium consisting

0.125 in. or a No. 30 drill). Pin bars may then be used for of about 2 weight% malt extract and 1.5 weight% agar.

handling.The volume of the blocks without the hole should be Sterilize the medium at 103 kPa (15 psi) for 20 min and allow

6.9 6 0.2 cm , determined by caliper or by mercury displace- to cool before inoculations.

ment. 8.2 Soil Substrate—Use a soil substrate with a water-

holding capacity between 20 and 40% (Note 4) and pH

NOTE 2—Store working stocks of test blocks and feeder strips in the

between 5.0 and 8.0 and weighing not less than 90g/120 cm .

conditioning room. It is desirable to weigh the blocks after they come to

After breaking up all clumps, mix and screen the soil through

approximateequilibriummoisturecontentinstorageorintheconditioning

the U.S. No. 6 sieve and store in large covered containers.The

room, and to sort them into fairly narrow-range weight groups. Since the

blocks are cut accurately to size this division into weight groups is, in soil should not be so wet when it is sifted that the particles

effect, a segregation into density groups (see 10.4).

again stick together. Pass a sample of air-dry soil through a

U.S. No. 6 sieve. Determine the water-holding capacity as

6.3 Feeder Strips:

follows. Use the sieved soil to fill a small Buchner funnel

6.3.1 General Considerations—One feeder strip is needed

approximately 50 mm in diameter and 25 mm in depth, and

for each block in a culture bottle. If test blocks other than pine

fitted with rapid-filtering paper, to somewhat more than capac-

are used for special investigations, the sapwood selected for

ity. Compact the soil by dropping the funnel three times

feeder strips should be capable of furnishing a satisfactory

through a height of 10 mm (0.4 in.) on a wooden tabletop.

growth of the test fungus; for example, sweetgum sapwood

Level the soil surface by cutting off excess soil with a spatula

often is used with hardwood test blocks and Coriolus versi-

atthetopofthefunnelwithoutfurthercompaction.Thenplace

color (L.) Quél.=[Polyporus versicolor L. ex. Fr.] fungus.

the filled funnel in a 400-cm beaker and retain in an upright

6.3.2 Size—The feeder strips should be approximately 3 by

position by wedges at the sides of the funnel.Add water to the

1 1 5

28 by 35 mm ( ⁄8 by 1 ⁄8 by 1 ⁄8 in.) with the grain of the wood

beaker to a depth slightly beyond the level of the filter paper.

parallel to the short dimension.

Allow the soil to wet by capillarity so as to reduce the danger

of entrapping air within the column. When the upper soil

7. Test Fungi

surface shows signs of wetting, add more water until the water

7.1 General Considerations—Always include a compara- level approximates the upper surface of the funnel. Place a

tivelytolerantfungus(see7.2and7.3)intestingapreservative. cover over the beaker, and allow the soil to soak for 12 h or

Othereconomicallyimportantfungimaybeusedinadditionto overnight. Then place the funnel in a suction flask which is

the tolerant fungus in special investigations, or in some cases connected to a water aspirator or vacuum pump, and apply full

substituted for it. suction for 15 min. During suctioning, cover the funnel with a

moist cloth on which an inverted cup is placed to prevent

NOTE 3—The following numbers refer to standard strains of test fungi

evaporation of water from the exposed soil surface. After 15

maintained in the American Type Culture Collection (ATCC), 12301

min remove the funnel from the suction flask, scrape the soil

Parklawn Drive, Rockville, MD 20852.

into a weighed receptacle, and weigh to obtain the wet weight,

7.2 Fungus Species for Softwood Sapwoods:

W .Ovendryfor24hat105 62°C(220F 64°F)andreweigh

7.2.1 Lentinus lepideus Fr. (Madison 534, ATCC No.

soil, W . Determine soil moisture content (water-holding ca-

12653)—A fungus particularly tolerant to creosote or to

pacity) based on the ovendry weight of soil.

mixtures containing creosotes.

Water2holdingcapacity ~WHC!,% 5[~W 2 W !/W # 3100 (1)

1 2 2

7.2.2 Gloeophyllum trabeum (Pers. ex. Fr.)

NOTE 4—The water-holding capacity of a soil should be considered as

Murr.=[Lenzites trabea Pers. ex. Fr.] (Madison 617, ATCC

that percentage of water, based on the ovendry weight of the soil, that is

No. 11539)—A fungus particularly tolerant to phenolic and

retained after subjecting the soil to the following procedure based on a

arsenic compounds.

method of Bouyoucos, G. J. A., “A Comparison Between the Suction

Method and the Centrifuge Method of Determining the Moisture Equiva-

lent of Soils.” Soils Science, Vol 40, 1935, pp. 165–170.

8.2.1 Preparation of Soil Culture Bottles—The soil sub-

“StandardforInspectionofTreatedTimberProducts,”AWPAStandardM2-73,

Section 5.51. strate, sifted and lightly compacted by tapping, should half-fill

D1413–99

and simplifies recording data. The suggested system of T designations is

aculturebottle.Thisamountofsoil,about120cm foran8-oz

as follows, record all weights in grams:

culturebottle,shouldweighnotlessthan90gwhenovendried.

Thewaterinthecompletedsoilculturebottleshouldbe130%

of the water-holding capacity of the soil. To determine the

T = initial weight of the conditioned or oven-dried test block

amount of additional water needed, weigh the volume of soil

before impregnation,

T = weight of the test block immediately after impregnation and

that will be used to half-fill a culture bottle, W . Dry this soil

wiping (equals T plus grams of treating solution absorbed),

at105 62°C(220 64°F)for12ha

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.