ASTM D5166-97(2016)

(Practice)Standard Practice for Laboratory Preparation of Gelled Vehicle Samples Using a Microwave Oven (Withdrawn 2022)

Standard Practice for Laboratory Preparation of Gelled Vehicle Samples Using a Microwave Oven (Withdrawn 2022)

SIGNIFICANCE AND USE

5.1 This practice provides a means of preparing a number of gel vehicle samples with minimum use of materials and time. It provides a means of quickly characterizing and comparing the gelability or reactivity of resins, vehicles, and gelling agents.

SCOPE

1.1 This practice outlines a procedure for preparing gelled vehicle samples using a microwave oven.

1.2 The test samples can be used for characterizing the gelability or reactivity of resins, gelling agents, and vehicles used in the manufacture of oil based printing inks, or both.

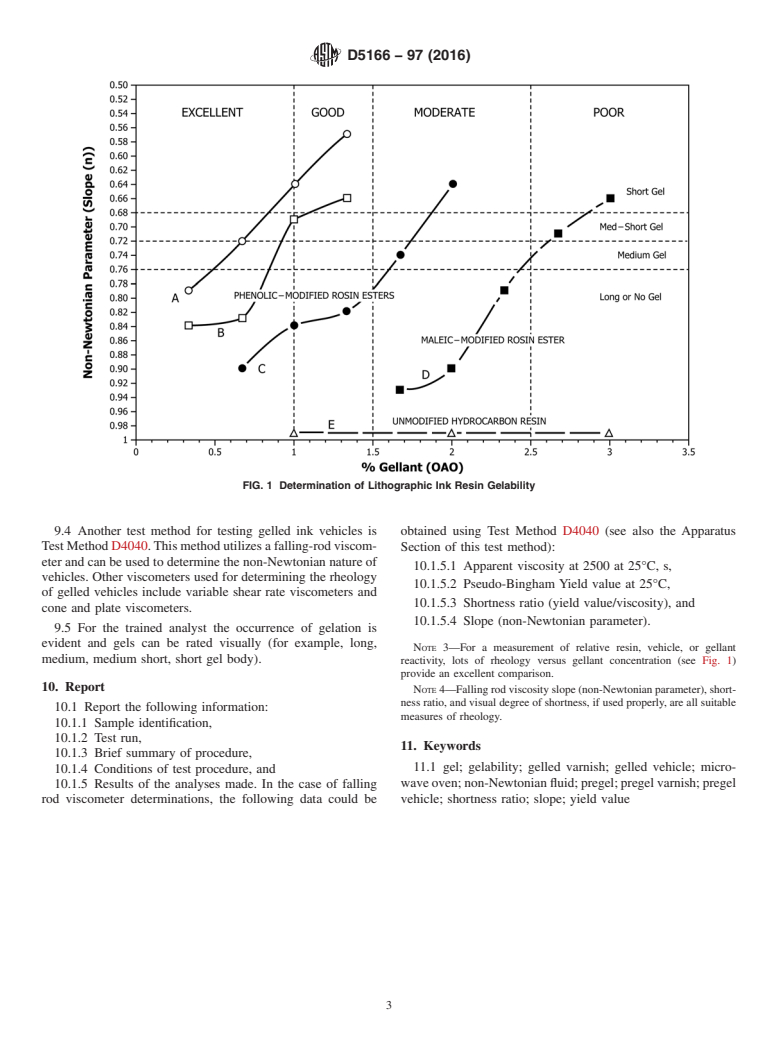

1.3 Evaluation of the gelled vehicles may, depending upon preference, be either visual or instrumental.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This practice outlines a procedure for preparing gelled vehicle samples using a microwave oven. The test samples can be used for characterizing the gelability or reactivity of resins, gelling agents, and vehicles used in the manufacture of oil based printing inks, or both. Evaluation of the gelled vehicles may, depending upon preference, be either visual or instrumental. The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

Formerly under the jurisdiction of Committee D01 on Paint and Related Coatings, Materials, and Applications, this test method was withdrawn in December 2022. This standard is being withdrawn without replacement because it is not in use and there is no interest in keeping it active.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5166 − 97 (Reapproved 2016)

Standard Practice for

Laboratory Preparation of Gelled Vehicle Samples Using a

1

Microwave Oven

This standard is issued under the fixed designation D5166; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope or cross-linking agent to build molecular weight and that

exhibits a pseudoplastic rheology. (Also called “gelled ve-

1.1 This practice outlines a procedure for preparing gelled

hicle.”)

vehicle samples using a microwave oven.

3.1.2 gelling agent, n—in the context of ink resins and

1.2 The test samples can be used for characterizing the

vehicles, gelling agents or gellants are typically organo-

gelability or reactivity of resins, gelling agents, and vehicles

aluminum compounds that react with carboxylic acid and

used in the manufacture of oil based printing inks, or both.

hydroxyl groups present on the backbone of resins and alkyds

1.3 Evaluation of the gelled vehicles may, depending upon

to form cross-linked networks. (Also called “gellant.”)

preference, be either visual or instrumental.

3.1.3 gel length, n—References to long, medium, and short

1.4 The values stated in SI units are to be regarded as

gel length refer to the length of a string of gelled vehicle

standard. No other units of measurement are included in this

observed when pulling apart a small sample of vehicle with a

standard.

spatula (that is, a long gel is very fluid and forms a “long”

filament; a short gel has little flow and forms a “short”

1.5 This standard does not purport to address all of the

filament).

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.1.4 pregel, n—The resin solution or vehicle components

priate safety and health practices and determine the applica-

comprising the vehicle prior to the addition of gelling agent

bility of regulatory limitations prior to use.

and viscosity adjusting solvent. (Also called “pregel vehicle.”)

2. Referenced Documents

4. Summary of Practice

2

2.1 ASTM Standards:

4.1 Prepare a pregel resin solution or vehicle.

D154 Guide for Testing Varnishes

4.2 Separate the pregel vehicle into five or more aliquots to

D1545 Test Method for Viscosity of Transparent Liquids by

which various levels of gellant are added. Alternately, various

Bubble Time Method

gellants can be added at a given concentration to compare their

D1725 Practice for Preparing Resin Solutions for Viscosity

effectiveness.

Measurement by Bubble Time Method

D4040 Test Method for Rheological Properties of Paste

4.3 Place the test samples on a turntable in the microwave

Printing and Vehicles by the Falling-Rod Viscometer

oven and heat the samples at full power until the desired test

E1 Specification for ASTM Liquid-in-Glass Thermometers

temperature is attained.

4.4 After the prescribed waiting period, test and rate

3. Terminology

samples for gelability.

3.1 Definitions of Terms Specific to This Standard:

3.1.1 gel, n—Any resin solution, or more complex blend of

5. Significance and Use

resinsandalkydsthathasbeencookedorreactedwithagelling

5.1 Thispracticeprovidesameansofpreparinganumberof

gel vehicle samples with minimum use of materials and time.

1

This practice is under the jurisdiction of ASTM Committee D01 on Paint and

It provides a means of quickly characterizing and comparing

Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.37 on Ink Vehicles.

the gelability or reactivity of resins, vehicles, and gelling

Current edition approved April 1, 2016. Published April 2016. Originally

agents.

ɛ1

approved in 1991. Last previous edition approved in 2008 as D5166 – 97 (2008) .

DOI: 10.1520/D5166-97R16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 6. Apparatus

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.1 Mercury Thermometer, capable of reading from 0 to

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 250°C and conforming to Specification E1.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5166 − 97 (2016)

3

TABLE 1 Microwave Gelability Test, Weights and Concentrations

6.2 Jars, (40 mm in diameter by 83 mm in height), 70 cm

for 50-g Samples

with nonmetallic screw-on lids.

Weight Gellant

3

6.3 Microwave Oven, common 750-watt. A

Gellant Actual Gellant

Solution, g A

Weight Ink Oil, g

Solution, % Concentration, % (at 33.3 %

6.4 Microwave Oven Carou

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.