ASTM F1793-97(2016)e1

(Specification)Standard Specification for Automatic Shut-Off Valves (Also Known as Excess Flow Valves, EFV) for Air or Nitrogen Service

Standard Specification for Automatic Shut-Off Valves (Also Known as Excess Flow Valves, EFV) for Air or Nitrogen Service

ABSTRACT

This specification covers self-contained automatic shutoff valves (also known as excess flow valves) for air or nitrogen service. They are intended to be installed as safety devices to quickly and automatically shut off flow under certain excess flow conditions caused by a downstream failure or casualty, such as a hose rupture. Automatic shut-off valves shall be of the following types, styles, sizes, pressure ratings, and end connections: Types I and II; Styles 1 and 2. Each automatic shut-off valve must pass the following tests: visual examination; hydrostatic shell test; seal tightness test; external leakage test; and set-point test.

SCOPE

1.1 This specification covers self-contained automatic shut-off valves (also known as excess flow valves) for air or nitrogen service. They are intended to be installed as safety devices to quickly and automatically shut off flow under certain excess flow conditions caused by a downstream failure or casualty, such as a hose rupture.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:F1793 −97 (Reapproved 2016) An American National Standard

Standard Specification for

Automatic Shut-Off Valves (Also Known as Excess Flow

Valves, EFV) for Air or Nitrogen Service

This standard is issued under the fixed designation F1793; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

ε NOTE—Keywords were added editorially in September 2016.

1. Scope ANSI B16.34 Valves—Flanged, Threaded, and Welded End

2.3 Military Standards and Specifications:

1.1 This specification covers self-contained automatic shut-

MIL-STD-167-1 Mechanical Vibrations of Shipboard

off valves (also known as excess flow valves) for air or

Equipment (Type I—Environmental and Type II—

nitrogen service. They are intended to be installed as safety

Internally Excited)

devicestoquicklyandautomaticallyshutoffflowundercertain

MIL-STD-740-1 Airborne Sound Measurements andAccep-

excess flow conditions caused by a downstream failure or

tance Criteria of Shipboard Equipment

casualty, such as a hose rupture.

MIL-S-901 Shock Tests, H.I. (High-Impact); Shipboard Ma-

1.2 The values stated in inch-pound units are to be regarded

chinery Equipment and Systems, Requirements for

as standard. The values given in parentheses are mathematical

MIL-F-1183 Fitting, Pipe, Cast Bronze, Silver-Brazing,

conversions to SI units that are provided for information only

General Specification for

and are not considered standard.

2.4 Government Drawings:

1.3 This international standard was developed in accor-

Naval Sea Systems Command (NAVSEA)

dance with internationally recognized principles on standard- NAVSEA 803-1385884 Unions, Fittings and Adapters Butt

ization established in the Decision on Principles for the

and Socket Welding 6000 PSI, WOG, NPS

Development of International Standards, Guides and Recom- NAVSEA 803-1385943 Unions, Silver Brazing 3000 PSI,

mendations issued by the World Trade Organization Technical

WOG, NPS, for UT Inspection

Barriers to Trade (TBT) Committee. NAVSEA 803-1385946 Unions, Bronze Silver Brazing,

WOG for UT Inspection

2. Referenced Documents

3. Terminology

2.1 ASTM Standards:

F992 Specification for Valve Label Plates 3.1 Definitions:

2.2 ANSI Standards:

3.1.1 automatic shut-off valve—automatic shut-off valves

ANSI B1.1 Unified Screw Threads (UN and UNR Thread covered by this specification trip shut in response to the

Form)

pressure differential across the valve.

ANSI B1.20.1 Pipe Threads, General Purpose (Inch)

3.1.2 bubble-tight—no visible leakage over a 3-min period

ANSI B16.11 Forged Steel Fittings, Socket-Welding and

usingeitherwatersubmersionortheapplicationofbubblefluid

Threaded

for detection.

ANSI B16.25 Buttwelding Ends

3.1.3 external leakage—leakage from the automatic shut-off

valve that escapes to atmosphere.

This specification is under the jurisdiction of ASTM Committee F25 on Ships

3.1.4 hydrostatic shell test pressure—the hydrostatic shell

and Marine Technology and is the direct responsibility of Subcommittee F25.11 on

test pressure that the automatic shut-off valve is required to

Machinery and Piping Systems.

Current edition approved Sept. 1, 2016. Published September 2016. Originally

withstand without damage.Automatic shut-off valve operation

approved in 1997. Last previous edition approved in 2010 as F1793 – 97 (2010).

is not required during application of shell test pressure, but it

DOI: 10.1520/F1793-97R16E01.

2 must meet all performance requirements after the shell test

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM pressure has been removed.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St., AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

4th Floor, New York, NY 10036, http://www.ansi.org. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

F1793−97 (2016)

3.1.5 pressure ratings—thepressureratingsoftheautomatic 4.1.2 Styles:

shut-off valves shall be as defined in the documents listed in 4.1.2.1 Style 1—Automatic Reset Construction—These

Table 1. The pressure ratings (also called pressure-temperature valves are designed to limit the flow of air or nitrogen upon

ratings) establish the maximum allowable working (service) closure to a small predetermined level. These valves reset

pressures of a component (valve, end connections, and so automatically once the service line downstream is made air or

forth) at various temperatures. nitrogen-tight and pressure is equalized across the valve.

4.1.2.2 Style 2—Manual Reset Construction—These valves

3.1.6 seat tightness—the ability of the automatic shut-off

are designed to stop the flow of air or nitrogen upon closure.

valve to prevent leakage from the valve-inlet to the valve-

These valves must be manually reset.

outlet.

4.1.3 Sizes—Automatic shut-off valves shall be of the fol-

3.1.7 set point—a combination of inlet pressure and flow, at

1 3 1

lowing NPS sizes: ⁄4 (13.5 mm), ⁄8 (17.2 mm), ⁄2 (21.3 mm),

which the valve trips shut.

3 1 1

⁄4(26.9mm),1(33.7mm),1 ⁄4(42.4mm),1 ⁄2(48.3mm),and

3.1.8 set point accuracy—the band of accuracy of the

2 (60.3 mm). Unless otherwise specified in 5.0, the valve inlet

automatic shut-off valve expressed as a range of flow rates at a

size shall be the same as the outlet size.

given inlet pressure, established by the following two points:

4.1.4 Pressure Ratings—Automatic shut-off valves shall

3.1.8.1 Discussion—Acombinationofinletpressure-flow,at

have pressure rating(s) selected (see 3.1.5) from Table 1. The

or below which the automatic shut-off valve will not trip shut

pressure rating(s) selected shall be specified in Section 5. The

(valvewillremainopen)regardlessofinfluencessuchasspring

inlet and outlet pressure ratings of the automatic shut-off valve

relaxation, mechanical shock or vibration, and so forth.

shall be the same for any given valve.

3.1.8.2 A combination of inlet pressure-flow, at or above

4.1.5 End Connections—Automatic shut-off valves shall

whichtheautomaticshut-offvalvewilltripshut(valvewillnot

have end connections selected from those listed in Table 1 and

remain open) regardless of influences tending to resist closure

specified in Section 5.

such as breakloose friction, corrosion, or sludge, and so forth.

5. Ordering Information

3.1.9 set-point range—the range of set points over which

the automatic shut-off valve can be adjusted. Expressed as a

5.1 Ordering documentation for automatic shut-off valves

range of flow rates at a given inlet pressure.

under this specification shall include the following

information,asrequired,todescribetheequipmentadequately:

4. Classification

5.1.1 ASTM designation and year of issue,

4.1 Automatic shut-off valves shall be of the following

5.1.2 Valve type (see 4.1.1),

types, styles, sizes, pressure ratings, and end connections:

5.1.3 Valve style (see 4.1.2),

4.1.1 Types:

5.1.4 Valve size (see 4.1.3),

4.1.1.1 Type I—Valves that can be adjusted or repaired

5.1.5 Valve pressure rating (see 4.1.4),

without removing the valve from pipe line.

5.1.6 End connections (see 4.1.5),

4.1.1.2 Type II—Valves that cannot be adjusted or repaired

5.1.7 Valve inlet operating pressure,

without removing the valve from pipe line. 5.1.8 Set point (see 3.1.7 and 7.2),

5.1.9 Tamper-proof set point adjustment, if required (see

6.3.2),

TABLE 1 Pressure Ratings for Automatic Shut-Off Valves

5.1.10 Supplementary requirements, if any (see S1 through

Applicable Documents for

Type of End

Pressure Rating Dimensional Details of End

S4), and

Connection

Connections

5.1.11 Maximum vibration frequency and displacement

Butt-welded ANSI B16.34 Class 150, ANSI B16.25

amplitude, if other than specified (see S1.2).

300, 400, 600, 900, 1500,

2500, or 4500

6. Valve Construction

Socket-welded ANSI B16.34 Class 150, ANSI B16.11

300, 400, 600, 900, 1500,

6.1 Valves shall incorporate the features specified in 6.2 –

2500, or 4500

6.16.

Threaded (tapered ANSI B16.34 Class 150, ANSI B1.20.1 and ANSI

pipe thread) 300, 400, 600, 900, 1500, B16.11

6.2 Materials of Construction—Material requirements for

or 2500

A

Union-end, MIL-F-1183 (O-ring type) MIL-F-1183 (O-ring type) 400 the automatic shut-off valve shall be as follows: The pressure-

2 2

Silver-brazed

400 lb/in. (2.758 MPa) lb/in. (2.758 MPa)

containing envelope shall be 300 series corrosion-resistant

A 2 2

Union-end, 803-1385946 1500 lb/in. 803-1385946 1500 lb/in.

steel (304, 304L, 316, or 316L). Internal parts including

Silver-brazed

(10.342 MPa) (10.342 MPa)

A 2 2

Union-end, 803-1385943 3000 lb/in. 803-1385943 3000 lb/in. springs, poppets, retainers, etc. shall be 300 series corrosion-

Silver-brazed

(20.684 MPa) (20.684 MPa)

resistantsteel,nickel-aluminum-bronze,nickel-copper(70-30),

A 2 2

Union-end, 803-1385884 6000 lb/in. 803-1385884 6000 lb/in.

or bronze. Other materials for both the pressure-containing

Butt/socket weld

(41.369 MPa) (41.369 MPa)

Other, as specified As specified As specified

envelope and internal parts may be selected to assure compat-

A

ibility with the line medium, weldability, and to provide

For Union inlet and outlet end connections, only the pertinent dimensions listed

in the applicable documents (Military Specification or NAVSEA Requirements)

corrosion resistance without requiring painting, coating, or

shall apply. The valve shall be supplied with the thread-pieces only, without the

plating. Materials for contacting parts shall be selected to

tail-pieces and union-nuts.

minimize electrolytic corrosion and galling.

´1

F1793−97 (2016)

6.3 General Requirements: adjustable with the valve in the line under pressure. Type II

valves may be removed from the line for adjustment. The set

6.3.1 Automatic shut-off valves shall be self-contained,

point shall incorporate right-hand threads so that a clockwise

requiring no external power source for operation. The auto-

rotation increases the set point. Means shall be used to prevent

matic shut-off valve shall be capable of meeting all require-

an accidental or inadvertent change in set point. The option of

ments of this specification and provide extended reliable

a tamper-proof set-point adjustment (lead seal, and so forth)

operation.

shall be available and shall be specified as in Section 5.

6.3.2 Automatic shut-off valves shall incorporate a provi-

sion for manually resetting. This shall constitute an isolatable

6.13 Port Configuration—The automatic shut-off valve

bleed-by which is operable with the valve in the pipeline under

shall have in-line inlet and outlet ports.

pressure and which functions by equalizing pressure across the

6.14 Springs—Spring incorporated in the automatic shut-off

poppet.Style1valvesshallinaddition,incorporateaprovision

valve shall not be compressed solid during operation. Spring

which automatically resets the valve, and which constitutes a

ends shall be squared and ground. Engagement or disengage-

small non-isolatable bleed-by.

ment of parts against spring compression shall not be permit-

6.4 Threads—Threads shall be as specified in ANSI B1.1.

ted.

Where necessary, provisions shall be incorporated to prevent

6.15 Guiding—The valve poppet shall be guided to prevent

the accidental loosening of threaded parts. The design shall be

binding or seizing, and to ensure proper seating under all

suchthatstandardwrenchescanbeusedonallexternalbolting.

operating conditions. Proper alignment of all internaloperating

Lock-wire shall not be used. Any exposed threads shall be

parts shall be maintained with interchangeable parts and under

protected by plastic caps for shipping.

all tolerance stack-up conditions.

6.5 Interchangeability—The automatic shut-off valve, in-

6.16 Accessibility—Type I automatic shut-off valve shall be

cluding all associated piece parts, shall have part number

accessible for adjustment or service, without removing the

identity, and shall be replaceable from stock or the manufac-

automatic shut-off valve from the line.

turer on a nonselective and random basis. Parts having the

samemanufacturer’spartnumbershallbedirectlyinterchange-

7. Performance Requirements

able with each other with respect to installation (physical) and

7.1 Automatic shut-off valves shall meet the requirements

performance (function). Physically interchangeable

of 7.2 – 7.8.

assemblies, components, and parts are those which are capable

7.2 Set Point—The required set point as defined in 3.1.7,

of being readily installed, removed or replaced without

shall be as specified (see Section 5).

alteration, misalignment, or damage to parts being installed or

to adjoining parts. Fabrication operations such as cutting,

7.3 Set-Point Accuracy—The set-point accuracy, as defined

filing, drilling, reaming, hammering, bending, prying, or forc-

in 3.1.8, shall be plus or minus 10 % of the set point.

ing shall not be required.

7.4 Range of Set-Point Adjustment—Automatic shut-off

6.6 Nonmetallic Element Interchangeability—Nonmetallic

valves shall be capable of meeting all performance require-

elements, including but not limited to, seat rings, poppet seat

ments when set at any point within plus or minus 25 % of the

inserts, cushions, and O-rings shall be treated as separately

nominal specified set point.

identified and readily replaceable parts.

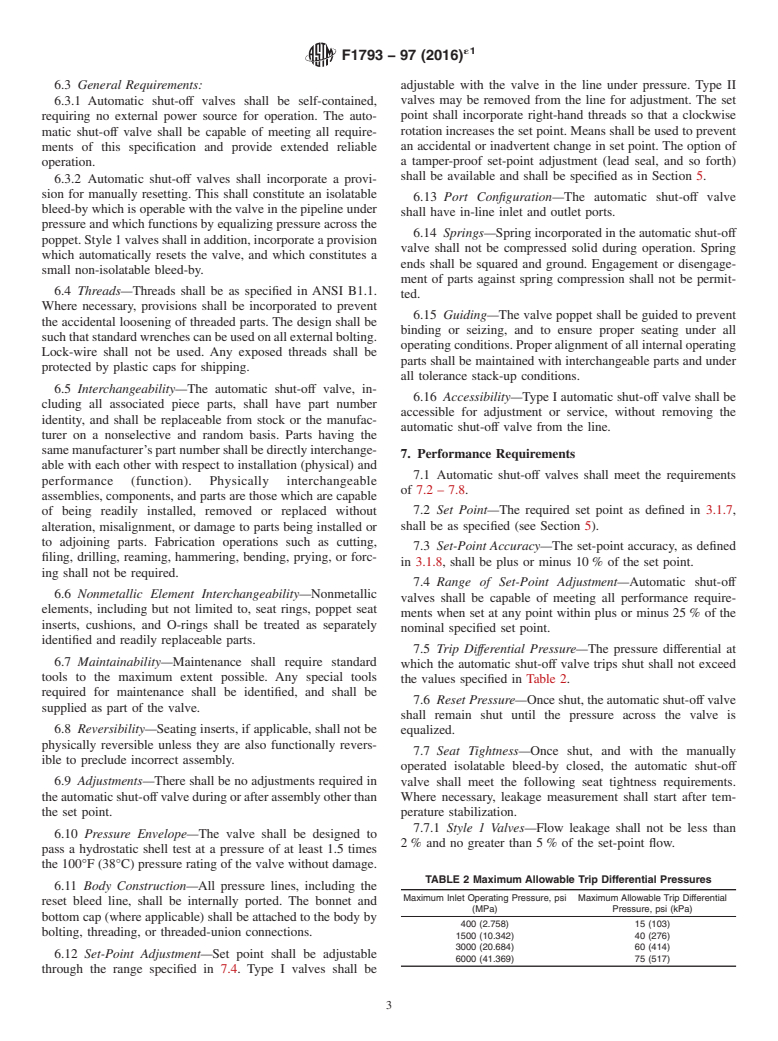

7.5 Trip Differential Pressure—The pressure differential at

6.7 Maintainability—Maintenance shall require standard

which the automatic shut-off valve trips shut shall not exceed

tools to the maximum extent possible. Any special tools

the values specified in Table 2.

required for maintenance shall be identified, and shall be

7.6 Reset Pressure—Once shut, the automatic shut-off valve

supplied as part of the valve.

shall remain shut until the pressure across the valve is

6.8 Reversibility—Seating inserts, if applicable, shall not be

equalized.

physically reversible unless they are also functionally revers-

7.7 Seat Tightness—Once shut, and with the manually

ible to preclude incorrect assembly.

operated isolatable bleed-by closed, the automatic shut-off

6.9 Adjustments—There shall be no adjustments required in valve shall meet the following seat tightness requirements.

theautomaticshut-offvalveduringorafterassemblyotherthan Where necessary, leakage measurement shall start a

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: F1793 − 97 (Reapproved 2010) F1793 − 97 (Reapproved 2016)An American National Standard

Standard Specification for

Automatic Shut-Off Valves (Also Known as Excess Flow

Valves, EFV) for Air or Nitrogen Service

This standard is issued under the fixed designation F1793; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

ε NOTE—Keywords were added editorially in September 2016.

1. Scope

1.1 This specification covers self-contained automatic shut-off valves (also known as excess flow valves) for air or nitrogen

service. They are intended to be installed as safety devices to quickly and automatically shut off flow under certain excess flow

conditions caused by a downstream failure or casualty, such as a hose rupture.

1.2 The values stated in this specification in inch-pound units are to be regarded as the standard. The SI equivalents shown

values given in parentheses are mathematical conversions to SI units that are provided for information only.only and are not

considered standard.

2. Referenced Documents

2.1 ASTM Standards:

F992 Specification for Valve Label Plates

2.2 American National Standards Institute (ANSI):ANSI Standards:

ANSI B1.1 Unified Screw Threads (UN and UNR Thread Form)

ANSI B1.20.1 Pipe Threads, General Purpose (Inch)

ANSI B16.11 Forged Steel Fittings, Socket-Welding and Threaded

ANSI B16.25 Buttwelding Ends

ANSI B16.34 Valves—Flanged, Threaded, and Welded End

2.3 Military Standards and Specifications:

MIL-STD-167-1 Mechanical Vibrations of Shipboard Equipment (Type I—Environmental and Type II—Internally Excited)

MIL-STD-740-1 Airborne Sound Measurements and Acceptance Criteria of Shipboard Equipment

MIL-S-901 Shock Tests, H.I. (High-Impact); Shipboard Machinery Equipment and Systems, Requirements for

MIL-F-1183 Fitting, Pipe, Cast Bronze, Silver-Brazing, General Specification for

2.4 Government Drawings:

NAVAL SEA SYSTEMS COMMANDNaval Sea Systems Command (NAVSEA)

NAVSEA 803-1385884 Unions, Fittings and Adapters Butt and Socket Welding 6000 PSI, WOG, NPS

NAVSEA 803-1385943 Unions, Silver Brazing 3000 PSI, WOG, NPS, for UT Inspection

NAVSEA 803-1385946 Unions, Bronze Silver Brazing, WOG for UT Inspection

3. Terminology

3.1 Definitions:

3.1.1 automatic shut-off valve—automatic shut-off valves covered by this specification trip shut in response to the pressure

differential across the valve.

This specification is under the jurisdiction of ASTM Committee F25 on Ships and Marine Technology and is the direct responsibility of Subcommittee F25.11 on

Machinery and Piping Systems.

Current edition approved May 1, 2010Sept. 1, 2016. Published June 2010September 2016. Originally approved in 1997. Last previous edition approved in 20042010 as

F1793 – 97 (2004).(2010). DOI: 10.1520/F1793-97R10.10.1520/F1793-97R16E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700 Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

F1793 − 97 (2016)

3.1.2 bubble-tight—no visible leakage over a 3-min period using either water submersion or the application of bubble fluid for

detection.

3.1.3 external leakage—leakage from the automatic shut-off valve that escapes to atmosphere.

3.1.4 hydrostatic shell test pressure—the hydrostatic shell test pressure that the automatic shut-off valve is required to withstand

without damage. Automatic shut-off valve operation is not required during application of shell test pressure, but it must meet all

performance requirements after the shell test pressure has been removed.

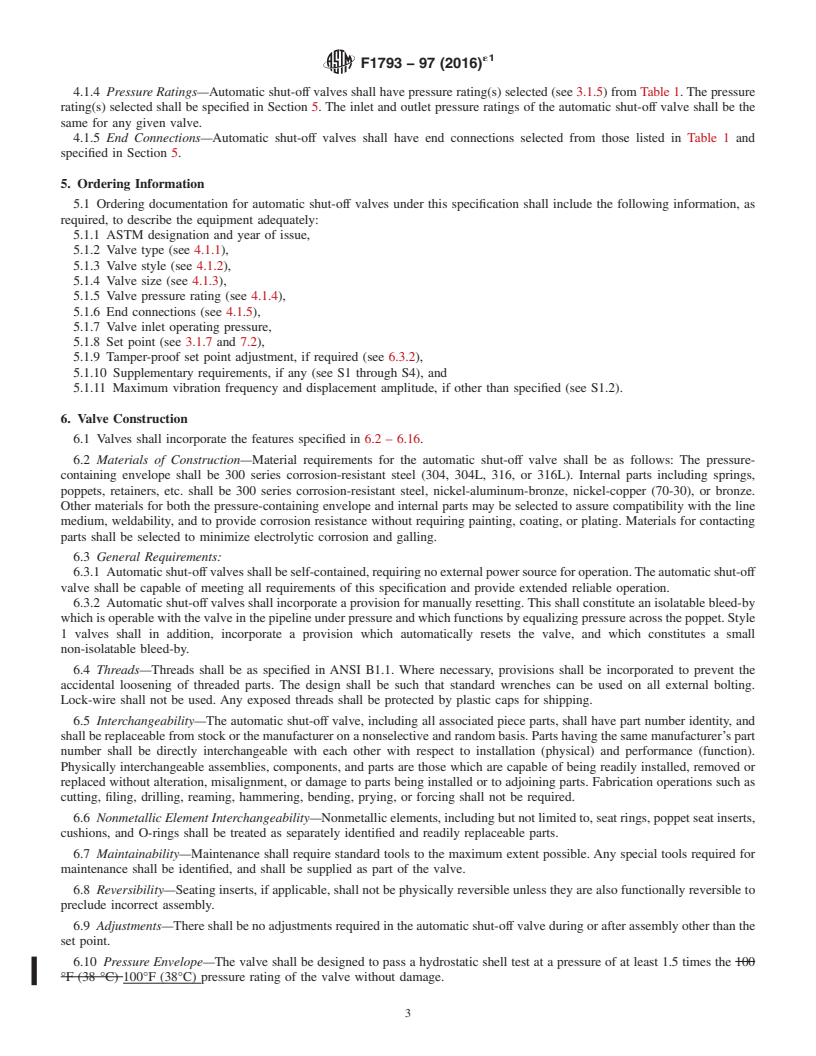

3.1.5 pressure ratings—the pressure ratings of the automatic shut-off valves shall be as defined in the documents listed in Table

1. The pressure ratings (also called pressure-temperature ratings) establish the maximum allowable working (service) pressures of

a component (valve, end connections, and so forth) at various temperatures.

3.1.6 seat tightness—the ability of the automatic shut-off valve to prevent leakage from the valve-inlet to the valve-outlet.

3.1.7 set point—a combination of inlet pressure and flow, at which the valve trips shut.

3.1.8 set point accuracy—the band of accuracy of the automatic shut-off valve expressed as a range of flow rates at a given inlet

pressure, established by the following two points:

3.1.8.1 Discussion—A combination of inlet pressure-flow, at or below which the automatic shut-off valve will not trip shut

(valve will remain open) regardless of influences such as spring relaxation, mechanical shock or vibration, and so forth.

3.1.8.2 A combination of inlet pressure-flow, at or above which the automatic shut-off valve will trip shut (valve will not remain

open) regardless of influences tending to resist closure such as breakloose friction, corrosion, or sludge, and so forth.

3.1.9 set-point range—the range of set points over which the automatic shut-off valve can be adjusted. Expressed as a range of

flow rates at a given inlet pressure.

4. Classification

4.1 Automatic shut-off valves shall be of the following types, styles, sizes, pressure ratings, and end connections:

4.1.1 Types:

4.1.1.1 Type I—Valves that can be adjusted or repaired without removing the valve from pipe line.

4.1.1.2 Type II—Valves that cannot be adjusted or repaired without removing the valve from pipe line.

4.1.2 Styles:

4.1.2.1 Style 1—Automatic Reset Construction—These valves are designed to limit the flow of air or nitrogen upon closure to

a small predetermined level. These valves reset automatically once the service line downstream is made air or nitrogen-tight and

pressure is equalized across the valve.

4.1.2.2 Style 2—Manual Reset Construction—These valves are designed to stop the flow of air or nitrogen upon closure. These

valves must be manually reset.

1 3 1 3

4.1.3 Sizes—Automatic shut-off valves shall be of the following NPS sizes: ⁄4 (13.5 mm), ⁄8 (17.2 mm), ⁄2 (21.3 mm), ⁄4 (26.9

1 1

mm), 1 (33.7 mm), 1 ⁄4 (42.4 mm), 1 ⁄2 (48.3 mm), and 2 (60.3 mm). Unless otherwise specified in 5.0, the valve inlet size shall

be the same as the outlet size.

TABLE 1 Pressure Ratings for Automatic Shut-Off Valves

Applicable Documents for

Type of End

Pressure Rating Dimensional Details of End

Connection

Connections

Butt-welded ANSI B16.34 Class 150, ANSI B16.25

300, 400, 600, 900, 1500,

2500, or 4500

Socket-welded ANSI B16.34 Class 150, ANSI B16.11

300, 400, 600, 900, 1500,

2500, or 4500

Threaded (tapered ANSI B16.34 Class 150, ANSI B1.20.1 and ANSI

pipe thread) 300, 400, 600, 900, 1500, B16.11

or 2500

A

Union-end, MIL-F-1183 (O-ring type) MIL-F-1183 (O-ring type) 400

Silver-brazed

400 lb/in. (2.758 MPa) lb/in. (2.758 MPa)

A 2 2

Union-end, 803-1385946 1500 lb/in. 803-1385946 1500 lb/in.

Silver-brazed

(10.342 MPa) (10.342 MPa)

A 2 2

Union-end, 803-1385943 3000 lb/in. 803-1385943 3000 lb/in.

Silver-brazed

(20.684 MPa) (20.684 MPa)

A 2 2

Union-end, 803-1385884 6000 lb/in. 803-1385884 6000 lb/in.

Butt/socket weld

(41.369 MPa) (41.369 MPa)

Other, as specified As specified As specified

A

For Union inlet and outlet end connections, only the pertinent dimensions listed

in the applicable documents (Military Specification or NAVSEA Requirements)

shall apply. The valve shall be supplied with the thread-pieces only, without the

tail-pieces and union-nuts.

´1

F1793 − 97 (2016)

4.1.4 Pressure Ratings—Automatic shut-off valves shall have pressure rating(s) selected (see 3.1.5) from Table 1. The pressure

rating(s) selected shall be specified in Section 5. The inlet and outlet pressure ratings of the automatic shut-off valve shall be the

same for any given valve.

4.1.5 End Connections—Automatic shut-off valves shall have end connections selected from those listed in Table 1 and

specified in Section 5.

5. Ordering Information

5.1 Ordering documentation for automatic shut-off valves under this specification shall include the following information, as

required, to describe the equipment adequately:

5.1.1 ASTM designation and year of issue,

5.1.2 Valve type (see 4.1.1),

5.1.3 Valve style (see 4.1.2),

5.1.4 Valve size (see 4.1.3),

5.1.5 Valve pressure rating (see 4.1.4),

5.1.6 End connections (see 4.1.5),

5.1.7 Valve inlet operating pressure,

5.1.8 Set point (see 3.1.7 and 7.2),

5.1.9 Tamper-proof set point adjustment, if required (see 6.3.2),

5.1.10 Supplementary requirements, if any (see S1 through S4), and

5.1.11 Maximum vibration frequency and displacement amplitude, if other than specified (see S1.2).

6. Valve Construction

6.1 Valves shall incorporate the features specified in 6.2 – 6.16.

6.2 Materials of Construction—Material requirements for the automatic shut-off valve shall be as follows: The pressure-

containing envelope shall be 300 series corrosion-resistant steel (304, 304L, 316, or 316L). Internal parts including springs,

poppets, retainers, etc. shall be 300 series corrosion-resistant steel, nickel-aluminum-bronze, nickel-copper (70-30), or bronze.

Other materials for both the pressure-containing envelope and internal parts may be selected to assure compatibility with the line

medium, weldability, and to provide corrosion resistance without requiring painting, coating, or plating. Materials for contacting

parts shall be selected to minimize electrolytic corrosion and galling.

6.3 General Requirements:

6.3.1 Automatic shut-off valves shall be self-contained, requiring no external power source for operation. The automatic shut-off

valve shall be capable of meeting all requirements of this specification and provide extended reliable operation.

6.3.2 Automatic shut-off valves shall incorporate a provision for manually resetting. This shall constitute an isolatable bleed-by

which is operable with the valve in the pipeline under pressure and which functions by equalizing pressure across the poppet. Style

1 valves shall in addition, incorporate a provision which automatically resets the valve, and which constitutes a small

non-isolatable bleed-by.

6.4 Threads—Threads shall be as specified in ANSI B1.1. Where necessary, provisions shall be incorporated to prevent the

accidental loosening of threaded parts. The design shall be such that standard wrenches can be used on all external bolting.

Lock-wire shall not be used. Any exposed threads shall be protected by plastic caps for shipping.

6.5 Interchangeability—The automatic shut-off valve, including all associated piece parts, shall have part number identity, and

shall be replaceable from stock or the manufacturer on a nonselective and random basis. Parts having the same manufacturer’s part

number shall be directly interchangeable with each other with respect to installation (physical) and performance (function).

Physically interchangeable assemblies, components, and parts are those which are capable of being readily installed, removed or

replaced without alteration, misalignment, or damage to parts being installed or to adjoining parts. Fabrication operations such as

cutting, filing, drilling, reaming, hammering, bending, prying, or forcing shall not be required.

6.6 Nonmetallic Element Interchangeability—Nonmetallic elements, including but not limited to, seat rings, poppet seat inserts,

cushions, and O-rings shall be treated as separately identified and readily replaceable parts.

6.7 Maintainability—Maintenance shall require standard tools to the maximum extent possible. Any special tools required for

maintenance shall be identified, and shall be supplied as part of the valve.

6.8 Reversibility—Seating inserts, if applicable, shall not be physically reversible unless they are also functionally reversible to

preclude incorrect assembly.

6.9 Adjustments—There shall be no adjustments required in the automatic shut-off valve during or after assembly other than the

set point.

6.10 Pressure Envelope—The valve shall be designed to pass a hydrostatic shell test at a pressure of at least 1.5 times the 100

°F (38 °C) 100°F (38°C) pressure rating of the valve without damage.

´1

F1793 − 97 (2016)

6.11 Body Construction—All pressure lines, including the reset bleed line, shall be internally ported. The bonnet and bottom

cap (where applicable) shall be attached to the body by bolting, threading, or threaded-union connections.

6.12 Set-Point Adjustment—Set point shall be adjustable through the range specified in 7.4. Type I valves shall be adjustable

with the valve in the line under pressure. Type II valves may be removed from the line for adjustment. The set point shall

incorporate right-hand threads so that a clockwise rotation increases the set point. Means shall be used to prevent an accidental

or inadvertent change in set point. The option of a tamper-proof set-point adjustment (lead seal, and so forth) shall be available

and shall be specified as in Section 5.

6.13 Port Configuration—The automatic shut-off valve shall have in-line inlet and outlet ports.

6.14 Springs—Spring incorporated in the automatic shut-off valve shall not be compressed solid during operation. Spring ends

shall be squared and ground. Engagement or disengagement of parts against spring compression shall not be permitted.

6.15 Guiding—The valve poppet shall be guided to prevent binding or seizing, and to ensure proper seating under all operating

conditions. Proper alignment of all internal operating parts shall be maintained with interchangeable parts and under all tolerance

stack-up conditions.

6.16 Accessibility—Type I automatic shut-off valve shall be accessible for adjustment or service, without removing the

automatic shut-off valve from the line.

7. Performance Requirements

7.1 Automatic shut-off valves shall meet the requirements of 7.2 – 7.8.

7.2 Set Point—The required set p

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.