ASTM D6520-06(2012)

(Practice)Standard Practice for the Solid Phase Micro Extraction (SPME) of Water and its Headspace for the Analysis of Volatile and Semi-Volatile Organic Compounds

Standard Practice for the Solid Phase Micro Extraction (SPME) of Water and its Headspace for the Analysis of Volatile and Semi-Volatile Organic Compounds

SIGNIFICANCE AND USE

This practice provides a general procedure for the solid-phase microextraction of volatile and semi-volatile organic compounds from an aqueous matrix or its headspace. Solid sorbent extraction is used as the initial step in the extraction of organic constituents for the purpose of quantifying or screening for extractable organic compounds.

Typical detection limits that can be achieved using SPME techniques with gas chromatography with flame ionization detector (FID), electron capture detector (ECD), or with a mass spectrometer (MS) range from mg/L to μg/L. The detection limit, linear concentration range, and sensitivity of the test method for a specific organic compound will depend upon the aqueous matrix, the fiber phase, the sample temperature, sample volume, sample mixing, and the determinative technique employed.

SPME has the advantages of speed, no desorption solvent, simple extraction device, and the use of small amounts of sample.

Extraction devices vary from a manual SPME fiber holder to automated commercial device specifically designed for SPME.

Listed below are examples of organic compounds that can be determined by this practice. This list includes both high and low boiling compounds. The numbers in parentheses refer to references at the end of this standard.

Volatile Organic Compounds (1,2,3) Pesticides, General (4,5) Organochlorine Pesticides (6) Organophosphorous Pesticides (7,8) Polyaromatic Hydrocarbons (9,10) Polychlorinated biphenyls (10) Phenols (11) Nitrophenols (12) Amines (13)

SPME may be used to screen water samples prior to purge and trap extraction to determine if dilution is necessary, thereby eliminating the possibility of trap overload.

SCOPE

1.1 This practice covers procedures for the extraction of volatile and semi-volatile organic compounds from water and its headspace using solid-phase microextraction (SPME).

1.2 The compounds of interest must have a greater affinity for the SPME-absorbent polymer or adsorbent or combinations of these than the water or headspace phase in which they reside.

1.3 Not all of the analytes that can be determined by SPME are addressed in this practice. The applicability of the absorbent polymer, adsorbent, or combination thereof, to extract the compound(s) of interest must be demonstrated before use.

1.4 This practice provides sample extracts suitable for quantitative or qualitative analysis by gas chromatography (GC) or gas chromatography-mass spectrometry (GC-MS).

1.5 Where used, it is the responsibility of the user to validate the application of SPME to the analysis of interest.

1.6 The values stated in SI units are to be regarded as the standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 10.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6520 − 06 (Reapproved 2012)

Standard Practice for

the Solid Phase Micro Extraction (SPME) of Water and its

Headspace for the Analysis of Volatile and Semi-Volatile

Organic Compounds

This standard is issued under the fixed designation D6520; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D1193 Specification for Reagent Water

D3370 Practices for Sampling Water from Closed Conduits

1.1 This practice covers procedures for the extraction of

D3694 Practices for Preparation of Sample Containers and

volatile and semi-volatile organic compounds from water and

for Preservation of Organic Constituents

its headspace using solid-phase microextraction (SPME).

D3856 Guide for Management Systems in Laboratories

1.2 The compounds of interest must have a greater affinity

Engaged in Analysis of Water

for the SPME-absorbent polymer or adsorbent or combinations

D4210 Practice for Intralaboratory Quality Control Proce-

of these than the water or headspace phase in which they

dures and a Discussion on Reporting Low-Level Data

reside. 3

(Withdrawn 2002)

D4448 Guide for Sampling Ground-Water MonitoringWells

1.3 Not all of the analytes that can be determined by SPME

are addressed in this practice. The applicability of the absor-

3. Terminology

bent polymer, adsorbent, or combination thereof, to extract the

compound(s) of interest must be demonstrated before use.

3.1 Definitions—For definitions of terms used in this

practice, refer to Terminology D1129.

1.4 This practice provides sample extracts suitable for

quantitative or qualitative analysis by gas chromatography

4. Summary of Practice

(GC) or gas chromatography-mass spectrometry (GC-MS).

4.1 This practice employs adsorbent/liquid or adsorbent/gas

1.5 Whereused,itistheresponsibilityoftheusertovalidate

extractiontoisolatecompoundsofinterest.Anaqueoussample

the application of SPME to the analysis of interest.

is added to a septum-sealed vial. The aqueous phase or its

1.6 The values stated in SI units are to be regarded as the

headspace is then exposed to an adsorbent coated on a fused

standard.

silica fiber.The fiber is desorbed in the heated injection port of

a GC or GC-MS or the injector of an HPLC.

1.7 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4.2 The desorbed organic analytes may be analyzed using

responsibility of the user of this standard to establish appro-

instrumental methods for specific volatile or semi-volatile

priate safety and health practices and determine the applica-

organic compounds. This practice does not include sample

bility of regulatory limitations prior to use. For specific hazard

extract clean-up procedures.

statements, see Section 10.

5. Significance and Use

2. Referenced Documents

5.1 This practice provides a general procedure for the

2.1 ASTM Standards:

solid-phase microextraction of volatile and semi-volatile or-

D1129 Terminology Relating to Water

ganic compounds from an aqueous matrix or its headspace.

Solid sorbent extraction is used as the initial step in the

extraction of organic constituents for the purpose of quantify-

This practice is under the jurisdiction ofASTM Committee D19 on Water and

ing or screening for extractable organic compounds.

is the direct responsibility of Subcommittee D19.06 on Methods for Analysis for

Organic Substances in Water.

5.2 Typical detection limits that can be achieved using

Current edition approved June 15, 2012. Published June 2012. Originally

SPME techniques with gas chromatography with flame ioniza-

approved in 2000. Last previous edition approved in 2012 as D6520 – 06. DOI:

tion detector (FID), electron capture detector (ECD), or with a

10.1520/D6520-06R12.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6520 − 06 (2012)

mass spectrometer (MS) range from mg/L to µg/L. The Once the glassware has been cleaned, it should be used

detection limit, linear concentration range, and sensitivity of immediately or stored wrapped in aluminum foil (shiny side

the test method for a specific organic compound will depend out) or under a stretched sheet of PTFE-fluorocarbon.

upon the aqueous matrix, the fiber phase, the sample 7.1.2 Plastics other than PTFE-fluorocarbon should be

temperature, sample volume, sample mixing, and the determi- avoided. They are a significant source of interference and can

native technique employed. adsorb some organics.

7.1.3 Afield blank prepared from water and carried through

5.3 SPME has the advantages of speed, no desorption

sampling, subsequent storage, and handling can serve as a

solvent,simpleextractiondevice,andtheuseofsmallamounts

check on sources of interferences from the containers.

of sample.

5.3.1 Extraction devices vary from a manual SPME fiber 7.2 When performing analyses for specific organic

holder to automated commercial device specifically designed compounds, matrix interferences may be caused by materials

for SPME. and constituents that are coextracted from the sample. The

5.3.2 Listed below are examples of organic compounds that extent of such matrix interferences will vary considerably

depending on the sample and the specific instrumental analysis

can be determined by this practice. This list includes both high

and low boiling compounds. The numbers in parentheses refer methodused.Matrixinterferencesmaybereducedbychoosing

to references at the end of this standard. an appropriate SPME adsorbing fiber.

Volatile Organic Compounds (1,2,3)

8. The Technique of SPME

Pesticides, General (4,5)

Organochlorine Pesticides (6)

8.1 The technique of SPME uses a short, thin solid rod of

Organophosphorous Pesticides (7,8)

fused silica (typically 1-cm long and 0.11-µm outer diameter),

Polyaromatic Hydrocarbons (9,10)

Polychlorinated biphenyls (10) coated with a film (30 to 100 µM) of a polymer, copolymer,

Phenols (11)

carbonaceousadsorbent,oracombinationofthese.Thecoated,

Nitrophenols (12)

fused silica (SMPE fiber) is attached to a metal rod and the

Amines (13)

entire assembly is a modified syringe (see Fig. 1).

5.3.3 SPME may be used to screen water samples prior to

8.2 In the standby position, withdraw the fiber into a

purge and trap extraction to determine if dilution is necessary,

protective sheath. Place an aqueous sample containing organic

thereby eliminating the possibility of trap overload.

analytes or a solid containing organic volatiles into a vial, and

seal the vial with a septum cap.

6. Principles of SPME

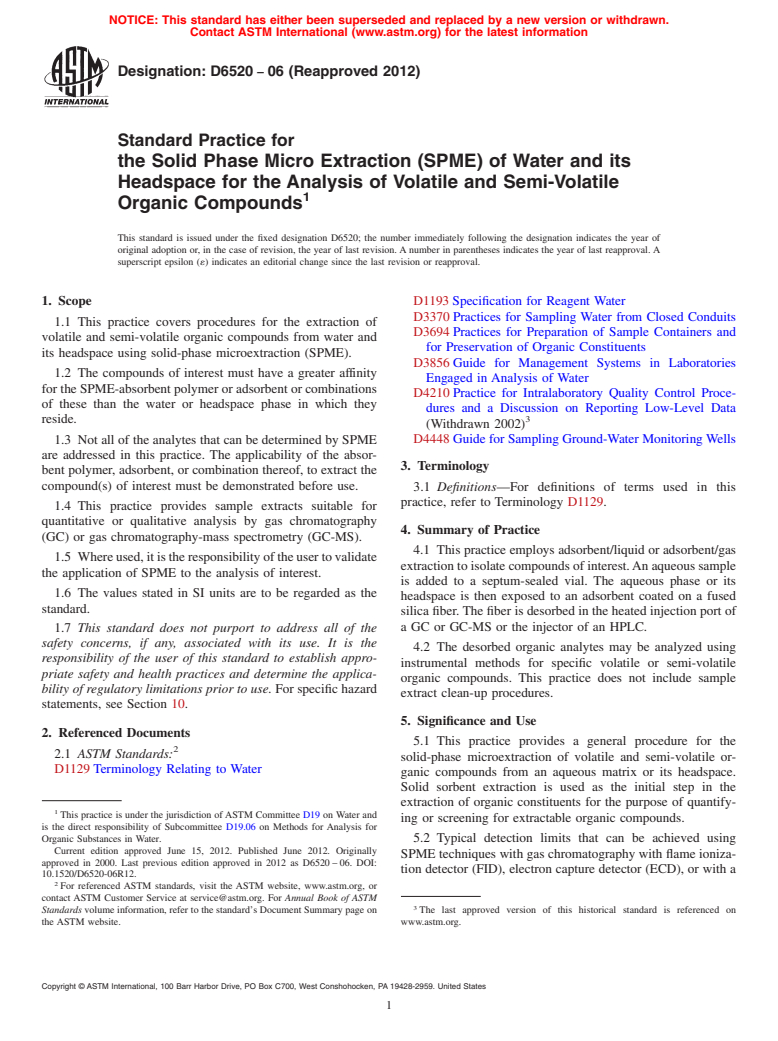

6.1 SPME is an equilibrium technique where analytes are 8.3 Push the sheath with fiber retracted through the vial

septum and lower into the body of the vial. Inject the fiber into

not completely extracted from the matrix.With liquid samples,

the recovery is dependent on the partitioning or equilibrium of theheadspaceortheaqueousportionofthesample(seeFig.2).

Generally, when 2-mL vials are used, headspace sampling

analytes among the three phases present in the sampling vial:

the aqueous sample and headspace (Phase 1), the fiber coating requires approximately 0.8 mL of sample and direct sampling

requires 1.2 mL.

and aqueous sample (Phase 2), and the fiber coating and the

headspace (Phase 3):

Phase1 K 5 C /C (1)

~ !

1 L g

Phase2 K 5 C /C (2)

~ !

2 F L

~Phase3! K 5 C /C (3)

3 F G

where C ,C and C are the concentrations of the analyte in

L G F

these phases.

6.1.1 Distribution of the analyte among the three phases can

be calculated using the following:

C V 5 C V 1C V 1C V (4)

0 L G G L L F F

6.1.2 Concentration of analyte in fiber can be calculated

using the following:

C 5 C V K K /V 1K V 1K K V (5)

F 0 L 1 2 G 1 L 1 2 F

7. Interferences

7.1 Reagents, glassware, septa, fiber coatings and other

sample processing hardware may yield discrete artifacts or

elevated baselines that can cause poor precision and accuracy.

7.1.1 Glassware should be washed with detergent, rinsed

with water, and finally rinsed with distilled-in-glass acetone.

NOTE 1—This figure is Fig. 5, p. 218, Vol 37, Advances in

Air dry or in 103°C oven. Additional cleaning steps may be

Chromatography, 1997. Used with permission.

required when the analysis requires levels of µg/L or below. FIG. 1 SPME Fiber Holder Assembly

D6520 − 06 (2012)

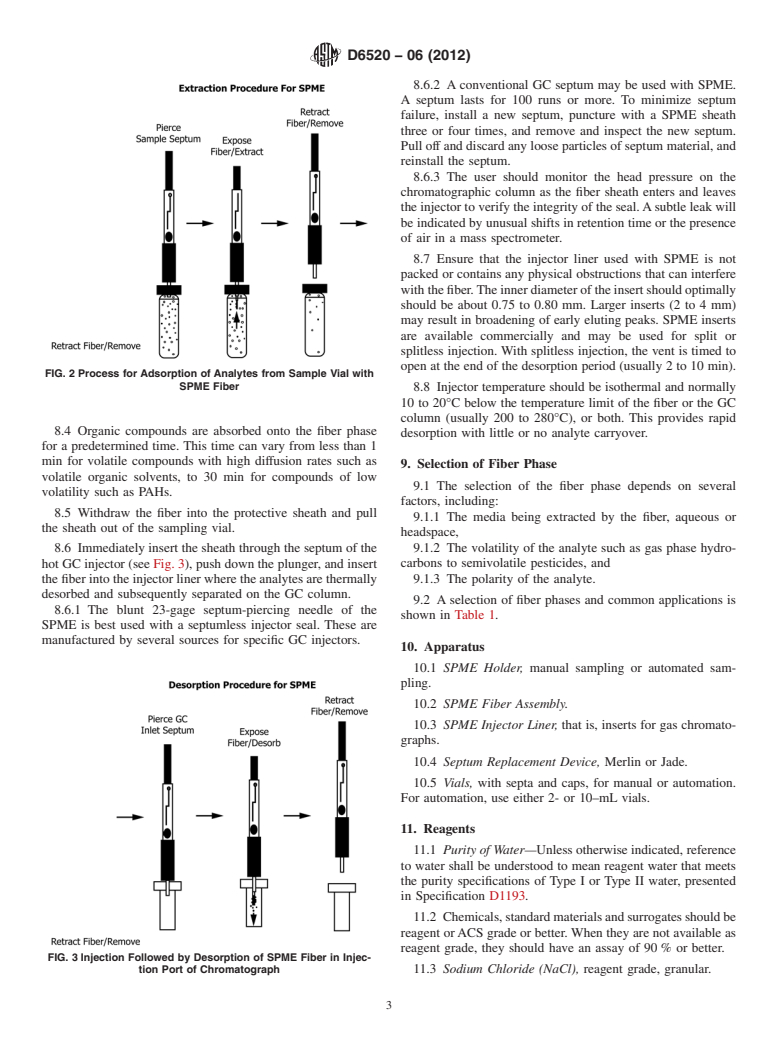

8.6.2 A conventional GC septum may be used with SPME.

A septum lasts for 100 runs or more. To minimize septum

failure, install a new septum, puncture with a SPME sheath

three or four times, and remove and inspect the new septum.

Pull off and discard any loose particles of septum material, and

reinstall the septum.

8.6.3 The user should monitor the head pressure on the

chromatographic column as the fiber sheath enters and leaves

the injector to verify the integrity of the seal.Asubtle leak will

be indicated by unusual shifts in retention time or the presence

of air in a mass spectrometer.

8.7 Ensure that the injector liner used with SPME is not

packed or contains any physical obstructions that can interfere

withthefiber.Theinnerdiameteroftheinsertshouldoptimally

should be about 0.75 to 0.80 mm. Larger inserts (2 to 4 mm)

may result in broadening of early eluting peaks. SPME inserts

are available commercially and may be used for split or

splitless injection. With splitless injection, the vent is timed to

open at the end of the desorption period (usually 2 to 10 min).

FIG. 2 Process for Adsorption of Analytes from Sample Vial with

SPME Fiber

8.8 Injector temperature should be isothermal and normally

10 to 20°C below the temperature limit of the fiber or the GC

column (usually 200 to 280°C), or both. This provides rapid

8.4 Organic compounds are absorbed onto the fiber phase

desorption with little or no analyte carryover.

for a predetermined time. This time can vary from less than 1

min for volatile compounds with high diffusion rates such as

9. Selection of Fiber Phase

volatile organic solvents, to 30 min for compounds of low

9.1 The selection of the fiber phase depends on several

volatility such as PAHs.

factors, including:

8.5 Withdraw the fiber into the protective sheath and pull

9.1.1 The media being extracted by the fiber, aqueous or

the sheath out of the sampling vial.

headspace,

8.6 Immediately insert the sheath through the septum of the 9.1.2 The volatility of the analyte such as gas phase hydro-

carbons to semivolatile pesticides, and

hot GC injector (see Fig. 3), push down the plunger, and insert

the fiber into the injector liner where the analytes are thermally 9.1.3 The polarity of the analyte.

desorbed and subsequently separated on the GC column.

9.2 A selection of fiber phases and common applications is

8.6.1 The blunt 23-gage septum-piercing needle of the

shown in Table 1.

SPME is best used with a septumless injector seal. These are

manufactured by several sources for specific GC injectors.

10. Apparatus

10.1 SPME Holder, manual sampling or automated sam-

pling.

10.2 SPME Fiber Assembly.

10.3 SPME Injector Liner, that is, inserts for gas chromato-

graphs.

10.4 Septum Replacement Device, Merlin or Jade.

10.5 Vials, with septa and caps, for manual or automation.

For automation, use either 2- or 10–mL vials.

11. Reagents

11.1 Purity of Water—Unless otherwise indicated, reference

to water shall be understood to mean reagent water that meets

the purity specifications of Type I or Type II water, presented

in Specification D1193.

11.2 Chemicals,standardmaterialsandsurrogatesshouldbe

reagent orACS grade or better. When they are not available as

reagent grade, they should have an assay of 90 % or better.

FIG. 3 Injection Followed by Desorption of SPME Fiber in Injec-

tion Port of Chromatograph 11.3 Sodium Chloride (NaCl), reagent grade, granular.

D6520 − 06 (2012)

TABLE 1 Commercially Available SPME Fibers for GC and GC/MS

Phase Polarity Features and Applications

Polydimethylsiloxane, 100 µM (PDMS) Non-polar High sample capacity, wide variety of applications; volatile organics to semivolatiles

PDMS, 30 µM Non-polar Semivolatiles, pesticides. Faster desorption, carryover minimized

PDMS, 7 µM Non-Polar Semivolatiles, higher desorption temperatures (320°C), reduces sample capacity

A

Polyacrylate, 85 µM Polar Phenols, polars, semivolatiles

Carbowax/divinyl benzene, 65 µM (CW-DVB) Polar Alcohols

CW-templated resin, 50 µM Polar Surfactants

PDMS-DVB, 65 µM Bi-Polar Alcohols, amines

PDMS-DVB, 60 µM Bi-Polar For HPLC, special more durable phase

Carboxen™ 1006-PDMS Bi-Polar Bi-polar light hydrocarbons, polar solvents, VOCs; sulfur gases, useful for air monitoring

DVB-Carboxen™—PDMS Bi-Polar volatiles

A

Phase more of a solid, so slower diffusion rates.

12. Hazards volatiles. Semi-volatiles are best extracted with SPME liquid

sampling. Headspace sampling is desirable if samples contain

12.1 The toxicity and carcinogenicity of chemicals used in

nonvolatile compounds such as salts, humic acids, or proteins.

this practice have not been precisely defined. Each chemical

should be treated as a potential health hazard. Exposure to

14.2 Sample mixing is effective in increasing the response

these chemicals should be minimized. Each laboratory is

of semi-volatile analytes. It reduces the equilibrium time for

responsible for maintaining awareness of OSHA regulations

the adsorption of the semi-volatile components. Mixing re-

regarding safe handling of chemicals used in this practice.

duces any analyte depleted area around the fiber phase and

12.2 If using either solvent, the hazard of peroxide forma- increases the diffusion of larger molecules from the aqueous

matrix. Mixing is much less effective for volatiles and is

tion should be considered. Test for the presence of peroxide

prior to use. generally not required.

14.3 Matrix modification through the addition of salt to the

13. Sample Handling

aqueous phase may be used to drive polar compounds into the

13.1 There are many procedures for acquiring representa-

headspace. It has very little effect on nonpolar compounds.

tive samples of water. The choice of procedure is site and

Adding salts to the sample also minimizes matrix differences

analysis specific.There are severalASTM guides and practices

when there are sample to sample variations i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.