ASTM B808-10(2020)

(Test Method)Standard Test Method for Monitoring of Atmospheric Corrosion Chambers by Quartz Crystal Microbalances

Standard Test Method for Monitoring of Atmospheric Corrosion Chambers by Quartz Crystal Microbalances

SIGNIFICANCE AND USE

4.1 Corrosion film growth with thicknesses varying from a monolayer of atoms up to 1 μm can readily be measured on a continuous, real-time, in-situ, basis with QCMs.

4.2 The test results obtained for this test method are influenced by various factors, including geometrical effects, temperature, humidity, film thickness, film materials, electrode conditions, gases in the corrosion chamber, atmospheric pressure, and so forth. Calibration of coated crystals and instrumentation and reproducible crystal operating conditions are necessary for consistent results.

SCOPE

1.1 This test method monitors the reactivity of a gaseous test environment in which metal surfaces (for example, electrical contacts, assembled printed wiring boards, and so forth) and other materials subject to pollutant gas attack undergo accelerated atmospheric corrosion testing. This test method is applicable to the growth of adherent corrosion films whose total corrosion film thickness ranges from a few atomic monolayers to approximately a micrometre.

1.2 The test method provides a dynamic, continuous, in-situ, procedure for monitoring the corrosion rate in corrosion chambers; the uniformity of corrosion chambers; and the corrosion rate on different surfaces. Response time in the order of seconds is possible.

1.3 With the proper samples, the quartz crystal microbalance (QCM) test method can also be used to monitor the weight loss from a surface as a result of the desorption of surface species (that is, reduction of an oxide in a reducing atmosphere). (Alternative names for QCM are quartz crystal oscillator, piezoelectric crystal oscillator, or thin-film evaporation monitor.)

1.4 This test method is not sufficient to specify the corrosion process that may be occurring in a chamber, since a variety of pollutant gases and environments may cause similar weight gains.

1.5 This test method is generally not applicable to test environments in which solid or liquid particles are deposited on the surface of the quartz crystal.

1.6 The values stated in SI units are to be regarded as standard. The values in parentheses are for information only.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Safety Data Sheet (SDS) for this product/material as provided by the manufacturer, to establish appropriate safety, health, and environmental practices, and determine the applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B808 − 10 (Reapproved 2020)

Standard Test Method for

Monitoring of Atmospheric Corrosion Chambers by Quartz

Crystal Microbalances

This standard is issued under the fixed designation B808; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Safety Data Sheet (SDS) for this product/material as provided

by the manufacturer, to establish appropriate safety, health,

1.1 This test method monitors the reactivity of a gaseous

and environmental practices, and determine the applicability

test environment in which metal surfaces (for example, elec-

of regulatory limitations prior to use.

trical contacts, assembled printed wiring boards, and so forth)

1.8 This international standard was developed in accor-

and other materials subject to pollutant gas attack undergo

dance with internationally recognized principles on standard-

accelerated atmospheric corrosion testing. This test method is

ization established in the Decision on Principles for the

applicable to the growth of adherent corrosion films whose

Development of International Standards, Guides and Recom-

total corrosion film thickness ranges from a few atomic

mendations issued by the World Trade Organization Technical

monolayers to approximately a micrometre.

Barriers to Trade (TBT) Committee.

1.2 The test method provides a dynamic, continuous, in-

situ, procedure for monitoring the corrosion rate in corrosion

2. Referenced Documents

chambers; the uniformity of corrosion chambers; and the

2.1 ASTM Standards:

corrosion rate on different surfaces. Response time in the order

B810 Test Method for Calibration of Atmospheric Corrosion

of seconds is possible.

Test Chambers by Change in Mass of Copper Coupons

1.3 With the proper samples, the quartz crystal microbal-

ance (QCM) test method can also be used to monitor the

3. Summary of Test Method

weight loss from a surface as a result of the desorption of

3.1 A single crystal of quartz has various natural resonant

surface species (that is, reduction of an oxide in a reducing

frequencies depending on the crystal’s size and shape. The

atmosphere). (Alternative names for QCM are quartz crystal

decrease in natural frequency is linearly proportional to the

oscillator, piezoelectric crystal oscillator, or thin-film evapora-

crystal mass and the mass of well-bonded surface films. For

tion monitor.)

crystals with reactive metal films on the surface (usually

1.4 This test method is not sufficient to specify the corrosion driving electrodes), the mass of the crystal/metal film increases

process that may be occurring in a chamber, since a variety of

as the metal oxidizes or forms other compounds with gases

3,4

pollutant gases and environments may cause similar weight adsorbed from the atmosphere. Thus, by measuring the rate

gains.

of resonant frequency change, a rate of corrosion is measured.

Non-adherent corrosion films, particles, and droplets yield

1.5 This test method is generally not applicable to test

ambiguous results. A review of theory and applications is given

environments in which solid or liquid particles are deposited on

in Lu and Czanderna. See Appendix X1 for discussion of the

the surface of the quartz crystal.

quantitative relationship between frequency change and mass

1.6 The values stated in SI units are to be regarded as

change.

standard. The values in parentheses are for information only.

3.2 The chamber environmental uniformity and corrosion

1.7 This standard does not purport to address all of the

rate can be measured by placing matching quartz crystals with

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to become familiar

with all hazards including those identified in the appropriate

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

This test method is under the jurisdiction of ASTM Committee B02 on the ASTM website.

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee King, W. H. Jr., Analytical Chemistry, Vol 36, 1964, p. 173.

B02.05 on Precious Metals and Electrical Contact Materials and Test Methods. Karmarkar, K. H. and Guilbaut, G. G., Analytical Chemistry Acta, Vol 75, 1975,

Current edition approved Oct. 1, 2020. Published October 2020. Originally p. 111.

approved in 1997. Last previous edition approved in 2015 as B808 – 10 (2015). Lu, C. and Czanderna, A. W. Eds., Applications of Piezoelectric Quartz Crystal

DOI: 10.1520/B0808-10R20. Microbalances, Elsevier, c1984.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B808 − 10 (2020)

matching reactive metal films at various locations in the crystal surface. The material under study or being used to

chamber. If the chamber and corrosion rate have been calibrate the system may be the same as or different than the

standardized, the corrosion rate on various surface materials electrode material. If the two materials are different, the

that have been deposited on the quartz crystal can be deter- potential corrosion of the electrodes shall be accounted for

mined. during the design and subsequent experiments. Depending on

the materials under test, the QCMs can have copper, silver,

4. Significance and Use

nickel, zinc, gold, etc. electrodes. The preferred method of

4.1 Corrosion film growth with thicknesses varying from a deposition is by evaporation for a high purity, smooth surface.

If sublayers are used to enhance the adhesion of the final

monolayer of atoms up to 1 μm can readily be measured on a

continuous, real-time, in-situ, basis with QCMs. electrode, they should be covered by the final electrode

material so that less than 1 % of the metallic area is of exposed

4.2 The test results obtained for this test method are

sublayer material. Because of the fragility of the metal elec-

influenced by various factors, including geometrical effects,

trode there should be multiple (three or more), spring-loaded

temperature, humidity, film thickness, film materials, electrode

contacts between the crystal and electronics.

conditions, gases in the corrosion chamber, atmospheric

6.3 After metallization of the crystals, they should be stored

pressure, and so forth. Calibration of coated crystals and

in desiccators. After two years storage or if the metallization

instrumentation and reproducible crystal operating conditions

shows discoloration or staining, the crystals shall be discarded.

are necessary for consistent results.

Crystal surfaces should not be chemically or mechanically

5. Apparatus

cleaned before use in the corrosion chamber. They should be

blown clean with inert compressed gas. Chilling and conden-

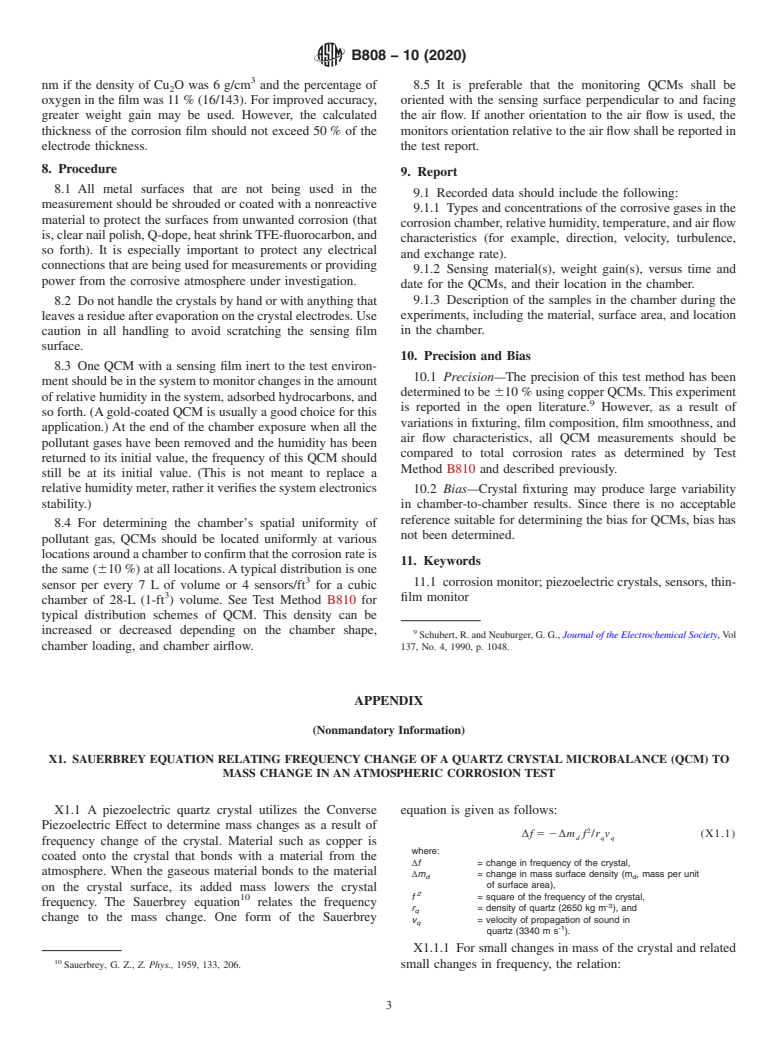

5.1 Apparatus can be a simple series circuit of crystal (with

sation on the surface, as can occur with the use of pressurized

electrodes and sensing film), oscillator (typically 6 MHz) and

fluorocarbons, shall be avoided. Care shall be exercised so that

frequency counter (610-Hz accuracy and stability), as sche-

the crystals are only handled by clean tweezers or tongs and

matically shown in Fig. 1.

never touched by hands.

7. Calibration

7.1 QCMs and its electronics shall be calibrated initially in

a given corrosion system and thereafter on an annual basis.

Calibration shall be performed with the same shape and size of

crystal holder to be used during operation. Recalibration shall

be performed if the crystal holder geometry is changed.

FIG. 1 Schematic of QCM and Related Electronics

Calibration can be done by comparison to a standard such as

actual gravimetric weighing on a microbalance (62 μg). Use a

5.2 Commercial, Thin-Film Monitors, incorporating those

sample of the same material as the sensing film with a

functions that read out thicknesses or weight gain are also

minimum area of 5 cm and a thickness of 0.1 to 0.6 mm (see

available and acceptable after they have been calibrated.

Test Method B810). Foil surface roughness should be within

620 % of the QCM sensing film roughness. The procedure for

5.3 Microbalance, with an accuracy of 62 μg is needed for

the generation (that is, evaporation) and cleaning of the

calibration procedures.

gravimetric sample should be the same as used for the sensing

5.4 Recording Devices or Computers are needed for real-

films. The age and storage of the gravimetric sample should be

time, continuous measurements.

comparable to the age of the QCM sensing film. Allow the foil

to e

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.