ASTM D8485-23

(Test Method)Standard Test Method for Corrosion Test for Electric Vehicle Coolants in Glassware

Standard Test Method for Corrosion Test for Electric Vehicle Coolants in Glassware

SIGNIFICANCE AND USE

5.1 This test method provides a method to distinguish between coolants that are deleterious from the corrosion standpoint and those suitable for further evaluation.

FIG. 1 Metal Specimens and Equipment for the 336 h Corrosion Test

FIG. 2 Tall Form Beaker Specimens and Equipment for the 336 h Corrosion Test

SCOPE

1.1 This test method covers a simple beaker-type procedure for evaluating the effects of glycol-based electric vehicle coolants on metal specimens under controlled laboratory conditions.

1.2 This test method evaluates the corrosion on test specimens of stainless steel and aluminum, with an option for a copper test specimen.

1.3 This test method evaluates coolants without the addition of any corrosive elements.

1.4 Additional types of metal test specimens may be evaluated.

1.5 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D8485 − 23

Standard Test Method for

1

Corrosion Test for Electric Vehicle Coolants in Glassware

This standard is issued under the fixed designation D8485; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Elements in Engine Coolant by Inductively Coupled

Plasma-Atomic Emission Spectroscopy

1.1 This test method covers a simple beaker-type procedure

E178 Practice for Dealing With Outlying Observations

for evaluating the effects of glycol-based electric vehicle

E2470 Specification for Polyester Grade Ethylene Glycol

coolants on metal specimens under controlled laboratory con-

ditions.

3. Terminology

1.2 This test method evaluates the corrosion on test speci-

3.1 Definitions: For definitions of general terms used in D15

mens of stainless steel and aluminum, with an option for a

standards, refer to Terminology D4725.

copper test specimen.

3.2 Definitions of Terms Specific to This Standard:

1.3 This test method evaluates coolants without the addition

3.2.1 electric vehicle, n—a motor vehicle that uses an

of any corrosive elements.

electric motor as a means of propulsion.

1.4 Additional types of metal test specimens may be evalu-

3.2.1.1 Discussion—An electric vehicle may be either a fuel

ated.

cell vehicle, battery electric vehicle or a plug-in hybrid electric

vehicle.

1.5 The values stated in SI units are to be regarded as

standard. The values given in parentheses after SI units are

4. Summary of Test Method

provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the

4.1 In this test method, specimens of metals typical of those

safety concerns, if any, associated with its use. It is the present in electric vehicle cooling systems are totally immersed

responsibility of the user of this standard to establish appro-

in aerated coolant solutions for 336 h at 88 °C. The corrosion-

priate safety, health, and environmental practices and deter- inhibitive properties of the test solution are evaluated on the

mine the applicability of regulatory limitations prior to use. change in weight incurred by the specimens. Each test is run in

1.7 This international standard was developed in accor-

triplicate, and the average weight change is determined for

dance with internationally recognized principles on standard- each metal.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

5. Significance and Use

mendations issued by the World Trade Organization Technical

5.1 This test method provides a method to distinguish

Barriers to Trade (TBT) Committee.

between coolants that are deleterious from the corrosion

standpoint and those suitable for further evaluation.

2. Referenced Documents

2.1 ASTM Standards:

6. Apparatus

D1125 Test Methods for Electrical Conductivity and Resis-

6.1 Container—1000 mL 3-Neck Glass Cylinder Reactor,

tivity of Water

Flat Bottom Reaction Flask with a PTFE O-Ring and clamp.

D1193 Specification for Reagent Water

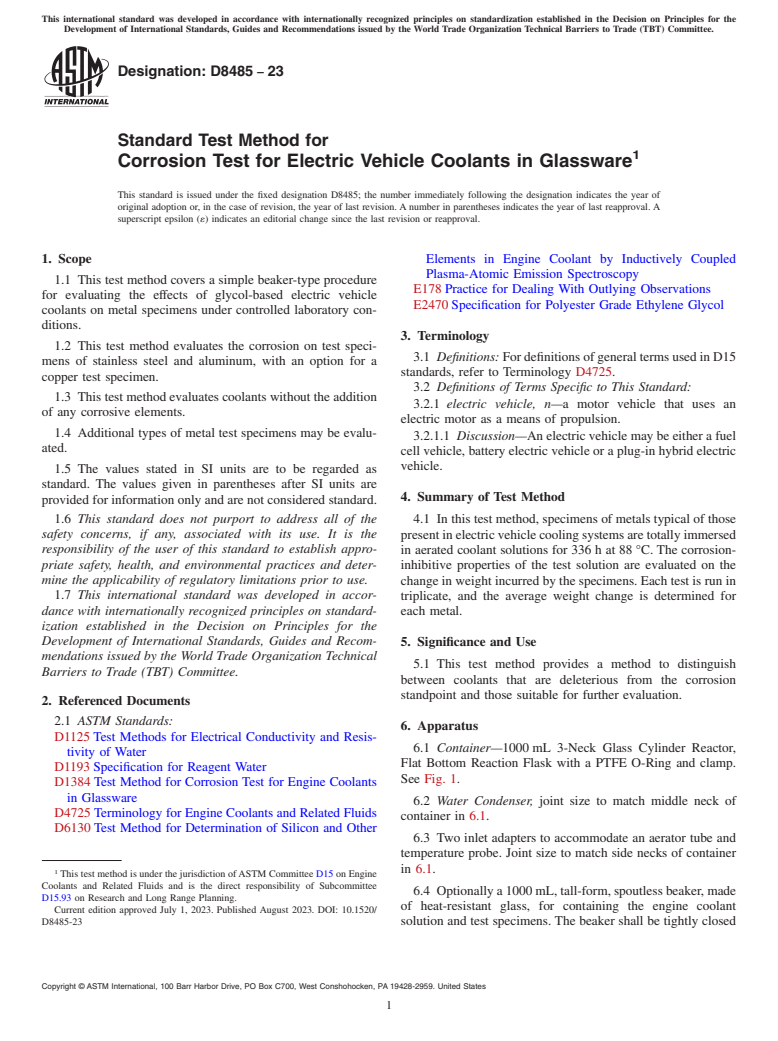

See Fig. 1.

D1384 Test Method for Corrosion Test for Engine Coolants

in Glassware

6.2 Water Condenser, joint size to match middle neck of

D4725 Terminology for Engine Coolants and Related Fluids

container in 6.1.

D6130 Test Method for Determination of Silicon and Other

6.3 Two inlet adapters to accommodate an aerator tube and

temperature probe. Joint size to match side necks of container

in 6.1.

1

This test method is under the jurisdiction of ASTM Committee D15 on Engine

Coolants and Related Fluids and is the direct responsibility of Subcommittee

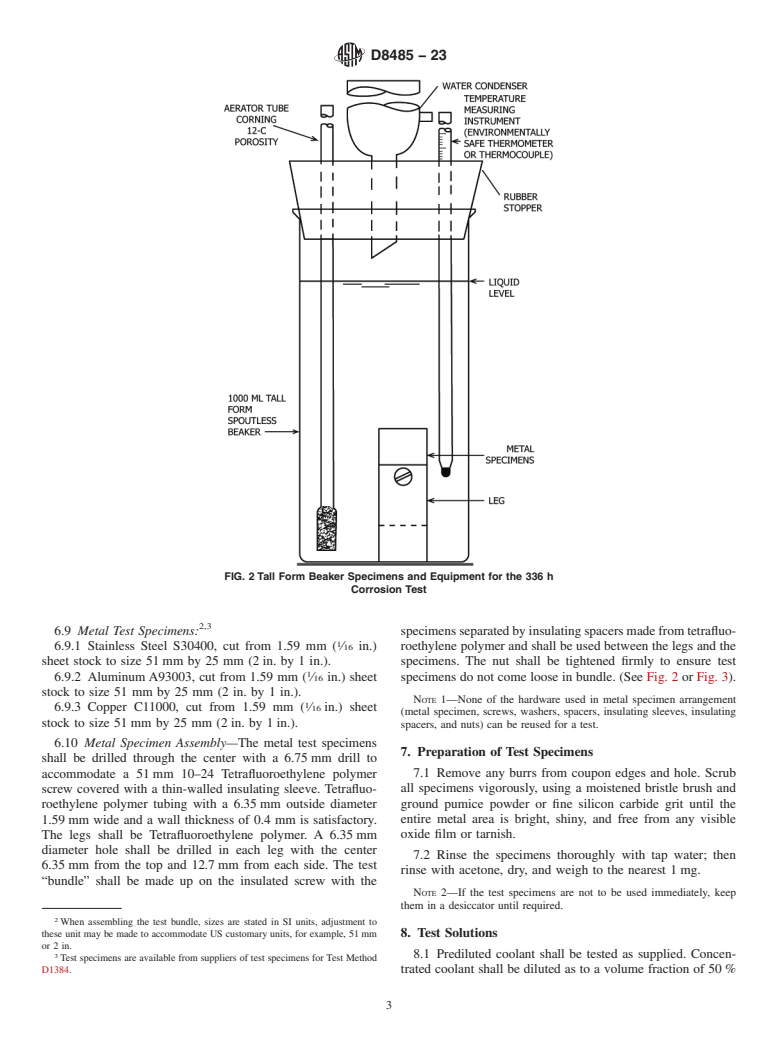

6.4 Optionally a 1000 mL, tall-form, spoutless beaker, made

D15.93 on Research and Long Range Planning.

of heat-resistant glass, for containing the engine coolant

Current edition approved July 1, 2023. Published August 2023. DOI: 10.1520/

D8485-23 solution and test specimens. The beaker shall be tightly closed

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D8485 − 23

FIG. 1 Metal Specimens and Equipment for the 336 h Corrosion

Test

with a No. 15 rubber stopper, having drill holes to accommo- 6.7 Temperature Measuring Instrument—An electronic tem-

date a water condenser, an aerator tube, and a thermometer as perature measuring and recording device with a minimum

shown in Fig. 2.

accuracy of 62 °C within the specified test temperature range

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.