ASTM C1750-11

(Guide)Standard Guide for Development, Verification, Validation, and Documentation of Simulated High-Level Tank Waste

Standard Guide for Development, Verification, Validation, and Documentation of Simulated High-Level Tank Waste

SCOPE

1.1 Intent:

1.1.1 The intent of this guideline is to provide general considerations for the development, verification, validation, and documentation of high-level waste (HLW) tank simulants. Due to the expense and hazards associated with obtaining and working with actual wastes, especially radioactive wastes, simulants are used in a wide variety of applications including process and equipment development and testing, equipment acceptance testing, and plant commissioning. This standard guide facilitates a consistent methodology for development, preparation, verification, validation, and documentation of waste simulants.

1.2 This guideline provides direction on (1) defining simulant use, (2) defining simulant-design requirements, (3) developing a simulant preparation procedure, (4) verifying and validating that the simulant meets design requirements, and (5) documenting simulant-development activities and simulant preparation procedures.

1.3 Applicability:

1.3.1 This guide is intended for persons and organizations tasked with developing HLW simulants to mimic certain characteristics and properties of actual wastes. The process for simulant development, verification, validation, and documentation is shown schematically in Fig. 1. Specific approval requirements for the simulants developed under this guideline are not provided. This topic is left to the performing organization.

1.3.2 While this guide is directed at HLW simulants, much of the guidance may also be applicable to other aqueous based solutions and slurries.

1.3.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 User Caveats:

1.4.1 This guideline is not a substitute for sound chemistry and chemical engineering skills, proven practices and experience. It is not intended to be prescriptive but rather to provide considerations for the development and use of waste simulants.

1.4.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

FIG. 1 Simulant Development, Verification, Validation, and Documentation Flowsheet

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1750 −11

Standard Guide for

Development, Verification, Validation, and Documentation of

Simulated High-Level Tank Waste

This standard is issued under the fixed designation C1750; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.4.1 This guideline is not a substitute for sound chemistry

and chemical engineering skills, proven practices and experi-

1.1 Intent:

ence. It is not intended to be prescriptive but rather to provide

1.1.1 The intent of this guideline is to provide general

considerationsforthedevelopmentanduseofwastesimulants.

considerations for the development, verification, validation,

1.4.2 This standard does not purport to address all of the

and documentation of high-level waste (HLW) tank simulants.

safety concerns, if any, associated with its use. It is the

Due to the expense and hazards associated with obtaining and

responsibility of the user of this standard to establish appro-

working with actual wastes, especially radioactive wastes,

priate safety and health practices and determine the applica-

simulants are used in a wide variety of applications including

bility of regulatory limitations prior to use.

process and equipment development and testing, equipment

acceptance testing, and plant commissioning. This standard

2. Referenced Documents

guide facilitates a consistent methodology for development,

2.1 ASTM Standards:

preparation, verification, validation, and documentation of

C1109 Practice for Analysis of Aqueous Leachates from

waste simulants.

Nuclear Waste Materials Using Inductively Coupled

1.2 This guideline provides direction on (1) defining simu-

Plasma-Atomic Emission Spectroscopy

lant use, (2) defining simulant-design requirements, (3) devel-

C1111 Test Method for Determining Elements in Waste

oping a simulant preparation procedure, (4) verifying and

StreamsbyInductivelyCoupledPlasma-AtomicEmission

validating that the simulant meets design requirements, and (5)

Spectroscopy

documenting simulant-development activities and simulant

C1752 Guide for Measuring Physical and Rheological Prop-

preparation procedures.

erties of Radioactive Solutions, Slurries, and Sludges

1.3 Applicability:

D4129 Test Method for Total and Organic Carbon in Water

1.3.1 This guide is intended for persons and organizations

by High Temperature Oxidation and by Coulometric

tasked with developing HLW simulants to mimic certain

Detection

characteristics and properties of actual wastes. The process for

2.2 Environmental Protection Agency SW-846 Methods:

simulant development, verification, validation, and documen-

Method 3010A Acid digestion of Aqueous Samples and

tation is shown schematically in Fig. 1. Specific approval

Extracts for total metals for Analysis by FLAA or ICP

requirements for the simulants developed under this guideline

Spectroscopy

are not provided. This topic is left to the performing organi-

Method 3050B Acid Digestion of Sediments, Sludges and

zation.

Soils

1.3.2 While this guide is directed at HLW simulants, much

Method 3051A Microwave Assisted Acid Digestion of

of the guidance may also be applicable to other aqueous based

Sediments, Sludges and Soils

solutions and slurries.

Method 3052 Microwave Assisted Acid Digestion of Sili-

1.3.3 The values stated in SI units are to be regarded as the

ceous and Organically Based Matricies

standard. The values given in parentheses are for information

Method 6010C Inductively Coupled Plasma-Atomic Emis-

only.

sion Spectrometry

1.4 User Caveats:

Method 6020A Inductively Coupled Plasma-Mass Spec-

trometry

This specification is under the jurisdiction of ASTM Committee C26 on

Nuclear Fuel Cycle and is the direct responsibility of Subcommittee C26.13 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Spent Fuel and High Level Waste. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved June 1, 2011. Published September 2011. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/C1750-11. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1750−11

FIG. 1Simulant Development, Verification, Validation, and Documentation Flowsheet

Method 9056A Determination of Inorganic Anions by Ion 3.2.7 NQA-1—Nuclear Quality Assurance

Chromatography

3.2.8 PSD—Particle Size Distribution

3.2.9 QA—Quality Assurance

3. Terminology

3.2.10 QC—Quality Control

3.1 Definitions of Terms Specific to This Standard:

3.1.1 cognizant engineer, n—lead engineer responsible for

4. Summary of Guide

overall supervision and direction of simulant development.

4.1 This guide provides general considerations on the

3.1.2 simulant, n—a solution or slurry that mimics or

development, preparation, validation, verification, and docu-

replicatesselectedchemical,physicalorrheologicalproperties,

mentation of HLW simulants.

or both, of an actual process or waste stream.

4.2 The first step in the process is to define the purpose for

3.1.3 simulant development test plan, n—a document that

which the simulant will be used. This first step also includes

describes the simulant development process that results in a

specifying the target values or range of values for the chemical

simulant that meets the usage and design requirements identi-

composition and physical and rheological properties of the

fied in the simulant requirements specification.

simulant. The quality assurance requirements are also defined

3.1.4 simulant preparation procedure, n—a document that

in the first step in accordance with the project requirements for

specifies the step by step process of producing the simulant.

which the simulant is being developed.

3.1.5 simulant requirements specification, n—a document

4.3 The next step is to define the simulant design require-

that specifies the simulant use and design requirements.

ments. This involves determining the necessary and sufficient

3.1.6 simulant validation, n—establishment of documented

simulant properties to be measured for each affected unit

evidencethatconfirmsthatbehaviorofthesimulantadequately

operation. Key simulant properties and acceptance criteria are

mimics the targeted actual waste behavior. Simulant validation

developed with regard to the project requirements for which

can be expressed by the query, “Are you making the correct

the simulant is being developed. Standardized chemical, physi-

simulant?” and refers back to the needs for which the simulant

cal and rheological property measurements are referenced.

is being developed.

Topics to be considered during the development and scale-up

3.1.7 simulantverification,n—establishmentofdocumented

of the simulant preparation procedure are provided.Amethod-

evidence which provides a high degree of assurance that the

ology for validation and verification of the simulant is dis-

simulant meets the predetermined design and quality require-

cussed along with suggested documentation.

ments. Simulant verification can be expressed by the query,

5. Significance and Use

“Are you making the simulant properly?”

3.2 Acronyms: 5.1 The development and use of simulants is generally

dictated by the difficulty of working with actual radioactive or

3.2.1 ASME—American Society of Mechanical Engineers

hazardous wastes, or both, and process streams. These diffi-

3.2.2 DI—Deionized Water

culties include large costs associated with obtaining samples of

3.2.3 GFC—Glass Forming Chemicals

significant size as well as significant environmental, safety and

3.2.4 HLW—High-Level Waste

health issues.

3.2.5 LAW—Low-Activity Waste

5.2 Simulant-Development Scope Statement:

3.2.6 N/A—Not Applicable 5.2.1 Simulant Use Definition:

C1750−11

5.2.1.1 The first step should be to determine what the process information, or feed vectors must be assessed. This

simulant is to be used for. Simulants may be used in a wide comparison should highlight analytical outlier values that will

variety of applications including evaluation of process

need to be addressed for an analyte.

performance, providing design input to equipment, facilities

5.2.2.3 For simulant compositions that mimic flow sheet

and operations, acceptance testing of procured equipment or

streams later in the process (after the best available waste

systems, commissioning of equipment or facilities, or trouble-

source-term analytical information on the incoming waste

shooting operations in existing equipment or facilities. A

stream is defined), process flow sheet model runs may be

simulant may be used for single or multiple unit operations.

required to provide estimates of the additional stream compo-

Through the simulant-use definition, the characteristics of the

sitions that incorporate recycle streams from other flow sheet

simulant required for development are determined. The char-

unit operations. Flow sheet runs should consider transient

acteristics may include chemical, physical, rheological or a

behavior of the process in order to provide a range of

combinationoftheseproperties.Theeffectofprocesschemical

compositions such that bounding conditions can be deter-

additions and recycle streams must also be assessed.

mined. The compositional waste-stream source-term data

5.2.1.2 The applicable quality assurance requirements

should be used as inputs to the process model. Any other

should be specified in accordance with the projects quality

planned operations that could affect flow sheet compositions

assurance program. For example in the DOE complex, these

being simulated (for example, adjustment of actual-waste-

requirements often include a QA program that implements

composition data to reflect future waste-feed delivery activities

ASME Nuclear Quality Assurance, NQA-1 (latest revision or

to arrive at the “best forecast composition range”) need to be

as specified by project) and its applicable portions of Part II,

considered. If available, analytical data from actual waste

Subpart 2.7 (latest revision or as specified by project) or Office

characterization and testing should be compared to waste-

of Civilian Radioactive Waste Management QualityAssurance

stream-modeling results to validate the modeling results. The

Requirements Document: QARD DOE/RW 0333P(latest revi-

assumptions and inputs to the process flow sheet used should

sion or as specified by project) QA requirements. Simulant-

bedescribedanddiscussed,andshouldbeincorporatedintothe

development activities that support regulatory and environ-

simulant requirements specification. By this process, the best

mental compliance-related aspects of a waste-vitrification

forecast simulant composition range would be traceable to

program may need to be performed in accordance with project

actual waste-characterization data.

quality-assurance requirements for generating environmental

regulatory data. The use of simulants for project testing that is 5.2.2.4 For simulant compositions formulated for specific

exploratory or scoping in nature may not need to comply with unit operations, the composition may be targeted to only the

specific QA requirements.

chemical, physical, and rheological properties that are known

5.2.2 Simulant Composition Definition: to affect specific key operating or processing parameters.

5.2.2.1 Approaches to simulant-composition development

5.2.2.5 For a simulant intended to bound the limits of a

will vary depending on the type of simulant required for

processorspecificpieceofequipment,arangeofcompositions

testing. Simulant compositions may be based on actual sample

should be developed to define these operational limits. For

characterization data, formulated for specific unit operations,

example, purely physical simulants may be used to determine

or used for bounding or testing the limits of a process or

the rheological bounds between which a specific vessel is able

specific piece of equipment. Key properties that are to be

to meet a required process condition. For this approach,

simulated should be identified as it may be difficult and

multiple simulants may be required to test numerous param-

unnecessary to develop simulants that exactly mimic all actual

eters.Abounding simulant may consist of an existing simulant

process stream properties at once.

spiked with specific compounds to test process performance

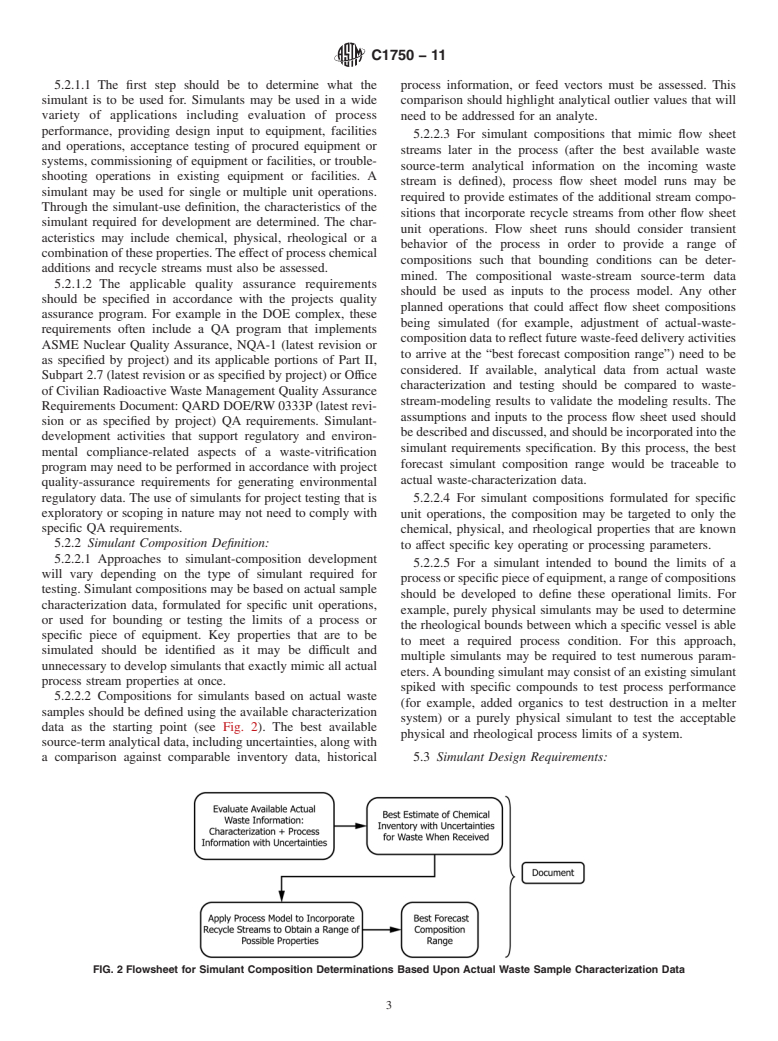

5.2.2.2 Compositions for simulants based on actual waste

(for example, added organics to test destruction in a melter

samples should be defined using the available characterization

system) or a purely physical simulant to test the acceptable

data as the starting point (see Fig. 2). The best available

physical and rheological process limits of a system.

source-term analytical data, including uncertainties, along with

a comparison against comparable inventory data, historical 5.3 Simulant Design Requirements:

FIG. 2Flowsheet for Simulant Composition Determinations Based Upon Actual Waste Sample Characterization Data

C1750−11

5.3.1 The cognizant engineer should determine the neces- 5.3.5 The key simulant properties and acceptance criteria

sary and sufficient simulant properties to measure for each may be documented in the simulant requirements specification,

preferably in table format.An example for a LAWMelter Feed

affected unit operation, waste, or recycle stream. These should

is provided in X2.1. Each project is encouraged to develop a

bethesameforbothactualwasteandsimulantwastewherethe

similar list.

simulant is based upon actual-waste characterization data.

5.3.6 Standardized chemical, physical, and rheological

Often trace amounts of polyvalent ions or organic constituents

property measurements for work performed should be used

can have a significant influence on physical and rheological

(see Section 2). Use of these property measurements is

properties and must be carefully considered. Appendix X1

essential to ensure standardized, comparable results between

provides an example of chemical, physical, and rheological

all actual-waste and simulant-based tests.

properties-measurement matrices for several common unit

5.4 Simulant Development Test Plan:

operations associated with tank waste treatment waste streams

5.4.1 The person or organization assigned to perform the

that may be considered in developing simulant-design require-

simulant development work may prepare a simulant develop-

ments. A similar chemical, physical, and rheological property-

ment test plan that implements the simulant requirements

measurement matrix shoul

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.