ASTM E617-97(2003)

(Specification)Standard Specification for Laboratory Weights And Precision Mass Standards

Standard Specification for Laboratory Weights And Precision Mass Standards

ABSTRACT

This specification covers laboratory weights and precision mass standards including their principal physical characteristics and metrological requirements. Maximum permissible error, magnetic property, density, and surface roughness for each weight shall be within the limits indicated in this specification. Physical characteristics shall be based on construction, design, surface area, materials, magnetism, density, surface finish, weight adjustment, and marking.

SCOPE

1.1 This specification covers weights and mass standards used in laboratories, specifically classes 0, 1, 2, 3, 4, 5, 6 and 7. This specification replaces National Bureau of Standards Circular 547, Section , which is out of print.

1.2 This specification further recognizes that International Recommendation R111 exists, that describes classes E1, E2, F1, F2, M1, M2 and M3. Users may choose to reference either R111 or this specification, depending on requirements.

1.3 This specification contains the principal physical characteristics and metrological requirements for weights that are used.

1.3.1 For the verification of weighing instruments;

1.3.2 For the verification of weights of a lower class of accuracy; and

1.3.3 With weighing instruments.

1.4 Tolerances and design restrictions for each class are described in order that both individual weights or sets of weights can be chosen for appropriate applications.

1.5 The values stated in SI units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 617 – 97 (Reapproved 2003)

Standard Specification for

Laboratory Weights and Precision Mass Standards

This standard is issued under the fixed designation E 617; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Profiling Methods, Part 1: Terms, Definitions and Param-

eters

1.1 This specification covers weights and mass standards

2.3 NCSL Standards:

used in laboratories, specifically classes 0, 1, 2, 3, 4, 5, 6 and

NCSL Glossary of Metrology—Related Terms

7. This specification replaces National Bureau of Standards

NCSL Recommended Practice-12 Determining and Report-

Circular 547, Section 1, which is out of print.

ing Measurement Uncertainties

1.2 This specification further recognizes that International

ANSI/NCSL-Z540-1-1994 American National Standard for

Recommendation R111 exists, that describes classes E1, E2,

Calibration-Calibration Laboratories and Measuring and

F1, F2, M1, M2 and M3. Users may choose to reference either

Test Equipment General Requirements

R111 or this specification, depending on requirements.

2.4 NIST Standards:

1.3 This specification contains the principal physical char-

NIST NVLAP Draft Handbook 150-2 National Voluntary

acteristics and metrological requirements for weights that are

Laboratory Accreditation Program Calibration Laborato-

used.

ries Technical Guide

1.3.1 For the verification of weighing instruments;

NIST NVLAP Handbook 150 National Voluntary Labora-

1.3.2 For the verification of weights of a lower class of

tory Accreditation Program (NVLAP), NIST Handbook

accuracy; and

150, Procedures and General Requirements

1.3.3 With weighing instruments.

NIST Technical Note 1297 (1994) Guidelines for Evaluat-

1.4 Tolerances and design restrictions for each class are

ing and Expressing the Uncertainty of NISTMeasurement

described in order that both individual weights or sets of

Results

weights can be chosen for appropriate applications.

2.5 OIML Standard:

1.5 The values stated in SI units are to be regarded as the

OIML Recommendation 33 Conventional Value of the Re-

standard.

sult of Weighing in Air

2. Referenced Documents

3. Terminology

2.1 ASTM Standards:

3.1 Definitions of Terms Specific to This Standard:

B 46.1-1995 Surface Texture (Surface Roughness, Wavi-

2 3.1.1 accuracy class of weights—a class of weights that

ness, and Lay) an American National Standard

meets certain metrological requirements intended to keep the

2.2 ISO Standards:

errors within specified limits.

International Vocabulary of Basic and General Terms in

3.1.2 calibration—the acts of determining the mass differ-

Metrology 1993, VIM, Geneve, Switzerland

3 ence between a standard of known mass value and an “un-

Guide to the Expression of Uncertainty in Measurement

known” test weight or set of weights, establishing the mass

ISO/DIS 4287-1, Edition 01-Jun-95, Geometric Product

value and conventional mass value of the “unknown”, and of

Specification (GPS), Determination of Surface Texture by

determining a quantitative estimate of the uncertainty to be

1 4

This specification is under the jurisdiction of ASTM Committee E41 on Available from NCSL, National Conference of Standards Laboratories, 1800

Laboratory Apparatus, and is the direct responsibility of Subcommittee E41.06 on 30th Street, Suite 305B, Boulder, Colorado 80301.

Weighing Devices. Available from NIST/NVLAP, National Voluntary Laboratory Accreditation

Current edition approved Nov. 10, 1997. Published March 1998. Originally Program, NIST, Gaithersburg, Maryland 20899. HB 150 available on-line: http://

published as E 617 – 78. Last previous edition E 617 – 91. ts.nist.gov/nvlap and Technical Note 1297 available on-line: http://physics.nist.gov/

Available from ASME Service Center, 22 Law Drive, PO Box 2900, Fairfield, Pubs/guidelines/outline.html.

New Jersey 07007-2900. Available from Organisation Internationale de Metrologie Legale, 11 Rue

Available from American National Standards Institute, 11 West 42nd Street, Turgot, 75009 Paris, France.

New York, New York 10036. Definition from OIML R111.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 617 – 97 (2003)

assigned to the stated mass or conventional mass value of the 3.1.13 uncertainty—parameter associated with the result of

“unknown”, or both. Set of operations that establish, under a measurement, that characterizes the dispersion of the values

specified conditions, the relationship between values of quan- that could reasonably be attributed to the measurand. The

tities indicated by a measuring instrument or measuring sys- range of values within which the true value is estimated to lie.

tem, or values represented by a material measure or a reference 3.1.14 U.S. National prototype standard—platinumiridium

material, and the corresponding values realized by standards. kilogramidentifiedasK20,maintainedattheNationalInstitute

3.1.3 certificate of tolerance test—document that certifies of Standards and Technology, with value assigned relative to

that the subject weights are within specified tolerances. the International Prototype Kilogram provides the United

3.1.3.1 Discussion—If traceability is claimed, some level of States access to the mass unit.

uncertainty must be addressed. 3.1.15 weight (mass standard)—a material measure of

3.1.4 certificate or report of calibration—document that mass, regulated in regard to its physical and metrological

presents calibration results and other information relevant to a characteristics: shape, dimension, material, surface quality,

9 7

calibration. nominal value, and maximum permissible error.

3.1.5 conventional mass—conventional value of the result 3.1.15.1 Discussion—Not to be confused with a gravita-

of weighing in air, in accordance to International Recommen- tional force.

dation OIML R 33. For a weight taken at 20°C, the conven-

tional mass is the mass of a reference weight of a density of 4. Maximum Permissible Errors (Tolerances)

3 3

8000 kg/m which it balances in air of density of 1.2 kg/m .

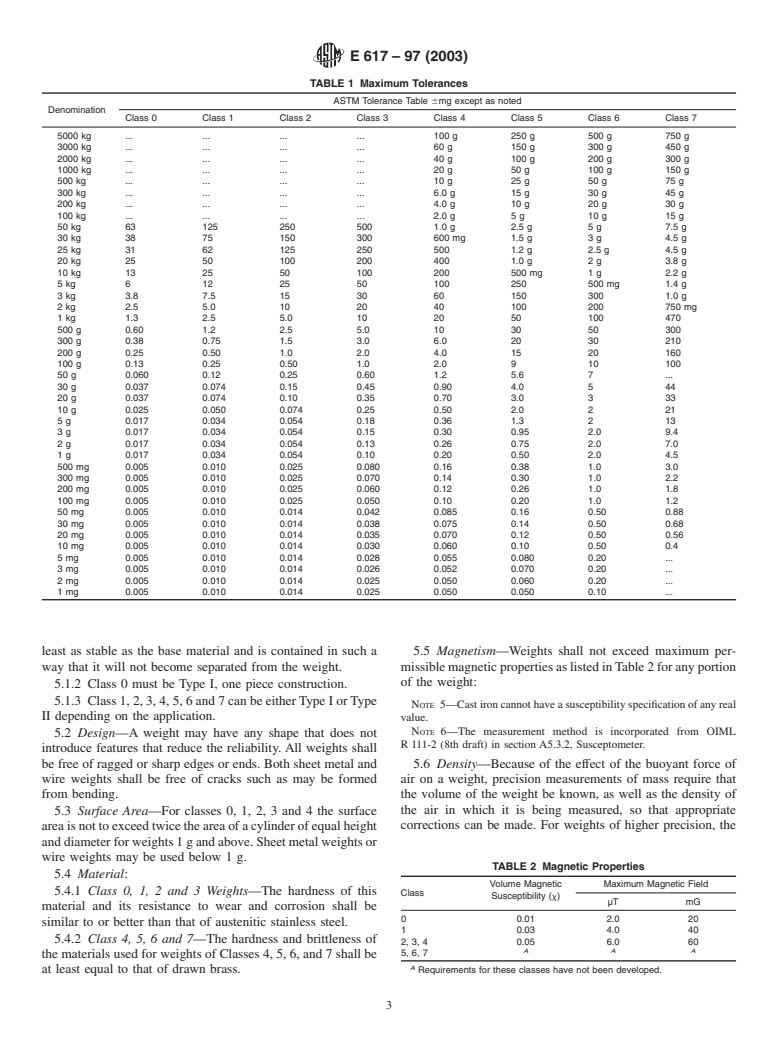

4.1 For each weight, the expanded uncertainty U at 95 %

3.1.5.1 Discussion—Formerly known as apparent mass ver-

confidence (SeeAnnex B of OIML R 111) of the conventional

sus 8.0 g/cm .

mass shall be less than or equal to one-third of the maximum

3.1.6 correction—mass values are traditionally expressed

permissible error given in Table 1.

by two numbers, one being the nominal mass of the weight,

4.1.1 For each weight, the conventional mass, m (deter-

c

and the second being a correction. The mass of the weight is

mined with an expanded uncertainty), shall not differ by more

the assigned nominal value plus the assigned correction.

than the difference: maximum permissible error dm minus

Positive corrections indicate that the weight embodies more

expanded uncertainty, from the nominal value of the weight,

mass than is indicated by the assigned nominal value.

m :

o

3.1.7 international prototype kilogram—the platinum-

m 2 dm 2 U # m # m 1 dm 2 U (1)

~ ! ~ ! ~ !

o c o

iridium cylinder maintained at the International Bureau of

Weights and Measures (BIPM), at Sevres, France with an

4.2 Maximumpermissibleerrors(tolerances)onverification

internationally accepted defined mass of 1 kg.

for classes 0, 1, 2, 3, 4, 5, 6 and 7 are given in Table 1. These

3.1.8 reference standard—a standard, generally of the high-

maximum permissible errors are related to conventional mass

est metrological quality available at a given location, from

values.

which measurements made at that location are derived.

3.1.9 set of weights—a series of weights, usually presented

NOTE 1—Consistent with OIML R 111 the concept of group tolerances

in a case so arranged to make possible any weighing of all

has been dropped in the 1997 revision of this specification.

loadsbetweenthemassoftheweightwiththesmallestnominal NOTE 2—Tolerances for weights of denominations intermediate be-

tween those listed can be determined as follows. If the unit of measure is

value and the sum of the masses of all weights of the series

non-metric use the conversion factor from the Abbreviations of Terms

with a progression in which the mass of the smallest nominal

table in Appendix X3 to convert the nominal value to a metric unit. For

value weight constitutes the smallest step of the series.

weights that are intermediate between those listed, the tolerance for the

3.1.10 tolerance (adjustment tolerance or maximum permis-

next lower weight shall be applied.

sible errors)—the maximum amount by which the conven-

NOTE 3—Class 0 is a new designation with tolerances that are 50 % of

tional mass of the weight is allowed to deviate from the

Class 1, with physical characteristics the same as those of OIML R 111

assigned nominal value.

Class E1.

3.1.11 tolerance test—verification that the conventional NOTE 4—Class 7 is a new designation with the same tolerances as the

former Class T in NBS Circular 3 (out of print).

mass of the weights and their corresponding uncertainties as

testedarecorrectwithinthemaximumpermissibleerrorsofthe

5. Physical Characteristics

respective weight class.

5.1 Construction:

3.1.12 traceability—propertyoftheresultofameasurement

5.1.1 Type—Weights are divided into two types based upon

or the value of a standard whereby it can be related to stated

the design:

references, usually national or international standards, through

5.1.1.1 Type I—Theseweightsareofone-piececonstruction

an unbroken chain of comparisons all having stated uncertain-

and contain no added adjusting material. They must be

ties.

specified when weights are to be used as standards for the

3.1.12.1 Discussion—For more information see 3.1.14.

calibration of weights of Classes 0, 1, 2 and 3, and where

maximum stability is required. A precise measurement of

Definition from International Vocabulary of Basic and General Terms in

density can only be made for one-piece weights.

Metrology.

5.1.1.2 Type II—Weights of this type can be of any appro-

Definition from NCSL Z-540-1-1994.

priate design such as screw knob, ring, or sealed plug.

Definition from OIML R33.

Definition from NIST/NVLAP Handbook 150. Adjusting material can be used as long as it is of a material at

E 617 – 97 (2003)

TABLE 1 Maximum Tolerances

ASTM Tolerance Table 6mg except as noted

Denomination

Class 0 Class 1 Class 2 Class 3 Class 4 Class 5 Class 6 Class 7

5000 kg . . . . 100 g 250 g 500 g 750 g

3000 kg . . . . 60 g 150 g 300 g 450 g

2000 kg . . . . 40 g 100 g 200 g 300 g

1000 kg . . . . 20 g 50 g 100 g 150 g

500 kg . . . . 10 g 25 g 50 g 75 g

300 kg . . . . 6.0 g 15 g 30 g 45 g

200 kg . . . . 4.0 g 10 g 20 g 30 g

100 kg . . . . 2.0 g 5 g 10 g 15 g

50 kg 63 125 250 500 1.0 g 2.5 g 5 g 7.5 g

30 kg 38 75 150 300 600 mg 1.5 g 3 g 4.5 g

25 kg 31 62 125 250 500 1.2 g 2.5 g 4.5 g

20 kg 25 50 100 200 400 1.0 g 2 g 3.8 g

10 kg 13 25 50 100 200 500 mg 1 g 2.2 g

5 kg 6 12 25 50 100 250 500 mg 1.4 g

3 kg 3.8 7.5 15 30 60 150 300 1.0 g

2 kg 2.5 5.0 10 20 40 100 200 750 mg

1 kg 1.3 2.5 5.0 10 20 50 100 470

500 g 0.60 1.2 2.5 5.0 10 30 50 300

300 g 0.38 0.75 1.5 3.0 6.0 20 30 210

200 g 0.25 0.50 1.0 2.0 4.0 15 20 160

100 g 0.13 0.25 0.50 1.0 2.0 9 10 100

50 g 0.060 0.12 0.25 0.60 1.2 5.6 7 .

30 g 0.037 0.074 0.15 0.45 0.90 4.0 5 44

20 g 0.037 0.074 0.10 0.35 0.70 3.0 3 33

10 g 0.025 0.050 0.074 0.25 0.50 2.0 2 21

5 g 0.017 0.034 0.054 0.18 0.36 1.3 2 13

3 g 0.017 0.034 0.054 0.15 0.30 0.95 2.0 9.4

2 g 0.017 0.034 0.054 0.13 0.26 0.75 2.0 7.0

1 g 0.017 0.034 0.054 0.10 0.20 0.50 2.0 4.5

500 mg 0.005 0.010 0.025 0.080 0.16 0.38 1.0 3.0

300 mg 0.005 0.010 0.025 0.070 0.14 0.30 1.0 2.2

200 mg 0.005 0.010 0.025 0.060 0.12 0.26 1.0 1.8

100 mg 0.005 0.010 0.025 0.050 0.10 0.20 1.0 1.2

50 mg 0.005 0.010 0.014 0.042 0.085 0.16 0.50 0.88

30 mg 0.005 0.010 0.014 0.038 0.075 0.14 0.50 0.68

20 mg 0.005 0.010 0.014 0.035 0.070 0.12 0.50 0.56

10 mg 0.005 0.010 0.014 0.030 0.060 0.10 0.50 0.4

5 mg 0.005 0.010 0.014 0.028 0.055 0.080 0.20 .

3 mg 0.005 0.010 0.014 0.026 0.052 0.070 0.20 .

2 mg 0.005 0.010 0.014 0.025 0.050 0.060 0.20 .

1 mg 0.005 0.010 0.014 0.025 0.050 0.050 0.10 .

least as stable as the base material and is contained in such a 5.5 Magnetism—Weights shall not exceed maximum per-

way that it will not become separated from the weight. missiblemagneticpropertiesaslistedinTable2foranyportion

of the weight:

5.1.2 Class 0 must be Type I, one piece construction.

5.1.3 Class 1, 2, 3, 4, 5, 6 and 7 can be eitherType I orType

NOTE 5—Castironcannothaveasusceptibilityspecificationofanyreal

II depending on the application.

value.

NOTE 6—The measurement method is incorporated from OIML

5.2 Design—A weight may have any shape that does not

R 111-2 (8th draft) in section A5.3.2, Susceptometer.

introduce features that reduce the reliability. All weights shall

be free of ragged or sharp edges or ends. Both sheet metal and 5.6 Density—Because of the effect of the buoyant force of

wire weights shall be free of cracks such as may be formed air on a weight, precision measurements of mass require that

from bending. the volume of the weight be known, as well as the density of

the air in which it is being measured, so that appropriate

5.3 Surface Area—For classes 0, 1, 2, 3 and 4 the surface

corrections can be made. For weights of higher precision, the

areaisnottoexceedtwicetheareaofacylinderofequalheight

anddiameterforweights1gandabove.Sheetmetalweightsor

wire weights may be used below 1 g.

TABLE 2 Magnetic Properties

5.4 Material:

Volume Magnetic Maximum Magnetic Field

5.4.1 Class 0, 1, 2 and 3 Weights—The hardness of this

Class

Susceptibility (x)

µT mG

material and its resistance to wear and corrosion shall be

0 0.01 2.0 20

similar to or better than that of austenitic stainless steel.

1 0.03 4.0 40

5.4.2 Class 4, 5, 6 and 7—The hardness and brittleness of

2, 3, 4 0.05 6.0 60

AA A

5, 6, 7

the materials used for weights of Classes 4, 5, 6, and 7 shall be

A

at least equal to that of drawn brass. Requirements for these classes have not been developed.

E 617 – 97 (2003)

TABLE 4 Maximum Values of Surface Roughness

range of density is limited to values at or near the density of

well-established standards, such as are used by primary cali- Classes 0 and 1 Classes 2, 3, 4 Class 5, 6, 7

R (µm) 0.025 0.05 0.8

A

bration laboratories. As lower precision of measurement is

R (µm) 0.35 0.67 3.2

Z

requir

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.