ASTM E1602-94

(Guide)Standard Guide for Construction of Solid Fuel Burning Masonry Heaters

Standard Guide for Construction of Solid Fuel Burning Masonry Heaters

SCOPE

1.1 This guide covers the design and construction of solid fuel burning masonry heaters. It provides dimensions for site constructed masonry heater components and clearances that have been derived by experience and found to be consistent with the safe installation of those masonry heaters.

1.2 Values given in SI units are to be regarded as standard. Inch/pound units may be rounded (see IEEE/ASTM SI-10). All dimensions are nominal unless specifically stated otherwise. All clearances listed in this guide are actual dimensions.

1.3 This guide applies to the design and construction of masonry heaters built on-site with the components and materials specified herein. It does not apply to the construction/installation requirements for component systems that have been safety tested and listed. The requirements for listed masonry heater systems are specified in the manufacturer's installation instructions.

1.4 The design and construction of solid fuel burning masonry heaters shall comply with applicable building codes.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 1602 – 94 An American National Standard

Standard Guide for

Construction of Solid Fuel Burning Masonry Heaters

This standard is issued under the fixed designation E 1602; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Building Heating Appliances

1.1 This guide covers the design and construction of solid

3. Terminology

fuel burning masonry heaters. It provides dimensions for site

3.1 Terms used in this guide are as defined in Terminology

constructed masonry heater components and clearances that

C 11, Definitions C 43, Terminology C 71, and Classification

have been derived by experience and found to be consistent

C 401.

with the safe installation of those appliances.

3.2 Definitions of Terms Specific to This Standard:

1.2 Values given in SI units are to be regarded as standard.

3.2.1 approved—acceptable to the authority having jurisdic-

Inch/pound units may be rounded (see Practice E 380). All

tion.

dimensions are nominal unless specifically stated otherwise.

3.2.2 authority having jurisdiction—the organization, of-

All clearances listed in this guide are actual dimensions.

fice, individual, or agent thereof, who is responsible for

1.3 This guide applies to the design and construction of

approving construction, materials, equipment, installation, pro-

masonry heaters built on-site with the components and mate-

cedure, etc. In most cases in which a building permit is

rials specified herein. It does not apply to the construction/

required, the authority is typically the building official or his

installation requirements for component systems that have

agent. Where a building permit is not required, the authority is

been safety tested and listed. The requirements for listed

typically the owner or his agent.

masonry heater systems are specified in the manufacturer’s

3.2.3 bypass damper—a valve or plate that provides a direct

installation instructions.

path to the chimney flue for the flue gases or portion thereof.

1.4 The design and construction of solid fuel burning

3.2.4 capping slab—a horizontal refractory barrier covering

masonry heaters shall comply with applicable building codes.

the top of the heater.

2. Referenced Documents 3.2.5 cleanout opening—an access opening in a flue pas-

sageway of the heater or chimney that is designed to allow

2.1 ASTM Standards:

access to the flue for purposes of inspecting for and removing

C 11 Terminology Relating to Gypsum and Related Build-

ash, soot, and other extraneous matter that may become

ing Materials and Systems

trapped.

C 43 Terminology of Structural Clay Products

3.2.6 damper—an adjustable valve or plate for controlling

C 71 Terminology Relating to Refractories

2,3

draft or the flow of gases, including air.

C 270 Specification for Mortar for Unit Masonry

3.2.7 firebox (firechamber)—that portion of the masonry

C 401 Classification of Alumina and Alumina-Silicate

heater that is designed for containing and burning the fuel

Castable Refractories

charge.

E 136 Test Method for Behavior of Materials in a Vertical

3.2.8 gas slot—a small fixed opening that provides a bypass

Tube Furnace at 750°C

for unburned flue gases, and is a critical safety feature in

E 380 Practice for Use of the International System of Units

certain heater designs (namely those of the Grundofen type

(SI) (the Modernized Metric System)

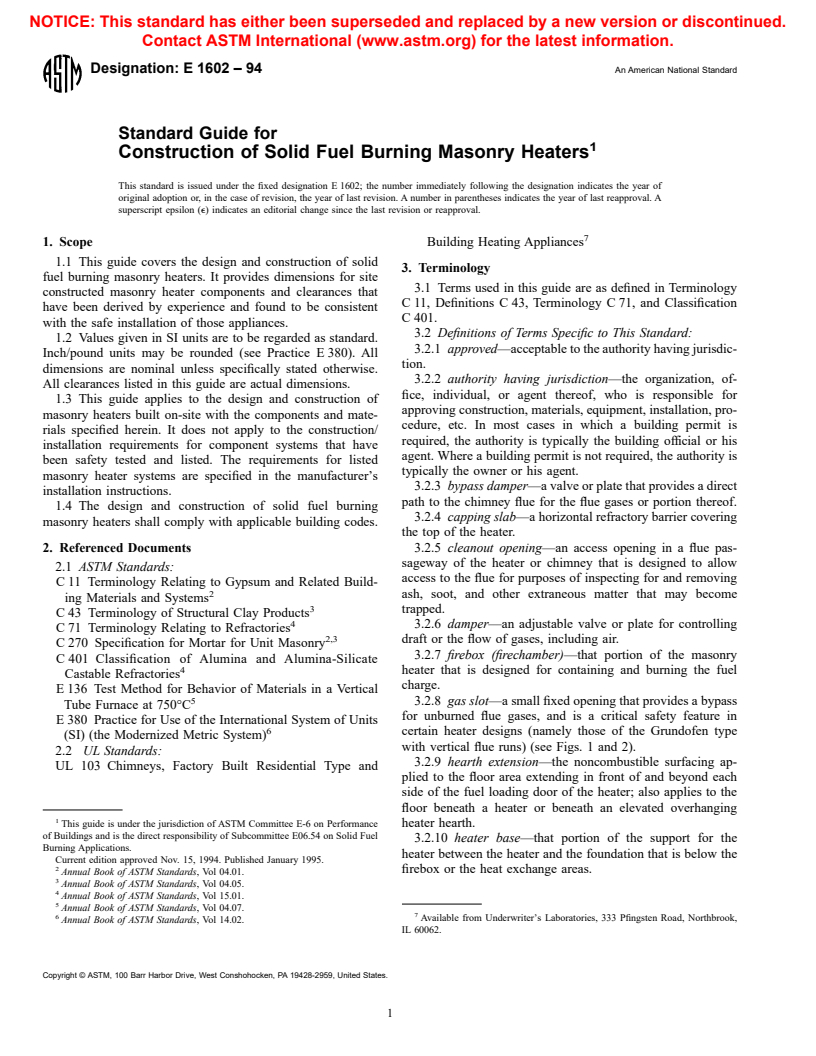

with vertical flue runs) (see Figs. 1 and 2).

2.2 UL Standards:

3.2.9 hearth extension—the noncombustible surfacing ap-

UL 103 Chimneys, Factory Built Residential Type and

plied to the floor area extending in front of and beyond each

side of the fuel loading door of the heater; also applies to the

floor beneath a heater or beneath an elevated overhanging

This guide is under the jurisdiction of ASTM Committee E-6 on Performance heater hearth.

of Buildings and is the direct responsibility of Subcommittee E06.54 on Solid Fuel

3.2.10 heater base—that portion of the support for the

Burning Applications.

heater between the heater and the foundation that is below the

Current edition approved Nov. 15, 1994. Published January 1995.

firebox or the heat exchange areas.

Annual Book of ASTM Standards, Vol 04.01.

Annual Book of ASTM Standards, Vol 04.05.

Annual Book of ASTM Standards, Vol 15.01.

Annual Book of ASTM Standards, Vol 04.07.

Available from Underwriter’s Laboratories, 333 Pfingsten Road, Northbrook,

Annual Book of ASTM Standards, Vol 14.02.

IL 60062.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

E 1602

1. Capping Slab 11. Flue Liner

2. Chimney 12. Gas Slot

3. Clean-Out 13. Brick

4. Combustion Air 14. Hearth Extension

5. Downdraft Channel 15. Heat Exchange Area

6. Exhaust Gas 16. Shut-Off Damper

7. Exterior Wall 17. Updraft Channel

8. Firebox 18. Expansion Joint

9. Firebox Door 19. Insulation Joint

10. Firebox Wall 20. Heater Base

FIG. 1 Multi-Flue Heater (Russian)

3.2.11 heat-exchange flue channel—a chamber or passage- 3.2.14 masonry heater—a vented heating system of pre-

way between the firebox and the chimney flue in which heat

dominantly masonry construction having a mass of at least 800

resulting directly from combustion of fuel is transferred to the

kg (1760 lbs), excluding the chimney and heater base. In

surrounding masonry.

particular, a unit designed specifically to capture and store a

3.2.12 kachel—a European term used to describe a masonry

substantial portion of the heat energy from a solid fuel fire in

heater tile; a refractory ceramic tile intended for the outer wall

the mass of the appliance through internal heat exchange flue

of a masonry heater that is designed specifically to store and

channels; enable a charge of solid fuel mixed with an adequate

transfer heat.

amount of air to burn rapidly and more completely at high

3.2.13 listed—equipment or materials included in a list

temperatures in order to reduce emission of unburned hydro-

published by an organization concerned with product evalua-

carbons; and be constructed of sufficient mass and surface area

tion acceptable to the authority having jurisdiction to conduct

such that under normal operating conditions, the external

periodic inspection of production of listed equipment or

surface temperature of the heater (except in the region imme-

materials and whole listing states either that the equipment or

diately surrounding the fuel loading door(s)), does not exceed

materials meet appropriate standards or have been tested and

110°C (230°F).

found suitable for use in a specified manner.

E 1602

4. Significance and Use

4.1 This guide can be used by code officials, architects, and

other interested parties to evaluate the design and construction

of masonry heaters. It is not restricted to a specific method of

construction, nor does it provide all specific details of con-

struction of a masonry heater. This guide does provide the

principles to be followed for the safe construction of masonry

heaters.

4.2 This guide is not intended as a complete set of directions

for construction of masonry heaters.

4.3 Construction of these units is complex, and in order to

ensure their safety and performance, construction shall be done

by or under the supervision of a skilled and experienced

masonry heater builder.

5. Requirements

5.1 Foundation—Masonry heater foundations and founda-

tion walls shall meet local building codes for standard masonry

fireplaces and shall be designed with consideration given to the

mass and size of the heater.

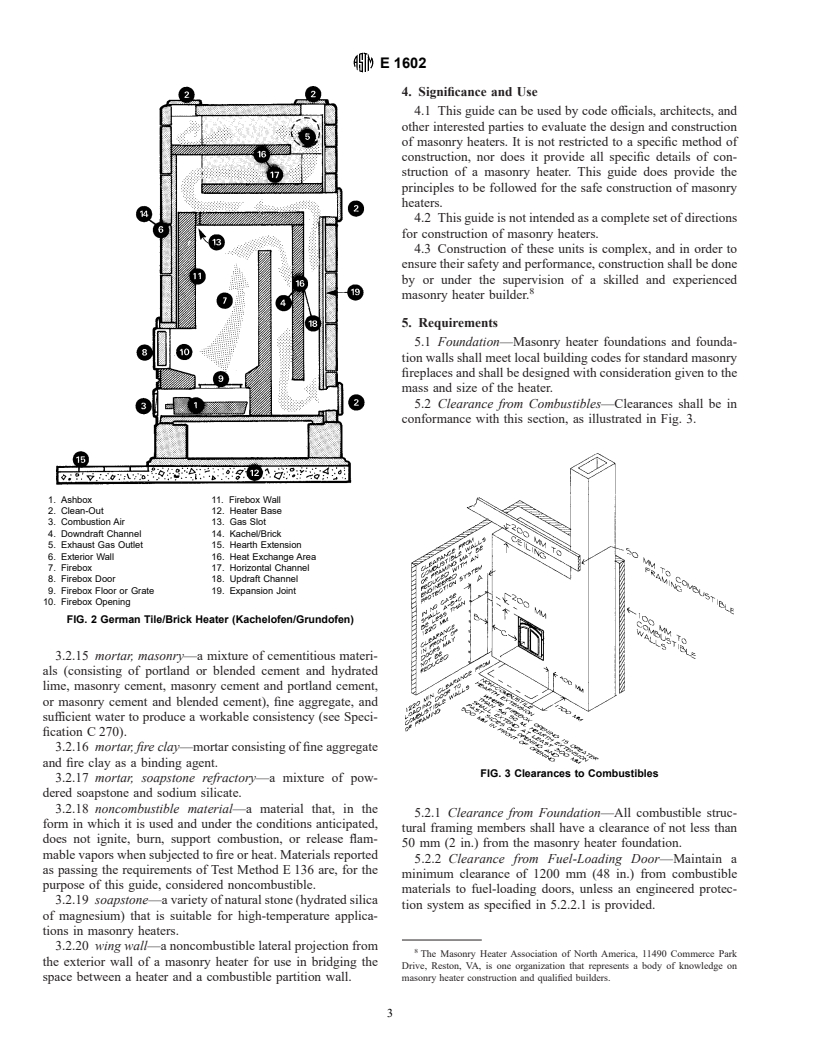

5.2 Clearance from Combustibles—Clearances shall be in

conformance with this section, as illustrated in Fig. 3.

1. Ashbox 11. Firebox Wall

2. Clean-Out 12. Heater Base

3. Combustion Air 13. Gas Slot

4. Downdraft Channel 14. Kachel/Brick

5. Exhaust Gas Outlet 15. Hearth Extension

6. Exterior Wall 16. Heat Exchange Area

7. Firebox 17. Horizontal Channel

8. Firebox Door 18. Updraft Channel

9. Firebox Floor or Grate 19. Expansion Joint

10. Firebox Opening

FIG. 2 German Tile/Brick Heater (Kachelofen/Grundofen)

3.2.15 mortar, masonry—a mixture of cementitious materi-

als (consisting of portland or blended cement and hydrated

lime, masonry cement, masonry cement and portland cement,

or masonry cement and blended cement), fine aggregate, and

sufficient water to produce a workable consistency (see Speci-

fication C 270).

3.2.16 mortar, fire clay—mortar consisting of fine aggregate

and fire clay as a binding agent.

FIG. 3 Clearances to Combustibles

3.2.17 mortar, soapstone refractory—a mixture of pow-

dered soapstone and sodium silicate.

3.2.18 noncombustible material—a material that, in the

5.2.1 Clearance from Foundation—All combustible struc-

form in which it is used and under the conditions anticipated,

tural framing members shall have a clearance of not less than

does not ignite, burn, support combustion, or release flam-

50 mm (2 in.) from the masonry heater foundation.

mable vapors when subjected to fire or heat. Materials reported

5.2.2 Clearance from Fuel-Loading Door—Maintain a

as passing the requirements of Test Method E 136 are, for the

minimum clearance of 1200 mm (48 in.) from combustible

purpose of this guide, considered noncombustible.

materials to fuel-loading doors, unless an engineered protec-

3.2.19 soapstone—a variety of natural stone (hydrated silica

tion system as specified in 5.2.2.1 is provided.

of magnesium) that is suitable for high-temperature applica-

tions in masonry heaters.

3.2.20 wing wall—a noncombustible lateral projection from

The Masonry Heater Association of North America, 11490 Commerce Park

the exterior wall of a masonry heater for use in bridging the

Drive, Reston,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.