ASTM D3401-97(2022)

(Test Method)Standard Test Methods for Water in Halogenated Organic Solvents and Their Admixtures

Standard Test Methods for Water in Halogenated Organic Solvents and Their Admixtures

SIGNIFICANCE AND USE

4.1 High water concentrations can have a detrimental effect on many uses of halogenated solvents.

4.1.1 Water can cause corrosion and spotting when solvents are used for metal cleaning.

4.1.2 Water can reduce the shelf life of aerosol formulations.

4.1.3 Water can inhibit desired reactions when solvents are used in formulations.

SCOPE

1.1 These test methods describe the use of the Karl Fischer (KF) titration for determination of water in halogenated organic solvents and mixtures thereof. Water concentrations from 2 ppm to 1000 ppm can be determined in these solvents. Two test methods are covered as follows:

1.1.1 Test Method A, Water Determination Using a Coulometric KF Titrator—The coulometric test method is known for its high degree of sensitivity (typically 2O) and should be the test method of choice if water concentrations are typically below 50 ppm or if only small amounts of sample are available for water determinations. This test method requires the use of equipment specifically designed for coulometric titrations.

1.1.2 Test Method B, Water Determination Using a Volumetric KF Titrator—The volumetric test method is a more traditional approach to KF water determinations. Although titrators are specifically designed for KF volumetric determinations, many automatic titrators on the market can be adapted to perform KF titrations.

1.2 Either of these test methods can be used to determine typical water concentrations (15 ppm to 500 ppm) found in halogenated solvents.

1.3 These test methods recommend the use of commercially available Karl Fischer titrators and reagents.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see Sections 11 and 15.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D3401 − 97 (Reapproved 2022)

Standard Test Methods for

Water in Halogenated Organic Solvents and Their

Admixtures

This standard is issued under the fixed designation D3401; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

1.1 These test methods describe the use of the Karl Fischer

Barriers to Trade (TBT) Committee.

(KF) titration for determination of water in halogenated or-

ganicsolventsandmixturesthereof.Waterconcentrationsfrom

2. Referenced Documents

2 ppm to 1000 ppm can be determined in these solvents. Two

2.1 ASTM Standard:

test methods are covered as follows:

E203 Test Method for Water Using Volumetric Karl Fischer

1.1.1 Test Method A, Water Determination Using a Coulo-

Titration

metric KF Titrator—The coulometric test method is known for

itshighdegreeofsensitivity(typically<10µgH O)andshould

3. Summary of Test Method

be the test method of choice if water concentrations are

typically below 50 ppm or if only small amounts of sample are 3.1 In the Karl Fischer reaction, water will react with iodine

available for water determinations. This test method requires in the presence of sulfur dioxide, alcohol, and an organic base

the use of equipment specifically designed for coulometric according to the following equation:

titrations.

H O1I 1SO 1CH OH13RN→ RNH SO CH 12 RNH I (1)

~ ! ~ !

2 2 2 3 4 3

1.1.2 TestMethodB,WaterDeterminationUsingaVolumet-

where RN = organic base.

ric KF Titrator—The volumetric test method is a more tradi-

tional approach to KF water determinations.Although titrators

3.2 When the volumetric titration test method is used for

are specifically designed for KF volumetric determinations,

this determination, the halogenated sample is added to a KF

many automatic titrators on the market can be adapted to

solvent that usually consists of sulfur dioxide and an amine

perform KF titrations.

dissolved in anhydrous methanol. This solution is titrated with

1.2 Either of these test methods can be used to determine an anhydrous solvent containing iodine. The iodine titrant is

first standardized by titrating a known amount of water.

typical water concentrations (15 ppm to 500 ppm) found in

halogenated solvents.

3.3 In the coulometric titration test method, the sample is

injected into an electrolytic cell where the iodine required for

1.3 These test methods recommend the use of commercially

the reaction with water is produced by anodic oxidation of

available Karl Fischer titrators and reagents.

iodide. With this technique, no standardization of reagents is

1.4 This standard does not purport to address all of the

required.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 3.4 In both test methods, the end point is determined

priate safety, health, and environmental practices and deter- amperometrically with a platinum electrode that senses a sharp

mine the applicability of regulatory limitations prior to use. change in cell resistance when the iodine has reacted with all

For specific precautionary statements, see Sections 11 and 15. of the water in the sample.

1.5 This international standard was developed in accor-

4. Significance and Use

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

4.1 High water concentrations can have a detrimental effect

on many uses of halogenated solvents.

These test methods are under the jurisdiction of ASTM Committee D26 on

Halogenated Organic Solvents and Fire Extinguishing Agents and are the direct

responsibility of Subcommittee D26.04 on Test Methods. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2022. Published May 2022. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1975. Last previous edition approved in 2017 as D3401 – 97(2017). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D3401-97R22. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3401 − 97 (2022)

NOTE 1—Pyridine was the organic amine that was traditionally used in

4.1.1 Water can cause corrosion and spotting when solvents

Karl Fisher reagents, however, pyridine-free formulations are now avail-

are used for metal cleaning.

ableandpreferredbymostKFinstrumentmanufacturersforusewiththeir

4.1.2 Water can reduce the shelf life of aerosol formula-

equipment. Pyridine-free reagents are said to be less toxic, less odorous,

tions.

and more stable than pyridine types.

4.1.3 Water can inhibit desired reactions when solvents are

used in formulations. 8. Sampling

8.1 Since halogenated solvents normally contain low con-

5. Interferences

centrations of water, care must be taken to eliminate the

5.1 Certain compounds or classes of compounds interfere

introduction of water from sampling equipment and atmo-

with the accurate determination of water by the Karl Fischer

spheric moisture.

test method. They include aldehydes, ketones, free halogens,

8.2 Without taking the proper sampling precautions, more

ferric salts, and strong oxidizing and reducing agents.

error is typically introduced into the determination of water

5.2 Free halogens can oxidize the iodate in the KF reagents

through sampling techniques than in the titration process itself.

to form iodine; this causes erroneously low water values.

8.3 Drysamplebottlesandclosuresinanovenat110 °Cfor

5.3 A more detailed discussion of KF interferences can be

several hours. Place caps on the bottles immediately after

3,4

found in Test Method E203 and other sources.

removing from the oven.

6. Apparatus 8.4 Transfer solvent to the bottles as quickly as possible.

5 Adjust the liquid level to come within 1 in. of the top of the

6.1 Coulometric Titrator, (for Test Method A only) con-

bottle. Immediately place the cap on the bottle and tighten.

sisting of a single or dual bath electrolytic cell, dual platinum

electrode, magnetic stirrer, and control unit. 8.5 When removing a portion of sample from the bottle for

5 KF analysis, use pipets or syringes that have been thoroughly

6.2 Volumetric Titrator, (for Test Method B only) consist-

dried. Replace the cap on the bottle immediately.

ing of a titration cell, dual platinum electrode, magnetic stirrer,

dispensing buret, and control unit. 8.6 If more than one portion of sample is to be taken from

the bottle or if the sample is to be retained for further water

6.3 Syringes, 2 mL, 5 mL, 10 mL, or 20 mL sizes.

analysis, it is a good practice to blanket the top of the bottle

6.4 Syringe, 5 µL size.

with dry nitrogen when removing the sample. If septum cap

closures are being used, dry nitrogen can be introduced with a

6.5 Silicon Rubber Blocks or Silicon Rubber Septa.

syringe at the same time a portion of the sample is being

6.6 Drying Oven, air circulating.

removed with a second syringe.

6.7 Desiccator.

TEST METHOD A—WATER DETERMINATION

6.8 Analytical Balance, capable of weighing to 60.01 g.

USING A COULOMETRIC KF TITRATOR

7. Reagents

9. Summary of Test Method

7.1 Anode Reagent, for dual bath titration (for Test Method

9.1 The dual bath coulometric titration cell consists of a

Aonly), use reagent recommended by manufacturer of titrator.

sealed vessel containing both an anode and cathode compart-

7.2 Cathode Reagent, for dual bath titration (for Test

ment. The anodic compartment usually contains a solution

MethodAonly), use reagent recommended by manufacturer of

consisting of sulfur dioxide, iodide, and an amine in a

titrator.

methanol/chloroform solvent. The cathodic compartment con-

7.3 Single Bath Reagent, (for Test Method A only), use

tains similar reagents optimized for cathodic reduction.

reagent recommended by manufacturer of titrator.

9.2 When a sample containing water is injected into the

7.4 Karl Fischer Volumetric Titrant, (for Test Method B

anode compartment, the electrolytic cell generates its own

only)typicallyconsistsofamixtureofanorganicamine,sulfur

supply of iodine from the iodide present. The iodine reacts

dioxide, and iodine dissolved in a non-hydroscopic solvent(s).

stoichiometrically with the water and the completion of the

Reagents with titers of 1.00 mg, 2.00 mg, and 5.00 mg of

reaction is detected with a platinum sensing electrode. The

H O/mL can be commercially obtained.

coulombs of electricity required to generate the necessary

amountofiodineisthentranslatedbythemicroprocessorinthe

7.5 Karl Fischer Solvent, (for Test Method B only)

control unit into the amount of water that was present in the

typically consists of a mixture of an organic amine and sulfur

sample.

dioxide dissolved in anhydrous methanol.

9.3 The single bath coulometric titration cell consists of a

3 sealed vessel filled with single bath reagent and dual platinum

Mitchell, J., Jr. and Smith, D. M., Aquametry—A Treatise on Methods for the

electrodes.When a sample containing water is injected into the

Determination of Water, Part III—The Karl Fischer Reagent, 2nd ed., J. Wiley and

Sons, Inc., New York, NY, 1977.

vessel, the electrolytic cell generates its own supply of iodine

Hydranal—Eugen Scholz Reagents for Karl Fischer Titration, 4th ed., by

from the iodide present in the single bath reagent. The iodine

Riedel-deHaen Aktiengesellschaft (US Distributor—Cresent Chemical Co., Inc.).

reacts stoichiometrically with the water and the completion of

Automatic coulometric and volumetric titrators are manufactured by many

different companies. the reaction is detected by a platinum sensing electrode. The

D3401 − 97 (2022)

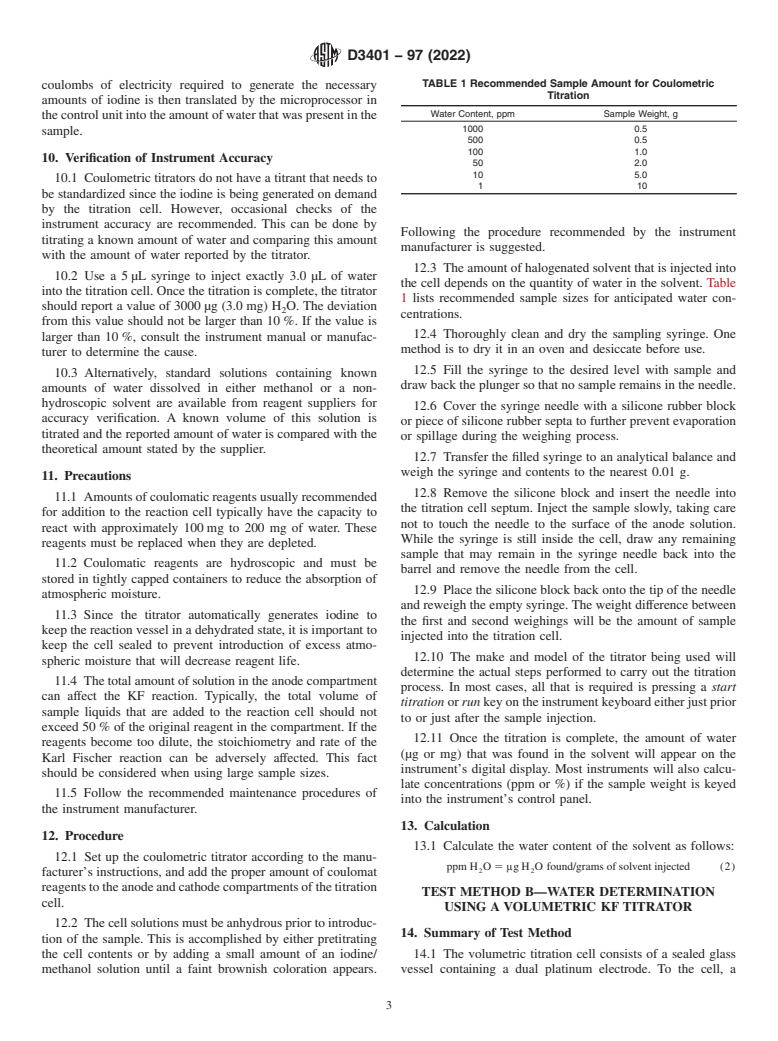

TABLE 1 Recommended Sample Amount for Coulometric

coulombs of electricity required to generate the necessary

Titration

amounts of iodine is then translated by the microprocessor in

Water Content, ppm Sample Weight, g

thecontrolunitintotheamountofwaterthatwaspresentinthe

1000 0.5

sample.

500 0.5

100 1.0

10. Verification of Instrument Accuracy

50 2.0

10 5.0

10.1 Coulometric titrators do not have a titrant that needs to

be standardized since the iodine is being generated on demand

by the titration cell. However, occasional checks of the

instrument accuracy are recommended. This can be done by

Following the procedure recommended by the instrument

titrating a known amount of water and comparing this amount

manufacturer is suggested.

with the amount of water reported by the titrator.

12.3 The amount of halogenated solvent that is injected into

10.2 Use a 5 µL syringe to inject exactly 3.0 µL of water

the cell depends on the quantity of water in the solvent. Table

into the titration cell. Once the titration is complete, the titrator

1 lists recommended sample sizes for anticipated water con-

should report a value of 3000 µg (3.0 mg) H O. The deviation

centrations.

from this value should not be larger than 10 %. If the value is

12.4 Thoroughly clean and dry the sampling syringe. One

larger than 10 %, consult the instrument manual or manufac-

method is to dry it in an oven and desiccate before use.

turer to determine the cause.

12.5 Fill the syringe to the desired level with sample and

10.3 Alternatively, standard solutions containing known

draw back the plunger so that no sample remains in the needle.

amounts of water dissolved in either methanol or a non-

hydroscopic solvent are available from reagent suppliers for

12.6 Cover the syringe needle with a silicone rubber block

accuracy verification. A known volume of this solution is

or piece of silicone rubber septa to further prevent evaporation

titrated and the reported amount of water is compared with the

or spillage during the weighing process.

theoretical amount stated by the supplier.

12.7 Transfer the filled syringe to an analytical balance and

weigh the syringe and contents to the nearest 0.01 g.

11. Precautions

12.8 Remove the silicone block and insert the needle into

11.1 Amounts of coulomatic reagents usually recommended

the titration cell septum. Inject the sample slowly, taking care

for addition to the reaction cell typically have the capacity to

not to touch the needle to the surface of the anode solution.

react with approximately 100 mg to 200 mg of water. These

While the syringe is still inside the cell, draw any remaining

reagents must be replaced when they are depleted.

sample that may remain in the syringe needle back into the

11.2 Coulomatic reagents are hydroscopic and must be

barrel and remove the needle from the cell.

stored in tightly capped containers to reduce the absorption of

12.9 Place the silicone block back onto the tip of the needle

atmospheric moisture.

and reweigh the empty syringe.The weight difference between

11.3 Since the titrator automatically generates iodine to

the first and second weighings will be the amount of sample

keep the reaction vessel in a dehydrated state, it is important to

injected into the titration cell.

keep the cell sealed to prevent introduction of excess atmo-

12.10 The make and model of the titrator being used will

spheric moisture that will decrease reagent life.

determine the actual steps performed to carry out the titration

11.4 The total amount of solution in the anode compartment

process. In most cases, all that is required is pressing a start

can affect the KF reaction. Typically, the total volume of

titrationorrunkeyontheinstrumentkeyboardeitherjustprior

sample liquids that are added to the reaction cell should not

to or just after the sample injection.

exceed 50 % of the original reagent in the compartment. If the

12.11 Once the titration is complete, the amount of water

reagents become too dilute, the stoichiometry and rate of the

(µg or mg) that was found in the solvent will appear on the

Karl Fischer reaction can be adversely affected. This fact

instrument’s digital display. Most instruments will also calcu-

should be considered when using large sample sizes.

late concentrations (ppm or %) if the sample weight is keyed

11.5 Follow the recommended maintenance procedures of

into the instrument’s control panel.

the instrument manufacturer.

13. Calculatio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.