ASTM F610/F610M-00a

(Test Method)Standard Test Method for Evaluating the Quality of Molded Poly(Vinyl Chloride) (PVC) Plastic Pipe Fittings by the Heat Reversion Technique

Standard Test Method for Evaluating the Quality of Molded Poly(Vinyl Chloride) (PVC) Plastic Pipe Fittings by the Heat Reversion Technique

SCOPE

1.1 This test method covers a procedure for evaluating the quality of molded poly(vinyl chloride) (PVC) plastic pipe fittings after exposure to heat.

1.2 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F 610/F 610M – 00a

Standard Test Method for

Evaluating the Quality of Molded Poly(Vinyl Chloride) (PVC)

Plastic Pipe Fittings by the Heat Reversion Technique

This standard is issued under the fixed designation F 610/F 610M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

NOTE 1—A cold slug is a piece of material that enters the mold at a

1. Scope

significantly lower temperature than the rest of the mass.

1.1 This test method covers a procedure for evaluating the

NOTE 2—A stress-free part will generally have better properties and

quality of molded poly(vinyl chloride) (PVC) plastic pipe

higher strength than those with a high degree of stress. Stress-free parts

fittings after exposure to heat.

will generally react better when exposed to chemicals.

1.2 The values stated in either inch-pound units or SI units

4. Apparatus

are to be regarded separately as standard. Within the text, the

SI units are shown in brackets. The values stated in each 4.1 Circulating Air Oven, thermostatically controlled, ca-

system are not exact equivalents; therefore, each system must

pable of operating at 302 6 5.4°F [150 6 3°C] such that after

be used independently of the other. Combining values from the insertion of the fittings to be tested the test temperature is

two systems may result in nonconformance with the specifi-

regained within 15 min or less. (See Annex A1.)

cation.

NOTE 3—The oven should be vented to the outside of the building.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5. Conditioning

responsibility of the user of this standard to establish appro-

5.1 A specific conditioning period is not required although

priate safety and health practices and determine the applica-

the fitting shall be at room temperature. This test can be

bility of regulatory limitations prior to use.

performed on a particular fitting any time after it has been

produced.

2. Summary of Test Method

2.1 A representative sample of the fitting being produced is

6. Procedure

placed in a thermostatically controlled oven at 302 6 5.4°F

6.1 Select the fittings to be tested and examine them for the

[150 6 3°C] for 30 min.The acceptability of the fitting quality,

following, making proper notation for the report:

after the required test time, is based or expressed as a

6.1.1 The condition and appearance of both inner and outer

percentage of the original wall thickness or surface area of the

surfaces of the fitting,

fitting.

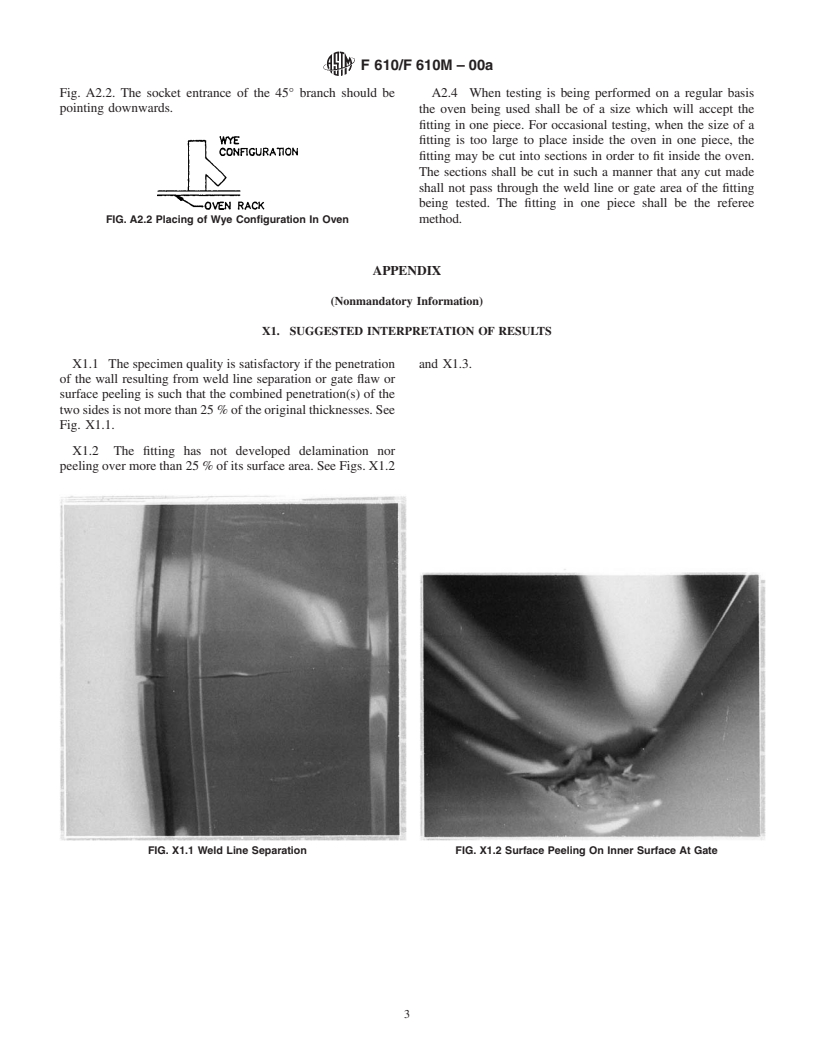

6.1.2 The condition and appearance of the weld lines and

areas adjacent to them,

3. Significance and Use

6.1.3 The condition and appearance of the gate and area

3.1 This test method is applicable to distinguish between

adjacent to it, and

properly and improperly molded PVC plastic pipe fittings. It

6.1.4 The condition and appearance of the internal surface

can be used to:

opposite the gate and gate area.

3.1.1 Determine whether cold slugs or unfused areas are

6.2 Place the fittings to be tested in the oven so that each

present (Note 1),

fitting stands on one of its socket entrances and with sufficient

3.1.2 Determine the amount of molded-in stress produced

separation between individual specimens so that the hot air can

by the molding process (Note 2),

flow freely between them. Record the time when the air in the

3.1.3 Reveal contamination, and

oven recovers to 302 6 5.4°F [150 6 3°C].After an additional

3.1.4 Show the quality of the weld line.

time as indicated in Table 1 at this temperature, remove the

fittings, taking care not to distort or otherwise damage them.

6.2.1 When the fitting being tested has a body and branch

This test method is under the jurisdiction of ASTM Committee F17 on Plastic

wall that falls within two different exposure times, two fittings

Piping Systems and is the direct responsibility of Subcommittee F17.40 on Test

shall be tested. One will be tested using the lower exposure

Methods.

time, and the other will be tested using the longer exposure

Current edition approved August 2000. Published November 2000. Originally

published as F 610 – 79. Last previous edition F 610 – 00. time.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 610/F 610M – 00a

TABLE 1 Exposure Time

8.1.1 Complete identification of the fitting, including the

A

Minimum Wall Thickness, e Exposure Time, min. nominal size, material type and production codes such as part

number, production date, shift, and machine number.

e# 0.118 in. (3 mm) 15

0.118 in. (3 mm) < e# 0.393 in (10 mm) 30

8.1.2 Condition and appearance of weld line and area

0.393 in. (10 mm) < e# 0.787 in (20 mm) 60

adjacent to weld line before and after test.

0.787 in. (20 mm) < e# 1.181 in (30 mm) 140

8.1.3 Condition and appearance of the gate and of the area

1.181 in. (30 mm) < e# 1.574 in (40 mm) 220

e > 1.574 in. (40 mm) 240

opposite the gate on the inner surface before and after the test.

A

Minimum wall thickness refers to the standard’s specified minimum body wall

8.1.4 Condition and appearance of the outer and inner

thickness for the fitting being tested. If a minimum wall thickness is not specified in

surfaces before and after the test.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.