ASTM C756-87(2021)

(Test Method)Standard Test Method for Cleanability of Surface Finishes

Standard Test Method for Cleanability of Surface Finishes

SIGNIFICANCE AND USE

4.1 This test method was developed to guide the user in selecting a finish coating or material that is resistant to soiling in a particular application.

4.2 The numerical values derived by this test method enables the user to rank finish coatings and materials in regard to soil retention or ease of soil removal.

SCOPE

1.1 This test method covers the numerical evaluation of the ease or difficulty of cleaning soiled surface finishes. This test method is applicable to all surface finishes not affected by water.

1.2 Values given in SI units are to be regarded as the standard. Inch-pound units are provided for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C756 − 87 (Reapproved 2021)

Standard Test Method for

1

Cleanability of Surface Finishes

This standard is issued under the fixed designation C756; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This test provides a procedure to quantify the cleanability of acid-resistant porcelain enamel using

a fluorescent water-soluble soil in agent, a reproducible machine-wiping technique, and a means of

measuring the amount of residual soil by fluorescence.

1. Scope and then cleaning the surface with a reproducible machine-

wiping technique. The soil remaining on the specimen after

1.1 This test method covers the numerical evaluation of the

wipingisextractedwithawatersolventandthefluorescenceof

ease or difficulty of cleaning soiled surface finishes. This test

the solution measured. A standard reference surface is treated

method is applicable to all surface finishes not affected by

inasimilarmanner.Thecleanabilityindexofthesurfaceunder

water.

testisexpressedastheratioofthefluorescenceofthesolutions

1.2 Values given in SI units are to be regarded as the

extracted from the test surface and from the standard reference

standard. Inch-pound units are provided for information only.

surface. Cleanability indexes greater than 1.0 indicate that the

1.3 This standard does not purport to address all of the

test surface is more difficult to clean than the standard

safety concerns, if any, associated with its use. It is the

reference surface, while indexes less than 1.0 indicate that the

responsibility of the user of this standard to establish appro-

test surface is more easily cleanable than the standard of

priate safety, health, and environmental practices and deter-

comparison.

mine the applicability of regulatory limitations prior to use.

3.2 The soiling agent used consists of polyethylene glycol,

1.4 This international standard was developed in accor-

a black dye, and a fluorescent tracer, each of which is readily

dance with internationally recognized principles on standard-

water soluble.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

4. Significance and Use

mendations issued by the World Trade Organization Technical

4.1 This test method was developed to guide the user in

Barriers to Trade (TBT) Committee.

selecting a finish coating or material that is resistant to soiling

2. Referenced Documents

in a particular application.

2

2.1 ASTM Standards:

4.2 The numerical values derived by this test method

C282 Test Method for Acid Resistance of Porcelain Enam-

enables the user to rank finish coatings and materials in regard

els(Citric Acid Spot Test)

to soil retention or ease of soil removal.

C614 Test Method forAlkali Resistance of Porcelain Enam-

5. Apparatus

els

5.1 Motor-Driven Lapping Plate, 203-mm (8-in.) diameter,

3. Summary of Test Method

3

speed 163 r/min.

3.1 The test method consists of applying an exact amount of

5.2 Automatic Polishing Unit, 11-s cycle, adjustable to

a fluorescent water-soluble soiling agent to a specimen surface

4

7

48-mm (1 ⁄8-in.) stroke.

1

ThistestmethodisunderthejurisdictionofASTMCommitteeB08onMetallic 5.3 Hypodermic Syringe, glass, 2-mL capacity, without

and Inorganic Coatings and is the direct responsibility of Subcommittee B08.12 on

needle.

Materials for Porcelain Enamel and Ceramic-Metal Systems.

Current edition approved April 1, 2021. Published May 2021. Originally

3

approvedin1973.Lastpreviouseditionapprovedin2016asC756 – 87(2016).DOI: Suitable lapping plates are available from Buehler Ltd., 2120 Greenwood St.,

10.1520/C0756-87R21. Evanston, IL60204, Struers, Inc., 20102 Progress Drive, Cleveland, OH, 44136; or

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or other Metallurgical Supply Sources.

4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM An Olsen “S.M.” Automatic Polisher has been found suitable and is available

Standards volume information, refer to the standard’s Document Summary page on under the code name OLPOL from Struers, Inc., 20102 Progress Drive, Cleveland,

the ASTM website. OH 44136.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

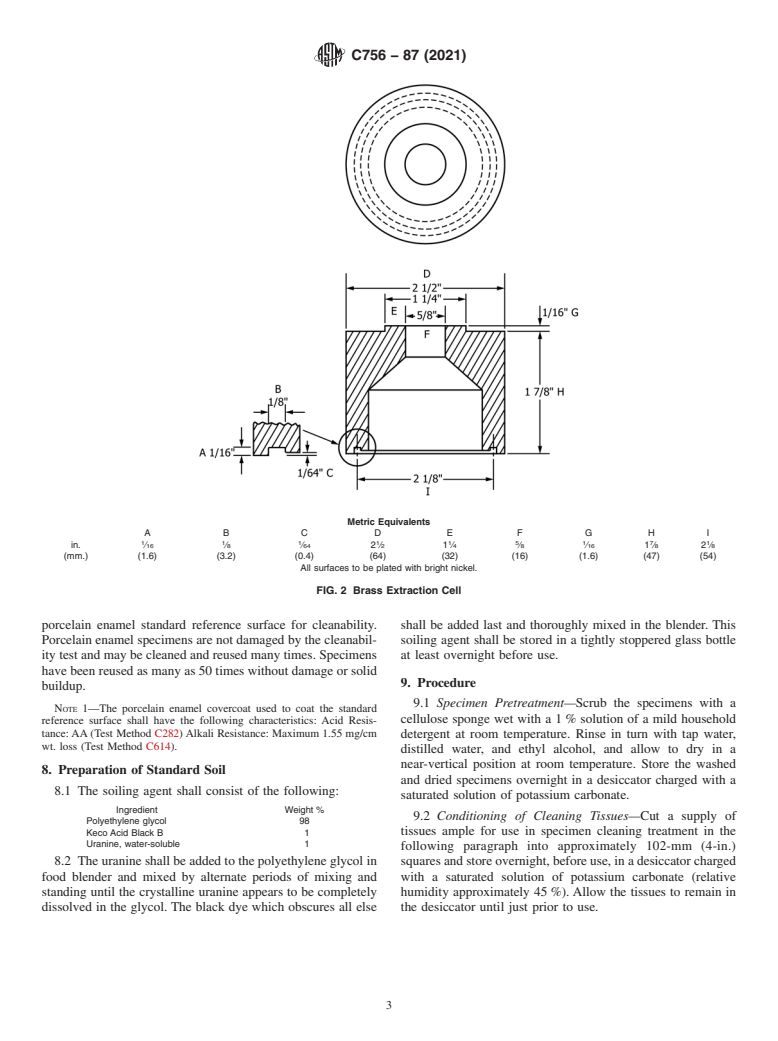

C756 − 87 (2021)

5.4 Repeating Pipet, 0.025 mL (25 µl) capacity. 6. Reagents and Materials

5.5 Repeating Pipet, 10-mL capacity.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.