ASTM D2561-17(2023)

(Test Method)Standard Test Method for Environmental Stress-Crack Resistance of Blow-Molded Polyethylene Containers

Standard Test Method for Environmental Stress-Crack Resistance of Blow-Molded Polyethylene Containers

SIGNIFICANCE AND USE

5.1 When properly used, these procedures serve to isolate such factors as material, blow-molding conditions, post-treatment, and so forth, on the stress-crack resistance of the container.

5.2 Environmental stress cracking of blow-molded containers is governed by many factors. Since variance of any of these factors can change the environmental stress-crack resistance of the container, the test results are representative only of a given test performed under defined conditions in the laboratory. The reproducibility of results between laboratories on containers made on more than one machine from more than one mold has not been established.

5.3 Results can be used for estimating the shelf life of blow-molded containers in terms of their resistance to environmental stress cracking provided this is done against a rigorous background of practical field experience and reproducible test data.

SCOPE

1.1 Under certain conditions of stress, and in the presence of environments such as soaps, wetting agents, oils, or detergents, blow-molded polyethylene containers exhibit mechanical failure by cracking at stresses appreciably below those that would cause cracking in the absence of these environments.

1.2 This test method measures the environmental stress crack resistance of blow-molded containers, which is the summation of the influence of container design, resin, blow-molding conditions, post treatment, or other factors that can affect this property. Three procedures are provided as follows:

1.2.1 Procedure A, Stress-Crack Resistance of Containers to Potential Stress-cracking Liquids—This procedure is particularly useful for determining the effect of container design on stress-crack resistance or the stress-crack resistance of a proposed container that contains a liquid product.

1.2.2 Procedure B, Stress-Crack Resistance of a Specific Container to Polyoxyethylated Nonylphenol (CAS 68412-54-4), a Stress-Cracking Agent—The conditions of test described in this procedure are designed for testing containers made from Class 3 polyethylene Specification D4976. Therefore, this procedure is recommended for containers made from Class 3 polyethylene only. This procedure is particularly useful for determining the effect of resin on the stress-crack resistance of the container.

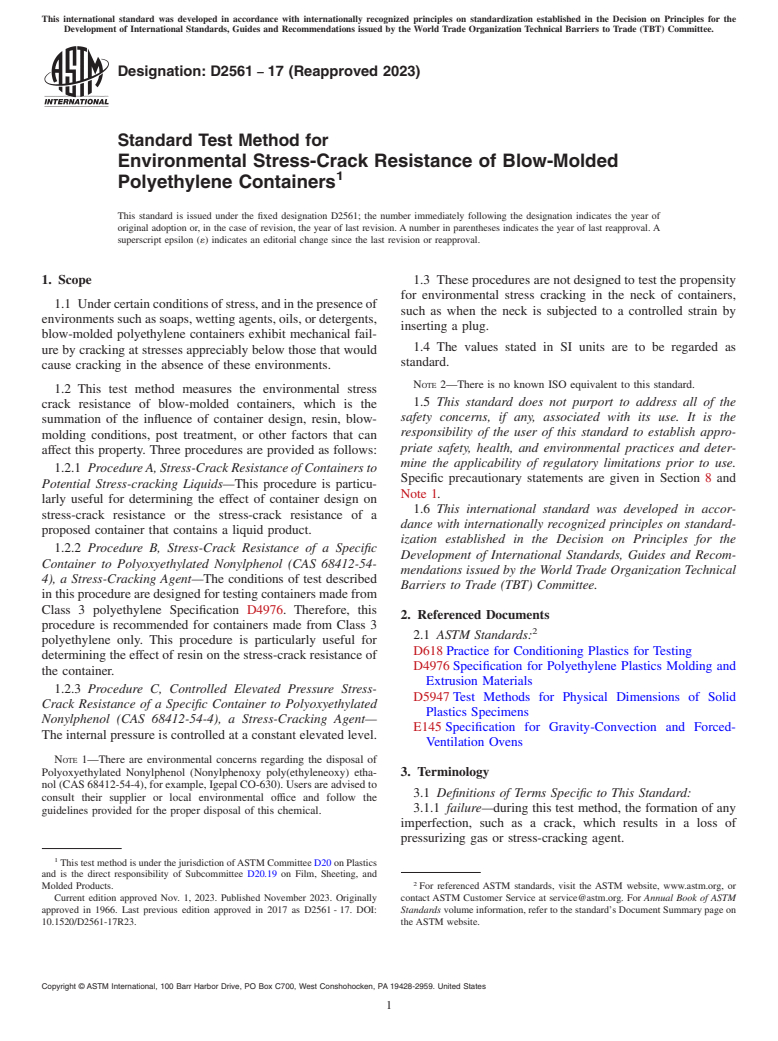

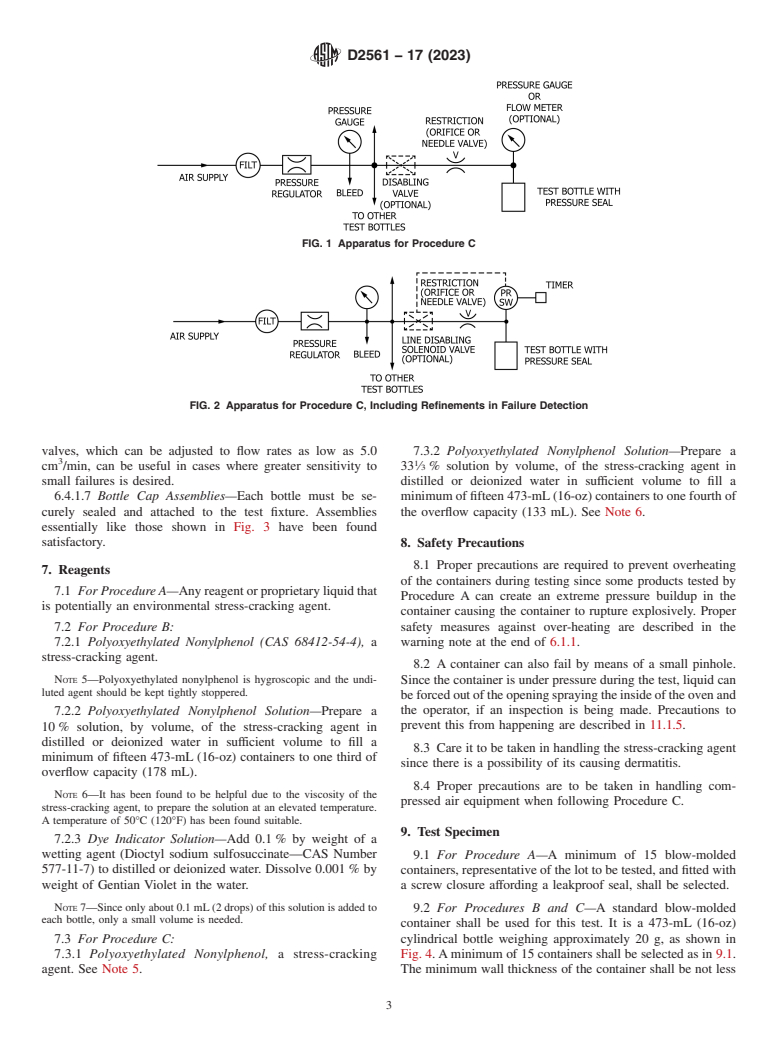

1.2.3 Procedure C, Controlled Elevated Pressure Stress-Crack Resistance of a Specific Container to Polyoxyethylated Nonylphenol (CAS 68412-54-4), a Stress-Cracking Agent—The internal pressure is controlled at a constant elevated level.

Note 1: There are environmental concerns regarding the disposal of Polyoxyethylated Nonylphenol (Nonylphenoxy poly(ethyleneoxy) ethanol (CAS 68412-54-4), for example, Igepal CO-630). Users are advised to consult their supplier or local environmental office and follow the guidelines provided for the proper disposal of this chemical.

1.3 These procedures are not designed to test the propensity for environmental stress cracking in the neck of containers, such as when the neck is subjected to a controlled strain by inserting a plug.

1.4 The values stated in SI units are to be regarded as standard.

Note 2: There is no known ISO equivalent to this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 8 and Note 1.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D2561 − 17 (Reapproved 2023)

Standard Test Method for

Environmental Stress-Crack Resistance of Blow-Molded

1

Polyethylene Containers

This standard is issued under the fixed designation D2561; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.3 These procedures are not designed to test the propensity

for environmental stress cracking in the neck of containers,

1.1 Under certain conditions of stress, and in the presence of

such as when the neck is subjected to a controlled strain by

environments such as soaps, wetting agents, oils, or detergents,

inserting a plug.

blow-molded polyethylene containers exhibit mechanical fail-

1.4 The values stated in SI units are to be regarded as

ure by cracking at stresses appreciably below those that would

standard.

cause cracking in the absence of these environments.

NOTE 2—There is no known ISO equivalent to this standard.

1.2 This test method measures the environmental stress

1.5 This standard does not purport to address all of the

crack resistance of blow-molded containers, which is the

safety concerns, if any, associated with its use. It is the

summation of the influence of container design, resin, blow-

responsibility of the user of this standard to establish appro-

molding conditions, post treatment, or other factors that can

priate safety, health, and environmental practices and deter-

affect this property. Three procedures are provided as follows:

mine the applicability of regulatory limitations prior to use.

1.2.1 Procedure A, Stress-Crack Resistance of Containers to

Specific precautionary statements are given in Section 8 and

Potential Stress-cracking Liquids—This procedure is particu-

Note 1.

larly useful for determining the effect of container design on

1.6 This international standard was developed in accor-

stress-crack resistance or the stress-crack resistance of a

dance with internationally recognized principles on standard-

proposed container that contains a liquid product.

ization established in the Decision on Principles for the

1.2.2 Procedure B, Stress-Crack Resistance of a Specific

Development of International Standards, Guides and Recom-

Container to Polyoxyethylated Nonylphenol (CAS 68412-54-

mendations issued by the World Trade Organization Technical

4), a Stress-Cracking Agent—The conditions of test described

Barriers to Trade (TBT) Committee.

in this procedure are designed for testing containers made from

Class 3 polyethylene Specification D4976. Therefore, this

2. Referenced Documents

procedure is recommended for containers made from Class 3

2

2.1 ASTM Standards:

polyethylene only. This procedure is particularly useful for

D618 Practice for Conditioning Plastics for Testing

determining the effect of resin on the stress-crack resistance of

D4976 Specification for Polyethylene Plastics Molding and

the container.

Extrusion Materials

1.2.3 Procedure C, Controlled Elevated Pressure Stress-

D5947 Test Methods for Physical Dimensions of Solid

Crack Resistance of a Specific Container to Polyoxyethylated

Plastics Specimens

Nonylphenol (CAS 68412-54-4), a Stress-Cracking Agent—

E145 Specification for Gravity-Convection and Forced-

The internal pressure is controlled at a constant elevated level.

Ventilation Ovens

NOTE 1—There are environmental concerns regarding the disposal of

Polyoxyethylated Nonylphenol (Nonylphenoxy poly(ethyleneoxy) etha- 3. Terminology

nol (CAS 68412-54-4), for example, Igepal CO-630). Users are advised to

3.1 Definitions of Terms Specific to This Standard:

consult their supplier or local environmental office and follow the

3.1.1 failure—during this test method, the formation of any

guidelines provided for the proper disposal of this chemical.

imperfection, such as a crack, which results in a loss of

pressurizing gas or stress-cracking agent.

1

This test method is under the jurisdiction of ASTM Committee D20 on Plastics

and is the direct responsibility of Subcommittee D20.19 on Film, Sheeting, and

2

Molded Products. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2023. Published November 2023. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1966. Last previous edition approved in 2017 as D2561 - 17. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D2561-17R23. the ASTM website.

Copyright © ASTM International, 10

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.