ASTM B784-01(2012)

(Specification)Standard Specification for Modified Concentric-Lay-Stranded Copper Conductors for Use in Insulated Electrical Cables

Standard Specification for Modified Concentric-Lay-Stranded Copper Conductors for Use in Insulated Electrical Cables

ABSTRACT

This specification covers bare modified concentric-lay-stranded conductors made from round copper wires, either uncoated or coated with tin, lead, or lead alloy for general use in insulated electrical cables. These conductors shall be constructed with a central core consisting of not more than seven wires, surrounded by one or more layers of helically laid wires. For the purposes of this specification, conductors are classified as Class B modified, class C modified, and Class D modified. The conductors shall meet the prescribed construction requirements such as number of wires and diameter. Welds and brazes may be made in rods or in wires prior to final drawing. Welds and brazes may be made in the finished individual wires composing the conductor, but shall not be closer together than prescribed distance. Tests for the electrical properties of wires composing conductors made from soft or annealed copper wire, bare or coated, shall be made before stranding. Tests for the physical properties of these materials may be made upon the wires before stranding or upon wires removed from the complete stranded conductor.

SCOPE

1.1 This specification covers bare modified concentric-lay-stranded conductors made from round copper wires, either uncoated or coated with tin, lead, or lead alloy for general use in insulated electrical cables. These conductors shall be constructed with a central core consisting of not more than seven wires, surrounded by one or more layers of helically laid wires.

1.2 For the purposes of this specification, conductors are classified as follows (Explanatory Note 1 and Note 2):

1.2.1 Class B Modified—Conductors to be insulated with various materials such as rubber, paper, and crosslink polyethylene.

1.2.2 Class C Modified and Class D Modified—Conductors where greater flexibility is required than is provided by Class B Modified conductors.

1.3 The values stated in inch-pound or SI units are to be regarded separately as standard. Each system shall be used independently of the other. Combining the values from the two systems may result in non- conformance with the specification. For conductor sizes designated by AWG or kcmil sizes, the requirements in SI units are numerically converted from the corresponding requirements in inch-pound units. For conductor sizes designated by AWG or kcmil, the requirements in SI units have been numerically converted from corresponding values stated or derived in inch-pound units. for conductor sizes designated by SI units only, the requirements are stated or derived in SI units.

1.3.1 For density, resitivity and temperature, the values stated in SI units are to be regarded as standard.

Note 1—The significant differences in this specification from Specification B8 are as follows: (1) The central core is permitted to contain up to seven wires drawn into the assembly with an infinite length of lay while Specification B8 permits only one, and (2) The construction is applicable only to stranded assemblies of 19 or more wires.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B784 −01 (Reapproved 2012)

Standard Specification for

Modified Concentric-Lay-Stranded Copper Conductors for

Use in Insulated Electrical Cables

This standard is issued under the fixed designation B784; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This specification covers bare modified concentric-lay- 2.1 The following documents of the issue in effect at the

stranded conductors made from round copper wires, either dateofmaterialpurchaseformapartofthisspecificationtothe

uncoated or coated with tin, lead, or lead alloy for general use extent referenced herein.

in insulated electrical cables. These conductors shall be con-

2.2 ASTM Standards:

structed with a central core consisting of not more than seven

B3 Specification for Soft or Annealed Copper Wire

wires, surrounded by one or more layers of helically laid wires.

B8 Specification for Concentric-Lay-Stranded Copper

1.2 For the purposes of this specification, conductors are Conductors, Hard, Medium-Hard, or Soft

B33 Specification for Tin-Coated Soft or Annealed Copper

classified as follows (Explanatory Note 1 and Note 2):

Wire for Electrical Purposes

1.2.1 Class B Modified—Conductors to be insulated with

B189 Specification for Lead-Coated and Lead-Alloy-Coated

various materials such as rubber, paper, and crosslink polyeth-

Soft Copper Wire for Electrical Purposes

ylene.

B263 Test Method for Determination of Cross-Sectional

1.2.2 Class C Modified and Class D Modified—Conductors

Area of Stranded Conductors

where greater flexibility is required than is provided by Class

B354 Terminology Relating to Uninsulated Metallic Electri-

B Modified conductors.

cal Conductors

1.3 The values stated in inch-pound or SI units are to be

2.3 Other Standard:

regarded separately as standard. Each system shall be used

NBS Handbook 100

independently of the other. Combining the values from the two

systems may result in non- conformance with the specification.

3. Ordering Information

For conductor sizes designated by AWG or kcmil sizes, the

requirements in SI units are numerically converted from the

3.1 Orders for material under this specification shall include

correspondingrequirementsininch-poundunits.Forconductor

the following information:

sizesdesignatedbyAWGorkcmil,therequirementsinSIunits

3.1.1 Quantity of each size and class,

have been numerically converted from corresponding values

3.1.2 Conductor size: circular-mil area or American Wire

stated or derived in inch-pound units. for conductor sizes

Gage (AWG) (Section 6),

designated by SI units only, the requirements are stated or

3.1.3 Class (see 1.2 and Table 1),

derived in SI units.

3.1.4 Temper (see 10.2),

1.3.1 For density, resitivity and temperature, the values

3.1.5 Whether coated or uncoated; if coated, designate type

stated in SI units are to be regarded as standard.

of coating (see 10.1 and 10.2),

NOTE 1—The significant differences in this specification from Specifi- 3.1.6 Details of special-purpose lays, if required (see 5.2),

cation B8 are as follows: (1)The central core is permitted to contain up to

3.1.7 Lagging, if required (see 14.2),

seven wires drawn into the assembly with an infinite length of lay while

3.1.8 Special package marking, if required (Section 13),

Specification B8 permits only one, and (2) The construction is applicable

only to stranded assemblies of 19 or more wires. 3.1.9 Place of inspection (Section 12), and

1 2

This specification is under the jurisdiction of ASTM Committee B01 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Electrical Conductors and is the direct responsibility of Subcommittee B01.04 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Conductors of Copper and Copper Alloys. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved April 1, 2012. Published August 2012. Originally the ASTM website.

approved in 1988. Last previous edition approved in 2006 as B784 – 01 (2006). Available from National Technical Information Service (NTIS), 5285 Port

DOI: 10.1520/B0784-01R12. Royal Rd., Springfield, VA 22161, http://www.ntis.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B784 − 01 (2012)

TABLE 1 Construction Requirements of Modified Concentric-Lay-Stranded Copper Conductors

NOTE 1—See Explanatory Note 5.

Size Class B Modified Class C Modified Class D Modified

Circular Mils American Number of Diameter Number of Diameter Number of Diameter

Wire Gage Wires (mils) (mm) Wires (mils) (mm) Wires (mils) (mm)

A

5 000 000 217 151.8 3.86 271 135.8 3.45 271 135.8 3.45

4 000 000 217 144.0 3.66 271 128.9 3.27 271 128.9 3.27

4 000 000 217 135.8 3.45 271 121.5 3.09 271 121.5 3.09

3 500 000 169 143.9 3.66 217 127.0 3.23 271 113.6 2.89

A

3 000 000 169 133.2 3.38 217 117.6 2.99 271 105.2 2.67

A

2 500 000 127 140.3 3.56 169 121.6 3.09 217 107.3 2.73

A

2 000 000 127 125.5 3.19 169 108.8 2.76 217 96.0 2.44

1 900 000 127 122.3 3.11 169 106.0 2.69 217 93.6 2.38

1 800 000 127 119.1 3.03 169 103.2 2.62 217 91.1 2.31

A

1 750 000 127 117.4 2.98 169 101.8 2.59 217 89.8 2.28

1 700 000 127 115.7 2.94 169 100.3 2.55 217 88.5 2.25

1 600 000 127 112.2 2.85 169 97.3 2.47 217 85.9 2.18

A

1 500 000 91 128.4 3.26 127 108.7 2.76 169 94.2 2.39

1 400 000 91 124.0 3.15 127 105.0 2.67 169 91.0 2.31

1 300 000 91 119.5 3.04 127 101.2 2.57 169 87.7 2.23

1 250 000 91 117.2 2.98 127 99.2 2.52 169 86.0 2.18

1 200 000 91 114.8 2.92 127 97.2 2.47 169 84.3 2.14

1 100 000 91 109.9 2.79 127 93.1 2.36 169 80.7 2.05

A

1 000 000 61 128.0 3.25 91 104.8 2.66 127 88.7 2.25

900 000 61 121.5 3.09 91 99.4 2.52 127 84.2 2.14

A

800 000 61 114.5 2.91 91 93.8 2.38 127 79.4 2.02

A

750 000 61 110.9 2.82 91 90.8 2.31 127 76.8 1.95

A

700 000 61 107.1 2.72 91 87.7 2.23 127 74.2 1.88

650 000 61 103.2 2.62 91 84.5 2.15 127 71.5 1.82

A

600 000 61 99.2 2.52 91 81.2 2.06 127 66.7 1.69

550 000 61 95.0 2.41 91 77.7 1.97 127 65.8 1.67

A

500 000 37 116.2 2.95 61 90.5 2.30 91 74.1 1.88

450 000 37 110.3 2.80 61 85.9 2.18 91 70.3 1.79

A

400 000 37 104.0 2.64 61 81.0 2.06 91 66.3 1.68

A

350 000 37 97.3 2.47 61 75.7 1.92 91 62.0 1.57

A

300 000 37 90.0 2.29 61 70.1 1.78 91 57.4 1.46

A

250 000 37 82.2 2.09 61 64.0 1.63 91 52.4 1.33

A

211 000 0000 19 105.5 2.68 37 75.6 1.92 61 58.9 1.50

A

167 000 000 19 94.0 2.39 37 67.3 1.71 61 52.4 1.33

A

133 000 00 19 83.7 2.13 37 60.0 1.52 61 46.7 1.19

A

105 000 0 19 74.5 1.89 37 53.4 1.36 61 41.6 1.06

A

83 000 1 19 66.4 1.69 37 47.6 1.21 61 37.0 0.94

A

These sizes of conductors provide for one or more schedules of preferred series and commonly are used in the industry. The sizes not marked are given simplyasa

matter of reference and it is suggested that their use be discouraged.

4. Joints 5.2 Other lays for special purposes shall be furnished by

special agreement between the manufacturer and the purchaser

4.1 Welds and brazes may be made in rods or in wires prior

(Explanatory Note 3).

to final drawing.Welds and brazes may be made in the finished

individual wires composing the conductor, but shall not be 5.3 The direction of lay of the outer layer shall be left-hand

closer together than prescribed in Table 2. unless the direction of lay is specified otherwise by the

purchaser.

5. Lay

5.4 The direction of lay shall be reversed in successive

5.1 The lay of a layer of wires shall be not less than eight

layers, unless otherwise specified by the purchaser.

nor more than sixteen times the outside diameter of that layer,

6. Construction

except that for conductors composed of 37 wires or more, this

requirement shall apply only to the two outer layers.The lay of 6.1 The areas of cross section, numbers, and diameters of

the layers other than the two outer layers shall be at the option wires in the various classes of concentric-lay-stranded conduc-

of the manufacturer, unless otherwise agreed upon. tors shall conform to the requirements prescribed in Table 1.

6.2 The diameters of the wires listed in Table 1 are nominal.

Where“combinationstrand’’isrequiredinordertoinsulatethe

TABLE 2 Minimum Distance Between Joints in the Completed

conductor properly (strands in the outer layer having a larger

Conductor

diameter than those in the inner layers) the diameters shall be

Number of Wires in Conductor Soft All Classes

19 1 ft subject to a tolerance of 6 5 %, provided that the area of cross

A

20 and over 1 ft in a layer

section after stranding is in accordance with Section 11.

A

Except as indicated, the limitations apply to closeness of joints throughout the

6.3 Where compressed stranding is required in order to

completed conductor.

insulate the conductor properly, one or more layers of any

B784 − 01 (2012)

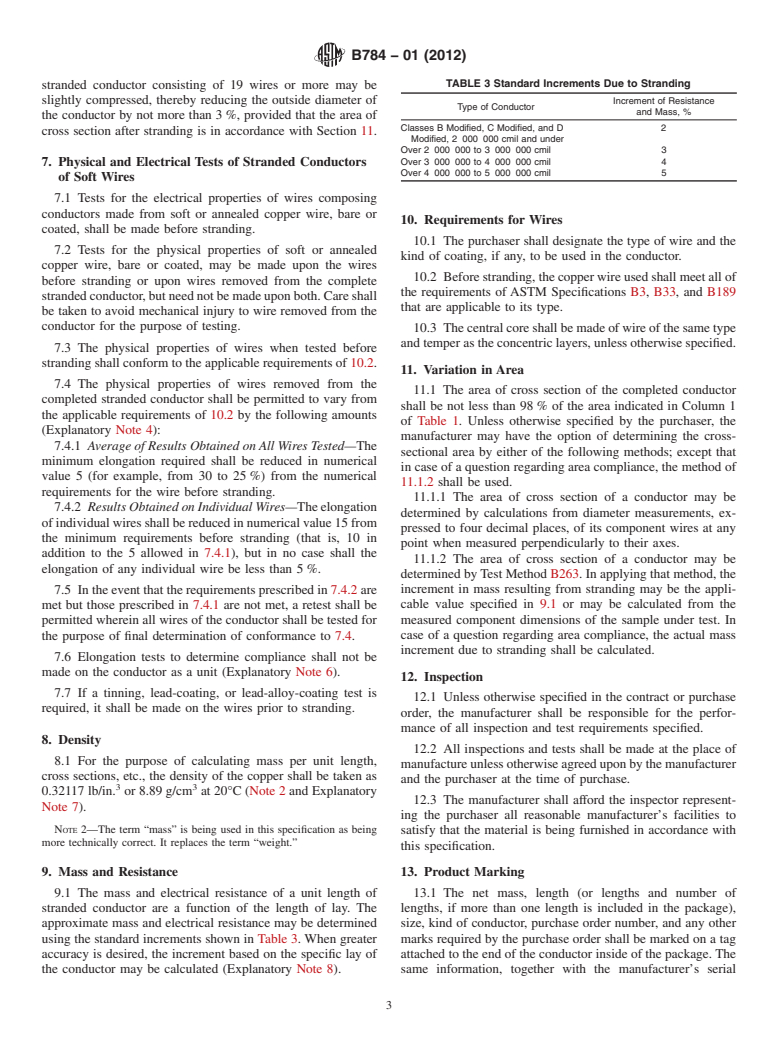

TABLE 3 Standard Increments Due to Stranding

stranded conductor consisting of 19 wires or more may be

slightly compressed, thereby reducing the outside diameter of Increment of Resistance

Type of Conductor

and Mass, %

the conductor by not more than 3 %, provided that the area of

Classes B Modified, C Modified, and D 2

cross section after stranding is in accordance with Section 11.

Modified, 2 000 000 cmil and under

Over 2 000 000 to 3 000 000 cmil 3

Over 3 000 000 to 4 000 000 cmil 4

7. Physical and Electrical Tests of Stranded Conductors

Over 4 000 000 to 5 000 000 cmil 5

of Soft Wires

7.1 Tests for the electrical properties of wires composing

conductors made from soft or annealed copper wire, bare or

10. Requirements for Wires

coated, shall be made before stranding.

10.1 The purchaser shall designate the type of wire and the

7.2 Tests for the physical properties of soft or annealed

kind of coating, if any, to be used in the conductor.

copper wire, bare or coated, may be made upon the wires

10.2 Beforestranding,thecopperwireusedshallmeetallof

before stranding or upon wires removed from the complete

the requirements of ASTM Specifications B3, B33, and B189

strandedconductor,butneednotbemadeuponboth.Careshall

that are applicable to its type.

be taken to avoid mechanical injury to wire removed from the

conductor for the purpose of testing.

10.3 Thecentralcoreshallbemadeofwireofthesametype

and temper as the concentric layers, unless otherwise specified.

7.3 The physical properties of wires when tested before

stranding shall conform to the applicable requirements of 10.2.

11. Variation in Area

7.4 The physical properties of wires removed from the

11.1 The area of cross section of the completed conductor

completed stranded conductor shall be permitted to vary from

shall be not less than 98 % of the area indicated in Column 1

the applicable requirements of 10.2 by the following amounts

of Table 1. Unless otherwise specified by the purchaser, the

(Explanatory Note 4):

manufacturer may have the option of determining the cross-

7.4.1 Average of Results Obtained on All Wires Tested—The

sectional area by either of the following methods; except that

minimum elongation required shall be reduced in numerical

in case of a question regarding area compliance, the method of

value 5 (for example, from 30 to 25 %) from the numerical

11.1.2 shall be used.

requirements for the wire before stranding.

11.1.1 The area of cross section of a conductor may be

7.4.2 Results Obtained on Individual Wires—Theelongation

determined by calculations from diameter measurements, ex-

ofindividualwiresshallbereducedinnumericalvalue15from

pressed to four decimal places, of its component wires at any

the minimum requirements before stranding (that is, 10 in

point when measured perpendicularly to their axes.

addition to the 5 allowed in 7.4.1), but in no case shall the

11.1.2 The area of cross section of a conductor may be

elongation of any individual wire be less than 5 %.

determined byTest Method B263. In applying that method, the

7.5 In the event that the requirements prescribed in 7.4.2 are increment in mass resulting from stranding may be the appli-

cable value specified in 9.1 or may be calculated from the

met but those prescribed in 7.4.1 are not met, a retest shall be

permitted wherein all wires of the conductor shall be tested for measured component dimensions of the sample under test. In

case of a question regarding area compliance, the actual mass

the purpose of final determination of conformance to 7.4.

increment due to stranding shall be calculated.

7.6 Elongation tests to determine compliance shall not be

made on the conductor as a unit (Explanatory Note 6).

12. Inspection

7.7 If a tinning, lead-coating, or lead-alloy-coating test is

12.1 Unless otherwise specified in the contract or purchase

required, it shall be made on the wires prior to stranding.

order, the manufacturer shall be responsible for the perfor-

mance of all inspection and test requirements specified.

8. Density

12.2 All inspections and tests shall be made at the place of

8.1 For the purpose of calculating mass per unit length,

manufactureunlessotherwiseagreeduponbythemanufacturer

cross sections, etc., the density of the copper shall be taken as

and the purchaser at the time of purchase.

3 3

0.32117 lb/in. or 8.89 g/cm at 20°C (Note 2 and Explanatory

12.3 The manufacturer shall afford the inspector represent-

Note 7).

ing the purchaser all reasonable manufacturer’s facilities to

NOTE 2—The term “mass” is being used in this specification as being

satisfy that the material is being furnished in accordance with

more technically correct. It replaces the term “weight.”

this specification.

9. Mass and Resistance 13. Product Marking

9.1 The mass and electrical resistance of a unit length of 13.1 The net mass, length (or lengths and number of

stranded conductor are a function of the length of lay. The lengths, if more than one length is included in the package),

approximate mass and electrical resistance may be determined size, kind of conductor, purchase order number, and any other

using the standard increments shown in Table 3. When greater marks required by the purchase order shall be marked on a tag

accuracy is desired, the increment based on the specific lay of attached to the end of the conductor inside of the package. The

the conductor may be calculated (Explanatory Note 8). same information, together with the manufacturer’s serial

B784 − 01 (2012)

number (if any) and all shipping marks required by the 14.2 The conductors shall be protected against damage in

purchaser, shall appear on the outside of each package. ordinary handling and shipping. If

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.