ASTM B903-15

(Specification)Standard Specification for Seamless Copper Heat Exchanger Tubes With Internal Enhancement

Standard Specification for Seamless Copper Heat Exchanger Tubes With Internal Enhancement

ABSTRACT

This specification covers seamless, internally enhanced copper tube, in straight lengths or coils, suitable for use in refrigeration and air-conditioning products or other heat exchangers. The material of manufacture shall be cast billet, bar, tube, or so forth of copper UNS No. C12200 and shall be of such purity and soundness as to be suitable for processing into the tubular product described. The tube shall be manufactured by such hot- and cold-working processes needed to produce a homogenous, uniform wrought structure in the finished product. The material shall conform to the chemical composition requirements specified. The grain size shall be determined in the wall beneath the ridges. The microstructure shall show complete recrystallization and shall have an average grain size within the limits specified. As-fabricated and O (annealed) temper tube shall conform to the mechanical properties specified. The specimens of annealed product shall withstand the specified expansion tested as specified. Each tube shall be subjected to an eddy-current test. Tubes shall be tested normally in the fabricated temper; however, they may be tested in the annealed temper at the option of the manufacturer.

SCOPE

1.1 This specification establishes the requirements for seamless, internally enhanced copper tube, in straight lengths or coils, suitable for use in refrigeration and air-conditioning products or other heat exchangers.

1.2 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 Tubes for this application are manufactured from the following copper:

Copper UNS No.

Type of Metal

C12200

Phosphorized, high residual phosphorus (DHP)

1.4 The following pertains to the test method described in 15.2.4 of this specification: This standard does not purport to address all the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B903 −15

Standard Specification for

Seamless Copper Heat Exchanger Tubes With Internal

1

Enhancement

This standard is issued under the fixed designation B903; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* E3 Guide for Preparation of Metallographic Specimens

E8/E8M Test Methods for Tension Testing of Metallic Ma-

1.1 This specification establishes the requirements for

terials

seamless, internally enhanced copper tube, in straight lengths

E29 Practice for Using Significant Digits in Test Data to

or coils, suitable for use in refrigeration and air-conditioning

Determine Conformance with Specifications

products or other heat exchangers.

E53 Test Method for Determination of Copper in Unalloyed

1.2 Units—The values stated in inch-pound units are to be

Copper by Gravimetry

regarded as standard. The values given in parentheses are

E62 Test Methods for Chemical Analysis of Copper and

mathematical conversions to SI units that are provided for 3

CopperAlloys (Photometric Methods) (Withdrawn 2010)

information only and are not considered standard.

E112 Test Methods for Determining Average Grain Size

1.3 Tubes for this application are manufactured from the E243 Practice for Electromagnetic (Eddy Current) Examina-

tion of Copper and Copper-Alloy Tubes

following copper:

E255 Practice for Sampling Copper and Copper Alloys for

Copper UNS No. Type of Metal

the Determination of Chemical Composition

C12200 Phosphorized, high residual phosphorus (DHP)

1.4 The following pertains to the test method described in

3. General Requirements

15.2.4 of this specification: This standard does not purport to

3.1 The following sections of Specification B251 constitute

address all the safety concerns, if any, associated with its use.

a part of this specification:

It is the responsibility of the user of this standard to establish

3.1.1 Workmanship, Finish, and Appearance.

appropriate safety and health practices and determine the

3.1.2 Sampling.

applicability of regulatory limitations prior to use.

3.1.3 Number of Tests and Retests.

2. Referenced Documents

3.1.4 Specimen Preparation.

2

2.1 ASTM Standards:

3.2 In addition, when a section with a title identical to those

B153 Test Method for Expansion (Pin Test) of Copper and

referenced in 3.1 appears in this specification, it contains

Copper-Alloy Pipe and Tubing

additional information which supplements those appearing in

B251 Specification for General Requirements for Wrought

Specification B251. In case of conflict, this specification shall

Seamless Copper and Copper-Alloy Tube

prevail.

B601 Classification forTemper Designations for Copper and

Copper Alloys—Wrought and Cast

4. Terminology

B846 Terminology for Copper and Copper Alloys

4.1 For definitions of terms related to copper and copper

B950 Guide for Editorial Procedures and Form of Product

alloys, refer to Terminology B846.

Specifications for Copper and Copper Alloys

4.2 Definitions of Terms Specific to This Standard:

4.2.1 bottom wall, n—the wall thickness measured from the

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

base of the enhancement to the outside surface.

and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe

and Tube.

4.2.2 enhancement, adj—a geometrical feature intentionally

Current edition approved Oct. 1, 2015. Published October 2015. Originally

formed on a tube I.D. surface to improve heat transfer.

approved in 2000. Last previous edition approved in 2010 as B903-10. DOI:

10.1520/B0903-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B903−15

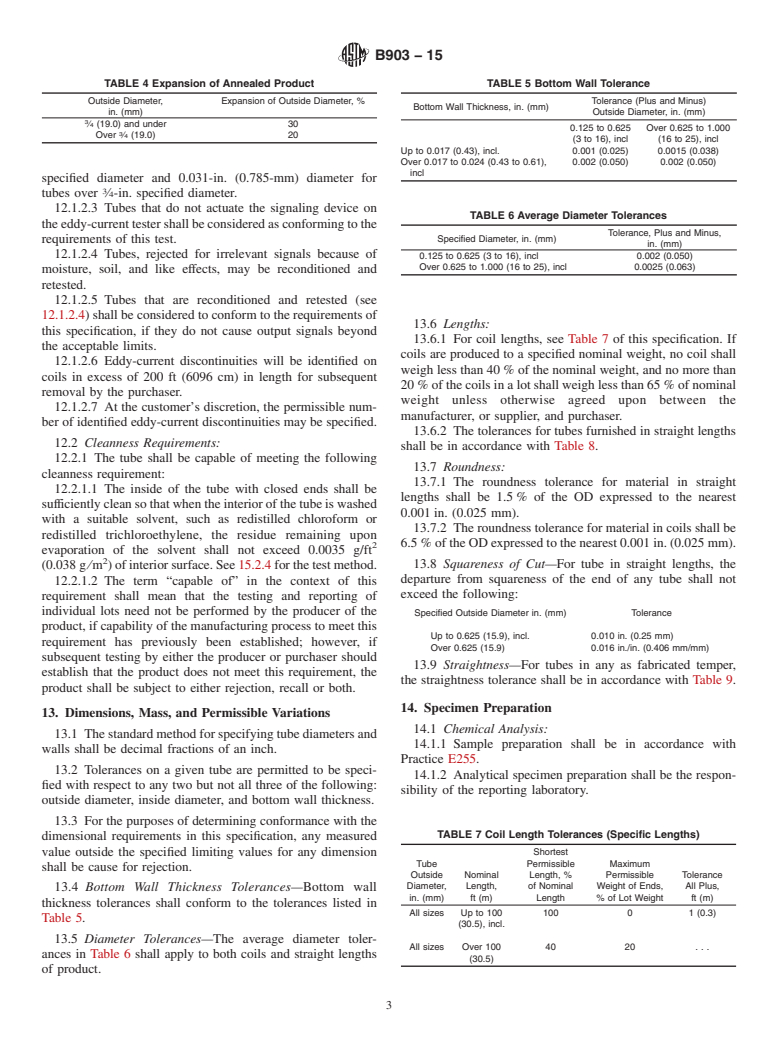

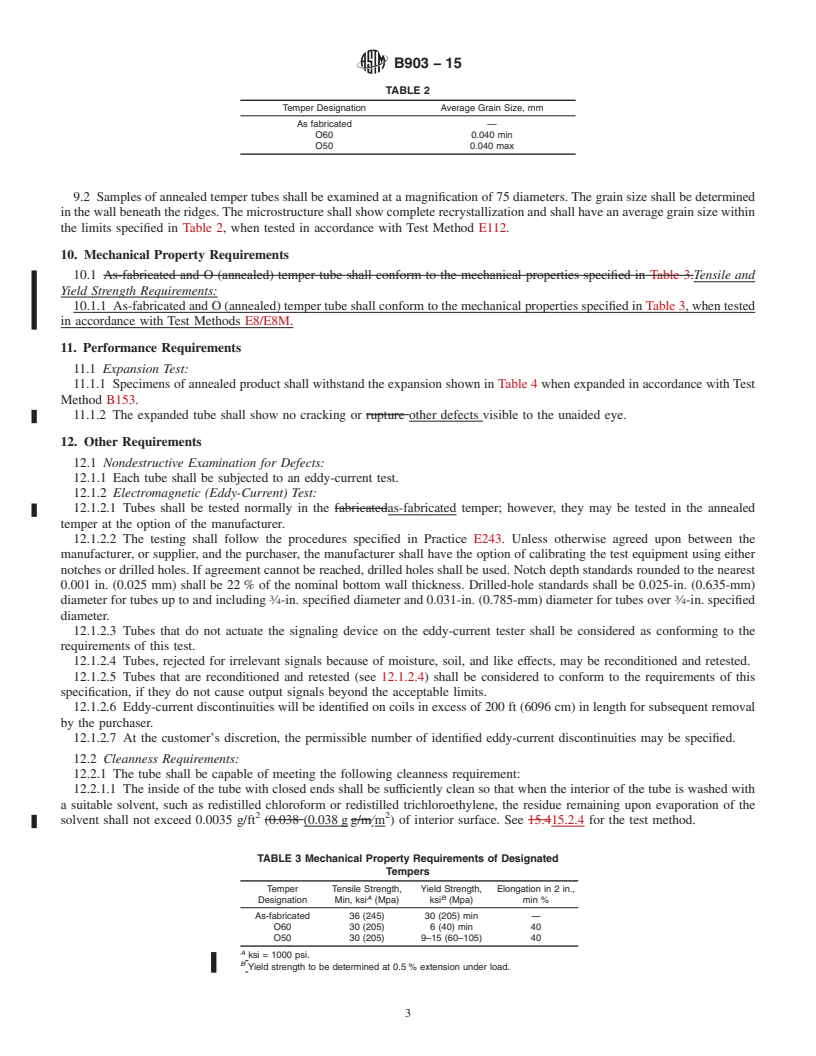

TABLE 2

5. Ordering Information

Temper Designation Average Grain Size, mm

5.1 Include the following specified choices when placing

As fabricated —

orders for products under this specification, as applicable:

O60 0.040 min

5.1.1 ASTM Designation number and the year of issue.

O50 0.040 max

5.1.2 Temper (Section 8).

5.1.3 Length, diameter, wall thickness, and enhancement

dimensions. Configuration of the enhanced surface shall be as

9. Grain Size for Annealed Tempers

agreed upon between the manufacturer, or supp

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B903 − 10 B903 − 15

Standard Specification for

Seamless Copper Heat Exchanger Tubes With Internal

1

Enhancement

This standard is issued under the fixed designation B903; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification establishes the requirements for seamless, internally enhanced copper tube, in straight lengths or coils,

suitable for use in refrigeration and air-conditioning products or other heat exchangers.

1.2 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are

mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 Tubes for this application are manufactured from the following copper:

Copper UNS No. Type of Metal

C12200 Phosphorized, high residual phosphorus (DHP)

1.4 The following pertains to the test method described in 15.415.2.4 of this specification:This standard does not purport to

address all the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish

appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

B153 Test Method for Expansion (Pin Test) of Copper and Copper-Alloy Pipe and Tubing

B251 Specification for General Requirements for Wrought Seamless Copper and Copper-Alloy Tube

B601 Classification for Temper Designations for Copper and Copper Alloys—Wrought and Cast

B846 Terminology for Copper and Copper Alloys

B950 Guide for Editorial Procedures and Form of Product Specifications for Copper and Copper Alloys

E3 Guide for Preparation of Metallographic Specimens

E8E8/E8M Test Methods for Tension Testing of Metallic Materials

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E53 Test Method for Determination of Copper in Unalloyed Copper by Gravimetry

3

E62 Test Methods for Chemical Analysis of Copper and Copper Alloys (Photometric Methods) (Withdrawn 2010)

E112 Test Methods for Determining Average Grain Size

E243 Practice for Electromagnetic (Eddy Current) Examination of Copper and Copper-Alloy Tubes

E255 Practice for Sampling Copper and Copper Alloys for the Determination of Chemical Composition

3. General Requirements

3.1 The following sections of Specification B251 constitute a part of this specification:

3.1.1 Workmanship, Finish, and Appearance.

3.1.2 Sampling.

3.1.3 Number of Tests and Retests.

3.1.4 Specimen Preparation.

1

This specification is under the jurisdiction of ASTM Committee B05 on Copper and Copper Alloys and is the direct responsibility of Subcommittee B05.04 on Pipe and

Tube.

Current edition approved April 1, 2010Oct. 1, 2015. Published May 2010October 2015. Originally approved in 2000. Last previous edition approved in 20052010 as

B903B903–00 (2005). -10. DOI: 10.1520/B0903-10. 10.1520/B0903-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B903 − 15

3.2 In addition, when a section with a title identical to those referenced in 3.1 appears in this specification, it contains additional

information which supplements those appearing in Specification B251. In case of conflict, this specification shall prevail.

4. Terminology

4.1 For definitions of terms related to copper and copper alloys, refer to Terminology B846.

4.2 Definitions of Terms Specific to This Standard:

4.1.1 For definitions of terms related to copper and copper alloys, refer to Terminology B846.

4.2.1 bottom wall, n—the wall thickness measured from the base of the enhancement to the outside surface.

4.2.2 enhancement, adj—a geometrical feature intentionally formed on a tube I.D. surface to improve heat transfer.

4.1.4 level wound, adj—a coil in which the turns

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.