ASTM E1680-95(2003)

(Test Method)Standard Test Method for Rate of Air Leakage Through Exterior Metal Roof Panel Systems

Standard Test Method for Rate of Air Leakage Through Exterior Metal Roof Panel Systems

SCOPE

1.1 This test method covers the determination of the resistance of exterior metal roof panel systems to air infiltration resulting from either positive or negative air pressure differences. The test method described is for tests with constant temperature and humidity across the specimen. This test method is a specialized adaption of Test Method E 283.

1.2 This test method is applicable to any roof area. This test method is intended to measure only the air leakage associated with the field of the roof, including the panel side laps and structural connections; it does not include leakage at the openings or perimeter or any other details.

1.3 The proper use of this test method requires knowledge of the principles of air flow and pressure measurements.

1.4 The text of this test method references notes and footnotes excluding tables and figures, which provide explanatory material. These notes and footnotes shall not be considered to be requirements of the test method.

1.5 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1680–95 (Reapproved 2003)

Standard Test Method for

Rate of Air Leakage Through Exterior Metal Roof Panel

Systems

This standard is issued under the fixed designation E1680; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E631 Terminology of Building Constructions

E1592 Test Method for Structural Performance of Sheet

1.1 This test method covers the determination of the resis-

Metal Roof and Siding Systems by Uniform Static Air

tance of exterior metal roof panel systems to air infiltration

Pressure Difference

resulting from either positive or negative air pressure differ-

E1646 Test Method forWater Penetration of Exterior Metal

ences. The test method described is for tests with constant

Roof Panel Systems by Uniform Static Air Pressure

temperature and humidity across the specimen. This test

Difference

method is a specialized adaption of Test Method E283.

2.2 Other Standard:

1.2 This test method is applicable to any roof area.This test

AAMA 501 Methods of Test for Metal Curtain Walls

method is intended to measure only the air leakage associated

with the field of the roof, including the panel side laps and

3. Terminology

structural connections; it does not include leakage at the

3.1 Definitions—For definitions of general terms relating to

openings or perimeter or any other details.

buildingconstructionusedinthistestmethod,seeTerminology

1.3 The proper use of this test method requires knowledge

E631.

of the principles of air flow and pressure measurements.

3.2 Definitions of Terms Specific to This Standard:

1.4 The text of this test method references notes and

3.2.1 air leakage (Q)—thevolumeofairflowingperunitof

footnotes excluding tables and figures, which provide explana-

time through the assembled specimen under a test pressure

tory material. These notes and footnotes shall not be consid-

difference,expressedincubicfeetperminute(cubicmetresper

ered to be requirements of the test method.

second).

1.5 The values stated in inch-pound units are to be regarded

3.2.2 extraneous air leakage (Q )—the difference between

L

as the standard. The values given in parentheses are for

the metered air flow (Q ) and air leakage (Q); the leakage of

m

information only.

the remainder of the test chamber.

1.6 This standard does not purport to address all of the

3.2.3 metered air flow (Q )—the volume of air flowing per

m

safety concerns, if any, associated with its use. It is the

unitoftimethroughtheairflowmeteringsystem, expressed in

responsibility of the user of this standard to establish appro-

cubic feet per minute (cubic metres per second).

priate safety and health practices and determine the applica-

3.2.4 rate of air leakage—the air leakage per unit of

bility of regulatory limitations prior to use. For specific

specimen area (A), expressed in cubic feet per minute per

precautionary statements, see Section 7.

square foot (cubic metres per second per square metre).

2. Referenced Documents 3.2.5 reference standard conditions—dryairatapressureof

2 29.92 in. Hg (101.3 kPa), temperature of 69.4°F (20.8°C), and

2.1 ASTM Standards:

3 3

air density of 0.075 lb/ft (1.2 kg/m ).

E283 Test Method for Determining Rate of Air Leakage

3.2.6 specimen—the entire assembled unit submitted for

Through Exterior Windows, Curtain Walls, and Doors

testing as described in Section 8.

UnderSpecifiedPressureDifferencesAcrosstheSpecimen

3.2.7 specimen area (A)—theareadeterminedbytheoverall

dimensions of the test specimen expressed in square feet

(square metres). The dimensions used to determine area shall

This test method is under the jurisdiction of ASTM Committee E06 on

not include exterior framework.

Performance of Buildings and is the direct responsibility of Subcommittee E06.57

3.2.8 test pressure difference—the specified difference in

on Performance of Metal Roofing Systems.

Current edition approved April 10, 2003. Published May 2003. Originally

static air pressure across the fixed specimen, expressed in

approved in 1995. Last previous edition approved in 1995 as E1680–95. DOI:

pounds-force per square foot (pascals).

10.1520/E1680-95R03.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from Architectural Aluminum Manufacturers Association (AAMA),

the ASTM website. 1827 Walden Office Square, Suite 550, Schaumburg, IL 60173.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E1680–95 (2003)

pressures after considering the test methods’ guidelines. Practical consid-

4. Summary of Test Method

erations suggest that every combination of panel thickness, span, and

4.1 The test procedure consists of sealing and fixing a test

design load need not be tested in order to substantiate product perfor-

specimen into or against one face of an air chamber, supplying

mance.

airtoorexhaustingairfromthechamberattheraterequiredto

maintain the specified test pressure difference across the

6. Apparatus

specimen, and measuring the resultant air flow through the

6.1 This description of the apparatus is general in nature,

specimen.

and any arrangement of equipment capable of performing the

test procedure within the allowable tolerances is permitted.

5. Significance and Use

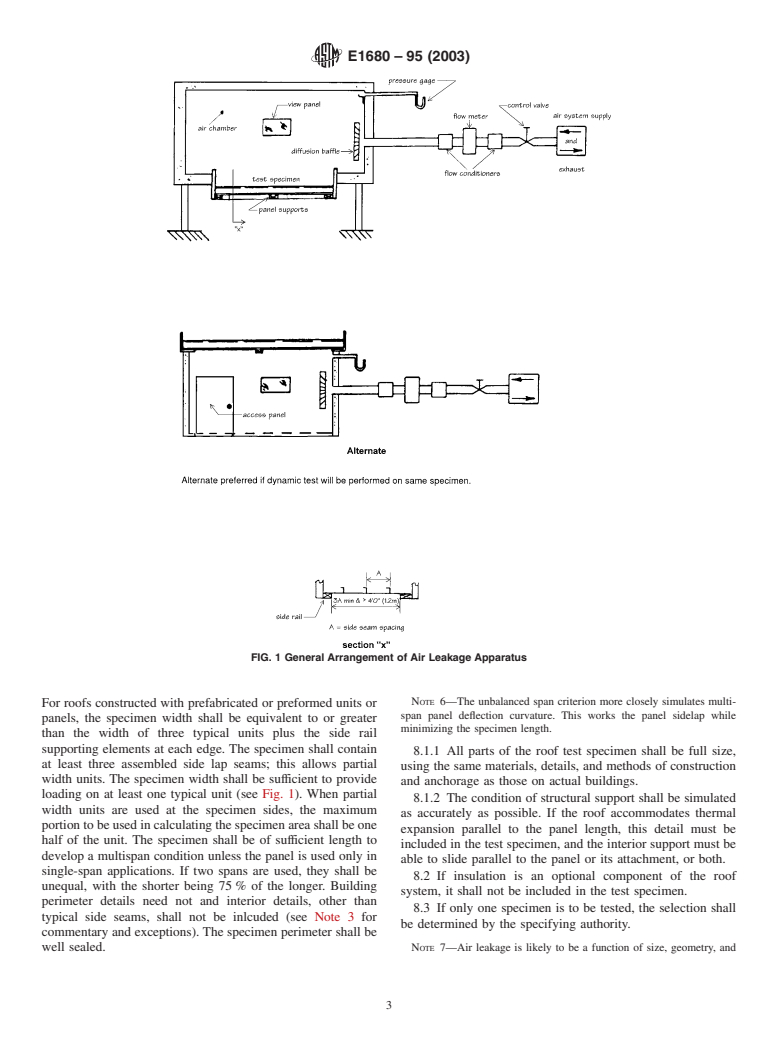

6.2 Major Components (see Fig. 1).

5.1 Thistestmethodisastandardprocedurefordetermining

6.2.1 Test Chamber—A well-sealed chamber or box with

air leakage characteristics under specified air pressure differ-

either an opening, a removable mounting panel, or one open

ences.

face in which or against which the specimen is installed and

sealed. The specimen shall be installed horizontally. At least

NOTE 1—Theairpressuredifferencesactingacrossabuildingenvelope

one static pressure tap shall be provided to measure the

vary greatly. The slope of the roof and other factors affecting air pressure

differences and the implications of the resulting air leakage relative to the chamber pressure.All pressure taps shall be located so that the

, ,

environment within buildings are discussed in the literature. These

reading is unaffected by the air supply either to or from the

factors shall be considered fully when specifying the test pressure

chamber. The air supply opening into the chamber shall be

difference to be used.

arranged so that air does not impinge directly on the test

NOTE 2— When applying the results of tests by this test method, note

specimen with any significant velocity. When required, a

that the performance of a roof or its components, or both, may be a

meansofaccessshallbeprovidedintothechambertofacilitate

functionofproperinstallationandadjustment.Theperformanceinservice

adjustments and observations after the specimen has been

willalsodependontherigidityofsupportingconstruction,thepresenceof

interior treatments, the roof slope, and the resistance of components to

installed.

deterioration by various causes: corrosive atmospheres, aging, ice, vibra-

6.2.2 Air System—A controllable blower, compressed air

tion, thermal expansion, and contraction, etc. It is difficult to simulate the

supply, exhaust system, or reversible blower designed to

identical complex environmental conditions that can be encountered in

provide the required air flow at the specified test pressure

service, including rapidly changing pressures due to wind gusting. Some

difference. the system shall provide constant air flow at a fixed

designs are more sensitive than others to these environmental conditions.

pressure for the period required to obtain readings of air flow

5.2 Rates of air leakage are sometimes used for comparison

and pressure difference, and it shall be capable of maintaining

purposes. The comparisons are not always valid unless the

positive and negative pressures.

components being tested and compared are of essentially the

6.2.3 Pressure MeasuringApparatus—Adeviceformeasur-

same size, configuration, and design.

ing the test pressure difference within a tolerance of 62%,or

NOTE 3—The specimen construction discussed in 1.2 and required in 6 0.01 in. (6 2.5 Pa), of water column, whichever is greater.

8.1 isolates a source of leakage. The rate of air leakage measured during

The device must measure positive and negative pressures.

thetestmethodhasunitsofcubicfeetperminutepersquarefoot(litresper

6.2.4 Air-Flow Metering System—A device to measure the

second per square metre). Openings and details such as end laps or roof

air flow within the limitations of error prescribed in 6.3. (The

curbs are excluded since leakage is measured more appropriately in cubic

,

publications listed in Footnotes 5 and 6 present background

feet per minute per foot (litres per second per metre) at these conditions.

information on fluid metering practices.)

Thetestspecimenareaisrelativelysmall;theinclusionofdetailswillgive

6.3 The air flow through the test specimen shall be deter-

unrealistic import to the detail’s presence when compared to actual roof

constructions. This test method shall not be relied on singularly to form mined with an error not greater than 6 5% when this flow

conclusions about overall air leakage through metal roofs.Aroof contains

equals or exceeds 2 ft /min (0.94 L/s) or 6 10% when the air

3 3

many details.Although prescribed modifications are outside the scope of 1

flow is below 2 ft /min but more than ⁄2 ft /min (0.24 L/s).

this test method, an experienced testing engineer is able to use the

NOTE 5—A greater percentage of error will usually be acceptable at

principles presented in the test method and to generate significant data by

lower flows. Special flow-measuring techniques are necessary if higher

isolating specific details and measuring leakage.

precision is required. The accuracy of the specimen leakage flow

Additionalleakagesourcesareintroducedifdetailsareincluded.Iftotal

measurement is affected by the accuracy of the flowmeter and amount of

leakage is then measured, the results will generally be conservative

extraneousleakageoftheapparatus(seeAnnexA1ofTestMethodE283).

relative to tests without details. To minimize the number of tests, the

specifier may allow details such as end laps when qualitative or general

quantitative results are desired and the isolation of sources is not required 7. Safety Precautions

for performance. Only one panel end lap shall be allowed. The user shall

7.1 Glass breakage and specimen failure will not normally

be aware of the bias when comparing alternate systems if end laps are

occur at the small pressure differences applied in this test

included.

procedure. Larger or excessive pressure differences occur

NOTE 4—This is a test procedure. It is the responsibility of the

duringpreload,duetoerrorinoperation,orwhentheapparatus

specifying agency to determine the specimen construction, size, and test

is used for other purposes such as structural testing; therefore

exercise adequate precautions to protect personnel.

ASHRAE Handbook of Fundamentals, American Society of Heating, Refrig-

eration and Air-Conditioning Engineers, Inc., 1972, Chapter 25.

8. Test Specimen

Fluid Meters—Their Theory and Application, 5th edition, 1959.

8.1 The roof specimen shall be of sufficient size to deter-

ASME—Power Test Code, 2nd edition, 1956, Part 5, Chapter 4, “Flow

Measurements.” mine the performance of all typical parts of the roof system.

E1680–95 (2003)

FIG. 1 General Arrangement of Air Leakage Apparatus

NOTE 6—The unbalanced span criterion more closely simulates multi-

For roofs constructed with prefabricated or preformed units or

span panel deflection curvature. This works the panel sidelap while

panels, the specimen width shall be equivalent to or greater

minimizing the specimen length.

than the width of three typical units plus the side rail

supporting elements at each edge. The specimen shall contain

8.1.1 All parts of the roof test specimen shall be full size,

at least three assembled side lap seams; this allows partial

using the same materials, details, and methods of construction

width units. The specimen width shall be sufficient to provide

and anchorage as those on actual buildings.

loading on at least one typical unit (see Fig. 1). When partial

8.1.2 The condition of structural support shall be simulated

width units are used at the specimen sides, the maximum

as accurately as possible. If the roof accommodates thermal

portiontobeusedincalculatingthespecimenareashallbeone

expansion parallel to the panel length, this detail must be

half of the unit. The specimen shall be of sufficient length to

included in the test specimen, and the interior support must be

develop a multispan condition unless the panel is used only in

able to slide parallel to the panel or its attachment, or both.

single-span applications. If two spans are used, they shall be

8.2 If insulation is an optional component of the roof

unequal, with the shorter being 75% of the longer. Building

system, it shall not be included in the test specimen.

perimeter details need not and interior details, other than

8.3 If only one specimen is to be tested, the selection shall

typical side seams, shall not be inlcuded (see Note 3 for

be determined by the specifying authority.

commentary and exceptions).The specimen perimeter shall be

well sealed. NOTE 7—Air leakage is likely to be a function of size, geometry, and

E1680–95 (2003)

stiffness. Therefore, select specimens covering the range of sizes to be

be−1.57 lbf/ft (−75 Pa). Unless otherwise specified, test-

used in a building. In general, the largest size and least stiff of a particular

pressure differences shall be both+and−1.57 lbf/ft for roof

design,type,construction,andconfigurationshallbetested(seeNote3for

applications steeper then 30° from horizontal.

related commentary).

NOTE 10—This commentary is included to assist the specifier in the

9. Calibration

selection of test pressures. This test method is consistent with the Test

9.1 Calibration shall be accomplished by mounting a ply- Method E283 default test pressure and the AAMA501 Methods of Test

for Metal Curtain Walls recommendations.

woodorsimilarrigidblanktothetestchamberinplaceofatest

Shallow roofs rarely see large positive wind pressures unless the

specimen, using the same mounting procedures as those used

resultant pressure is caused by building openings. The Test Method E283

7 1

for standard specimens. The blank sha

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.