ASTM D7918-23

(Test Method)Standard Test Method for Measurement of Flow Properties and Evaluation of Wear, Contaminants, and Oxidative Properties of Lubricating Grease by Die Extrusion Method and Preparation

Standard Test Method for Measurement of Flow Properties and Evaluation of Wear, Contaminants, and Oxidative Properties of Lubricating Grease by Die Extrusion Method and Preparation

SIGNIFICANCE AND USE

5.1 Trending the wear, contamination, consistency, and oxidative properties of a lubricating grease is a crucial part of condition-monitoring programs. Changes in these properties or deviations from the new grease can be indicative of problems within the lubricated component, such as the mixing of incompatible thickener types, excessive wear or contaminant levels, or significant depletion of antioxidant levels. These test methods also makes it possible to develop trends that can be used to predict failures before they occur and allow for corrective action to be taken.

SCOPE

1.1 This test method covers the determination and evaluation of flow properties, wear levels, contaminants, and oxidative condition of new and in-service lubricating grease.

1.2 This test method provides guidance on evaluating in-service grease samples, NLGI grades 00 to 3, for wear, consistency, contamination, and oxidation.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3.1 Exception—The exception to this will be where units of references were developed by the developers of the test equipment and necessary to report the results of the test.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7918 − 23

Standard Test Method for

Measurement of Flow Properties and Evaluation of Wear,

Contaminants, and Oxidative Properties of Lubricating

1

Grease by Die Extrusion Method and Preparation

This standard is issued under the fixed designation D7918; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This test method covers the determination and evalua-

D217 Test Methods for Cone Penetration of Lubricating

tion of flow properties, wear levels, contaminants, and oxida-

Grease

tive condition of new and in-service lubricating grease.

D6300 Practice for Determination of Precision and Bias

1.2 This test method provides guidance on evaluating in-

Data for Use in Test Methods for Petroleum Products,

service grease samples, NLGI grades 00 to 3, for wear,

Liquid Fuels, and Lubricants

consistency, contamination, and oxidation.

D6595 Test Method for Determination of Wear Metals and

Contaminants in Used Lubricating Oils or Used Hydraulic

1.3 The values stated in SI units are to be regarded as the

Fluids by Rotating Disc Electrode Atomic Emission Spec-

standard. The values given in parentheses are for information

trometry

only.

D7527 Test Method for Measurement of Antioxidant Con-

1.3.1 Exception—The exception to this will be where units

tent in Lubricating Greases by Linear Sweep Voltammetry

of references were developed by the developers of the test

D7546 Test Method for Determination of Moisture in New

equipment and necessary to report the results of the test.

and In-Service Lubricating Oils and Additives by Relative

1.4 This standard does not purport to address all of the

Humidity Sensor

safety concerns, if any, associated with its use. It is the

D7718 Practice for Obtaining In-Service Samples of Lubri-

responsibility of the user of this standard to establish appro-

cating Grease

priate safety, health, and environmental practices and deter-

D7843 Test Method for Measurement of Lubricant Gener-

mine the applicability of regulatory limitations prior to use.

ated Insoluble Color Bodies in In-Service Turbine Oils

1.5 This international standard was developed in accor-

using Membrane Patch Colorimetry

dance with internationally recognized principles on standard-

E177 Practice for Use of the Terms Precision and Bias in

ization established in the Decision on Principles for the

ASTM Test Methods

Development of International Standards, Guides and Recom-

E691 Practice for Conducting an Interlaboratory Study to

mendations issued by the World Trade Organization Technical

Determine the Precision of a Test Method

Barriers to Trade (TBT) Committee.

3. Terminology

3.1 Definitions:

1

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.96.07 on Integrated Testers, Instrumentation Techniques for

2

In-Service Lubricants. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2023. Published November 2023. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2015. Last previous edition approved in 2017 as D7918 – 17a. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D7918-23. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7918 − 23

3.1.1 active grease sampling device, n—device designed to pressed as a percent when compared to the average of three

take an active sample of a lubricating grease from a bearing, unique test conditions of the unused lubricating grease base-

gear, or drive shaft located in a grease lubricated component. line.

D7718

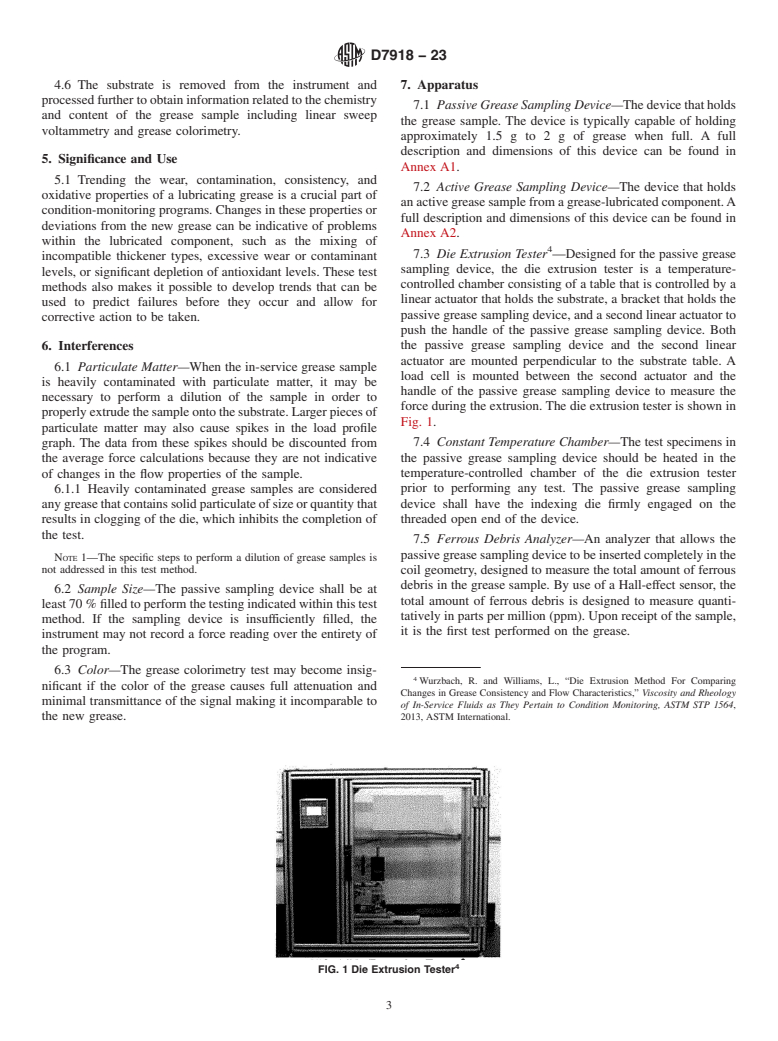

3.2.2 die extrusion tester, n—a device that measures the

3.1.1.1 Discussion—The Grease Thief (trademarked) Type

consistency of in-service lubricating greases and compares the

3

2 is a tool which meets this description and can be used to

measurement to the values obtained from a baseline sample of

obtain an active grease sample from a lubricated component. A

lubricating grease.

full description and dimensions of this device can be found in

3.2.3 ferrous debris level, n—the total amount of ferrous

Annex A2.

me

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7918 − 17a D7918 − 23

Standard Test Method for

Measurement of Flow Properties and Evaluation of Wear,

Contaminants, and Oxidative Properties of Lubricating

1

Grease by Die Extrusion Method and Preparation

This standard is issued under the fixed designation D7918; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the determination and evaluation of flow properties, wear levels, contaminants, and oxidative

condition of new and in-service lubricating grease.

1.2 This test method provides guidance on evaluating in-service grease samples, NLGI grades 00 to 3, for wear, consistency,

contamination, and oxidation.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3.1 Exception—The exception to this will be where units of references were developed by the developers of the test equipment

and necessary to report the results of the test.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D217 Test Methods for Cone Penetration of Lubricating Grease

D6300 Practice for Determination of Precision and Bias Data for Use in Test Methods for Petroleum Products, Liquid Fuels, and

Lubricants

D6595 Test Method for Determination of Wear Metals and Contaminants in Used Lubricating Oils or Used Hydraulic Fluids by

Rotating Disc Electrode Atomic Emission Spectrometry

D7527 Test Method for Measurement of Antioxidant Content in Lubricating Greases by Linear Sweep Voltammetry

D7546 Test Method for Determination of Moisture in New and In-Service Lubricating Oils and Additives by Relative Humidity

Sensor

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.96.07 on Integrated Testers, Instrumentation Techniques for In-Service Lubricants.

Current edition approved Nov. 15, 2017Oct. 1, 2023. Published December 2017November 2023. Originally approved in 2015. Last previous edition approved in 2017 as

D7918 – 17.D7918 – 17a. DOI: 10.1520/D7918-17A.10.1520/D7918-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7918 − 23

D7718 Practice for Obtaining In-Service Samples of Lubricating Grease

D7843 Test Method for Measurement of Lubricant Generated Insoluble Color Bodies in In-Service Turbine Oils using

Membrane Patch Colorimetry

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions:

3.1.1 active grease sampling device, n—device designed to take an active sample of a lubricating grease from a bearing, gear, or

drive shaft located in a grease lubricated component. D7718

3.1.1.1 Discussion—

3

The Grease Thief (trademarked) Type 2 is a tool which meets this description and can be used to obtain an active grease sample

from a lubricated component. A full description and dimensions of this device can be found in Annex A2.

3.1.2 active sampling, v—to use a sampling device to actively gather an in-service lubricating grease sample from a

grease-lubricated component. D7718

3.1.3 calibration, n—the determination of the values of the significant

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.