ASTM D7313-07a

(Test Method)Standard Test Method for Determining Fracture Energy of Asphalt-Aggregate Mixtures Using the Disk-Shaped Compact Tension Geometry

Standard Test Method for Determining Fracture Energy of Asphalt-Aggregate Mixtures Using the Disk-Shaped Compact Tension Geometry

SIGNIFICANCE AND USE

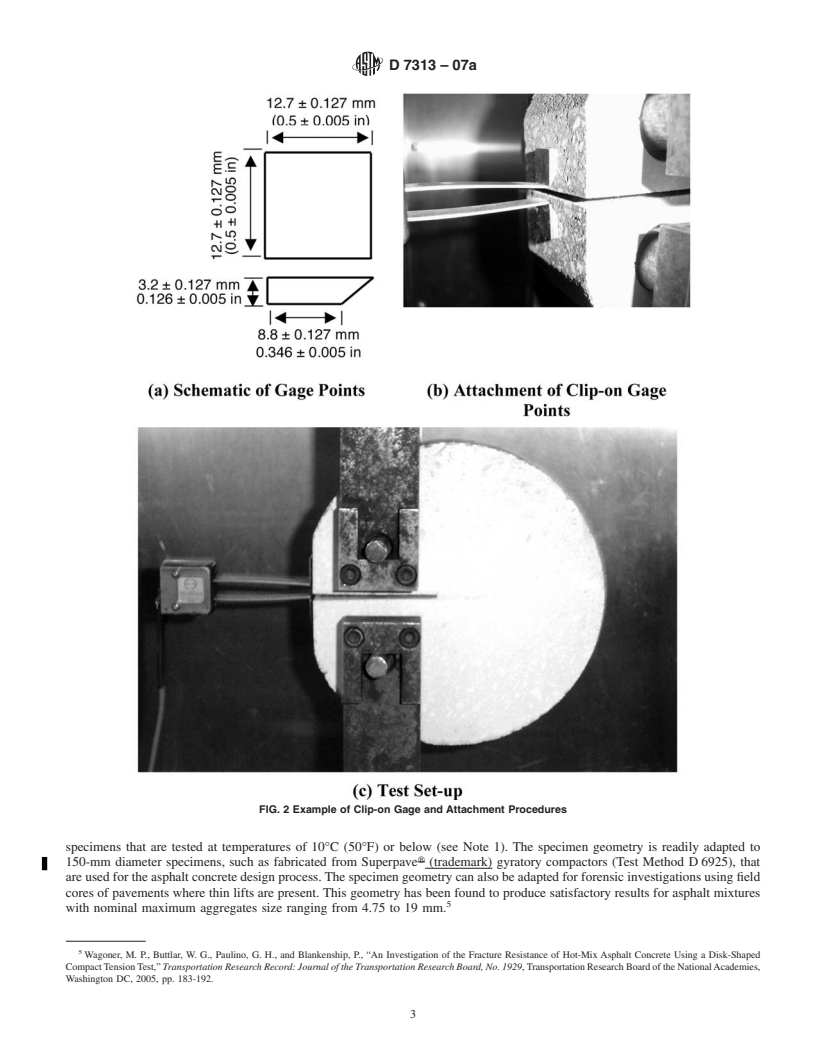

The test method was developed for determining the fracture resistance of asphalt-aggregate mixtures. The fracture resistance can help differentiate mixtures whose service life might be compromised by cracking. The test method is generally valid for specimens that are tested at temperatures of 10°C (50°F) or below (see Note 1). The specimen geometry is readily adapted to 150-mm diameter specimens, such as fabricated from Superpave (trademark) gyratory compactors (Test Method D 6925), that are used for the asphalt concrete design process. The specimen geometry can also be adapted for forensic investigations using field cores of pavements where thin lifts are present. This geometry has been found to produce satisfactory results for asphalt mixtures with nominal maximum aggregates size ranging from 4.75 to 19 mm.

Note 1—The stiffness of the asphalt binder tends to influence the assessment of a valid test as described in 7.4. For instance a soft asphalt binder, which may be required for a very cold climate might not lead to a mixture that would produce valid results at 10°C and conversely, a hard asphalt binder utilized in hot climates may require higher temperatures to provide any meaningful information.

Note 2—The quality of the results produced by this test method are dependent on the competence of the personnel performing the procedure and the capability, calibration, and maintenance of the equipment used. Agencies that meet the criteria of Specification D 3666 are generally considered capable of competent and objective testing/sampling/inspection/etc. Users of this test method are cautioned that compliance with Specification D 3666 alone does not completely assure reliable results. Reliable results may depend on many factors; following the suggestions of Specification D 3666 or some similar acceptable guidelines provides a means of evaluating and controlling some of those factors.

SCOPE

1.1 This test method covers the determination of fracture energy (Gf) of asphalt-aggregate mixtures using the disk-shaped compact tension geometry. The disk-shaped compact tension geometry is a circular specimen with a single edge notch loaded in tension. The fracture energy can be utilized as a parameter to describe the fracture resistance of asphalt concrete. The fracture energy parameter is particularly useful in the evaluation of mixtures with ductile binders, such as polymer-modified asphalt concrete, and has been shown to discriminate between these materials more broadly than the indirect tensile strength parameter (AASHTO T322, Wagoner ). The test is generally valid at temperatures of 10°C (50°F) and below, or for material and temperature combinations which produce valid material fracture, as outlined in 7.4.

1.2 The specimen geometry and terminology (disk-shaped compact tension, DC(T)) is modeled after Test Method E 399 for Plane-Strain Fracture Toughness of Metallic Materials, Appendix A6, with modifications to allow fracture testing of asphalt concrete.

1.3 The test method describes the testing apparatus, instrumentation, specimen fabrication, and analysis procedures required to determine fracture energy of asphalt concrete and similar quasi-brittle materials.

1.4 The standard unit of measurement for fracture energy is Joules/meter2 (J/m2) [inch-pound/inch2 (in.-lbf/in.2)].

1.5 The text of this test method references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the test method.

1.6 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limi...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7313 − 07a

StandardTest Method for

Determining Fracture Energy of Asphalt-Aggregate Mixtures

1

Using the Disk-Shaped Compact Tension Geometry

This standard is issued under the fixed designation D7313; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.7 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method covers the determination of fracture

responsibility of the user of this standard to establish appro-

energy (G) of asphalt-aggregate mixtures using the disk-

f

priate safety and health practices and determine the applica-

shaped compact tension geometry. The disk-shaped compact

bility of regulatory limitations prior to use.

tension geometry is a circular specimen with a single edge

notch loaded in tension. The fracture energy can be utilized as

2. Referenced Documents

a parameter to describe the fracture resistance of asphalt

3

concrete. The fracture energy parameter is particularly useful

2.1 ASTM Standards:

in the evaluation of mixtures with ductile binders, such as

D8 Terminology Relating to Materials for Roads and Pave-

polymer-modified asphalt concrete, and has been shown to

ments

discriminate between these materials more broadly than the

D3666 Specification for Minimum Requirements for Agen-

indirect tensile strength parameter (AASHTO T322, Wag-

cies Testing and Inspecting Road and Paving Materials

2

oner ). The test is generally valid at temperatures of 10°C

D6373 Specification for Performance Graded Asphalt

(50°F) and below, or for material and temperature combina-

Binder

tions which produce valid material fracture, as outlined in 7.4.

D6925 Test Method for Preparation and Determination of

the Relative Density of Hot Mix Asphalt (HMA) Speci-

1.2 The specimen geometry and terminology (disk-shaped

compact tension, DC(T)) is modeled after Test Method E399 mens by Means of the Superpave Gyratory Compactor

for Plane-Strain Fracture Toughness of Metallic Materials, E399 Test Method for Linear-Elastic Plane-Strain Fracture

Appendix A6, with modifications to allow fracture testing of Toughness K of Metallic Materials

Ic

asphalt concrete. E1823 TerminologyRelatingtoFatigueandFractureTesting

1.3 The test method describes the testing apparatus,

2.2 AASHTO Standard:

instrumentation, specimen fabrication, and analysis procedures AASHTO T322 Standard Method of Test for Determining

required to determine fracture energy of asphalt concrete and

the Creep Compliance and Strength of Hot Mix Asphalt

4

similar quasi-brittle materials. (HMA) Using the Indirect Tensile Test Device

1.4 The standard unit of measurement for fracture energy is

2 2 2 2

3. Terminology

Joules/meter (J/m ) [inch-pound/inch (in.-lbf/in. )].

3.1 Definitions—Terminologies E1823 and D8 are appli-

1.5 The text of this test method references notes and

cable to this test method.

footnotes which provide explanatory material. These notes and

footnotes (excluding those in tables and figures) shall not be

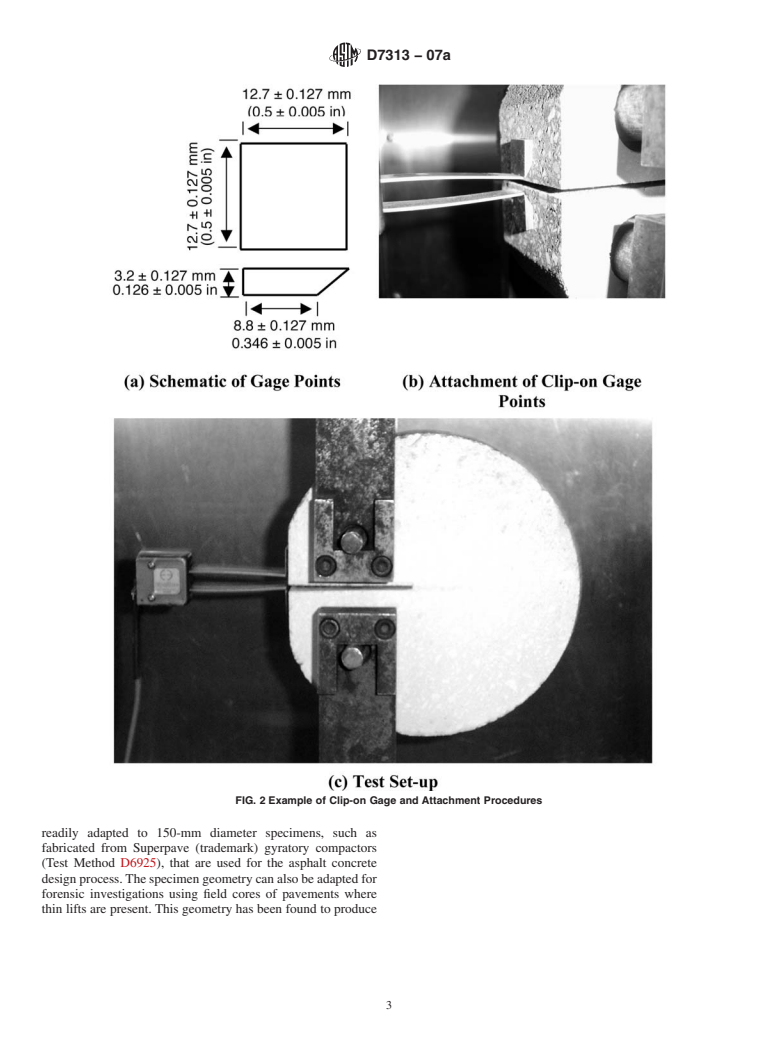

3.1.1 crack mouth—portion of the notch that is on the flat

considered as requirements of the test method. surface of the specimen, that is, opposite the notch tip (see Fig.

3).

1.6 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information

3.1.2 crack mouth opening displacement (CMOD)—the

only.

relative displacement of the crack mouth.

1

This test method is under the jurisdiction of ASTM Committee D04 on Road

and Paving Materials and is the direct responsibility of Subcommittee D04.26 on

3

Fundamental/Mechanistic Tests. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Dec. 1, 2007. Published January 2008. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2007. Last previous edition approved in 2007 as D7313 – 07. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D7313-07A. the ASTM website.

2 4

Wagoner, M. P., Buttlar, W. G., Paulino, G. H., and Blankenship, P., “Labora- Available from American Association of State Highway and Transportation

tory Testing Suite for Characterization ofAsphalt Concrete Mixtures Obtained from Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001,

Field Cores,” Journal of the Association of Asphalt Paving Technologists, 2006. http://www.transportation.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ---

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D7313–07 Designation: D 7313 – 07a

Standard Test Method for

Determining Fracture Energy of Asphalt-Aggregate Mixtures

1

Using the Disk-Shaped Compact Tension Geometry

This standard is issued under the fixed designation D 7313; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of fracture energy (G) of asphalt-aggregate mixtures using the disk-shaped

f

compact tension geometry. The disk-shaped compact tension geometry is a circular specimen with a single edge notch loaded in

tension. The fracture energy can be utilized as a parameter to describe the fracture resistance of asphalt concrete. The fracture

energy parameter is particularly useful in the evaluation of mixtures with ductile binders, such as polymer-modified asphalt

concrete, and has been shown to discriminate between these materials more broadly than the indirect tensile strength parameter

2

(AASHTOT322,Wagoner ).The test is generally valid at temperatures of 10°C (50°F) and below, or for material and temperature

combinations which produce valid material fracture, as outlined in 7.4.

1.2 The specimen geometry and terminology (disk-shaped compact tension, DC(T)) is modeled after Test Method E 399 for

Plane-Strain Fracture Toughness of Metallic Materials, Appendix A6, with modifications to allow fracture testing of asphalt

concrete.

1.3 The test method describes the testing apparatus, instrumentation, specimen fabrication, and analysis procedures required to

determine fracture energy of asphalt concrete and similar quasi-brittle materials.

2 2 2 2

1.4 The standard unit of measurement for fracture energy is Joules/meter (J/m ) [inch-pound/inch (in.-lbf/in. )].

1.5 The text of this standard test method references notes and footnotes which provide explanatory material. These notes and

footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard. test method.

1.6 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

3

2.1 ASTM Standards:

D 8 Terminology Relating to Materials for Roads and Pavements

D 3666 Specification for Minimum Requirements for Agencies Testing and Inspecting Road and Paving Materials

D 6373 Specification for Performance Graded Asphalt Binder

D 6925 Test Method for Preparation and Determination of the Relative Density of Hot Mix Asphalt (HMA) Specimens by

Means of the Superpave Gyratory Compactor

E 399 Test Method for Linear-Elastic Plane-Strain Fracture Toughness K of Metallic Materials

Ic

E 1823 Terminology Relating to Fatigue and Fracture Testing

2.2 AASHTO Standard:

AASHTO T322 Standard Method of Test for Determining the Creep Compliance and Strength of Hot Mix Asphalt (HMA)

4

Using the Indirect Tensile Test Device

1

This test method is under the jurisdiction of ASTM Committee D04 on Road and Paving Materials and is the direct responsibility of Subcommittee D04.26 on

Fundamental/Mechanistic Tests.

Current edition approved March 15, 2007. Published April 2007.

Current edition approved Dec. 1, 2007. Published January 2008. Originally approved in 2007. Last previous edition approved in 2007 as D 7313 – 07.

2

Wagoner, M. P., Buttlar, W. G., Paulino, G. H., and Blankenship, P., “Laboratory Testing Suite for Characterization of Asphalt Concrete Mixtures Obtained from Field

Cores,” Journal of the Association of Asphalt Paving Technologists, 2006.

3

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

4

Available from American Association of State Highway and Transportation Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001,

http://www.transportation.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.