ASTM B93/B93M-06

(Specification)Standard Specification for Magnesium Alloys in Ingot Form for Sand Castings, Permanent Mold Castings, and Die Castings

Standard Specification for Magnesium Alloys in Ingot Form for Sand Castings, Permanent Mold Castings, and Die Castings

SCOPE

1.1 This specification covers magnesium alloys in ingot form for remelting for the manufacture of sand castings, permanent mold castings, investment castings, and die castings. Note 1

Supplementary information pertaining to the alloys covered by this specification when used in the form of castings is given in Specifications B 80, B 94, B 199 and B 403.

1.2 The values stated in either inch-pound units or SI units are to be regarded separately as standard. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 93/B 93M – 06

Standard Specification for

Magnesium Alloys in Ingot Form for Sand Castings,

1

Permanent Mold Castings, and Die Castings

This standard is issued under the fixed designation B 93/B 93M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* B 403 Specification for Magnesium-Alloy Investment Cast-

ings

1.1 This specification covers magnesium alloys in ingot

E29 Practice for Using Significant Digits in Test Data to

form for remelting for the manufacture of sand castings,

Determine Conformance with Specifications

permanent mold castings, investment castings, and die cast-

E35 Test Methods for Chemical Analysis of Magnesium

ings.

and Magnesium Alloys

NOTE 1—Supplementary information pertaining to the alloys covered

E88 Practice for Sampling Nonferrous Metals and Alloys

by this specification when used in the form of castings is given in

in Cast Form for Determination of Chemical Composition

Specifications B 80, B 94, B 199 and B 403.

E 527 Practice for Numbering Metals and Alloys (UNS)

1.2 The values stated in either inch-pound units or SI units

3. Ordering Information

are to be regarded separately as standard. The values stated in

each system are not exact equivalents; therefore, each system

3.1 Orders for ingot to this specification shall include the

shall be used independently of the other.

following information:

1.3 This standard does not purport to address all of the

3.1.1 Quantity in pounds (kilograms)

safety concerns, if any, associated with its use. It is the

3.1.2 Alloy (Section 4 and Table 1 or Table 2), and

responsibility of the user of this standard to establish appro-

3.1.3 Form: as agreed upon between the purchaser and

priate safety and health practices and determine the applica-

seller. Some forms in commercial use are:

bility of regulatory limitations prior to use.

Approximate

Approximate Size Length by Width

Form Weight,

by Height, in. (mm)

2. Referenced Documents

lb (kg)

3 3

Five-segment 23 by 2 ⁄4 by 1 ⁄4 (583 by 70 by 44) 5 (2.3)

2.1 The following documents of the issue in effect on date

1

Four-segment 28 by 4 ⁄2 by 4 (711 by 114 by 102) 20 (9.1)

1 5 5

of order acceptance form a part of this specification to the

Self-Palletizing 26 ⁄2 by 6 ⁄8 by 2 ⁄8 (672 by 168 by 67) 25 (11.3)

extent referenced herein:

3.1.4 Inspection required at the manufacturer’s works (see

2

2.2 ASTM Standards:

8.1).

B80 Specification for Magnesium-Alloy Sand Castings

3.1.5 For inch-pound orders specify B93; for metric orders

B94 Specification for Magnesium-Alloy Die Castings

specify B93M. Do not mix units.

B 199 Specification for Magnesium-Alloy Permanent Mold

Castings

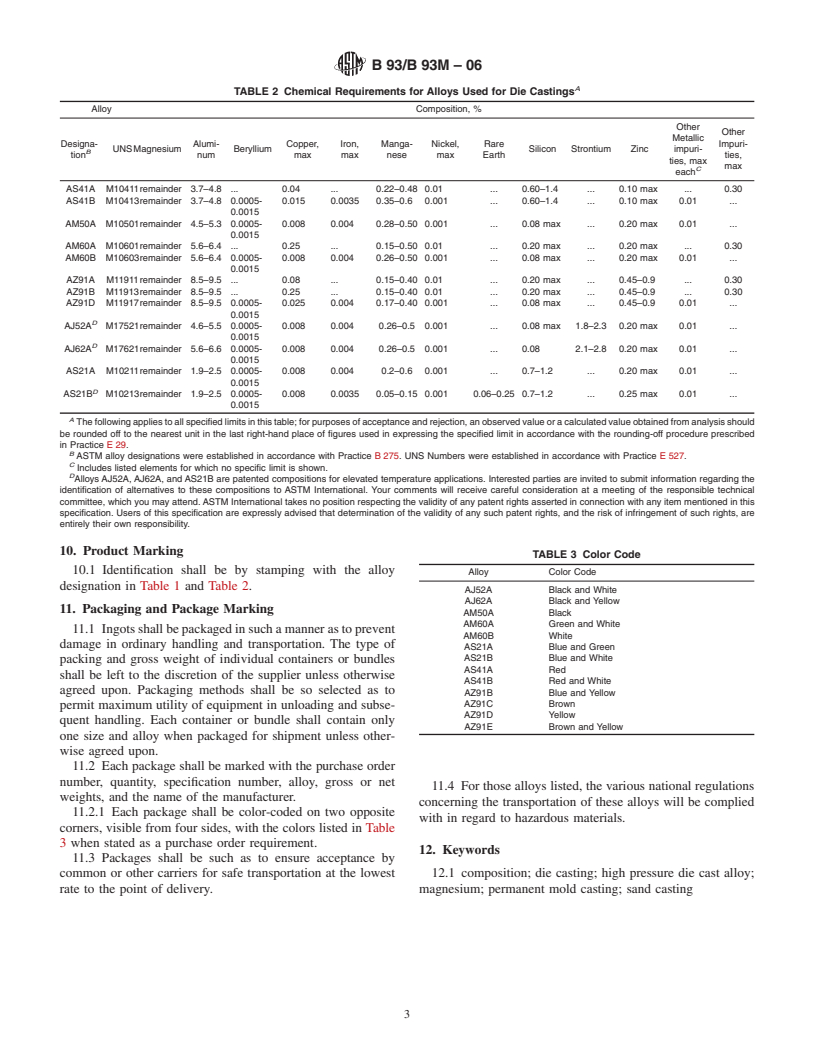

4. Chemical Composition

B 275 Practice for Codification of Certain Nonferrous Met-

4.1 The ingots shall conform to the chemical composition

als and Alloys, Cast and Wrought

limits prescribed in Table 1 for sand cast alloys and permanent

mold-cast alloys and in Table 2 for die-cast alloys. Conform-

ance shall be determined by the manufacturer by analyzing

1

This specification is under the jurisdiction of ASTM Committee B07 on Light

samples taken at the time the ingots are poured or samples

Metals and Alloys and is the direct responsibility of Subcommittee B07.04 on

taken from the ingots. If the manufacturer has determined the

Magnesium Alloy Cast and Wrought Products.

chemical composition of the material during manufacture, he

Current edition approved Sept. 1, 2006. Published September 2006. Originally

approved in 1934. Last previous edition approved in 2005 as B 93/B 93M – 05.

shall not be required to sample and analyze the ingots.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.2 The alloys shall conform to the chemical composition

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

requirements prescribed in Table 1 and Table 2 (Note 2 and

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Note 3).

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B 93/B 93M – 06

TABLE 1 Chemical Requirements for Alloy Ingot for Remelt to Sand, Permanent, Mold and Investment Castings—Composition %

Lithium, Others Total

A

Alloy Mag- Alumi- Copper, Gadol- Iron, Manga- Neody- Nickel, Rare Silicon, Zir-

UNS Silver Yttrium Zinc each Others,

ASTM nesium num max inium max nese mium max

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.