ASTM A263-94a(1999)

(Specification)Standard Specification for Corrosion-Resisting Chromium Steel-Clad Plate, Sheet, and Strip

Standard Specification for Corrosion-Resisting Chromium Steel-Clad Plate, Sheet, and Strip

SCOPE

1.1 This specification covers plate, sheet, and strip of a carbon steel or low-alloy steel base to which is integrally and continuously bonded on one or both sides a layer of corrosion-resisting chromium steel. The material is generally intended for pressure vessel use.

1.2 The values stated in inch-pound units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 263 – 94a (Reapproved 1999)

Standard Specification for

Corrosion-Resisting Chromium Steel-Clad Plate, Sheet, and

Strip

This standard is issued under the fixed designation A 263; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.3 plate—Material ⁄16 in. (2.73 mm) and over in thick-

2 ness and over 10 in. (254 mm) in width.

1.1 This specification covers plate, sheet, and strip of a

3.1.4 sheet—Material under ⁄16 in. in thickness and 24 in.

carbon steel or low-alloy steel base to which is integrally and

(609.6 mm) and over in width, material under ⁄16 in. in

continuously bonded on one or both sides a layer of corrosion-

thickness and all widths and finishes of Nos. 3 to 8 inclusive,

resisting chromium steel. The material is generally intended for

and

pressure vessel use.

3.1.5 strip—Cold-rolled material under 24 in. in width and

1.2 The values stated in inch-pound units are to be regarded

⁄16 in. and under in thickness.

as the standard.

4. Ordering Information

2. Referenced Documents

4.1 It is the responsibility of the purchaser to specify all

2.1 ASTM Standards:

requirements that are necessary for material ordered under this

A 20/A 20M Specification for General Requirements for

specification. Such requirements may include, but are not

Steel Plates for Pressure Vessels

limited to, the following:

A 240/A 240M Specification for Heat-Resisting Chromium

4.1.1 Quantity (mass or number of pieces).

and Chromium-Nickel Stainless Steel Plate, Sheet, and

4.1.2 Name of material (corrosion-resisting chromium steel-

Strip for Pressure Vessels

clad plate, sheet or strip).

A 370 Test Methods and Definitions for Mechanical Testing

4.1.3 Cladding alloy.

of Steel Products

4.1.4 Base metal.

A 480/A 480M Specification for General Requirements for

4.1.5 Dimensions including the thickness of the cladding

Flat-Rolled Stainless and Heat-Resisting Steel Plate,

alloy.

Sheet, and Strip

4.1.6 Product analysis, if required (see Section 8).

A 751 Test Methods, Practices, and Terminology for

4.1.7 Mechanical properties (see Sections 7, 14, and 15).

Chemical Analysis of Steel Products

4.1.8 Finish (see Section 11).

2.2 ASME Code:

4.1.9 Restrictions, if required, on repair by welding (see

Boiler and Pressure Vessel Code, Section IX, Welding

5 Section 12).

Qualifications

4.1.10 Additions to the specification or special require-

3. Terminology ments.

3.1 Definitions of Terms Specific to This Standard:

5. Materials and Manufacture

3.1.1 This material is considered as single-clad or double-

5.1 Process:

clad corrosion-resisting chromium-steel plate, sheet, or strip

5.1.1 The steel shall be made by the open-hearth, electric-

depending on whether one or both sides are covered.

furnace (with separate degassing and refining optional), or

3.1.2 The terms plate, sheet, and strip as used in this

basic-oxygen processes, or by secondary processes whereby

specification apply to the following:

steel made from these primary processes is remelted using

electroslag remelting or vacuum-arc remelting processes.

This specification is under the jurisdiction of ASTM Committee A-1 on Steel,

5.1.2 The alloy-cladding metal may be metallurgically

Stainless Steel and Related Alloys, and is the direct responsibility of Subcommittee

bonded to the base metal by any method that will produce a

A01.17 for Flat Stainless Steel Products.

Current edition approved Dec. 15, 1994. Published February 1995. Originally

clad steel that will conform to the requirements of this

published as A 263 – 43 T. Last previous edition A 263 – 94.

specification.

For ASME Boiler and Pressure Vessel Code applications see related Specifi-

5.2 Heat Treatment—Unless otherwise specified or agreed

cation SA-263 in Section II of that Code.

upon between the purchaser and the manufacturer, all plates

Annual Book of ASTM Standards, Vol 01.04.

Annual Book of ASTM Standards, Vol 01.03.

shall be furnished in the normalized or tempered condition, or

5 th

Available from American Society of Mechanical Engineers, 345 E. 47 St.,

both.

New York, NY 10017.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

A 263

6. Chemical Composition

6.1 The composite plate, sheet, or strip shall conform to any

desired combination of alloy-cladding metal and base metal as

described in 6.2 and 6.3 and as agreed upon between the

purchaser and the manufacturer.

6.2 Alloy Cladding Metal—The alloy-cladding metal speci-

fied shall conform to the requirements as to chemical compo-

sition prescribed for the respective chromium steel in Specifi-

cation A 240/A 240M.

6.3 Base Metal—The base metal may be carbon steel or

low-alloy steel conforming to the ASTM specifications for

steels for pressure vessels. The base metal shall conform to the

chemical requirements of the specification to which it is

ordered.

7. Mechanical Properties

Metric Equivalents

7.1 Plate:

in. mm in. mm

7.1.1 Tensile Requirements:

0.005 0.127 1 25.4

7.1.1.1 The tensile properties shall be determined by a

1 1

⁄8 3.18 2 ⁄2 64.5

tension test of the composite plate for clad plates that meet all

⁄4 19.1 3 76.2

of the following conditions. However, if the cladding is for

FIG. 1 Test Specimen and Method of Making Shear Test of Clad

corrosion allowance only, the cladding may be removed before

Plate

tensile testing. The tensile properties thus determined shall be

not less than the minimum and not more than 5000 psi (35

7.1.4 Bond Strength—As an alternative to the shear strength

MPa) over the maximum prescribed in the specification for the

test provided in 7.1.2 and when required by the purchaser, three

base steel used. All other tensile test requirements of the

bend tests shall be made with the alloy cladding in compression

specification for the base steel shall be met.

to determine the quality of the bond. These bend tests shall be

(a) (a) The composite gage is less than or equal to 1 ⁄2 in.

made in accordance with the specifications for the cladding

(b) (b) The specified minimum tensile strength of the base

metal. At least two of the three tests shall show not more than

steel is less than or equal to 70 000 psi (485 MPa).

50 % separation on both edges of the bent portion. Greater

(c) (c) The specified minimum yield strength of the base

separation shall be cause for rejection.

steel is less than or equal to 40 000 psi (275 MPa).

7.2 Sheet and Strip:

7.1.1.2 The tensile properties shall be determined by a

7.2.1 The bend test specimens of sheet and strip shall stand

tension test of the base steel only for clad plates that meet one

being bent cold, without cracking on the outside of the bent

of the following conditions. The properties thus determined

portion, through an angle of 180°.

shall meet all of the tensile test requirements for the base steel.

7.2.2 The bend test specimens shall be bent over a single

(a) (a) The composite gage is greater than 1 ⁄2 in.

piece of flat stock of the same thickness as the material tested,

(b) (b) The specified minimum tensile strength of the base

allowing the test material to form its natural curvature. The axis

steel is greater than 70 000 psi (485 MPa).

of the bend shall be transverse to the direction of rolling.

(c) (c) The specified minimum yield strength of the base

NOTE 1—The bend may be made over a diameter equal to the thickness

steel is greater than 40 000 psi (275 MPa).

of the test material.

7.1.2 Ductility—Two bend tests of the composite plate shall

be made, one with the alloy cladding in tension and the other 7.2.3 The bond between the alloy cladding and the base

with the alloy cladding in compression, to determine the metal shall be ascertained by observation of the behavior of the

ductility of the materials. On double-clad plates, the bend tests composite sheet or strip when sheared with the alloy side

shall be made so that one specimen represents the alloy down.

cladding in tension on one side while the other specimen 7.3 Methods and practices relating to mechanical testing

represents the alloy cladding in tension on the opposite side. required by this specification shall be in accordance with Test

The bend test having the alloy cladding in tension shall be Methods and Definitions A 370.

made in accordance with the requirements prescribed in the

8. Product Analysis

specifications for the cladding metal. The bend test having the

base metal in tension shall be made in accordance with the 8.1 Product analyses may be required on the finished

requirements prescribed in the specifications for the base

product only when the composite plate thickness is sufficient to

metal. permit obtaining drillings or millings without danger of con-

7.1.3 Shear Strength—When required by the purchaser, the tamination from the adjacent layer.

minimum shear strength of the alloy cladding and base metals 8.2 If product analysis is specified by the purchaser, it shall

shall be 20 000 psi (140 MPa). The shear test, when specified, be made from drillings or millings taken from the final piece or

shall be made in the manner indicated in Fig. 1. a broken test specimen. In order to avoid contamination by the

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

A 263

base plate metal, cladding samples shall be taken from the test 11.2 Plate alloy surfaces shall be sand-blasted, pickled, or

coupon by removal and discard of all the base metal plate blast-cleaned and pickled.

material, plus 40 % of the cladding thickness from the bonded 11.3 The finish for the alloy surfaces of sheets and strips

side, not to exceed ⁄16 in. (1.588 mm). The material shall be shall be as specified in the applicable sections of Specification

chemically cleaned and millings shall be taken to represent the A 240/A 240M.

full cross-section of the remainder.

12. Repair of Cladding by Welding

8.3 Methods and practices relating to chemical analysis

required by this specification shall be in accordance with Test

12.1 The material manufacturer may repair defects in clad-

Methods, Practices, and Terminology A 751.

ding by welding provided the following requirements are met:

8.4 Results of the product analysis shall conform to the

12.1.1 Prior approval shall be obtained from the purchaser if

requirements of Section 7 of Specification A 480/A 480M.

the repaired area exceeds 3 % of the cladding surface.

12.1.2 The welding procedure and the welders or welding

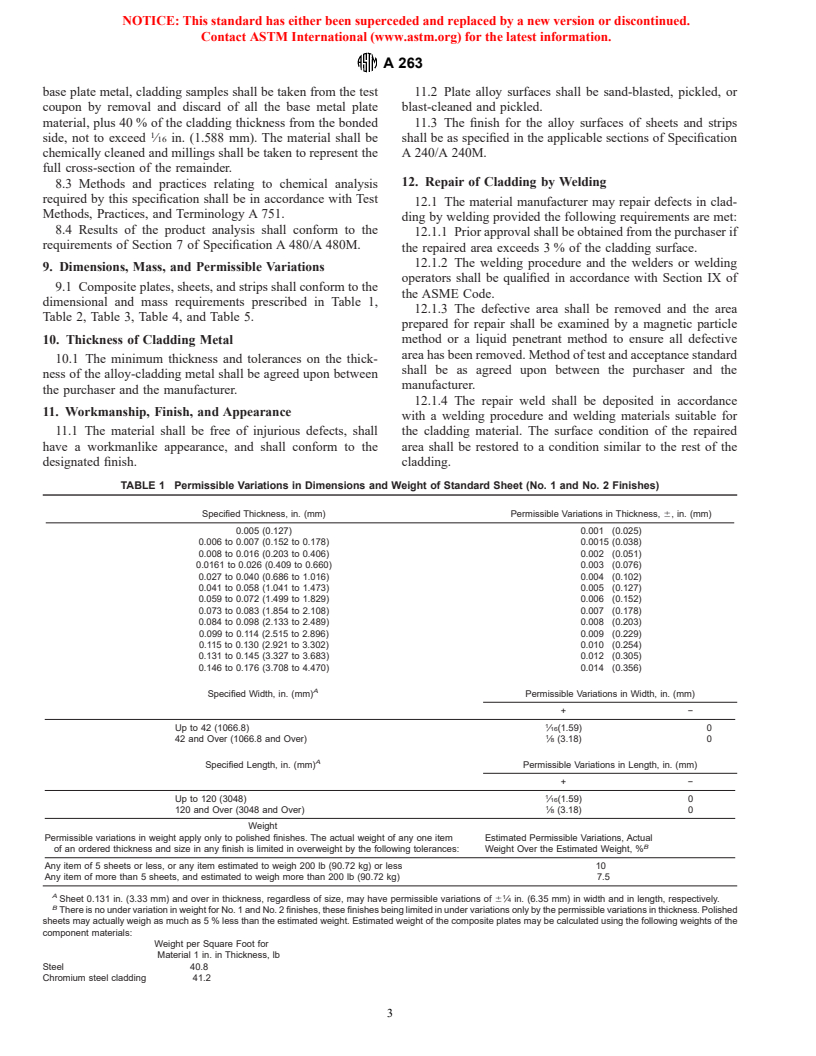

9. Dimensions, Mass, and Permissible Variations

operators shall be qualified in accordance with Section IX of

9.1 Composite plates, sheets, and strips shall conform to the

the ASME Code.

dimensional and mass requirements prescribed in Table 1,

12.1.3 The defective area shall be removed and the area

Table 2, Table 3, Table 4, and Table 5.

prepared for repair shall be examined by a magnetic particle

10. Thickness of Cladding Metal method or a liquid penetrant method to ensure all defective

area has been removed. Method of test and acceptance standard

10.1 The minimum thickness and tolerances on the thick-

shall be as agreed upon between the purchaser and the

ness of the alloy-cladding metal shall be agreed upon between

manufacturer.

the purchaser and the manufacturer.

12.1.4 The repair weld shall be deposited in accordance

11. Workmanship, Finish, and Appearance

with a welding procedure and welding materials suitable for

11.1 The material shall be free of injurious defects, shall the cladding material. The surface condition of the repaired

have a workmanlike appearance, and shall conform to the area shall be restored to a condition similar to the rest of the

designated finish. cladding.

TABLE 1 Permissible Variations in Dimensions and Weight of Standard Sheet (No. 1 and No. 2 Finishes)

Specified Thickness, in. (mm) Permissible Variations in Thickness, 6, in. (mm)

0.005 (0.127) 0.001 (0.025)

0.006 to 0.007 (0.152 to 0.178) 0.0015 (0.038)

0.008 to 0.016 (0.203 to 0.406) 0.002 (0.051)

0.0161 to 0.026 (0.409 to 0.660) 0.003 (0.076)

0.027 to 0.040 (0.686 to 1.016) 0.004 (0.102)

0.041 to 0.058 (1.041 to 1.473) 0.005 (0.127)

0.059 to 0.072 (1.499 to 1.829) 0.006 (0.152)

0.073 to 0.083 (1.854 to 2.108) 0.007 (0.178)

0.084 to 0.098 (2.133 to 2.489) 0.008 (0.203)

0.099 to 0.114 (2.515 to 2.896) 0.009 (0.229)

0.115 to 0.130 (2.921 to 3.302) 0.010 (0.254)

0.131 to 0.145 (3.327 to 3.683) 0.012 (0.305)

0.146 to 0.176 (3.708 to 4.470) 0.014 (0.356)

A

Specified Width, in. (mm) Permissible Variations in Width, in. (mm)

+−

Up to 42 (1066.8) ⁄16(1.59) 0

42 and Over (1066.8 and Over) ⁄8 (3.18) 0

A

Specified Length, in. (mm) Permissible Variations in Length, in. (mm)

+−

Up to 120 (3048) ⁄16(1.59) 0

120 and Over (3048 and Over) ⁄8 (3.18) 0

Weight

Permissible variations in weight apply only to polished finishes. The actual weight of any one item Estimated Permissible Variations, Actual

B

of an ordered thickness and size in any finish is limited in overweight by the following tolerances: Weight Over the Estimated Weight, %

Any item of 5 sheets or less, or any item estimated to weigh 200 lb (90.72 kg) or less 10

Any item of more than 5 sheets, and estimated to weigh more than 200 lb (90.72 kg) 7.5

A

Sheet 0.131 in. (3.33 mm) and over in thickness, regardless of size, may have permissible variations of 6 ⁄4 in. (6.35 mm) in width and in length, respectively.

B

There is no under variation in weight for No. 1 and No. 2 finishes, these finishes being limited in under variations only by the permissible variations in thickness. Polished

sheets may actually weigh as much as 5 % less than the estimated weight. Estimated weight of the composite plates may be calculated using the following weights of the

component materials:

Weight per Square Foot for

Material 1 in. in Thickness, lb

Steel 40.8

Chromium steel cladding 41.2

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

A 263

TABLE 2 Permissible Variations in Thickness of Cold-Rolled Strip

NOTE—Permissible variations in thickness are based on measurements taken ⁄8 in. (9.53 mm) in from the edge on cold-rolled strip 1 in. (25.4 mm or

over in width and at any place on the strip on material less

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.