ASTM C1421-01b(2007)

(Test Method)Standard Test Methods for Determination of Fracture Toughness of Advanced Ceramics at Ambient Temperature

Standard Test Methods for Determination of Fracture Toughness of Advanced Ceramics at Ambient Temperature

SIGNIFICANCE AND USE

These test methods may be used for material development, material comparison, quality assessment, and characterization.

The pb and the vb fracture toughness values provide information on the fracture resistance of advanced ceramics containing large sharp cracks, while the sc fracture toughness value provides this information for small cracks comparable in size to natural fracture sources.

Note 4—Cracks of different sizes may be used for the sc method. If the fracture toughness values vary as a function of the surface crack size it can be expected that KIsc will differ from KIpb and KIvb.

SCOPE

1.1 These test methods cover the fracture toughness determination of KIpb (precracked beam test specimen), KIsc (surface crack in flexure), and KIvb (chevron-notched beam test specimen) of advanced ceramics at ambient temperature. The fracture toughness values are determined using beam test specimens with a sharp crack. The crack is either a straight-through crack (pb), or a semi-elliptical surface crack (sc), or it is propagated in a chevron notch (vb).Note 1

The terms bend(ing) and flexure are synonymous in these test methods.

1.2 These test methods determine fracture toughness values based on a force and crack length measurement (pb, sc), or a force measurement and an inferred crack length (vb). In general, the fracture toughness is determined from maximum force. Applied force and displacement or an alternative (for example, time) are recorded for the pb test specimen and vb test specimen.

1.3 These test methods are applicable to materials with either flat or with rising R-curves. The fracture toughness measured from stable crack extension may be different than that measured from unstable crack extension. This difference may be more pronounced for materials exhibiting a rising R-curve.Note 2

One difference between the procedures in these test methods and test methods such as Test Method E 399, which measure fracture toughness, KIc, by one set of specific operational procedures, is that Test Method E 399 focuses on the start of crack extension from a fatigue precrack for metallic materials. In these test methods the test methods for advanced ceramics make use of either a sharp precrack formed via bridge flexure (pb) or via Knoop indent (sc) prior to the test, or a crack formed during the test (vb). Differences in test procedure and analysis may cause the values from each test method to be different. Therefore, fracture toughness values determined with these methods cannot be interchanged with KIc as defined in Test Method E 399 and may not be interchangeable with each other.

1.4 These test methods give fracture toughness values, KIpb, KIsc, and KIvb, for specific conditions of environment, test rate and temperature. The fracture toughness values, KIpb, KIsc, and KIvb for a material can be functions of environment, test rate and temperature.

1.5 These test methods are intended primarily for use with advanced ceramics which are macroscopically homogeneous. Certain whisker- or particle-reinforced ceramics may also meet the macroscopic behavior assumptions.

1.6 These test methods are divided into three major parts and related sub parts as shown below. The first major part is the main body and provides general information on the test methods described, the applicability to materials comparison and qualification, and requirements and recommendations for fracture toughness testing. The second major part is composed of annexes that provide procedures, test specimen design, precracking, testing, and data analysis for each method. Annex A1 describes suggested test fixtures, Annex A2 describes the pb method, Annex A3 describes the sc method, and Annex A4 describes the vb method. The third major part consists of three appendices detailing issues related to the fractography and precracking used for the sc method.

1.7 Values expressed in these test methods are in accordance with the International Syst...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 1421 – 01b (Reapproved 2007)

Standard Test Methods for

Determination of Fracture Toughness of Advanced Ceramics

at Ambient Temperature

This standard is issued under the fixed designation C1421; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 1.4 Thesetestmethodsgivefracturetoughnessvalues,K ,

Ipb

K , and K , for specific conditions of environment, test rate

1.1 These test methods cover the fracture toughness deter- Isc Ivb

andtemperature.Thefracturetoughnessvalues,K ,K ,and

Ipb Isc

mination of K (precracked beam test specimen), K (surface

Ipb Isc

K for a material can be functions of environment, test rate

crack in flexure), and K (chevron-notched beam test speci- Ivb

Ivb

and temperature.

men) of advanced ceramics at ambient temperature. The

1.5 These test methods are intended primarily for use with

fracture toughness values are determined using beam test

advanced ceramics which are macroscopically homogeneous.

specimens with a sharp crack. The crack is either a straight-

Certainwhisker-orparticle-reinforcedceramicsmayalsomeet

through crack (pb), or a semi-elliptical surface crack (sc), or it

the macroscopic behavior assumptions.

is propagated in a chevron notch (vb).

1.6 These test methods are divided into three major parts

NOTE 1—Thetermsbend(ing)andflexurearesynonymousinthesetest

andrelatedsubpartsasshownbelow.Thefirstmajorpartisthe

methods.

main body and provides general information on the test

1.2 These test methods determine fracture toughness values

methods described, the applicability to materials comparison

based on a force and crack length measurement (pb, sc), or a

and qualification, and requirements and recommendations for

force measurement and an inferred crack length (vb). In

fracture toughness testing. The second major part is composed

general, the fracture toughness is determined from maximum

of annexes that provide procedures, test specimen design,

force. Applied force and displacement or an alternative (for

precracking, testing, and data analysis for each method.Annex

example, time) are recorded for the pb test specimen and vb

A1 describes suggested test fixtures, Annex A2 describes the

test specimen.

pb method,AnnexA3 describes the sc method, andAnnexA4

1.3 These test methods are applicable to materials with

describes the vb method.The third major part consists of three

either flat or with rising R-curves. The fracture toughness

appendices detailing issues related to the fractography and

measured from stable crack extension may be different than

precracking used for the sc method.

that measured from unstable crack extension. This difference

Main Body Section

may be more pronounced for materials exhibiting a rising Scope 1

Referenced Documents 2

R-curve.

Terminology (including definitions, orientation and symbols) 3

Summary of Test Methods 4

NOTE 2—One difference between the procedures in these test methods

Significance and Use 5

and test methods such as Test Method E399, which measure fracture

Interferences 6

toughness, K , by one set of specific operational procedures, is that Test

Ic

Apparatus 7

Method E399 focuses on the start of crack extension from a fatigue

Test Specimen Configurations, Dimensions and Preparations 8

precrack for metallic materials. In these test methods the test methods for General Procedures 9

Report (including reporting tables) 10

advanced ceramics make use of either a sharp precrack formed via bridge

Precision and Bias 11

flexure (pb) or via Knoop indent (sc) prior to the test, or a crack formed

Annexes

during the test (vb). Differences in test procedure and analysis may cause

Test Fixture Geometries A1

the values from each test method to be different. Therefore, fracture

Special Requirements for Precracked Beam Method A2

toughness values determined with these methods cannot be interchanged

Special Requirements for Surface Crack in Flexure Method A3

with K as defined inTest Method E399 and may not be interchangeable Special Requirements for Chevron Notch Flexure Method A4

Ic

Appendices

with each other.

Precrack Characterization, Surface Crack in Flexure Method X1

Complications in Interpreting Surface Crack in Flexure Precracks X2

Alternative Precracking Procedure, Surface Crack in Flexure X3

This test method is under the jurisdiction of ASTM Committee C28 on Method

Advanced Ceramics and is the direct responsibility of Subcommittee C28.01 .

1.7 Valuesexpressedinthesetestmethodsareinaccordance

Current edition approved Feb. 1, 2007. Published March 2007. Originally

approved in 1999. Last previous edition approved in 2001 as C1421-01b. withtheInternationalSystemofUnits(SI)andPracticeE380.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C 1421 – 01b (2007)

1.8 This standard does not purport to address all of the particular mode in a homogeneous, linear-elastic body.

safety concerns, if any, associated with its use. It is the (E 1823)

responsibility of the user of this standard to establish appro-

3.2 Definitions of Terms Specific to This Standard:

priate safety and health practices and determine the applica-

3.2.1 back-face strain—the strain as measured with a strain

bility of regulatory limitations prior to use.

gagemountedlongitudinallyonthecompressivesurfaceofthe

test specimen, opposite the crack or notch mouth (often this is

2. Referenced Documents

the top surface of the test specimen as tested)

2.1 ASTM Standards:

3.2.2 crack depth, a [L]—in surface-cracked test speci-

C1161 Test Method for Flexural Strength of Advanced

mens, the normal distance from the cracked beam surface to

Ceramics at Ambient Temperature

the point of maximum penetration of crack front in the

C1322 Practice for Fractography and Characterization of

material.

Fracture Origins in Advanced Ceramics

3.2.3 crack orientation—a description of the plane and

E4 Practices for Force Verification of Testing Machines

directionofafractureinrelationtoacharacteristicdirectionof

E112 Test Methods for Determining Average Grain Size

the product. This identification is designated by a letter or

E177 Practice for Use of the Terms Precision and Bias in

letters indicating the plane and direction of crack extension.

ASTM Test Methods

The letter or letters represent the direction normal to the crack

E337 Test Method for Measuring Humidity with a Psy-

plane and the direction of crack propagation.

chrometer (the Measurement of Wet- and Dry-Bulb Tem-

3.2.3.1 Discussion—The characteristic direction may be

peratures)

associated with the product geometry or with the microstruc-

E399 Test Method for Linear-Elastic Plane-Strain Fracture

tural texture of the product.

Toughness K of Metallic Materials

Ic

3.2.3.2 Discussion—The fracture toughness of a material

E691 Practice for Conducting an Interlaboratory Study to

may depend on the orientation and direction of the crack in

Determine the Precision of a Test Method

relation to the material anisotropy, if such exists. Anisotropy

E740 Practice for Fracture Testing with Surface-Crack

maydependontheprincipalpressingdirections,ifany,applied

Tension Specimens

during green body forming (for example, uniaxial or isopress-

E1823 Terminology Relating to Fatigue and Fracture Test-

ing, extrusion, pressure casting) or sintering (for example,

ing

uniaxial hot-pressing, hot isostatic pressing). Thermal gradi-

IEEE/ASTM SI10 Standard for Use of the International

ents during firing can also lead to microstructural anisotropy.

System of Units (SI) (The Modern Metric System)

3.2.3.3 Discussion—The crack plane is defined by letter(s)

2.2 Reference Material:

representing the direction normal to the crack plane as shown

NIST SRM 2100 Fracture Toughness of Ceramics

in Fig. 1, Fig. 2, and Fig. 3.The direction of crack extension is

defined also by the letter(s) representing the direction parallel

3. Terminology

tothecharacteristicdirection(axis)oftheproductasillustrated

3.1 Definitions:

in Fig. 1b, Fig. 2b and Fig. 3b.

3.1.1 The terms described in Terminology E1823 are ap-

HP = hot-pressing direction (See Fig. 1)

plicable to these test methods. Appropriate sources for each

EX = extrusion direction (See Fig. 2)

AXL = axial, or longitudinal axis (if HP or EX are not applicable)

definition are provided after each definition in parentheses.

-3/2 -1 R = radial direction (See Fig. 1, Fig. 2 and Fig. 3)

3.1.2 crack extension resistance, K [FL ], G [FL ], or

R R

C = circumferential direction (See Fig. 1, Fig. 2 and Fig. 3)

-1

J [FL ],—a measure of the resistance of a material to crack

R/C = mixed radial and circumferential directions (See Fig. 3b)

R

extension expressed in terms of the stress-intensity factor, K,

3.2.3.4 Discussion—For a rectangular product, R and C

strain energy release rate, G, or values of J derived using the

may be replaced by rectilinear axes x and y, corresponding to

J-integral concept. (E 1823)

two sides of the plate.

3.1.3 fracture toughness—a generic term for measures of

3.2.3.5 Discussion—Depending on how test specimens are

resistance of extension of a crack. (E 399, E 1823)

sliced out of a ceramic product, the crack plane may be

3.1.4 R-curve—a plot of crack-extension resistance as a

circumferential,radial,oramixtureofbothasshowninFig.3.

function of stable crack extension.

3.2.3.6 Identification of the plane and direction of crack

3.1.5 slow crack growth (SCG)—sub critical crack growth

extension is recommended. The plane and direction of crack

(extension)whichmayresultfrom,butisnotrestrictedto,such

extension are denoted by a hyphenated code with the first

mechanisms as environmentally-assisted stress corrosion or

letter(s) representing the direction normal to the crack plane,

diffusive crack growth.

-3/2

and the second letter(s) designating the expected direction of

3.1.6 stress-intensity factor, K [FL ]—the magnitude of

crack extension. See Fig. 1, Fig. 2 and Fig. 3.

the ideal-crack-tip stress field (stress field singularity) for a

3.2.3.7 Discussion—In many ceramics, specification of the

crack plane is sufficient.

3.2.3.8 Isopressed products, amorphous ceramics, glasses

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

and glass ceramics are often isotropic, and crack plane orien-

Standards volume information, refer to the standard’s Document Summary page on

tation has little effect on fracture toughness. Nevertheless, the

the ASTM website.

designation of crack plane relative to product geometry is

Available from National Institute of Standards and Technology (NIST), 100

Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov. recommended.Forexample,iftheproductisisopressed(either

C 1421 – 01b (2007)

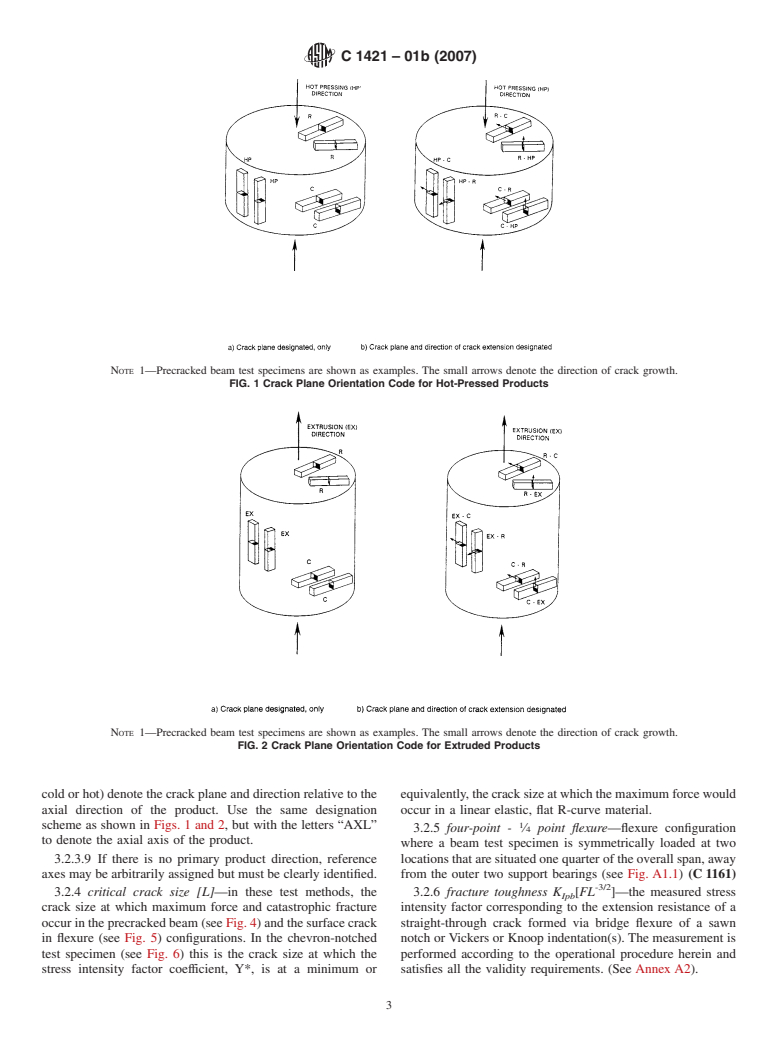

NOTE 1—Precracked beam test specimens are shown as examples. The small arrows denote the direction of crack growth.

FIG. 1 Crack Plane Orientation Code for Hot-Pressed Products

NOTE 1—Precracked beam test specimens are shown as examples. The small arrows denote the direction of crack growth.

FIG. 2 Crack Plane Orientation Code for Extruded Products

coldorhot)denotethecrackplaneanddirectionrelativetothe equivalently,thecracksizeatwhichthemaximumforcewould

axial direction of the product. Use the same designation occur in a linear elastic, flat R-curve material.

scheme as shown in Figs. 1 and 2, but with the letters “AXL”

3.2.5 four-point - ⁄4 point flexure—flexure configuration

to denote the axial axis of the product.

where a beam test specimen is symmetrically loaded at two

3.2.3.9 If there is no primary product direction, reference locationsthataresituatedonequarteroftheoverallspan,away

axes may be arbitrarily assigned but must be clearly identified. from the outer two support bearings (see Fig. A1.1) (C 1161)

-3/2

3.2.4 critical crack size [L]—in these test methods, the 3.2.6 fracture toughness K [FL ]—the measured stress

Ipb

crack size at which maximum force and catastrophic fracture intensity factor corresponding to the extension resistance of a

occurintheprecrackedbeam(seeFig.4)andthesurfacecrack straight-through crack formed via bridge flexure of a sawn

in flexure (see Fig. 5) configurations. In the chevron-notched notch or Vickers or Knoop indentation(s). The measurement is

test specimen (see Fig. 6) this is the crack size at which the performed according to the operational procedure herein and

stress intensity factor coefficient, Y*, is at a minimum or satisfies all the validity requirements. (See Annex A2).

C 1421 – 01b (2007)

NOTE 1—The R/C mix shown in b) is a consequence of the parallel slicing of the test specimens from the product.

NOTE 2—Precracked beam test specimens are shown as examples. The small arrows denote the direction of crack growth.

FIG. 3 Code for Crack Plane and Direction of Crack Extension in Test Specimens with Axial Primary Product Direction

FIG. 4 Cross Section of a pb Test Specimen Showing the

Precrack Configuration (a ,a ,a are the Points for Crack

0.25 0.50 0.75

Length Measurements)

FIG.5aandbCross Section of sc Test Specimens Showing the

Precrack Configurations for Two Orientations

-3/2

3.2.7 fracture toughness K or K *[FL ]—the mea-

Isc Isc

sured (K ) or apparent (K *) stress intensity factor corre-

Isc Isc

The measurement is performed according to the operational

sponding to the extension resistance of a semi-elliptical crack

procedure herein and satisfies all the validity requirements.

formed via Knoop indentation, for which the residual stress

(See Annex A4).

fieldduetoindentationhasbeenremoved.Themeasurementis

3.2.9 minimum stress-intensity factor coeffıcient, Y* —the

performed according to the operational procedure herein and

min

minimum value of Y* determined from Y* as a function of

satisfies all the validity requirements. (See Annex A3).

-3/2

dimensionless crack length, a = a/W.

3.2.8 fracture toughness K [FL ]—the measured stress

Ivb

intensity factor corresponding to the extension resistance of a 3.2.10 pop-in—in these test methods, the sudden formation

stably-extending crack in a chevron-notched test specimen. or extension of a crack without catastrophic fracture of the test

C 1421 – 01b (2007)

3.3.11 c—asusedinthesetestmethods,crackhalfwidth,sc

method, see Fig. 5 and Fig. A3.2.

3.3.12 d—as used in these test methods, length of long

diagonalforaKnoopindent,lengthofadiagonalforaVickers

indent, sc method.

3.3.13 E—elastic modulus.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.