ASTM D8237-21

(Test Method)Standard Test Method for Determining Fatigue Failure of Asphalt-Aggregate Mixtures with the Four-Point Beam Fatigue Device

Standard Test Method for Determining Fatigue Failure of Asphalt-Aggregate Mixtures with the Four-Point Beam Fatigue Device

SIGNIFICANCE AND USE

5.1 The laboratory fatigue life determined by this standard for beam specimens has been used to estimate the fatigue life of asphalt mixture pavement layers under repeated traffic loading. Although the field performance of asphalt mixtures is impacted by many factors (traffic variation, loading rate, and wander; climate variation; rest periods between loads; aging; etc.), it has been more accurately predicted when laboratory properties are known along with an estimate of the strain level induced at the layer depth by the traffic wheel load traveling over the pavement.

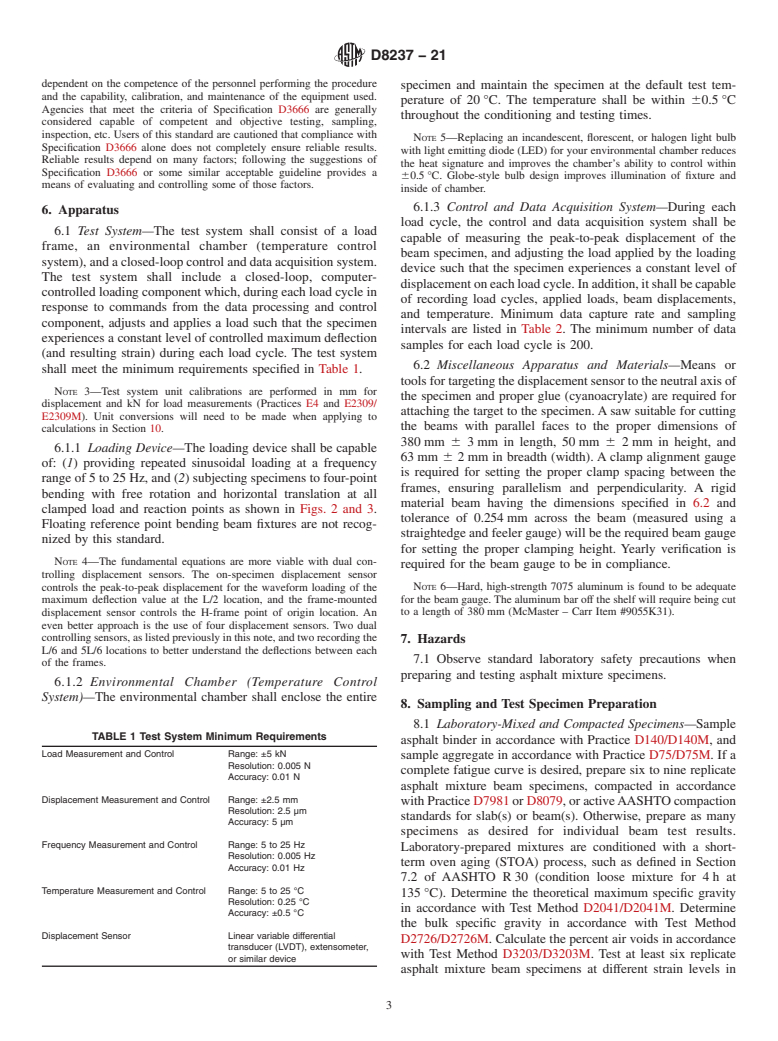

Note 2: The quality of the results produced by this standard are dependent on the competence of the personnel performing the procedure and the capability, calibration, and maintenance of the equipment used. Agencies that meet the criteria of Specification D3666 are generally considered capable of competent and objective testing, sampling, inspection, etc. Users of this standard are cautioned that compliance with Specification D3666 alone does not completely ensure reliable results. Reliable results depend on many factors; following the suggestions of Specification D3666 or some similar acceptable guideline provides a means of evaluating and controlling some of those factors.

SCOPE

1.1 This test method provides a procedure for determining a fatigue curve that is developed using three or more strain levels. The resulting data can be used in the fatigue models for mechanistic-empirical pavement design (that is, Pavement ME). Failure points are determined for estimating the fatigue life of 380 mm long by 50 mm thick by 63 mm in breadth (width) asphalt mixture beam (rectangular prism) specimens sawed from laboratory or field-compacted asphalt mixture, which are subjected to repeated flexural bending.

1.2 The largest nominal maximum aggregate size (NMAS) recommended for beams 50 mm thick is 19 mm. Beams made with an NMAS greater than 19 mm might significantly interfere with the material response, thereby affecting the repeatability of the test.

1.3 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

1.4 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard, with the exception of degrees (°) where angle is specified in accordance with IEEE/ASTM SI 10.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D8237 − 21

Standard Test Method for

Determining Fatigue Failure of Asphalt-Aggregate Mixtures

1

with the Four-Point Beam Fatigue Device

This standard is issued under the fixed designation D8237; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 Thistestmethodprovidesaprocedurefordetermininga 2.1 ASTM Standards:

fatigue curve that is developed using three or more strain D8Terminology Relating to Materials for Roads and Pave-

levels.The resulting data can be used in the fatigue models for ments

mechanistic-empirical pavement design (that is, Pavement D75/D75MPractice for Sampling Aggregates

ME). Failure points are determined for estimating the fatigue D140/D140MPractice for Sampling Asphalt Materials

life of 380mm long by 50mm thick by 63mm in breadth D979/D979MPractice for Sampling Bituminous Paving

(width) asphalt mixture beam (rectangular prism) specimens Mixtures

sawed from laboratory or field-compacted asphalt mixture, D2041/D2041MTest Method for Theoretical Maximum

which are subjected to repeated flexural bending. Specific Gravity and Density of Asphalt Mixtures

D2726/D2726MTest Method for Bulk Specific Gravity and

1.2 The largest nominal maximum aggregate size (NMAS)

Density of Non-Absorptive Compacted Asphalt Mixtures

recommended for beams 50mm thick is 19mm. Beams made

D3203/D3203MTest Method for PercentAirVoids in Com-

with an NMAS greater than 19mm might significantly inter-

pacted Asphalt Mixtures

fere with the material response, thereby affecting the repeat-

D3549/D3549MTest Method for Thickness or Height of

ability of the test.

Compacted Asphalt Mixture Specimens

1.3 The text of this standard references notes and footnotes

D3666Specification for Minimum Requirements for Agen-

whichprovideexplanatorymaterial.Thesenotesandfootnotes

cies Testing and Inspecting Road and Paving Materials

(excluding those in tables and figures) shall not be considered

D5361/D5361MPractice for Sampling Compacted Asphalt

as requirements of the standard.

Mixtures for Laboratory Testing

D7981Practice for Compaction of PrismaticAsphalt Speci-

1.4 Units—The values stated in SI units are to be regarded

asstandard.Nootherunitsofmeasurementareincludedinthis mens by Means of the Shear Box Compactor

D8079Practice for Preparation of Compacted Slab Asphalt

standard, with the exception of degrees (°) where angle is

specified in accordance with IEEE/ASTM SI 10. Mix Samples Using a Segmented Rolling Compactor

E4Practices for Force Verification of Testing Machines

1.5 This standard does not purport to address all of the

E29Practice for Using Significant Digits in Test Data to

safety concerns, if any, associated with its use. It is the

Determine Conformance with Specifications

responsibility of the user of this standard to establish appro-

E2309/E2309MPractices for Verification of Displacement

priate safety, health, and environmental practices and deter-

Measuring Systems and Devices Used in MaterialTesting

mine the applicability of regulatory limitations prior to use.

Machines

1.6 This international standard was developed in accor-

IEEE/ASTM SI 10American National Standard for Metric

dance with internationally recognized principles on standard-

Practice

ization established in the Decision on Principles for the

3

2.2 AASHTO Standard:

Development of International Standards, Guides and Recom-

R30StandardPracticeforMixtureConditioningofHot-Mix

mendations issued by the World Trade Organization Technical

Asphalt (HMA)

Barriers to Trade (TBT) Committee.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

This test method is under the jurisdiction of ASTM Committee D04 on Road contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

and Paving Materials and is the direct responsibility of Subcommittee D04.26 on Standards volume information, refer to the standard’s Document Summary page on

Fundamental/Mechanistic Tests. the ASTM website.

3

CurrenteditionapprovedJuly1,2021.PublishedJuly2021.Originallyapproved Available from American Association of State Highway and Transportation

in 2018. Last previous edition approved in 2018 as D8237–18. DOI: 10.1520/ Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001,

D8237-21. http://www.transportation.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

------------------

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D8237 − 18 D8237 − 21

Standard Test Method for

Determining Fatigue Failure of Asphalt-Aggregate Mixtures

1

Withwith the Four-Point Beam Fatigue Device

This standard is issued under the fixed designation D8237; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method provides a procedure for determining a fatigue curve that is developed using three or more strain levels. The

resulting data can be used in the fatigue models for mechanistic-empirical pavement design (that is, Pavement ME). Failure points

are determined for estimating the fatigue life of 380 mm long by 50 mm thick by 63 mm in breadth (width) asphalt mixture beam

(rectangular prism) specimens sawed from laboratory or field-compacted asphalt mixture, which are subjected to repeated flexural

bending.

1.2 The largest nominal maximum aggregate size (NMAS) recommended for beams 50 mm thick is 19 mm. Beams made with an

NMAS greater than 19 mm might significantly interfere with the material response, thereby affecting the repeatability of the test.

1.3 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes

(excluding those in tables and figures) shall not be considered as requirements of the standard.

1.4 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this

standard, with the exception of degrees (°) where angle is specified in accordance with IEEE/ASTM SI 10.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D8 Terminology Relating to Materials for Roads and Pavements

D75/D75M Practice for Sampling Aggregates

D140/D140M Practice for Sampling Asphalt Materials

D979/D979M Practice for Sampling Bituminous Paving Mixtures

D2041/D2041M Test Method for Theoretical Maximum Specific Gravity and Density of Asphalt Mixtures

1

This test method is under the jurisdiction of ASTM Committee D04 on Road and Paving Materials and is the direct responsibility of Subcommittee D04.26 on

Fundamental/Mechanistic Tests.

Current edition approved Dec. 1, 2018July 1, 2021. Published December 2018July 2021. Originally approved in 2018. Last previous edition approved in 2018 as

D8237 – 18. DOI: 10.1520/D8237-18.10.1520/D8237-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D8237 − 21

D2726/D2726M Test Method for Bulk Specific Gravity and Density of Non-Absorptive Compacted Asphalt Mixtures

D3203/D3203M Test Method for Percent Air Voids in Compacted Asphalt Mixtures

D3549/D3549M Test Method for Thickness or Height of Compacted Asphalt Mixture Specimens

D3666 Specification for Minimum Requirements for Agencies Testing and Inspecting Road and Paving Materials

D5361/D5361M Practice for Sampling Compacted Asphalt Mixtures for Laboratory Testing

D7981 Practice for Compaction of Prismatic Asphalt Specimens by Means of the Shear Box Compactor

D8079 Practice for Preparation of Compacted Slab Asphalt Mix Samples Using a Segmented Rolling Compactor

E4 Practices for Force Verification of Testing Machines

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E2309/E2309M Practices for Verification of Displacement Measuring Systems and Devices Used in Material Testing Machines

IEEE/ASTM SI 10 American National Standard for Metric Practice

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.