ASTM F2102-01e1

(Guide)Standard Guide for Evaluating the Extent of Oxidation in Ultra-High-Molecular-Weight Polyethylene Fabricated Forms Intended for Surgical Implants

Standard Guide for Evaluating the Extent of Oxidation in Ultra-High-Molecular-Weight Polyethylene Fabricated Forms Intended for Surgical Implants

SCOPE

1.1 This guide describes a method for the measurement of the relative extent of oxidation present in ultra-high-molecular-weight polyethylene (UHMWPE) intended for use in medical implants. The material is analyzed by infrared spectroscopy. The intensity (area) of the carbonyl absorptions (>C=O) centered near 1720 cm-1 is related to the amount of chemically bound oxygen present in the material. Other forms of chemically bound oxygen (C-O-C, C-O-O-C, C-O-H, and so forth) are not captured by this method.

1.2 Although this method may give the investigator a means to compare the relative extent of carbonyl oxidation present in various UHMWPE samples, it is recognized that other forms of chemically bound oxygen may be important contributors to these materials' characteristics.

1.3 The applicability of the infrared method has been demonstrated by many literature reports. This particular method, using the intensity (area) of the C-H absorption centered near 1370 cm-1 to normalize for the sample's thickness, has been validated by an Interlaboratory Study (ILS) conducted according to Practice E691.

1.4 The following precautionary caveat pertains only to the test method portion, Section 5, of this specification:This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: F 2102 – 01

Standard Guide for

Evaluating the Extent of Oxidation in Ultra-High-Molecular-

Weight Polyethylene Fabricated Forms Intended for Surgical

1

Implants

This standard is issued under the fixed designation F 2102; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1

e NOTE—Section 4.1.1 was editorially corrected in October 2001.

1. Scope 3. Terminology

1.1 This guide describes a method for the measurement of 3.1 Definitions:

the relative extent of oxidation present in ultra-high-molecular- 3.1.1 bulk oxidation index (BOI)—a sample’s bulk oxida-

weight polyethylene (UHMWPE) intended for use in medical tion index (BOI) is the average of the oxidation indices

implants. The material is analyzed by infrared spectroscopy. collected over a 500-µm section at the center of the sample.

The intensity (area) of the carbonyl absorptions (>C=O) 3.1.1.1 Discussion—Typically, this is a plateau region with

-1

centered near 1720 cm is related to the amount of chemically the smallest oxidation indices.

bound oxygen present in the material. Other forms of chemi- 3.1.1.2 Discussion—For samples less than about 8 to 10

cally bound oxygen (C-O-C, C-O-O-C, C-O-H, and so forth) mm thick, this central region may display the sample’s highest

are not captured by this method. oxidation indices, depending on its state of oxidation.

1.2 Althoughthismethodmaygivetheinvestigatorameans 3.1.2 depth locator (DL)—a measurement of the distance

to compare the relative extent of carbonyl oxidation present in fromthearticularsurface,orsurfaceofinterest,thataspectrum

variousUHMWPEsamples,itisrecognizedthatotherformsof was collected and a corresponding OI calculated.

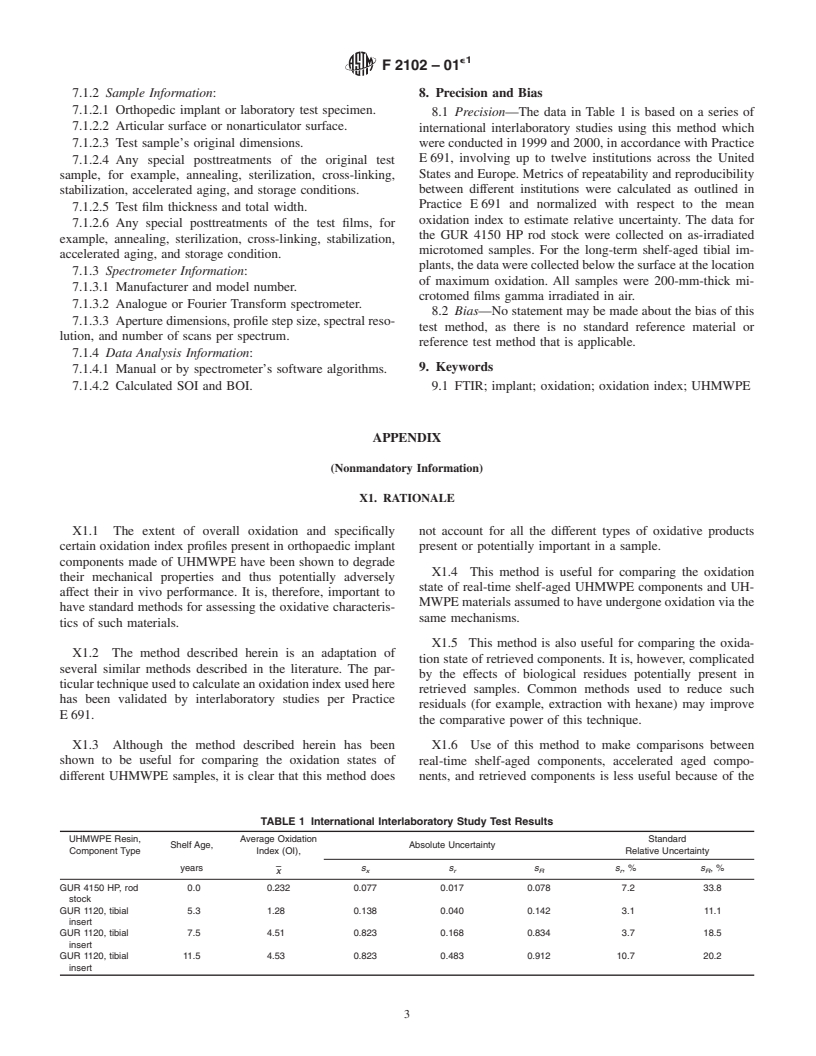

chemically bound oxygen may be important contributors to 3.1.3 oxidation index (OI)—an oxidation index (OI) is

these materials’ characteristics. defined as the ratio of the area of the absorption peak(s)

-1

1.3 The applicability of the infrared method has been between 1650 and 1850 cm to the area of the absorption

-1

demonstrated by many literature reports. This particular peak(s) between 1330 and 1396 cm , as shown in Fig. 1.

method, using the intensity (area) of the C-H absorption 3.1.4 oxidation index profile—an oxidation index profile is

-1

centered near 1370 cm to normalize for the sample’s thick- the graphical representation of variation of the sample’s

ness, has been validated by an Interlaboratory Study (ILS) oxidation index with distance from its articular surface or the

conducted according to Practice E 691. surface of interest.This is a plot of an OI versus DL.Typically,

1.4 The following precautionary caveat pertains only to the the graph will show the profile through the entire thickness of

test method portion, Section 5, of this specification: This the sample.

standard may involve hazardous materials, operations, and 3.1.5 surface oxidation index (SOI)—a sample’s surface

equipment. This standard does not purport to address all of the oxidation index (SOI) is the average of the oxidation indices

safety concerns, if any, associated with its use. It is the fromthesample’sarticularsurface,orthesurfaceofinterest,to

responsibility of the user of this standard to establish appro- a depth of 3-mm subsurface.

priate safety and health practices and determine the applica-

4. Apparatus

bility of regulatory requirements prior to use.

4.1 Infrared Spectrometer:

2. Referenced Documents

4.1.1 A calibrated infrared spectrometer capable of record-

2.1 ASTM Standards: ing a transmission absorption spectrum over the range of about

-1

E 691 Practice for Conducting an Interlaboratory Study to 1200 to about 2000 cm using about 200-µm-thick films at a

-1

2

Determine the Precision of a Test Method resolution of 4 cm and an aperture of about 200 by 200 µm.

4.1.1.1 Othermodesofcollection(thatis,percentreflection,

attenuated total reflection (ATR), and so forth) and aperture

1

This guide is under the jurisdiction of ASTM Committee F04 on Medical and

and increment sizes may be used to generate the sample’s

Surgical Materials and Devices and is the direct responsibility of Subcommittee

absorption spectrum provided they can be demonstrated to

F04.15 on Material Test Methods.

Current edition approved May 10, 2001. Published June 2001.

2

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

e1

F2102–01

from the articular surface, or surface of interest, across the

width of the film to the opposite surface.

5.3.2.1 Larger incr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.