ASTM D5543-94(1999)e1

(Test Method)Standard Test Methods for Low-Level Dissolved Oxygen in Water

Standard Test Methods for Low-Level Dissolved Oxygen in Water

SCOPE

1.1 These test methods cover the determination of low-level (∧lt;100 [mu]g/L) dissolved oxygen in thermal-cycle steam condensate, deaerated boiler feedwater, boiler water, and deaerated deionized water. The following test methods are included: Range, mg/L Sections Test Method A--Color Comparator Test 0 to 100 8 to 17 Method Using Self-Filling Glass Ampoules Test Method B--Instrument Test Method 0 to 100 18 to 26 Using Self-Filling Glass Ampoules

1.2 These test methods may be applicable to electronic-grade, pharmaceutical-grade, and other high-purity waters, although these were not addressed in the collaborative study.

1.3 Test Method A is a colorimetric procedure applicable to dissolved oxygen in water in the range from 0 to 100 [mu]g/L.

1.4 Test Method B is an instrumented colorimetric procedure applicable to dissolved oxygen in water in the range from 0 to 100 [mu]g/L.

1.5 It is the user's responsibility to ensure the validity of these test methods for waters of untested matrices.

1.6 The values stated in SI units are to be regarded as the standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

e1

Designation:D 5543–94 (Reapproved 1999)

Standard Test Methods for

Low-Level Dissolved Oxygen in Water

This standard is issued under the fixed designation D 5543; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Footnotes were editorially removed in June 1999.

1. Scope D 2777 Practice for Determination of Precision and Bias of

Applicable Methods of Committee D-19 on Water

1.1 These test methods cover the determination of low-level

D 3370 Practices for Sampling Water from Closed Con-

(<100µ g/L) dissolved oxygen in thermal-cycle steam conden-

duits

sate, deaerated boiler feedwater, boiler water, and deaerated

deionized water. The following test methods are included:

3. Terminology

Range, µg/L Sections

3.1 Definitions—For definitions of terms used in these test

Test Method A—Color Comparator Test 0to100 8to17

Method Using Self-Filling Glass

methods, refer to Terminology D 1129.

Ampoules

Test Method B—Instrument Test Method 0 to 100 18 to 26

4. Significance and Use

Using Self-Filling Glass Ampoules

4.1 Dissolved oxygen is detrimental in certain boiler and

1.2 These test methods may be applicable to electronic-

steam cycles because it may accelerate corrosion. Concentra-

grade, pharmaceutical-grade, and other high-purity waters,

tions above 10 µg/L are unacceptable in many high-pressure

although these were not addressed in the collaborative study.

boiler systems. The efficiency of dissolved oxygen removal

1.3 Test MethodAis a colorimetric procedure applicable to

from boiler feedwater by chemical or mechanical means, or

dissolved oxygen in water in the range from 0 to 100 µg/L.

both, is determined by measuring the concentration before and

1.4 Test Method B is an instrumented colorimetric proce-

after the process. The measurement is also made to check for

dure applicable to dissolved oxygen in water in the range from

air leakage into the boiler system.

0 to 100 µg/L.

4.2 The oxygen treatment method for boiler corrosion

1.5 It is the user’s responsibility to ensure the validity of

reduction requires injection of oxygen into the boiler feedwa-

these test methods for waters of untested matrices.

ter. The resulting oxygen level is monitored for control

1.6 The values stated in SI units are to be regarded as the

purposes.

standard.

1.7 This standard does not purport to address all of the

5. Reagents

safety concerns, if any, associated with its use. It is the

5.1 This test method does not require the preparation of any

responsibility of the user of this standard to establish appro-

reagents.All the necessary analytical reagents are provided by

priate safety and health practices and determine the applica-

the manufacturer in sealed ampoules.

bility of regulatory limitations prior to use.

5.2 Purity of Water— Unless otherwise indicated, refer-

ences to water shall be understood to mean reagent water as

2. Referenced Documents

defined by Type II of Specification D 1193.

2.1 ASTM Standards:

D 1066 Practice for Sampling Steam

6. Precautions

D 1129 Terminology Relating to Water

6.1 Users must exercise caution by using finger cots, in

D 1192 Specification for Equipment for Sampling Water

accordance with the manufacturer’s instructions, when han-

and Steam in Closed Conduits

dling the mixing of sample and reagent in the glass ampoules.

D 1193 Specification for Reagent Water

7. Sampling

7.1 Sampling is the most critical part of any dissolved

These test methods are under the jurisdiction of ASTM Committee D19 on

Water and are the direct responsibility of Subcommittee D19.03 on Sampling of oxygen test. The sample stream must be completely leak-free,

Water and Water-Formed Deposits, Surveillance of Water, and Flow Measurement

since even the smallest leak can elevate the oxygen level in the

of Water.

sample and cause large errors in the results. New or intermit-

Current edition approved Nov. 15, 1994. Published January 1995.

tentlyusedsamplingsystemsmustbepurgedforaminimumof

Annual Book of ASTM Standards, Vol 11.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D 5543–94 (1999)

4 h. Sample streams that are used routinely may require only a peroxide at a concentration of 0.1 mg/L yields a positive

few minutes of purging. interference of 10 µg/L dissolved oxygen; and ( 3) added

7.2 Collect the samples in accordance with Practices hydrogen peroxide in a concentration range from 0.5 to 650

D 1066 and D 3370 and Specification D 1192. mg/L yields a positive interference of 20 to 25 µg/L.

7.3 With water under pressure, connect a tube of inert

NOTE 1—Measurements of 0 to 100 µg/L of dissolved oxygen are

material to the inlet and extend the tube outlet to the bottom of

unaffected by the presence of 2200 mg/Lboron present as boric acid at pH

the sample bottle or tube. Use stainless steel, Type 304 or 316,

6 and above in the absence of hydrogen peroxide.

or glass tubing with short neoprene connections. Do not use

10.5 Benzoquinone, an oxidation product of hydroquinone,

copper tubing, long sections of neoprene tubing, or other types

interferes with this test method. One hundred micrograms per

of elastomeric polymeric materials. If the water being sampled

litreofbenzoquinonemayappearas33µg/Ldissolvedoxygen.

is above room temperature, the sample line shall contain a

10.6 Reducing agents such as hydrazine and sulfite do not

suitable cooling coil to cool it to approximate room tempera-

interfere at 5-mg/L (ppm) levels in the sample.

ture.

10.7 Ampoules must be protected from light to prevent

darkening. Follow the manufacturer’s storage recommenda-

TEST METHOD A—COLOR COMPARATOR TEST

tions.

METHOD USING SELF-FILLING GLASS AMPOULES

10.8 Colorcomparatortubesmustbeprotectedfromlightto

8. Scope

prevent fading. Follow the manufacturer’s storage recommen-

dations.

8.1 This test method covers the rapid, routine determination

of dissolved oxygen in steam condensate, deaerated boiler

11. Apparatus

feedwater, and deaerated deionized water. Color comparators

11.1 Color Comparator,for0,2,4,6,8,12,16,and20µg/L

allow the estimation of concentrations ranging from 0 to 100

(ppb) of oxygen.

µg/L (ppb) oxygen.

11.2 Color Comparator, for 0, 5, 10, 15, 20, 25, 30, and 40

8.2 This test method was tested in steam condensate,

µg/L (ppb) of oxygen.

deaerated boiler feedwater, and deaerated deionized water. It is

11.3 Color Comparator, for 0, 10, 20, 30, 40, 60, 80, and

the user’s responsibility to ensure the validity of the test

100 µg/L (ppb) of oxygen.

method for waters of untested matrices.

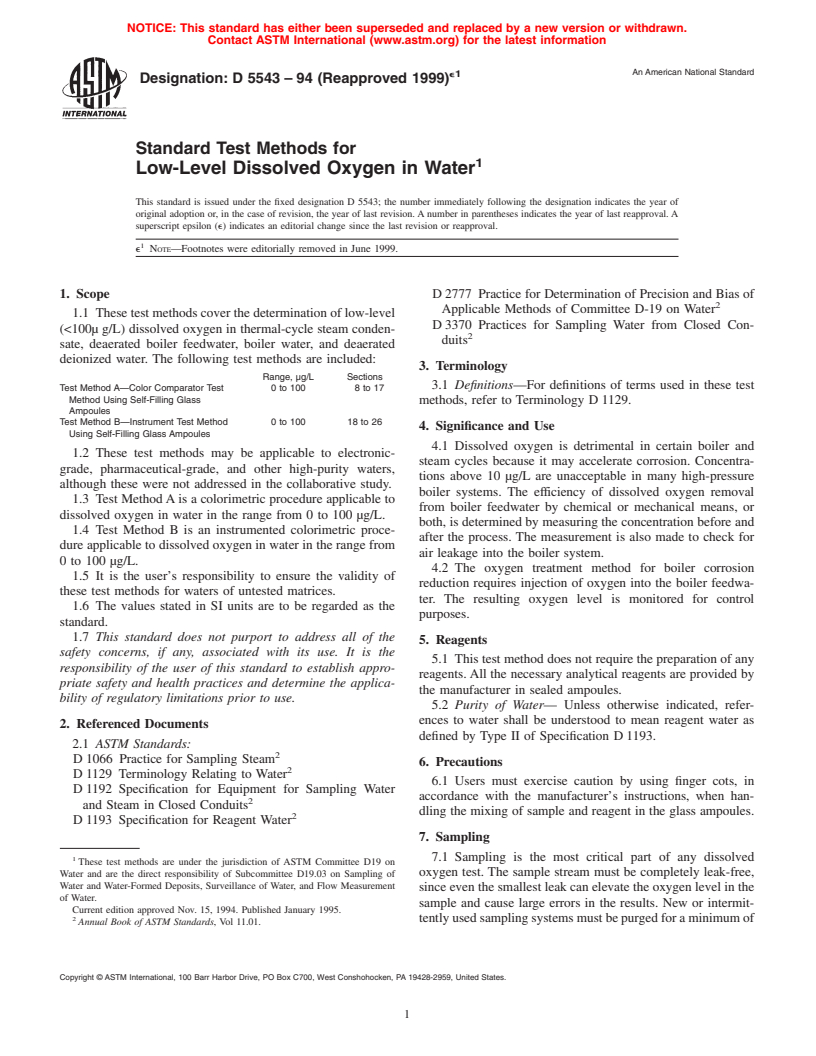

11.4 Sampling Tube. See Fig. 1.

9. Summary of Test Method

12. Reagents and Materials

9.1 The tip of a partially evacuated sealed ampoule is

12.1 Sealed, evacuated glass ampoules containing oxygen-

broken while submerged in a flowing water sample. The

sensitive indicator.

sample is drawn into the ampoule where it reacts instanta-

neously with the oxygen-sensitive indicator to produce a

13. Sampling

reddish violet color whose intensity is proportional to the

13.1 Attach the feedwater source to the plastic sampling

concentration of dissolved oxygen.

tube as described in 7.3. Clamps may be attached to the tube to

10. Interferences

10.1 Color, turbidity, and oxidizing impurities interfere in

this test method to yield high results. If the sample is colored

or turbid or contains oxidizing impurities, the amount of

interference that may be contributed by such effects must be

determined independently prior to using this test method.

10.2 Easily reduced metal ions may interfere in this test

method to cause high results. For example, 100 µg/L (ppb) Cu

+2 may appear as 5 µg/L(ppb) dissolved oxygen, and 100 µg/L

+3

Fe may appear as 7 µg/L dissolved oxygen. However, less

+2 +3

than 50 µg/L Cu or Fe cause less than 1-µg/L interference.

10.3 Hydrogen peroxide alone in concentrations up to 200

µg/L does not affect the measurement of 1.5 µg/L of dissolved

oxygen.Above 200 µg/Lhydrogen peroxide, there is a positive

interference of 3.3 µg/L dissolved oxygen per 100 µg/L excess

over 200 µg/L hydrogen peroxide.

10.4 The following interferences occur in the presence of

2200 mg/L boron present as boric acid: (1) at pH levels below

pH 6, recovery can be as low as 80 %; ( 2) added hydrogen

Spokes, G. N., Dissolved Oxygen in Water Measurement and Standardization,

EPRI PWR Plant Chemists’ Meeting, San Diego, CA, Nov. 17–20, 1992. Copies FIG. 1 Sampling Tube for Use with Ampoules to Measure

obtainable from CHEMetrics Inc., Route 28, Calverton, VA 22016. Dissolved Oxygen in a Flowing Water Sample

e1

D 5543–94 (1999)

NOTE 5—The color intensity may continue to increase after the rapid

hold it vertical, or it can be attached to a vertical rod or pipe

initial color reaction. However, it is the initial color reaction that is

above a sink, drain, or bucket.

complete within 30 s, and to which the system calibrations apply.

14. Calibration and Standardization

15.4.1 Find the analytical result from the concentration

14.1 No calibration is required.

value of the closest matching color standard as designated on

the comparator label. Estimate the concentration to within a

NOTE 2—The color comparator standards are precalibrated by the

half color standard interval.

manufacturer for measurement of dissolved oxygen in water.

14.2 A dissolved-oxygen-in-water standard may be gener-

16. Calculation

ated by following the procedures given in Appendix X1.

16.1 The dissolved oxygen content of the sample is the

15. Procedure

value obtained in 15.4. Use the average of the two resulting

values if two ampoules are used.

15.1 Insert the ampoule into the sampling device, with the

pointed end down. Allow the sample to flow at least 5 min.

17. Precision and Bias

A15-min wait time may be necessary to achieve the best

accuracy for samples with below 20 µg/Lof dissolved oxygen.

17.1 The overall precision and bias of this test method

15.2 Gently press the ampoule toward the wall of the

cannot be determined by round-robin testing because of the

sampling tube to snap off the tip, and remove thc ampoule,

instability of shipping solutions.

keeping the tip down, immediately after filling is complete.

17.2 This test method was evaluated for single-operator

15.3 Usingaprotectiverubberfingercot,placeafingerover

precision by eight laboratories, with a total of 15 operators

the broken tip. Caution: glass may be sharp. Invert the

running a total of 200 samples in triplicate. The collaborative

ampoule several times to mix the contents, allowing the bubble

test data were obtained on the samples available at the

to travel from end to end each time. Wipe all liquid from the

laboratory site locations. These data may not apply for other

exterior of the ampoule.

matrices.

17.2.1 The single-operator precision, S , of this test method

NOTE 3—A small bubble of inert gas will remain in the ampoule to

o

facilitate mixing.

was found to be dependent on the ampoule type and to be

NOTE 4—Due to the possibility of air leaking in during this step, it is

partly dependent on the dissolved oxygen content of the

advisable to run tests in duplicate. It should be noted, however, that some

sample. The data are summarized in the tables that follow.

variation in observed concentrations may be due to changes in system

17.2.1.1 Thedatainthefollowingtablewereobtainedusing

conditions.

0 to 20-µg/L (ppb) range ampoules and comparators. A total

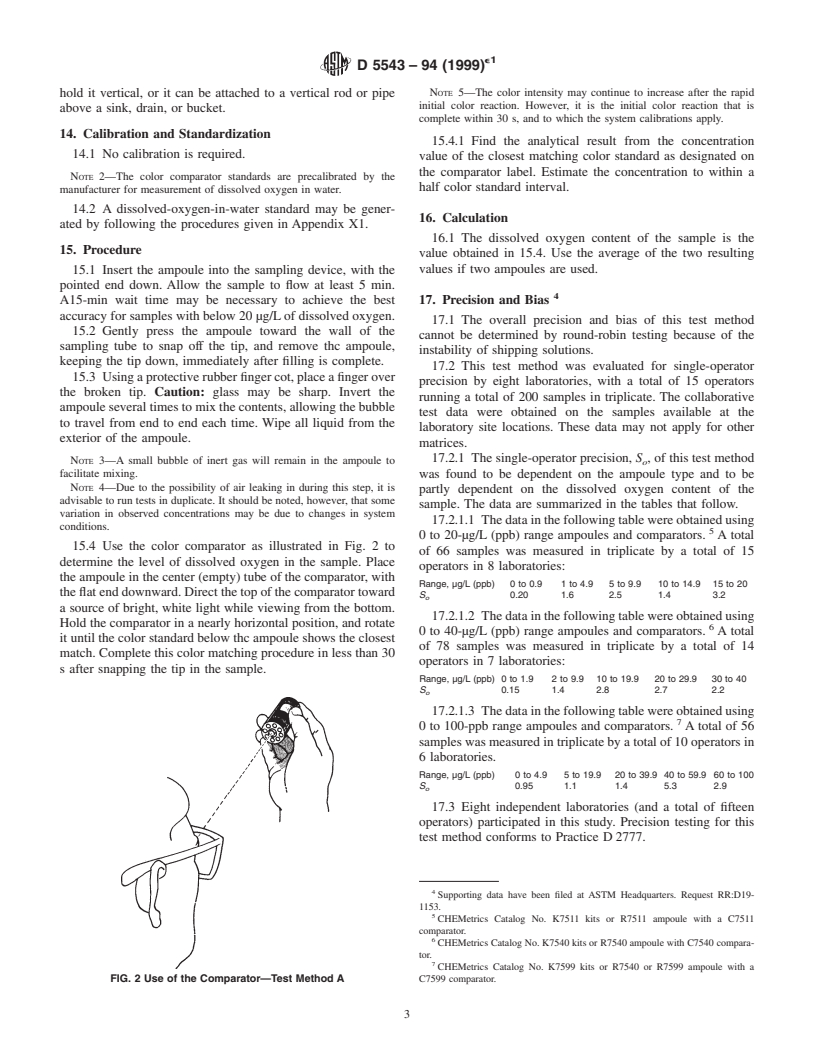

15.4 Use the color comparator as illustrated in Fig. 2 to

of 66 samples was measured in triplicate by a total of 15

determine the level of dissolved oxygen in the sample. Place

operators in 8 laboratories:

the ampoule in the center (empty) tube of the comparator, with

Range, µg/L (ppb) 0 to 0.9 1 to 4.9 5 to 9.9 10 to 14.9 15 to 20

the flat end downward. Direct the top of the comparator toward

S 0.20 1.6 2.5 1.4 3.2

o

a source of bright, white light while viewing from the bottom.

17.2.1.2 Thedatainthefollowingtablewereobtainedusing

Hold the comparator in a nearly horizontal position, and rotate

0 to 40-µg/L (ppb) range ampoules and comparators. A total

it until the color standard below thc ampoule shows the closest

of 78 samples was measured in triplicate by a total of 14

match. Complete this color matching procedure in less than 30

operators in 7 laboratories:

s after snapping the tip in the sample.

Range, µg/L (ppb) 0 to 1.9 2 to 9.9 10 to 19.9 20 to 29.9 30 to 40

S 0.15 1.4 2.8 2.7 2.2

o

17.2.1.3 Thedatainthefollowingtablewereobtainedusing

0 to 100-ppb range ampoules and comparators. A total of 56

samples was measured in triplicate by a total of 10 operators in

6 laboratories.

Range, µg/L (ppb) 0 to 4.9 5 to 19.9 20 to 39.9 40 to 59.9 60 to 100

S 0.95 1.1 1.4 5.3 2.9

o

17.3 Eight independent laboratories (and a total of fifteen

operators) participated in this study. Precision testing for this

test method conforms to Practice D 2777.

Supporting data have been filed at ASTM Headquarters. Request RR:D19-

1153.

CHEMetrics Catalog No. K7511 kits or R7511 ampoule with a C7511

comparator.

CHEMetrics Catalog No. K7540 kits or R7540 ampoule with C7540 compara-

tor.

CHEMetrics Catalog No. K7599 kits or R7540 or R7599 ampoule with a

FIG. 2 Use of the Comparator—Test Method A C7599 comparator.

e1

D 5543–94 (1999)

TEST METHOD B—INSTRUMENT TEST METHOD 21. Apparatus

USING SELF-FILLING GLASS AMPOULES

21.1 Bichromatic Instrument, microprocessor-controlled,

for measuring from 0.0 to 100 µg/L dissolved oxygen.

18. Scope

21.2 Sampling Tube. See Fig. 1.

18.1 Thistestmethodcoverstherapidroutinedetermination

of dissolved oxygen in steam condensate, deaerated boiler

22. Reagents and Materials

feedwater, and deaerated deionized water. This instrumental

22.1 Sealed, evacuated glass ampoules containing oxygen-

test method provides a digital presentation of dissolved oxygen

sensitive indicator.

concentrations ranging from 0 to 100 µg/L (ppb).

18.2 This test method was tested on steam condensate,

23. Sampling

deaerated boiler feedwater, and deaerated deionized water. It is

23.1 Attach the feedwater source to the plastic sampling

the user’s responsibility to ensure the validity of the test

tube in accordance with 7.3. Clamps may be attached to the

method for waters of untested matrices.

tube to hold it vertical, or it can be attached to a vertical rod or

pipe above a sink, drain, or bucket.

19. Summary of Test Method

19.1 The tip of a partially evacuated sealed a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.