ASTM D1754-97(2002)

(Test Method)Standard Test Method for Effect of Heat and Air on Asphaltic Materials (Thin-Film Oven Test)

Standard Test Method for Effect of Heat and Air on Asphaltic Materials (Thin-Film Oven Test)

SIGNIFICANCE AND USE

This method indicates approximate change in properties of asphalt during conventional hot-mixing at about 150°C (302°F) as indicated by viscosity, penetration, or ductility measurements. It yields a residue which approximates the asphalt condition as incorporated in the pavement. If the mixing temperature differs appreciably from the 150°C (302°F) level, more or less effect on properties will occur.

SCOPE

1.1 This test method covers the determination of the effect of heat and air on a film of semisolid asphaltic materials. The effects of this treatment are determined from measurements of selected asphalt properties before and after the test.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1754–97 (Reapproved 2002)

Standard Test Method for

Effects of Heat and Air on Asphaltic Materials (Thin-Film

1

Oven Test)

This standard is issued under the fixed designation D 1754; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Significance and Use

1.1 This test method covers the determination of the effects 4.1 This method indicates approximate change in properties

of heat and air on a film of semisolid asphaltic materials. The of asphalt during conventional hot-mixing at about 150°C

effects of this treatment are determined from measurements of (302°F) as indicated by viscosity, penetration, or ductility

selected asphalt properties before and after the test. measurements. It yields a residue which approximates the

1.2 The values stated in SI units are to be regarded as the asphalt condition as incorporated in the pavement. If the

standard. mixing temperature differs appreciably from the 150°C

1.3 This standard does not purport to address all of the (302°F) level, more or less effect on properties will occur.

safety concerns, if any, associated with its use. It is the

5. Apparatus

responsibility of the user of this standard to establish appro-

5.1 Oven—The oven shall be electrically heated and shall

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. conform to the performance requirements of Specification

E 145, Type IB (Gravity-Convection), for operating tempera-

2. Referenced Documents

tures up to 180°C (356°F). During the tests for compliance to

2.1 ASTM Standards: Specification E 145 requirements, the oven shelf, properly

2

D 5 Test Method for Penetration of Bituminous Materials centered as described in 5.1.2 shall be in place and rotating.

2

D 113 Test Method for Ductility of Bituminous Materials 5.1.1 Construction—The oven shall be rectangular, and

D 2170 Test Method for Kinematic Viscosity of Asphalts each interior dimension (exclusive of space occupied by the

2

(Bitumens) heating element) shall be a minimum of 330 mm (13 in.) and

D 2171 Test Method for Viscosity of Asphalts by Vacuum a maximum of 535 mm (21 in.). The oven shall have, in front,

2

Capillary Viscometer atightlyfittedhingeddoor,whichshallprovideaclearopening

3

E 1 Specification for ASTM Thermometers substantially the same as the interior height and width of the

E 145 Specification for Gravity-Convection and Forced- oven. The door may contain a window with dimensions of at

4

Ventilation Ovens least 100 by 100 mm (4 by 4 in.) and with two sheets of glass

separated by an air space, through which a vertical thermom-

3. Summary of Test Method

eter, located as specified in 5.2, may be read without opening

3.1 Afilm of asphaltic material is heated in an oven for 5 h

thedoor;ortheovenmaybeprovidedwithaninnerglassdoor,

at 163°C (325°F). The effects of heat and air are determined through which the thermometer may be observed on opening

from changes incurred in physical properties measured before

the outer door momentarily. The oven shall be adequately

andaftertheoventreatment.Anoptionalprocedureisprovided ventilated by convection currents of air and for this purpose

for determining the change in sample mass.

shall be provided with openings for the entrance of air and for

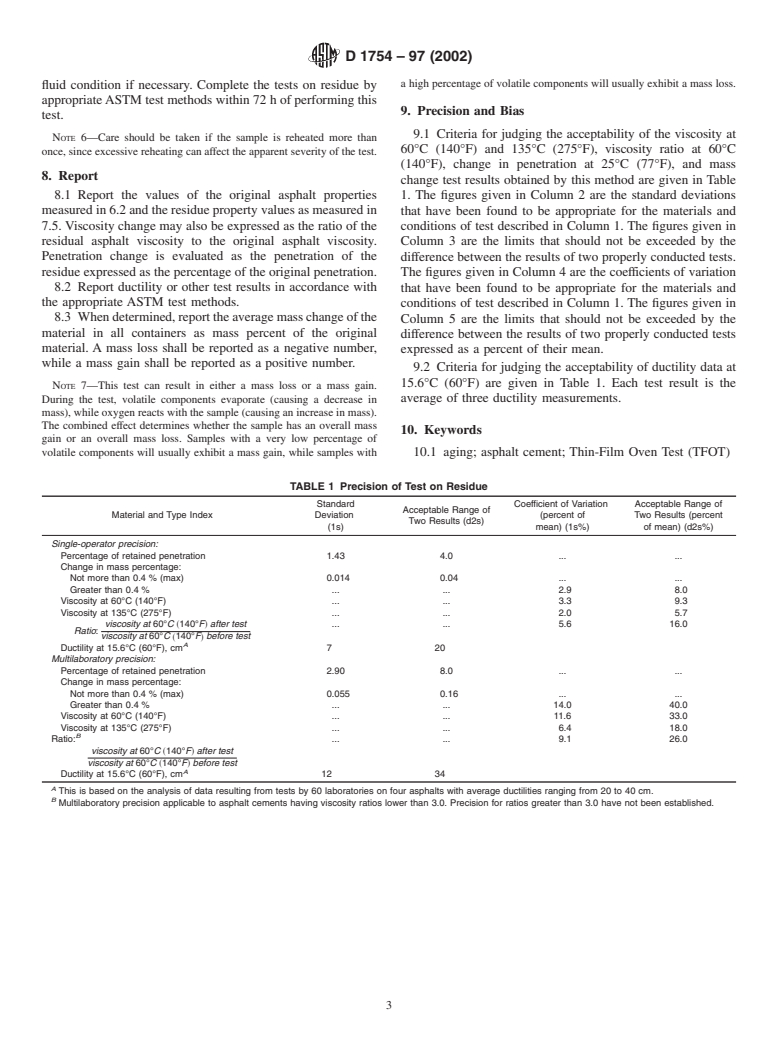

3.2 Precisionvaluesforthemethodhavebeendevelopedfor the exit of heated air and vapors. Openings may be of any size

viscosity, viscosity change, penetration change, mass change,

and arrangement provided the requirements of Specification

and ductility. E 145, Type IB, are met.

5.1.2 Rotating Shelf—The oven shall be provided with a

single metal circular shelf having a minimum diameter of 250

1

This test method is under the jurisdiction of ASTM Committee D04 on Road

mm (9.8 in.) and a maximum diameter of 450 mm (18 in.).The

and Paving Materials and is the direct responsibility of Subcommittee D04.46 on

shelf construction shall be such that it provides a flat surface

Durability and Distillation Test.

Current edition approved Aug. 10, 1997. Published February 1998. Originally

forsupportofthecontainerswithoutblockingallaircirculation

published as D 1754 – 60 T. Last previous edition D 1754 – 94.

through the shelf when the containers are in place. The shelf

2

Annual Book of ASTM Standards, Vol 04.03.

3 shallbesuspendedbyaverticalshaftandcenteredwithrespect

Annual Book of ASTM Standards, Vol 14.03.

4

Annual Book of ASTM Standards, Vol 14.04. to the horizontal interior dimensions of the oven and shall be

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, Uni

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.