ASTM E2452-12

(Practice)Standard Practice for Equipment Management Process Maturity (EMPM) Model

Standard Practice for Equipment Management Process Maturity (EMPM) Model

SIGNIFICANCE AND USE

5.1 Internal—The EMPM provides assessment results that are easy to understand and communicate. Areas requiring additional resources become apparent, and thus, can be more readily addressed. Improvement can be tracked in meaningful ways. Assessment detail allows attention to be drawn to processes of exceptional maturity and areas in which changes or additional resources, or both, are required to achieve process improvements.

5.2 External—Meaningful comparisons to external requirements are enabled. Comparisons of equipment management between entities in different operational or business environments become meaningful and provide insight previously unavailable.

SCOPE

1.1 This practice covers a process for the assessment and reporting of an entity’s overall equipment management process maturity (EMPM).

1.2 The highest value is placed on continuous improvement as reflected in measured increases in maturity over time.

1.3 The EMPM model is designed to be applicable and appropriate for all equipment-holding entities, however, the EMPM may not be the only acceptable assessment model available.

1.4 It includes all aspects of equipment management.

1.5 In addition to applicability to equipment and equipment management as defined in this practice, this practice may in whole or in part be effectively applied to intangible property, real property, and material.

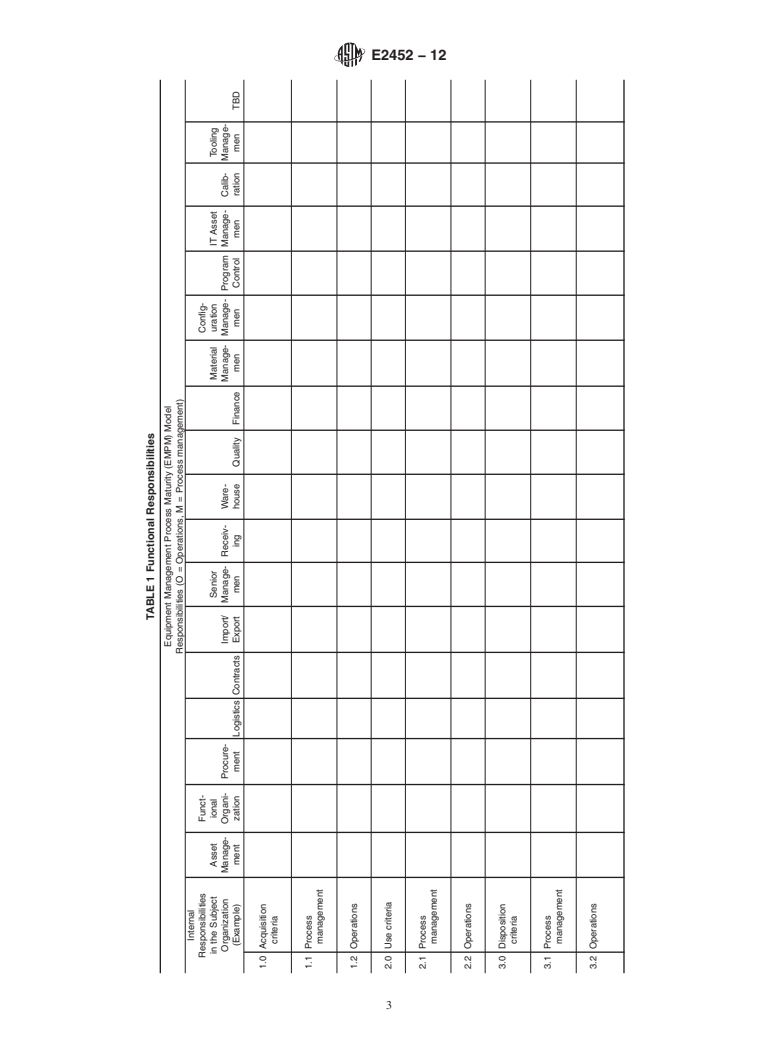

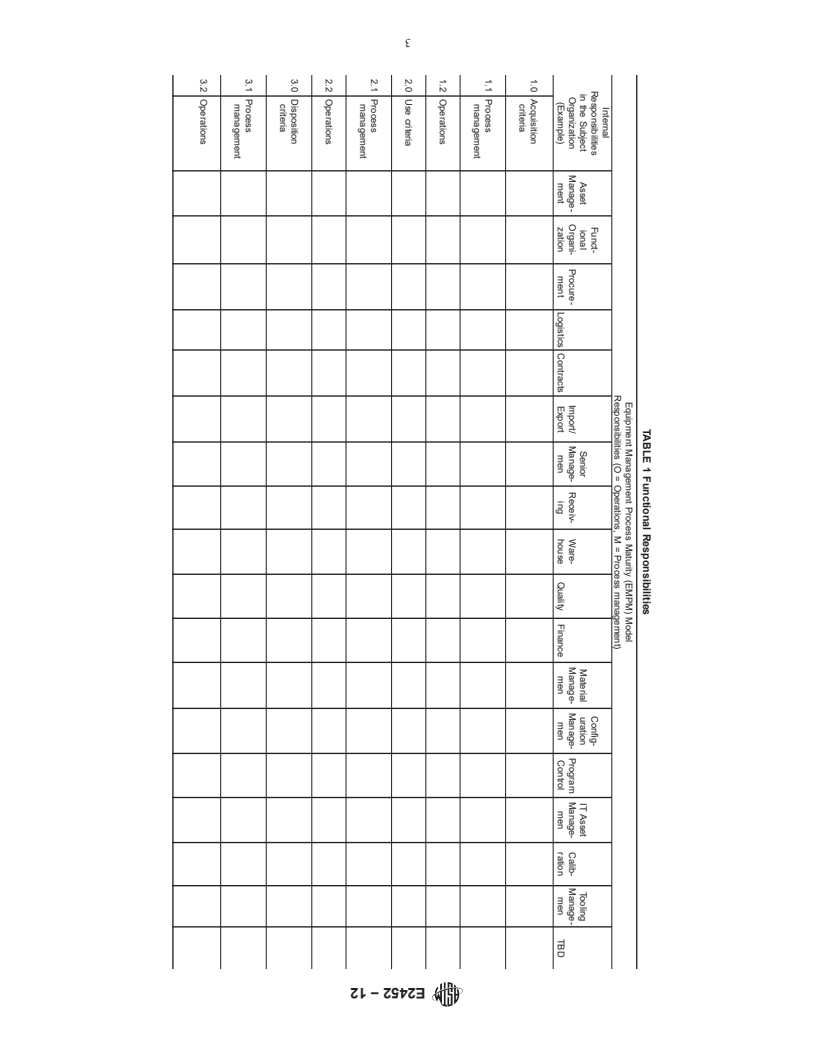

1.6 There is great variation across organizations regarding the internal departments that accomplish the various aspects of equipment management. Thus, all criteria are not applicable to all entities.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2452 − 12

Standard Practice for

1

Equipment Management Process Maturity (EMPM) Model

This standard is issued under the fixed designation E2452; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Life-cycle equipment management has a great impact on business operations of almost all entities.

In fact, the success or failure on an entity may hinge on how effectively and efficiently an entity

performs in the equipment management life-cycle. Entities that sustain high maturity levels will

generally be more effective or competitive or both than entities with lower maturity levels in that these

entities will more efficiently and effectively acquire what is needed, use and control equipment better,

and dispose of equipment when no longer sufficiently suitable for operations.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This practice covers a process for the assessment and

E2131 Practice for Addressing and Reporting Losses of

reporting of an entity’s overall equipment management process

Tangible Property

maturity (EMPM).

E2132 Practice for Inventory Verification: Electronic and

1.2 The highest value is placed on continuous improvement

Physical Inventory of Assets

as reflected in measured increases in maturity over time.

E2135 Terminology for Property and Asset Management

E2219 Practice forValuation and Management of Moveable,

1.3 The EMPM model is designed to be applicable and

3

Durable Property (Withdrawn 2009)

appropriate for all equipment-holding entities, however, the

E2220 Practice for Establishing the Full Valuation of the

EMPM may not be the only acceptable assessment model

Loss/Overage Population Identified During the Inventory

available.

3

of Moveable, Durable Property (Withdrawn 2009)

1.4 It includes all aspects of equipment management. E2221 Practice for Administrative Control of Property

3

(Withdrawn 2011)

1.5 In addition to applicability to equipment and equipment

E2279 Practice for Establishing the Guiding Principles of

management as defined in this practice, this practice may in

Property Asset Management

whole or in part be effectively applied to intangible property,

real property, and material.

3. Terminology

3.1 Definitions:

1.6 There is great variation across organizations regarding

3.1.1 entity, n—agency, company, organization, or institu-

the internal departments that accomplish the various aspects of

tion.

equipment management. Thus, all criteria are not applicable to

all entities.

3.1.2 equipment, n—non-expendable, tangible, moveable

property needed for the performance of a task or useful in

1.7 This standard does not purport to address all of the

effecting an obligation. E2135

safety concerns, if any, associated with its use. It is the

3.1.3 equipment management, n—systematic planning and

responsibility of the user of this standard to establish appro-

control of equipment to optimize its service delivery potential

priate safety and health practices and determine the applica-

and the management of associated risks and costs throughout

bility of regulatory limitations prior to use.

its life-cycle in support of organizational objectives. This

1 2

This practice is under the jurisdiction of ASTM Committee E53 on Asset For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Management and is the direct responsibility of Subcommittee E53.01 on Process contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Management. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Sept. 15, 2012. Published October 2012. Originally the ASTM website.

3

approved in 2005. Last previous edition approved in 2010 as E2452 – 10. DOI: The last approved version of this historical standard is referenced on

10.1520/E2452-12. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2452 − 12

includes the process management and operations of acquisition 6. Applicability

or construction of the equipment; its operation, maintenance,

6.1 This practice may be applied to the entirety of the legal

and modification while in use; and its disposal when no longer

entity or a clearly defined, designated constituent part.

required.

6.2 An entity’s equipment holdings may encompass equip-

3.1.4 operations, n—exercise of the tasks that constitute

ment acquired by all legal means:

equipment management.

6.2.1 Company owned equipment,

3.1.5 practice, n—a definitive set of instructions fo

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E2452 − 10 E2452 − 12

Standard Practice for

1

Equipment Management Process Maturity (EMPM) Model

This standard is issued under the fixed designation E2452; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Life-cycle equipment management has a great impact on business operations of almost all entities.

In fact, the success or failure on an entity may hinge on how effectively and efficiently an entity

performs in the equipment management life-cycle. Entities that sustain high maturity levels will

generally be more effective or competitive or both than entities with lower maturity levels in that these

entities will more efficiently and effectively acquire what is needed, use and control equipment better,

and dispose of equipment when no longer sufficiently suitable for operations.

1. Scope

1.1 This practice covers a process for the assessment and reporting of an entity’s overall equipment management process

maturity (EMPM).

1.2 The highest value is placed on continuous improvement as reflected in measured increases in maturity over time.

1.3 The EMPM model is designed to be applicable and appropriate for all equipment-holding entities, however, the EMPM may

not be the only acceptable assessment model available.

1.4 It includes all aspects of equipment management.

1.5 In addition to applicability to equipment and equipment management as defined in this practice, this practice may in whole

or in part be effectively applied to intangible property, real property, and material.

1.6 There is great variation across organizations regarding the internal departments that accomplish the various aspects of

equipment management. Thus, all criteria are not applicable to all entities.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E2131 Practice for Addressing and Reporting Loss, Damage, or Destruction of Tangible Property

E2132 Practice for Inventory Verification: Electronic and Physical Inventory of Assets

E2135 Terminology for Property and Asset Management

3

E2219 Practice for Valuation and Management of Moveable, Durable Property (Withdrawn 2009)

E2220 Practice for Establishing the Full Valuation of the Loss/Overage Population Identified During the Inventory of Moveable,

3

Durable Property (Withdrawn 2009)

3

E2221 Practice for Administrative Control of Property (Withdrawn 2011)

E2279 Practice for Establishing the Guiding Principles of Property Management

1

This practice is under the jurisdiction of ASTM Committee E53 on Property Management Systems and is the direct responsibility of Subcommittee E53.05E53.06 on

Property Management MaturityTerminology.

Current edition approved July 1, 2010Sept. 15, 2012. Published October 2010October 2012. Originally approved in 2005. Last previous edition approved in 20052010

ε1

as E2452 – 05E2452 – 10. . DOI: 10.1520/E2452-10.10.1520/E2452-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2452 − 12

3. Terminology

3.1 Definitions:

3.1.1 entity, n—agency, company, organization, or institution.

3.1.2 equipment, n—non-expendable, tangible, moveable property needed for the performance of a task or useful in effecting

an obligation. E2135

3.1.3 equipment management, n—systematic planning and control of equipment to optimize its service delivery potential and

the management of associated risks and costs throughout its life-cycle in support of organizational objectives. This includes the

process management and operations of acquisition or construction of the equipment; its operation, maintenance, and modification

while in use; and its disposal when no longer

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.