ASTM F2397-09(2015)

(Specification)Standard Specification for Protective Headgear Used in Martial Arts

Standard Specification for Protective Headgear Used in Martial Arts

ABSTRACT

This specification delas with the performance requirements for head protection used for training and competition in martial arts such as karate, wushu, and taekwondo, where normal contact between participants may be repeated, but is limited to a level that is not intended to produce injury. These activities typically take place in indoor or outdoor environments where the temperature is moderate. This specification recognizes the desirability of a lightweight and streamlined construction, and ventilation; however it is a performance specification, and is not intended to restrict design. Headgears shall be tested for the following and using the following test methods: reference marking, configuration, materials, projections, vision, retention test, stability or roll-off test, low-energy falling impact test, high-energy falling impact test, low-energy striking impact test, high-energy striking impact test, and high and low speed errors. The apparatus which shall be used are the test headforms, stability test instruments and equipment, falling impact test instruments and equipment, and striking impact instruments and equipment. The significance and use, conditioning environments, and test schedule are also detailed.

SCOPE

1.1 This specification covers performance requirements for head protection used for training and competition in martial arts such as karate, wushu, and taekwondo, where normal contact between participants may be repeated, but is limited to a level that is not intended to produce injury. These activities typically take place in indoor or outdoor environments where the temperature is moderate. This specification recognizes the desirability of a lightweight and streamlined construction, and ventilation; however it is a performance specification, and is not intended to restrict design.

1.2 All testing and requirements of this specification shall be in accordance with Test Methods F1446, except where noted in this specification.

1.3 Partial utilization of this standard is prohibited. Any statement of compliance with this specification shall be a certification that the product meets all of the requirements of the specification in its entirety. A product that fails to meet any one of the requirements of this specification is considered to have failed the specification, and shall not be distributed or sold with any indication that it meets parts of the specification.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 The following safety caveat applies to the chemical, mechanical, or physical, or a combination thereof, test methods described herein and is meant specifically for those performing the tests (in an effort to provide them with notice to take the appropriate precautions when conducting the tests): This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2397 −09 (Reapproved 2015) An American National Standard

Standard Specification for

Protective Headgear Used in Martial Arts

This standard is issued under the fixed designation F2397; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This specification covers performance requirements for

F1446 Test Methods for Equipment and Procedures Used in

head protection used for training and competition in martial

Evaluating the Performance Characteristics of Protective

arts such as karate, wushu, and taekwondo, where normal

Headgear

contact between participants may be repeated, but is limited to

a level that is not intended to produce injury. These activities

3. Terminology

typically take place in indoor or outdoor environments where

3.1 See Test Methods F1446.

the temperature is moderate. This specification recognizes the

desirability of a lightweight and streamlined construction, and

4. Significance and Use

ventilation; however it is a performance specification, and is

not intended to restrict design.

4.1 The purpose of this specification is to provide reliable

and repeatable test methods for the evaluation of protective

1.2 All testing and requirements of this specification shall

headgear for martial arts training and competition. Injuries

beinaccordancewithTestMethodsF1446,exceptwherenoted

resulting from accidentally hard hand-to-head impacts, foot-to-

in this specification.

headimpacts,andhead-to-groundimpactsmaybedecreasedin

1.3 Partial utilization of this standard is prohibited. Any severity and, in some cases, prevented. No headgear can

statement of compliance with this specification shall be a protect against all impacts, foreseeable or not. Forces resulting

certification that the product meets all of the requirements of from strikes to the head due to kicks, punches, and falls are not

well understood. The mechanism of possible injury is not

the specification in its entirety.Aproduct that fails to meet any

one of the requirements of this specification is considered to addressed in this specification.

have failed the specification, and shall not be distributed or

5. Certification

sold with any indication that it meets parts of the specification.

5.1 See Test Methods F1446.

1.4 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

6. Apparatus

standard.

6.1 Test Headforms—Headforms to be used for the stability

1.5 The following safety caveat applies to the chemical,

and falling impact tests in this specification are as defined in

mechanical,orphysical,oracombinationthereof,testmethods

Test Methods F1446. The appropriate size headform shall be

described herein and is meant specifically for those performing

selected for the headgear to be tested. For the striking impact

the tests (in an effort to provide them with notice to take the

tests in this specification, it is acceptable to use the appropriate

appropriate precautions when conducting the tests): This stan-

size Hybrid III head- and neck-forms.

dard does not purport to address all of the safety concerns, if

6.2 Stability Test Instruments and Equipment—Stability test

any, associated with its use. It is the responsibility of the user

instruments and equipment shall be in accordance with the

of this standard to establish appropriate safety and health

requirements of the roll-off test described in Test Methods

practices and determine the applicability of regulatory limita-

F1446.

tions prior to use.

6.3 Falling Impact Test Instruments and Equipment—

Impact test instruments and equipment for falling impact shall

This specification is under the jurisdiction ofASTM Committee F08 on Sports

Equipment, Playing Surfaces, and Facilitiesand is the direct responsibility of

Subcommittee F08.53 on Headgear and Helmets. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Jan. 1, 2015. Published February 2015. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2004. Last previous edition approved in 2009 as F2397 – 09. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F2397-09R15. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2397−09 (2015)

beinaccordancewiththerequirementsofTestMethodsF1446, 7.2 Number of Samples—A test normally requires seven

using the flat anvil described in Test Methods F1446. samples of each size. All testing may be done on two size

groups only if the material, material thickness, and construc-

6.4 Striking Impact Instruments and Equipment—All tests

tion of all the sizes are the same, that is, differing in coverage

for striking impact shall be performed with a Hybrid III

area only. If only two size groups are tested, the sizes must

headform and neck. A tri-axial accelerometer capable of

represent the largest and smallest sizes that will fit the

measuring impact of at least 1000-G and frequencies greater

appropriate headform. If the material, material thickness, or

than 3 kHz, mounted at the center of mass of the headform,

construction is different between each size, then all sizes must

shall be used to measure the resultant acceleration of the

be tested.

headform. The headform and neck are to be rigidly connected

at the neck to a 25-kg steel mass, and suspended head-down on

8. Calibration and Standardization

a flexible joint. The striker shall be an aluminum tube with a

length of 500 6 5 mm from its pivot point to the strike point,

8.1 See Test Methods F1446.

extend an additional 50 6 5 mm beyond the strike point, and

have an external diameter of 80 6 5 mm. The mass of the tube

9. Conditioning Environments

shall be 4.5 6 0.2 kg, uniformly distributed along its length.

9.1 See Test Methods F1446. The ambient temperature and

The striker shall be loaded with a spring or a falling mass, such

water immersion environments shall be used.

that when the striker is rotated back and released, it rotates

forward toward the headform and strikes it at the designated 9.2 The following modified high temperature environment

shall be used. The sample shall be kept in a 47 to 53°C

points. No force is to be applied to the striker by the spring or

falling mass once the striker rotates forward beyond the initial environment for 4 to 24 h. The sample shall then be kept in a

35 to 40°C environment for 4 to 24 h. Testing must begin

impact point, however, the striker must be free to rotate

forward after impact. Rotating the striker further backwards within 1 min after removal from this final conditioning

environment. Before further testing, the headgear must be

before releasing it can increase the striking speed.The terminal

speed impact shall be measured within 100 mm of the point of returned to the final conditioning environment within 3 min, or

be reconditioned for 5 min for each minute it is out of the final

free rotation. A schematic diagram of a typical striking impact

tester is shown in Fig. 1. conditioning environment beyond the allowed 3 min.

7. Samples for Testing

10. Test Schedule

7.1 Conditions and attachments in accordance with Test

10.1 One sample from each size group to be tested will be

Methods F1446.

inspected according to the schedule listed in Test Methods

F1446.

10.2 Two headgear will be assigned to the ambient condi-

tioning environment. Two headgear will be assigned to each of

the other two conditioning environments.

10.3 Testing will be performed in the following order:

10.3.1 Retention test,

10.3.2 Low-energy falling impact test,

10.3.3 High-energy falling impact test,

10.3.4 Low-energy striking impact test, and

10.3.5 High-energy striking impact test.

10.4 Testing must be complete 30 min after initial removal

from the conditioning environment. Once testing has begun on

a sample, all tests on that sample must be completed within 3

min. For each minute, or fraction thereof, this time limit is

exceeded, the sample must be returned to the conditioning

environment for an additional 5 min.

11. Test Methods

11.1 Reference Marking:

11.1.1 Place the headgear on the appropriate headform in

accordance with Test Methods F1446. Pre-load with a ballast

of 5 kg.

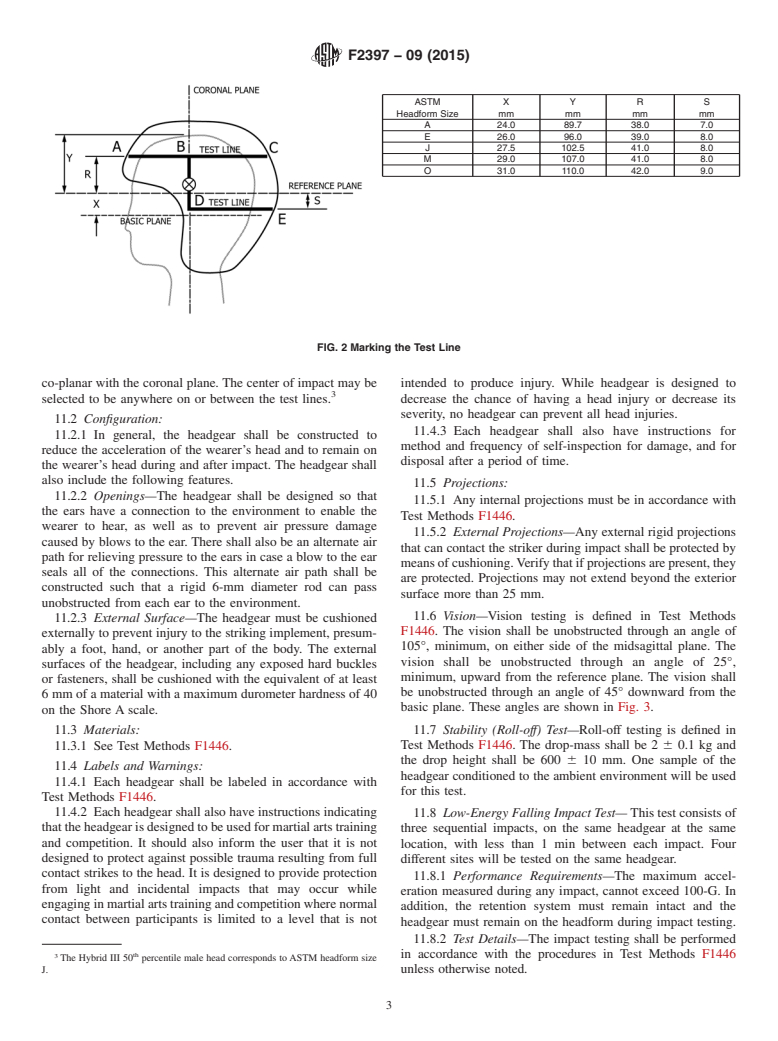

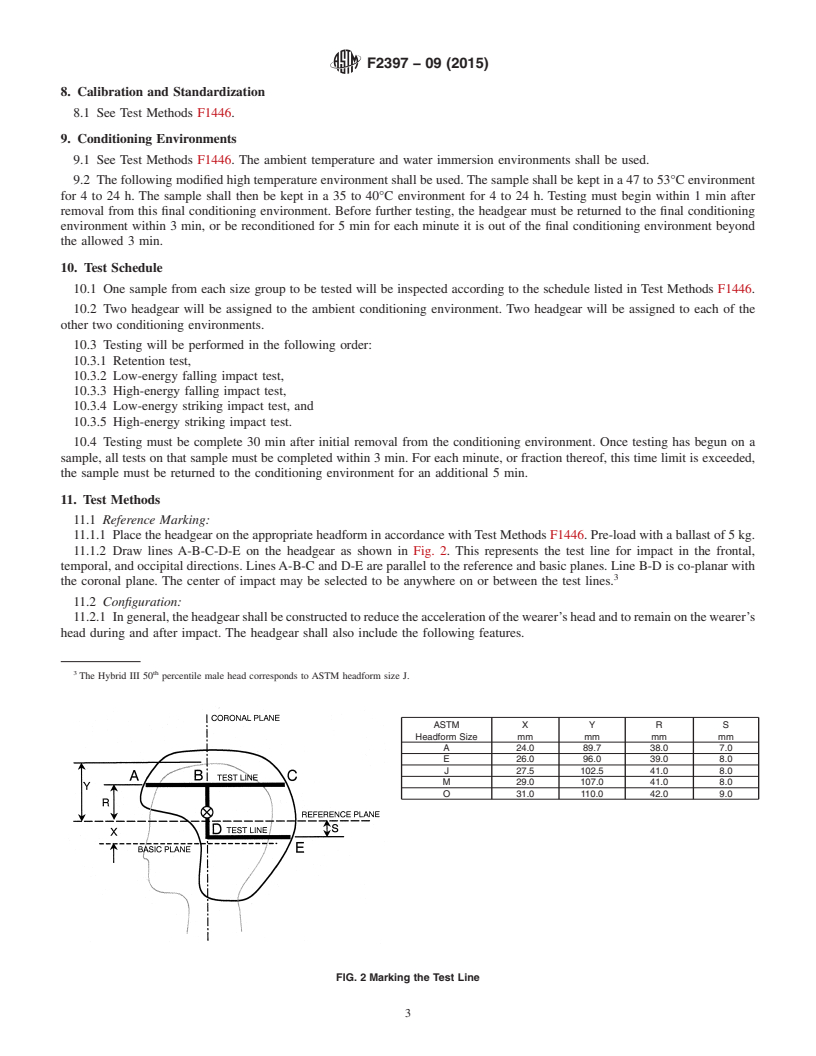

11.1.2 Draw lines A-B-C-D-E on the headgear as shown in

Fig. 2. This represents the test line for impact in the frontal,

temporal, and occipital directions. Lines A-B-C and D-E are

FIG. 1Striking Impact Test. parallel to the reference and basic planes. Line B-D is

F2397−09 (2015)

ASTM X Y R S

Headform Size mm mm mm mm

A 24.0 89.7 38.0 7.0

E 26.0 96.0 39.0 8.0

J 27.5 102.5 41.0 8.0

M 29.0 107.0 41.0 8.0

O 31.0 110.0 42.0 9.0

FIG. 2Marking the Test Line

co-planar with the coronal plane. The center of impact may be intended to produce injury. While headgear is designed to

selected to be anywhere on or between the test lines. decrease the chance of having a head injury or decrease its

severity, no headgear can prevent all head injuries.

11.2 Configuration:

11.4.3 Each headgear shall also have instructions for

11.2.1 In general, the headgear shall be constructed to

method and frequency of self-inspection for damage, and for

reduce the acceleration of the wearer’s head and to remain on

disposal after a period of time.

the wearer’s head during and after impact. The headgear shall

also include the following features.

11.5 Projections:

11.2.2 Openings—The headgear shall be designed so that

11.5.1 Any internal projections must be in accordance with

the ears have a connecti

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2397 − 09 F2397 − 09 (Reapproved 2015) An American National Standard

Standard Specification for

Protective Headgear Used in Martial Arts

This standard is issued under the fixed designation F2397; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers performance requirements for head protection used for training and competition in martial arts

such as karate, wushu, and taekwondo, where normal contact between participants may be repeated, but is limited to a level that

is not intended to produce injury. These activities typically take place in indoor or outdoor environments where the temperature

is moderate. This specification recognizes the desirability of a lightweight and streamlined construction, and ventilation; however

it is a performance specification, and is not intended to restrict design.

1.2 All testing and requirements of this specification shall be in accordance with Test Methods F1446, except where noted in

this specification.

1.3 Partial utilization of this standard is prohibited. Any statement of compliance with this specification shall be a certification

that the product meets all of the requirements of the specification in its entirety. A product that fails to meet any one of the

requirements of this specification is considered to have failed the specification, and shall not be distributed or sold with any

indication that it meets parts of the specification.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 The following safety caveat applies to the chemical, mechanical, or physical, or a combination thereof, test methods

described herein and is meant specifically for those performing the tests (in an effort to provide them with notice to take the

appropriate precautions when conducting the tests): This standard does not purport to address all of the safety concerns, if any,

associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and

determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

F1446 Test Methods for Equipment and Procedures Used in Evaluating the Performance Characteristics of Protective Headgear

3. Terminology

3.1 See Test Methods F1446.

4. Significance and Use

4.1 The purpose of this specification is to provide reliable and repeatable test methods for the evaluation of protective headgear

for martial arts training and competition. Injuries resulting from accidentally hard hand-to-head impacts, foot-to-head impacts, and

head-to-ground impacts may be decreased in severity and, in some cases, prevented. No headgear can protect against all impacts,

foreseeable or not. Forces resulting from strikes to the head due to kicks, punches, and falls are not well understood. The

mechanism of possible injury is not addressed in this specification.

5. Certification

5.1 See Test Methods F1446.

This specification is under the jurisdiction of ASTM Committee F08 on Sports Equipment, Playing Surfaces, and Facilitiesand is the direct responsibility of Subcommittee

F08.53 on Headgear and Helmets.

Current edition approved Nov. 1, 2009Jan. 1, 2015. Published December 2009February 2015. Originally approved in 2004. Last previous edition approved in 20042009

as F2397 – 04a.F2397 – 09. DOI: 10.1520/F2397-09.10.1520/F2397-09R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2397 − 09 (2015)

6. Apparatus

6.1 Test Headforms—Headforms to be used for the stability and falling impact tests in this specification are as defined in Test

Methods F1446. The appropriate size headform shall be selected for the headgear to be tested. For the striking impact tests in this

specification, it is acceptable to use the appropriate size Hybrid III head- and neck-forms.

6.2 Stability Test Instruments and Equipment—Stability test instruments and equipment shall be in accordance with the

requirements of the roll-off test described in Test Methods F1446.

6.3 Falling Impact Test Instruments and Equipment—Impact test instruments and equipment for falling impact shall be in

accordance with the requirements of Test Methods F1446, using the flat anvil described in Test Methods F1446.

6.4 Striking Impact Instruments and Equipment—All tests for striking impact shall be performed with a Hybrid III headform

and neck. A tri-axial accelerometer capable of measuring impact of at least 1000-G and frequencies greater than 3 kHz, mounted

at the center of mass of the headform, shall be used to measure the resultant acceleration of the headform. The headform and neck

are to be rigidly connected at the neck to a 25-kg steel mass, and suspended head-down on a flexible joint. The striker shall be

an aluminum tube with a length of 500 6 5 mm from its pivot point to the strike point, extend an additional 50 6 5 mm beyond

the strike point, and have an external diameter of 80 6 5 mm. The mass of the tube shall be 4.5 6 0.2 kg, uniformly distributed

along its length. The striker shall be loaded with a spring or a falling mass, such that when the striker is rotated back and released,

it rotates forward toward the headform and strikes it at the designated points. No force is to be applied to the striker by the spring

or falling mass once the striker rotates forward beyond the initial impact point, however, the striker must be free to rotate forward

after impact. Rotating the striker further backwards before releasing it can increase the striking speed. The terminal speed impact

shall be measured within 100 mm of the point of free rotation. A schematic diagram of a typical striking impact tester is shown

in Fig. 1.

7. Samples for Testing

7.1 Conditions and attachments in accordance with Test Methods F1446.

7.2 Number of Samples—A test normally requires seven samples of each size. All testing may be done on two size groups only

if the material, material thickness, and construction of all the sizes are the same, that is, differing in coverage area only. If only

two size groups are tested, the sizes must represent the largest and smallest sizes that will fit the appropriate headform. If the

material, material thickness, or construction is different between each size, then all sizes must be tested.

FIG. 1 Striking Impact Test.

F2397 − 09 (2015)

8. Calibration and Standardization

8.1 See Test Methods F1446.

9. Conditioning Environments

9.1 See Test Methods F1446. The ambient temperature and water immersion environments shall be used.

9.2 The following modified high temperature environment shall be used. The sample shall be kept in a 47 to 53°C environment

for 4 to 24 h. The sample shall then be kept in a 35 to 40°C environment for 4 to 24 h. Testing must begin within 1 min after

removal from this final conditioning environment. Before further testing, the headgear must be returned to the final conditioning

environment within 3 min, or be reconditioned for 5 min for each minute it is out of the final conditioning environment beyond

the allowed 3 min.

10. Test Schedule

10.1 One sample from each size group to be tested will be inspected according to the schedule listed in Test Methods F1446.

10.2 Two headgear will be assigned to the ambient conditioning environment. Two headgear will be assigned to each of the

other two conditioning environments.

10.3 Testing will be performed in the following order:

10.3.1 Retention test,

10.3.2 Low-energy falling impact test,

10.3.3 High-energy falling impact test,

10.3.4 Low-energy striking impact test, and

10.3.5 High-energy striking impact test.

10.4 Testing must be complete 30 min after initial removal from the conditioning environment. Once testing has begun on a

sample, all tests on that sample must be completed within 3 min. For each minute, or fraction thereof, this time limit is exceeded,

the sample must be returned to the conditioning environment for an additional 5 min.

11. Test Methods

11.1 Reference Marking:

11.1.1 Place the headgear on the appropriate headform in accordance with Test Methods F1446. Pre-load with a ballast of 5 kg.

11.1.2 Draw lines A-B-C-D-E on the headgear as shown in Fig. 2. This represents the test line for impact in the frontal,

temporal, and occipital directions. Lines A-B-C and D-E are parallel to the reference and basic planes. Line B-D is co-planar with

the coronal plane. The center of impact may be selected to be anywhere on or between the test lines.

11.2 Configuration:

11.2.1 In general, the headgear shall be constructed to reduce the acceleration of the wearer’s head and to remain on the wearer’s

head during and after impact. The headgear shall also include the following features.

th

The Hybrid III 50 percentile male head corresponds to ASTM headform size J.

ASTM X Y R S

Headform Size mm mm mm mm

A 24.0 89.7 38.0 7.0

E 26.0 96.0 39.0 8.0

J 27.5 102.5 41.0 8.0

M 29.0 107.0 41.0 8.0

O 31.0 110.0 42.0 9.0

FIG. 2 Marking the Test Line

F2397 − 09 (2015)

11.2.2 Openings—The headgear shall be designed so that the ears have a connection to the environment to enable the wearer

to hear, as well as to prevent air pressure damage caused by blows to

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.