ASTM F481-97(2014)

(Practice)Standard Practice for Installation of Thermoplastic Pipe and Corrugated Pipe in Septic Tank Leach Fields

Standard Practice for Installation of Thermoplastic Pipe and Corrugated Pipe in Septic Tank Leach Fields

ABSTRACT

This practice describes procedures for handling and installing thermoplastic pipe and corrugated pipe in septic tank leach fields, curtain drains, and from the septic tank to the leach field. Proper installation ensures that the pipe will satisfactorily convey and distribute partially treated waste water to a leaching field for additional treatment and disposal by soil absorption. The curtain or perimeter drain will function to protect the soil absorption capacity of the leach field. Pipe should be stored with support from a flat surface to prevent the pipe from developing a permanent set. Care should be exercised during loading, unloading, and in transit because pipe may be damaged by abrasion and sharp edges. Because thermoplastics are temporarily softened by high temperatures, care should be taken under these conditions to avoid damage during handling operations. Coiled pipe is not recommended for use in leach fields because it is difficult to install at the proper grade and alignment; it is acceptable with special equipment installation. Pipe can reach comparatively high temperatures when exposed to the sun and this reduces the pipe stiffness appreciably. Therefore, precautions must be taken to prevent the impact of sharp or heavy objects, the sudden imposition of heavy overburden or excessive pull on such pipe. The pipe regains full strength and stiffness as the temperature decreases to that of the soil; this will normally require about five minutes. Care in handling and installation should be exercised under low-temperature conditions to avoid damage. As temperatures decrease, some types of pipe tend to become more brittle and less flexible.

SCOPE

1.1 This practice describes procedures for handling and installing thermoplastic pipe and corrugated pipe in septic tank leach fields, curtain drains, and from the septic tank to the leach field. Proper installation ensures that the pipe will satisfactorily convey and distribute partially treated waste water to a leaching field for additional treatment and disposal by soil absorption. The curtain or perimeter drain will function to protect the soil absorption capacity of the leach field.

1.2 To ensure compliance with local regulatory provisions, the local approving authority (local health departments and so forth) should be contacted regarding specific requirements for leach field design materials and installation.

1.3 This practice applies to pipe and fittings made under each of the following ASTM specifications:

1.3.1 For transport from tank to leach field: Specifications D2680, D2729, D2751, D2852, D3034, F405, F758, F789, F810, F891, F892, and F949.

1.3.2 Perforated, for use in leach field or curtain drain: Specifications D2729, D2751, F405, F810, F891, and F892.

1.4 Pipe intended for installation in accordance with this practice should have a minimum pipe stiffness as specified in the appropriate product standard referenced in 1.3.1 or 1.3.2.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see Section 7.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F481 − 97 (Reapproved 2014)

Standard Practice for

Installation of Thermoplastic Pipe and Corrugated Pipe in

Septic Tank Leach Fields

ThisstandardisissuedunderthefixeddesignationF481;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This practice describes procedures for handling and

2.1 ASTM Standards:

installing thermoplastic pipe and corrugated pipe in septic tank

D1600 Terminology forAbbreviatedTerms Relating to Plas-

leachfields,curtaindrains,andfromtheseptictanktotheleach

tics

field. Proper installation ensures that the pipe will satisfactorily

D2321 PracticeforUndergroundInstallationofThermoplas-

convey and distribute partially treated waste water to a

tic Pipe for Sewers and Other Gravity-Flow Applications

leaching field for additional treatment and disposal by soil

D2680 Specification for Acrylonitrile-Butadiene-Styrene

absorption. The curtain or perimeter drain will function to

(ABS) and Poly(Vinyl Chloride) (PVC) Composite Sewer

protect the soil absorption capacity of the leach field.

Piping

D2729 Specification for Poly(Vinyl Chloride) (PVC) Sewer

1.2 To ensure compliance with local regulatory provisions,

Pipe and Fittings

the local approving authority (local health departments and so

D2751 Specification for Acrylonitrile-Butadiene-Styrene

forth) should be contacted regarding specific requirements for

(ABS) Sewer Pipe and Fittings (Withdrawn 2014)

leach field design materials and installation.

D2852 Specification for Styrene-Rubber (SR) Plastic Drain

1.3 This practice applies to pipe and fittings made under

Pipe and Fittings

each of the following ASTM specifications:

D3034 Specification for Type PSM Poly(Vinyl Chloride)

1.3.1 For transport from tank to leach field: Specifications

(PVC) Sewer Pipe and Fittings

D2680, D2729, D2751, D2852, D3034, F405, F758, F789,

F405 Specification for Corrugated Polyethylene (PE) Pipe

F810, F891, F892, and F949.

and Fittings

1.3.2 Perforated, for use in leach field or curtain drain:

F412 Terminology Relating to Plastic Piping Systems

Specifications D2729, D2751, F405, F810, F891, and F892.

F449 Practice for Subsurface Installation of Corrugated

Polyethylene Pipe for Agricultural Drainage or Water

1.4 Pipe intended for installation in accordance with this

Table Control

practice should have a minimum pipe stiffness as specified in

F758 Specification for Smooth-Wall Poly(Vinyl Chloride)

the appropriate product standard referenced in 1.3.1 or 1.3.2.

(PVC) Plastic Underdrain Systems for Highway, Airport,

1.5 The values stated in inch-pound units are to be regarded

and Similar Drainage

as standard. The values given in parentheses are mathematical

F789 Specification for Type PS-46 and Type PS-115 Poly-

conversions to SI units that are provided for information only

(Vinyl Chloride) (PVC) Plastic Gravity Flow Sewer Pipe

and are not considered standard.

and Fittings (Withdrawn 2004)

1.6 This standard does not purport to address all of the F810 Specification for Smoothwall Polyethylene (PE) Pipe

safety concerns, if any, associated with its use. It is the

for Use in Drainage andWaste DisposalAbsorption Fields

responsibility of the user of this standard to establish appro- F891 Specification for Coextruded Poly(Vinyl Chloride)

priate safety and health practices and determine the applica- (PVC) Plastic Pipe With a Cellular Core

bility of regulatory limitations prior to use. For specific F892 Specification for Polyethylene (PE) Corrugated Pipe

precautionary statements, see Section 7. With a Smooth Interior and Fittings (Withdrawn 2001)

1 2

This practice is under the jurisdiction of ASTM Committee F17 on Plastic For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Piping Systems and is the direct responsibility of Subcommittee F17.65 on Land contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Drainage. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Aug. 1, 2014. Published November 2014. Originally the ASTM website.

approvedin1976.Lastpreviouseditionapprovedin2008asF481 – 97(2008).DOI: The last approved version of this historical standard is referenced on

10.1520/F0481-97R14. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F481 − 97 (2014)

F949 Specification for Poly(Vinyl Chloride) (PVC) Corru-

gated Sewer Pipe With a Smooth Interior and Fittings

3. Terminology

3.1 Definitions are in accordance with Terminology F412

and abbreviations are in accordance with Terminology D1600,

unless otherwise specified.

3.2 Definitions of Terms Specific to This Standard:

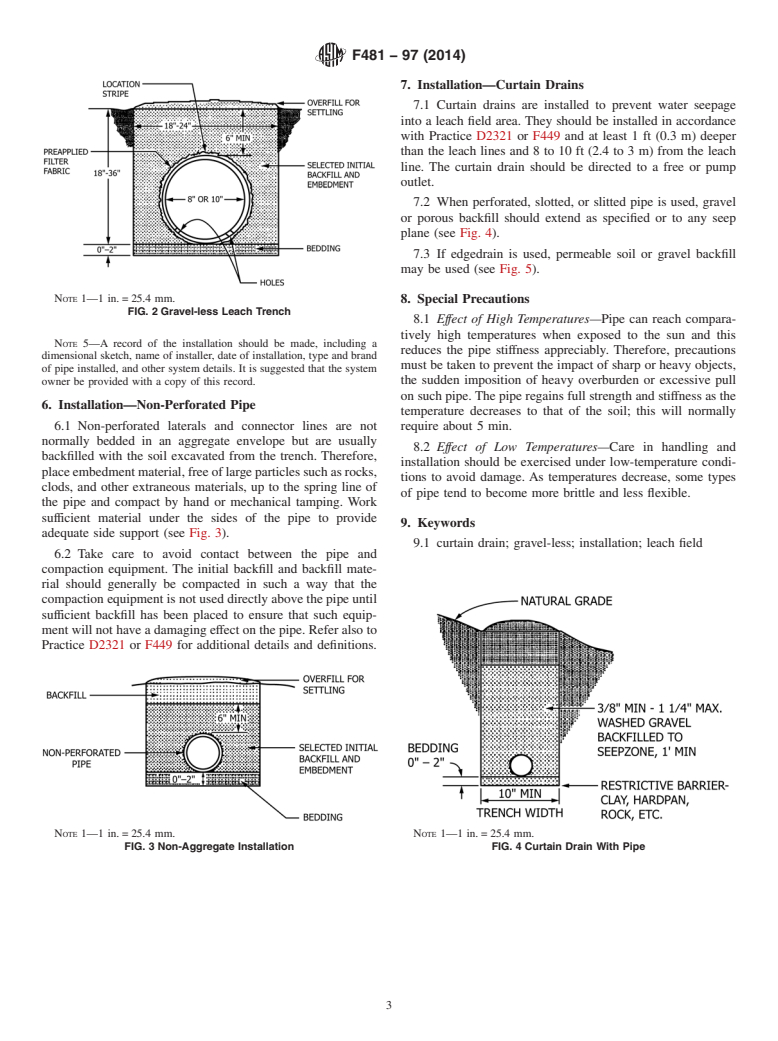

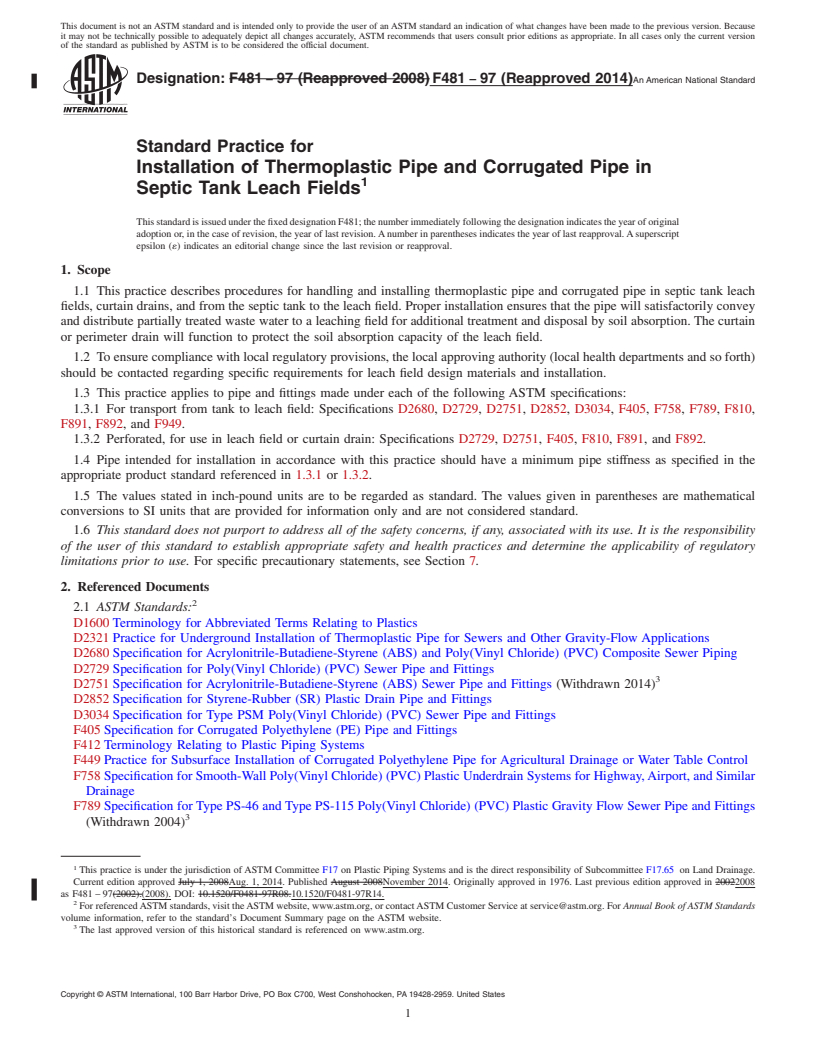

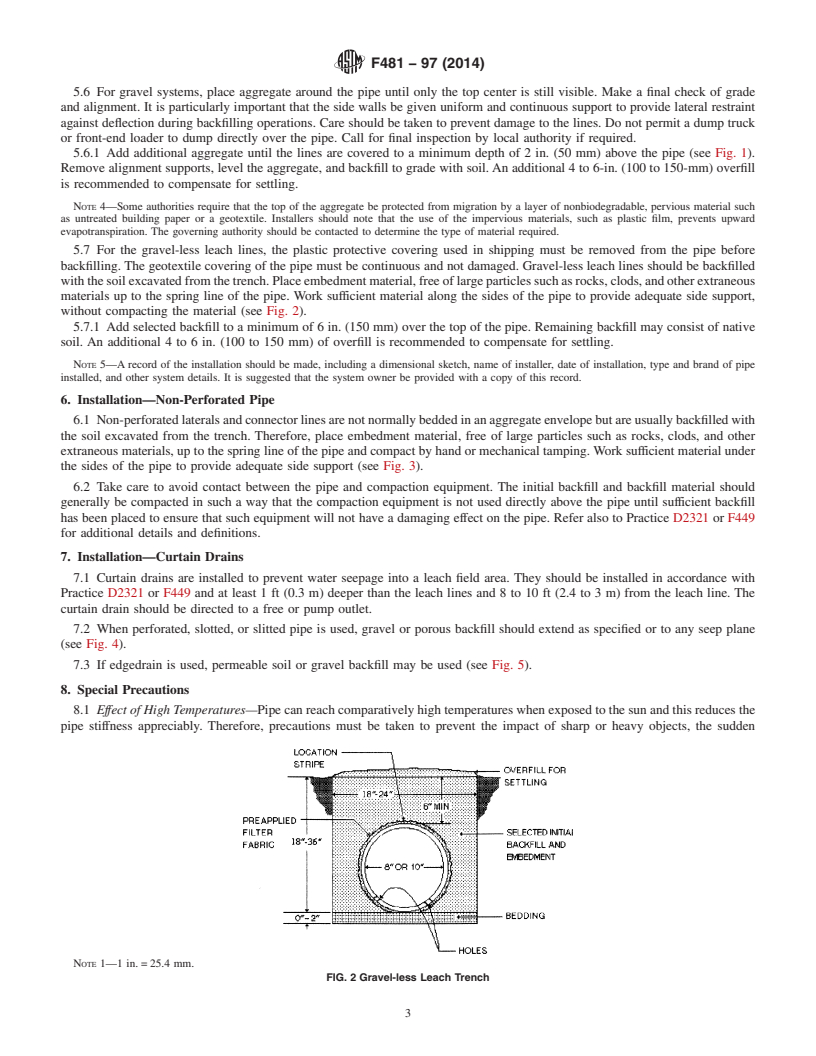

NOTE 1—1 in. = 25.4 mm.

3.2.1 dual-wall pipe—pipe with corrugated exterior and

FIG. 1 Gravel Leach Trench

smooth interior.

3.2.2 pipe—smooth or corrugated interior wall thermoplas-

tic pipe.

5.4 Fittings recommended by the pipe manufacturer should

be used at all joints and for changes of direction except that

4. General Requirements

pipe may be bent to a radius of not less than 5 times the

diameter.

4.1 Storage—Pipe should be stored with support from a flat

surface to prevent the pipe from developing a permanent set.

5.5 Unless otherwise specified, pipe should be laid true to

grade and aligned in the center of the trench, with the top print

4.2 Handling—Care should be exercised during loading,

line or location stripe at the 12 o’clock position so that holes

unloading, and in transit because pipe may be damaged by

are placed down. It should be held in place by alignment

abrasion and sharp edges. Because thermoplastics are tempo-

supports, such as wooden stakes or steel rods.

rarily softened by high temperatures, care should be taken

under these conditions to avoid damage during handling NOTE 3—Some authorities require the covering of the line with

untreated building paper or a geotextile to prevent entry of aggregate,

operations.

prior to the next step.This is usually required only in areas that require the

4.3 If contact with chemicals not ordinarily present in perforations to be oriented on the top instead of the bottom of the pipe.

sanitary sewage is anticipated, the approval of the regulatory

5.6 For gravel systems, place aggregate around the pipe

authority to install pipe should be obtained.

until only the top center is still visible. Make a final check of

grade and alignment. It is particularly important that the side

NOTE 1—The manufacturer should be contacted for information on

walls be given uniform and continuous support to provide

chemical resistance.

lateralrestraintagainstdeflectionduringbackfillingoperations.

4.4 Coiled pipe is not recommended for use in leach fields

Care should be taken to prevent damage to the lines. Do not

because it is difficult to install at the proper grade and

permit a dump truck or front-end loader to dump directly o

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F481 − 97 (Reapproved 2008) F481 − 97 (Reapproved 2014)An American National Standard

Standard Practice for

Installation of Thermoplastic Pipe and Corrugated Pipe in

Septic Tank Leach Fields

This standard is issued under the fixed designation F481; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice describes procedures for handling and installing thermoplastic pipe and corrugated pipe in septic tank leach

fields, curtain drains, and from the septic tank to the leach field. Proper installation ensures that the pipe will satisfactorily convey

and distribute partially treated waste water to a leaching field for additional treatment and disposal by soil absorption. The curtain

or perimeter drain will function to protect the soil absorption capacity of the leach field.

1.2 To ensure compliance with local regulatory provisions, the local approving authority (local health departments and so forth)

should be contacted regarding specific requirements for leach field design materials and installation.

1.3 This practice applies to pipe and fittings made under each of the following ASTM specifications:

1.3.1 For transport from tank to leach field: Specifications D2680, D2729, D2751, D2852, D3034, F405, F758, F789, F810,

F891, F892, and F949.

1.3.2 Perforated, for use in leach field or curtain drain: Specifications D2729, D2751, F405, F810, F891, and F892.

1.4 Pipe intended for installation in accordance with this practice should have a minimum pipe stiffness as specified in the

appropriate product standard referenced in 1.3.1 or 1.3.2.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific precautionary statements, see Section 7.

2. Referenced Documents

2.1 ASTM Standards:

D1600 Terminology for Abbreviated Terms Relating to Plastics

D2321 Practice for Underground Installation of Thermoplastic Pipe for Sewers and Other Gravity-Flow Applications

D2680 Specification for Acrylonitrile-Butadiene-Styrene (ABS) and Poly(Vinyl Chloride) (PVC) Composite Sewer Piping

D2729 Specification for Poly(Vinyl Chloride) (PVC) Sewer Pipe and Fittings

D2751 Specification for Acrylonitrile-Butadiene-Styrene (ABS) Sewer Pipe and Fittings (Withdrawn 2014)

D2852 Specification for Styrene-Rubber (SR) Plastic Drain Pipe and Fittings

D3034 Specification for Type PSM Poly(Vinyl Chloride) (PVC) Sewer Pipe and Fittings

F405 Specification for Corrugated Polyethylene (PE) Pipe and Fittings

F412 Terminology Relating to Plastic Piping Systems

F449 Practice for Subsurface Installation of Corrugated Polyethylene Pipe for Agricultural Drainage or Water Table Control

F758 Specification for Smooth-Wall Poly(Vinyl Chloride) (PVC) Plastic Underdrain Systems for Highway, Airport, and Similar

Drainage

F789 Specification for Type PS-46 and Type PS-115 Poly(Vinyl Chloride) (PVC) Plastic Gravity Flow Sewer Pipe and Fittings

(Withdrawn 2004)

This practice is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.65 on Land Drainage.

Current edition approved July 1, 2008Aug. 1, 2014. Published August 2008November 2014. Originally approved in 1976. Last previous edition approved in 20022008

as F481 – 97(2002).(2008). DOI: 10.1520/F0481-97R08.10.1520/F0481-97R14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F481 − 97 (2014)

F810 Specification for Smoothwall Polyethylene (PE) Pipe for Use in Drainage and Waste Disposal Absorption Fields

F891 Specification for Coextruded Poly(Vinyl Chloride) (PVC) Plastic Pipe With a Cellular Core

F892 Specification for Polyethylene (PE) Corrugated Pipe With a Smooth Interior and Fittings (Withdrawn 2001)

F949 Specification for Poly(Vinyl Chloride) (PVC) Corrugated Sewer Pipe With a Smooth Interior and Fittings

3. Terminology

3.1 Definitions are in accordance with Terminology F412 and abbreviations are in accordance with Terminology D1600, unless

otherwise specified.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 dual-wall pipe—pipe with corrugated exterior and smooth interior.

3.2.2 pipe—smooth or corrugated interior wall thermoplastic pipe.

4. General Requirements

4.1 Storage—Pipe should be stored with support from a flat surface to prevent the pipe from developing a permanent set.

4.2 Handling—Care should be exercised during loading, unloading, and in transit because pipe may be damaged by abrasion

and sharp edges. Because thermoplastics are temporarily softened by high temperatures, care should be taken under these

conditions to avoid damage during handling operations.

4.3 If contact with chemicals not ordinarily present in sanitary sewage is anticipated, the approval of the regulatory authority

to install pipe should be obtained.

NOTE 1—The manufacturer should be contacted for information on chemical resistance.

4.4 Coiled pipe is not recommended for use in leach fields because it is difficult to install at the proper grade and alignment;

it is acceptable with special equipment installation.

NOTE 2—Corrugated interior pipe should not be used between the dwelling and the waste water treatment unit (septic tank or similar device) because

the corrugations may inhibit the flow of solids contained in the waste.

5. Installation—Leach Field

5.1 Leach fields should be constructed to meet the requirements of the local Department of Health or other governing authority,

which should be contacted for information and requirements on design, location, installation, materials, and so forth.

5.2 Before installation, pipe should be inspected for damage such as kinks, crushed portions, splits, and so forth. Any damaged

portions of pipe shall be cut out as a cylinder and discarded. Make a visual check of the bore to ensure it is clear of foreign objects

that might impede flow.

5.3 Gravel Systems—For proper waste water flow into the surrounding soils and to provide for support of pipe, a uniform layer

of 4 to 6 in. (100 to 150 mm) of graded aggregate should be placed in the trench bottom and leveled true to gr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.