ASTM D4312-95a(2010)

(Test Method)Standard Test Method for Toluene-Insoluble (TI) Content of Tar and Pitch (Short Method)

Standard Test Method for Toluene-Insoluble (TI) Content of Tar and Pitch (Short Method)

SIGNIFICANCE AND USE

This test method is useful for evaluating and characterizing tars and pitches and is one element in establishing the uniformity of shipment or sources of supply.

SCOPE

1.1 This test method covers the determination of toluene-insoluble matter (TI) in tar and pitch.

1.2 Since this test method is empirical, strict adherence to all details of the procedure is necessary.

1.3 The values stated in SI units are to be regarded as standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4312 − 95a(Reapproved 2010)

Standard Test Method for

Toluene-Insoluble (TI) Content of Tar and Pitch (Short

Method)

This standard is issued under the fixed designation D4312; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Summary of Test Method

3.1 The sample is digested, then extracted with hot toluene

1.1 This test method covers the determination of toluene-

insoluble matter (TI) in tar and pitch. in an alundum thimble. The insoluble matter is dried and

weighed.

1.2 Since this test method is empirical, strict adherence to

all details of the procedure is necessary.

4. Significance and Use

1.3 The values stated in SI units are to be regarded as

4.1 This test method is useful for evaluating and character-

standard.

izing tars and pitches and is one element in establishing the

uniformity of shipment or sources of supply.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5. Apparatus

responsibility of the user of this standard to establish appro-

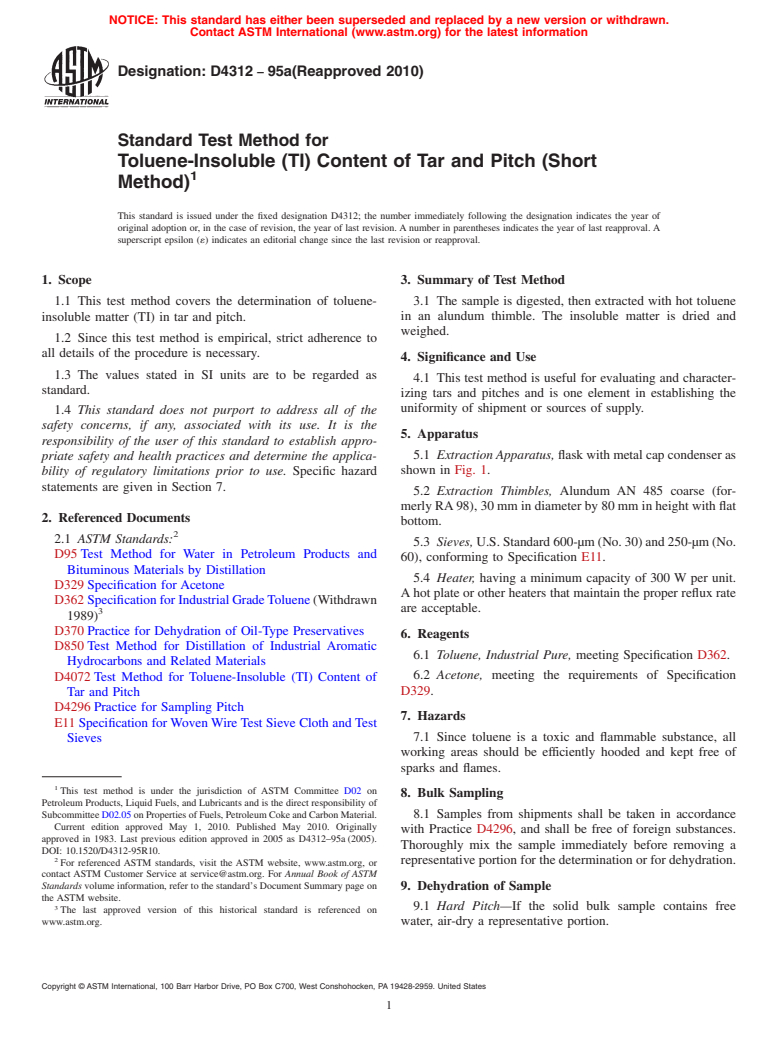

5.1 ExtractionApparatus, flask with metal cap condenser as

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. Specific hazard shown in Fig. 1.

statements are given in Section 7.

5.2 Extraction Thimbles, Alundum AN 485 coarse (for-

merly RA98), 30 mm in diameter by 80 mm in height with flat

2. Referenced Documents

bottom.

2.1 ASTM Standards:

5.3 Sieves,U.S.Standard 600-µm(No.30)and250-µm(No.

D95 Test Method for Water in Petroleum Products and

60), conforming to Specification E11.

Bituminous Materials by Distillation

5.4 Heater, having a minimum capacity of 300 W per unit.

D329 Specification for Acetone

Ahot plate or other heaters that maintain the proper reflux rate

D362 SpecificationforIndustrialGradeToluene(Withdrawn

are acceptable.

1989)

D370 Practice for Dehydration of Oil-Type Preservatives

6. Reagents

D850 Test Method for Distillation of Industrial Aromatic

6.1 Toluene, Industrial Pure, meeting Specification D362.

Hydrocarbons and Related Materials

6.2 Acetone, meeting the requirements of Specification

D4072 Test Method for Toluene-Insoluble (TI) Content of

D329.

Tar and Pitch

D4296 Practice for Sampling Pitch

7. Hazards

E11 Specification for Woven Wire Test Sieve Cloth and Test

7.1 Since toluene is a toxic and flammable substance, all

Sieves

working areas should be efficiently hooded and kept free of

sparks and flames.

This test method is under the jurisdiction of ASTM Committee D02 on

8. Bulk Sampling

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

SubcommitteeD02.05onPropertiesofFuels,PetroleumCokeandCarbonMaterial.

8.1 Samples from shipments shall be taken in accordance

Current edition approved May 1, 2010. Published May 2010. Originally

with Practice D4296, and shall be free of foreign substances.

approved in 1983. Last previous edition approved in 2005 as D4312–95a (2005).

Thoroughly mix the sample immediately before removing a

DOI: 10.1520/D4312-95R10.

representative portion for the determination or for dehydration.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on 9. Dehydration of Sample

the ASTM website.

9.1 Hard Pitch—If the solid bulk sample contains free

The last approved version of this historical standard is referenced on

www.astm.org. water, air-dry a representative portion.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4312 − 95a (2010)

the lowest temperature that will permit passage through

600-µm (No. 30) sieve, taking care to avoid excessive loss of

volatile matter. Do not exceed 10 min for this melting period.

Pass the heated sample through the 600-µm sieve to remove

foreign matter.

10.3 Tar—Heat a representative portion of the dry tar to the

lowest temperature that will permit passage through the

600-µm (No. 30) sieve, then filter through this sieve to remove

foreign matter.

10.4 Discard working sample 24 h after crushing and

sieving as changes in composition sometimes occur in pulver-

ized pitch.

11. Preparation of Alundum Thimble

11.1 Dry the clean thimble in an oven at 105 6 5°C for 45

FIG. 1 Extraction Apparatus

min, cool in a desiccator, and weigh to the nearest 0.5 mg.

Record the mass.

9.2 Soft Pitch—If the presence of water is indicated by

11.1.1 After each use, ignite the thimble at 700 to 800°C for

surface foam on heating, maintain a representative portion of

a few hours. Cool the thimble slowly by placing in a drying

the bulk sample of a temperature between 125 and 150°C in an

oven for 1 h after removal from the furnace to prevent

open container until the surface is free of foam. Take care not

cracking. Before reuse, condition the thimble as described in

to overheat, and remove heat source immediately when foam

11.1.

subsides.

11.1.2 After repeated use, boil the thimble in hydrochloric

9.3 Tar—Dehydrate a representative portion of the bulk acid (1 + 1) to remove residual ash from the pores. Then boil

thethimbleindistilledwaterandwashwithwater.Afterdrying

sample in accordance with Test Method D370, but stop the

distillation when the temperature reaches 170°C. Separate any at 105°C, ignite and condition the thimble as described in 11.1

and 11.1.1.

oil from the water that has distilled over. (If crystals are

present,warmsufficientlytoensuretheirsolution).Thoroughly

mix the oil with the residual tar in the still after the latter has 12. Procedure

cooled to a moderate temperature.

12.1 Weigh 0.50 g sample to the nearest 0.5 mg in a 150 mL

9.3.1 Dehydrate a representative portion of the bulk sample

tared beaker.

at atmo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.