ASTM D658-91

(Test Method)Standard Test Method for Abrasion Resistance of Organic Coatings by Air Blast Abrasive (Withdrawn 1996)

Standard Test Method for Abrasion Resistance of Organic Coatings by Air Blast Abrasive (Withdrawn 1996)

SCOPE

1.1 This test method covers the determination of the resistance of organic coatings to abrasion produced by an air blast of abrasive on coatings applied to a plane, rigid surface, such as a metal or glass panel.

1.2 This standard does not purport to address the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.>

General Information

Standards Content (Sample)

ÄSTN-Db58 93 W 0759530 0070698 T

AMERICAN SOCIETY FOR TESTING AND MATERIALS

1916 RaceSt. Philadelphia, Pa 19103

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Designation: D 658 - 91

If not listed in the current combined index, will appear in the next edition.

Standard Test Method for

Abrasion Resistance of Organic Coatings by Air Blast

Abrasive'

This standard is issued under the fixed designation D 658; the number immediately following the designation indicafes the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicafes an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the

resistance of organic coatings to abrasion produced by an air

blast of abrasive on coatings applied to a plane, rigid surface,

such as a metal or glass panel.

1.2 This standard does not purport to address the safety

problems associated with its use. It is the responsibility of the

user of this standard to establish appropriate safety and

health practices and determine the applicability of regulatory

limitations prior to use.

FROM

41R CONTROL

2. Referenced Documents APPARATUS

2.1 ASTM Standards:

FLOWMETER

D823 Test Methods for Producing Films of Uniform

\

Thickness of Paint, Varnish, and Related Products on

a

Test Panels2

D968 Test Method for Abrasion Resistance of Organic

Coatings by Falling Abrasive2

D1005 Test Methods for Measurement of Dry Film

Thickness of Organic Coatings Using Micrometers2

D 1 186 Test Methods for Nondestructive Measurement of

Dry Film Thickness of Nonmagnetic Coatings Applied

to a Ferrous Base2

D 1400 Test Method for Nondestructive Measurement of

Dry Film Thickness of Nonconductive Coatings Ap-

plied to a Nonferrous Metal Base2

E 11 Specification for Wire-Cloth Sieves For Testing

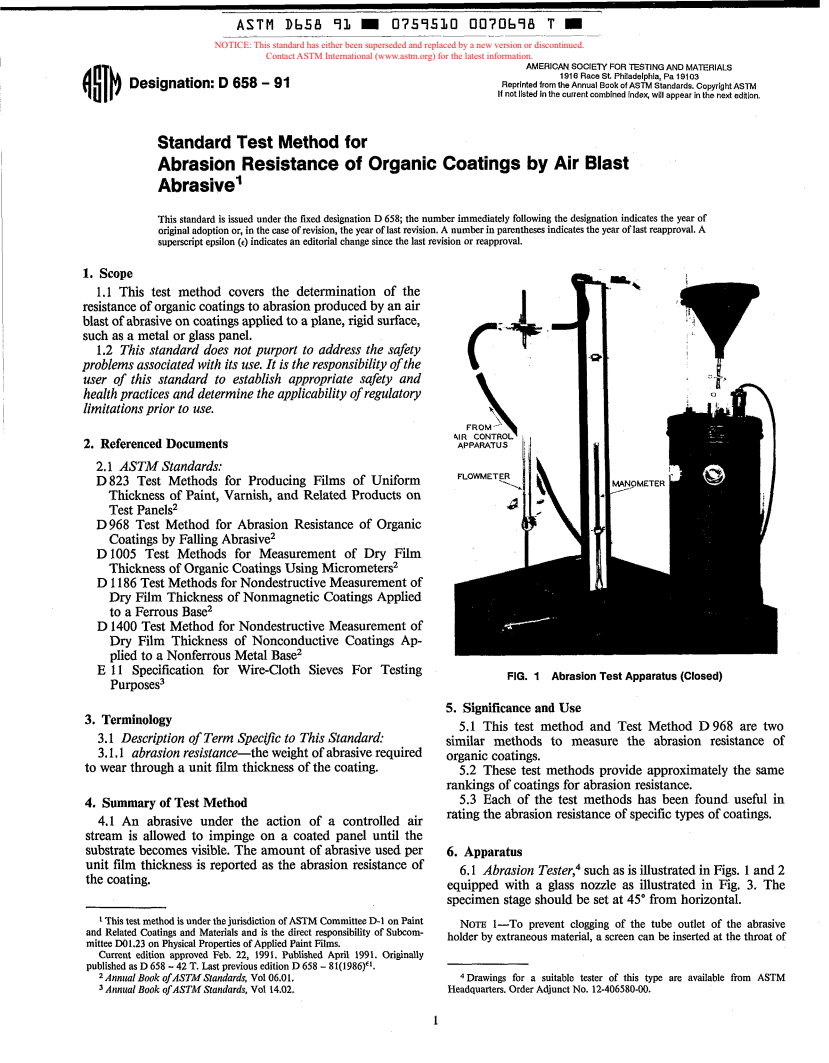

FIG. 1 Abrasion Test Apparatus (Closed)

Purposes3

5. Significance and Use

3. Terminology

5.1 This test method and Test Method D 968 are two

3.1 Description of Term Specific to This Standard:

similar methods to measure the abrasion resistance of

3.1.1 abrasion resistance-the weight of abrasive required

organic coatings.

to wear through a unit fdm thickness of the coating.

5.2 These test methods provide approximately the same

rankings of coatings for abrasion resistance.

5.3 Each of the test methods has been found useful in

4. Summary of Test Method

rating the abrasion resistance of specific types of coatings.

4.1 An abrasive under the action of a controlled air

on a coated panel until the

stream is allowed to impinge

substrate becomes visible. The amount of abrasive used per

6. Apparatus

unit film thickness is reported as the abrasion resistance of

6.1 Abrasion Tester: such as is illustrated in Figs. 1 and 2

the coating.

equipped with a giass nozzle as illustrated in Fig. 3, The

specimen stage should be set at 45" from horizontal.

This test method is under the juridiction of ASTM Committee D-1 on Paint

NOTE 1-To prevent clogging of the tube outlet of the abrasive

and Related Coatings and Materials and is the direct responsibility of Subcom-

holder by extraneous material, a screen can be inserted at the throat of

mittee W1.23 on Physical Properties of Applied Paint Films.

Current edition approved Feb. 22, 1991. Published Apd 1991. Originaiiy

published as D 658 - 42 T. Last previous edition D 658 - 81(1986)".

Anniial Book o$ASTMStandards, Vol 06.01, 4Drawings for a suitable tester of this type are available from ASTM

Annical Book of ASTM Standards, Vol 14.02. Headquarters. Order Adjunct No. 12-406580-00.

1

---------------------- Page: 1 ----------------------

ASTM Db58 93 0759530 0070b99 3

4m D658

8. Standardization

8.1 Assemble the abrasion tester and connect the inner

tube of the nozzle by a flexible tube to a suitable oil-free air

GY supply under pressure.

8.2 Set the air supply pressure at a value that will provide

approximately the desired flow rate of abrasive.

8.2.1 Unless otherwise agreed upon between the pur-

i*

chaser and seiler, the abrasive flow rate should be 45 f 2

t

g/min. An air supply pressure of approximately 13 kPa (100

t z

mmHg) should provide this rate.

-LW *

FROM

WNOMETER

NOTE 6-For some types of coatings, it may be desirable to use a

higher flow rate of abrasive. A rate of 15 f 2 g/min has been found to be

useful in some instances.

REAR LAMP2

ABRASION &&-FRONT LAMP

8.3 Place a metal panel on the specimen stage of the

NOZZLE -

abrader. Using the operating steps outlined in the procedure

SPECIMEN

srm

section, determine the flow rate of the abrasive by allowing

the abrasive to flow for 3 min and weighing the amount

collected.

8.4 If needed, make further adjustments to the air pres-

sure and make repeated checks of the flow rate until the

specified rate is obtained,

9. Conditioning

9.1 Unless otherwise

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.