ASTM E911-98

(Specification)Standard Specification for Glass Stopcocks with Polytetrafluoroethylene (PTFE) Plugs

Standard Specification for Glass Stopcocks with Polytetrafluoroethylene (PTFE) Plugs

SCOPE

1.1 This specification provides standard dimensional requirements for obtaining, within practical limits, interchangeability in glass stopcocks (Note 1) with polytetrafluoroethylene (PTFE) plugs for ordinary laboratory and industrial applications. It covers dimensional interchangeability only and does not involve design characteristics of the item except where specified, nor does it involve physical or chemical characteristics of the material used. It does not cover glass stopcocks with glass plugs (Note 2), or stopcocks intended for use in high-vacuum work. Note 1-A stopcock is defined as consisting of a plug and barrel in assembled configuration. Note 2-Glass stopcocks with glass plugs are covered by Specification E675. Note 3-The dimensions pertaining to stopcocks were taken from the now obsolete Commercial Standard CS 21-58 of the U. S. Department of Commerce and Product Standard PS 28-70 published by the National Bureau of Standards. Note 4-For packaging standards, choose among the following standards: Specification E920, Specification E921; Practice E1133, and Specification E1157.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 911 – 98

Standard Specification for

Glass Stopcocks with Polytetrafluoroethylene (PTFE) Plugs

This standard is issued under the fixed designation E 911; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 921 Specification for Export Packaged Laboratory Appa-

ratus

1.1 This specification provides standard dimensional re-

E 1133 Practice for Performance Testing of Packaged Labo-

quirements for obtaining, within practical limits, interchange-

ratory Apparatus for United States Government Procure-

ability in glass stopcocks (Note 1) with polytetrafluoroethylene

ments

(PTFE) plugs for ordinary laboratory and industrial applica-

E 1157 Specification for Sampling and Testing of Reusable

tions. It covers dimensional interchangeability only and does

Laboratory Glassware

not involve design characteristics of the item except where

2.2 Other Standard:

specified, nor does it involve physical or chemical character-

PS 28-70 Glass Stopcocks With Polytetrafluoroethylene

istics of the material used. It does not cover glass stopcocks

(PTFE) Plugs

with glass plugs (Note 2) or stopcocks intended for use in

high-vacuum work.

3. Material

NOTE 1—A stopcock is defined as consisting of a plug and barrel in

3.1 The polytetrafluoroethylene material used to manufac-

assembled configuration.

ture the plugs shall meet the requirements of Specification

NOTE 2—Glass stopcocks with glass plugs are covered by Specification

D 1457 Types I and IV, extrusion and molding grade resins.

E 675.

NOTE 3—The dimensions pertaining to stopcocks were taken from the

4. Requirements for Single Straight-Bore Stopcocks

now obsolete Commercial Standard CS 21-58 of the U.S. Department of

Commerce and Product Standard PS 28-70 published by the National 4.1 The designations and dimensions for single straight-

Bureau of Standards.

bore stopcocks are shown in Fig. 1 and Table 1.

NOTE 4—Although glass is the most common material for stopcocks,

4.2 Taper (Note 3)—All straight-bore stopcocks shall have

other materials may be used as specified. Stopcocks constructed from

a taper of 2 6 0.006 mm of diameter per 10 mm of length (1

glass shall conform to Specifications E 438 and E 671.

to 5).

2. Referenced Documents

NOTE 5—The lines of contact of the mating surfaces should form a

conical section having a taper of 2 6 0.006 mm per 1 cm of axial length

2.1 ASTM Standards:

(before compression of the plug surface) for an axial distance of at least

D 374 Test Methods for Thickness of Solid Electrical Insu-

10 mm on each side of the bore.

lation

D 1457 Specification for Polytetrafluoroethylene (PTFE)

5. Requirements for Single Oblique-Bore Stopcocks

Molding and Extrusion Materials

5.1 The designations and dimensions for single oblique-

E 438 Specification for Glasses in Laboratory Apparatus

bore stopcocks are shown in Fig. 2 and Table 2.

E 671 Specification for Maximum Permissible Thermal Re-

5.2 Taper (Note 4)—All single oblique-bore stopcocks shall

sidual Stress in Annealed Glass Laboratory Apparatus

have a taper of 2 6 0.006 mm of diameter per 10 mm of length

E 675 Specification for Interchangeable Taper-Ground

(1 to 5).

Stopcocks and Stoppers

E 920 Specification for Commercially Packaged Laboratory

6. Requirements for Double Oblique-Bore (3-Way)

Apparatus

Stopcocks

6.1 The designations and dimensions for double-oblique-

bore stopcocks are shown in Fig. 3 and Table 3.

This specification is under the jurisdiction of ASTM Committee E-41 on

Laboratory Apparatus and is the direct responsibility of Subcommittee E41.01 on

Glass Apparatus.

Current edition approved April 10, 1998. Published February 1999. Originally

published as E 911 – 82. Last previous edition of E 911 – 93.

Annual Book of ASTM Standards, Vol 10.01.

3 5

Annual Book of ASTM Standards, Vol 08.01. Commercial Standards and Product Standards are available from the National

Annual Book of ASTM Standards, Vol 14.04. Institute of Standards and Technology, (NIST), Gaithersburg, MD 20899

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E911

FIG. 1 Stopcock

FIG. 3 Double Oblique-Bore (3-Way) Stopcock

TABLE 1 Single Straight-Bore Stopcocks

8. Test Methods

Stopcock Designation Diameter of plug at

and Bore of Hole in Centerline of Bore Length of Shell E,mm 8.1 Dimensions—Determine dimensions in accordance with

Plug B,mm D,mm

Method B of Test Methods D 374, except that micrometer

111 6 0.06 25 6 0.5

calipers graduated to 0.01 mm shall be used.

211 6 0.06 25 6 0.5

8.2 Taper —Measure taper by using a sine bar and plate or

3 15.2 6 0.10 30 6 0.5

an air gage.

4 15.2 6 0.10 30 6 0.5

616 6 0.20 35 6 0.5

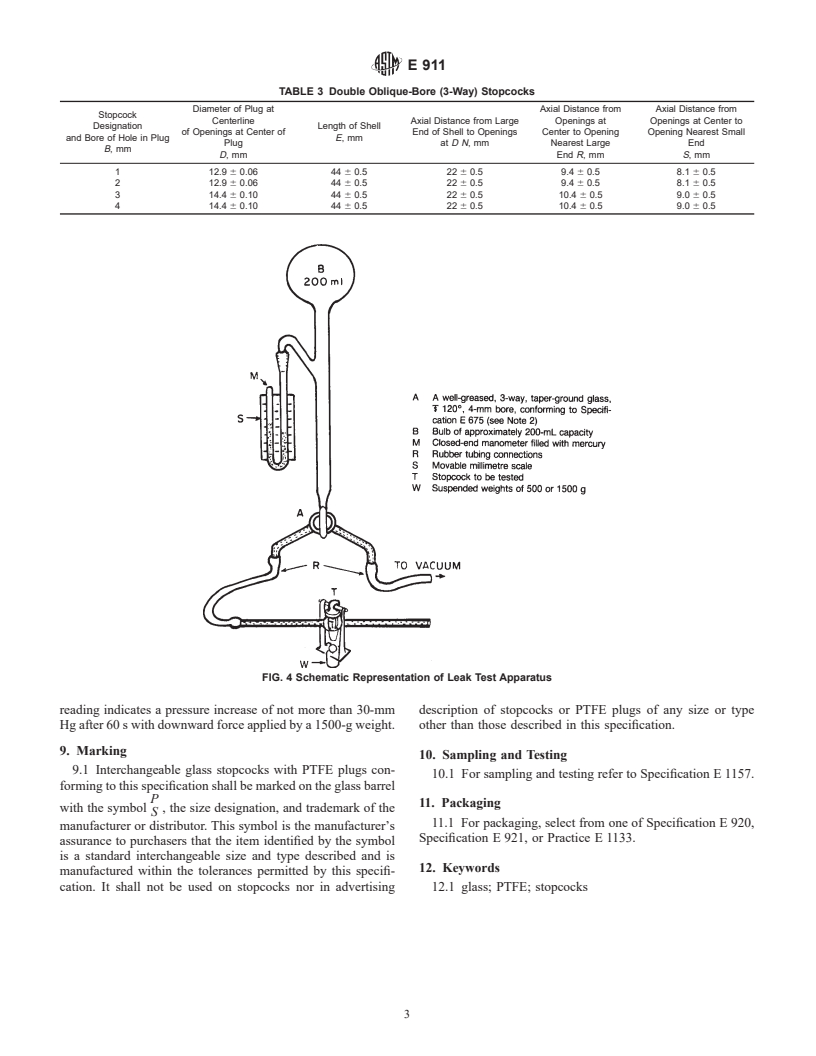

8.3 Leak Rate—Use the leak test apparatus illustrated in

Fig. 4, or one functionally similar to it. Suspend weights of 500

to 1500 g from the test plug to apply downward force for

properly seating the plug in the barrel. Conduct the test as

follows:

8.3.1 Check the apparatus setup, Fig. 1, for any leakage

under the test conditions before testing any stopcocks, T.

8.3.2 Clean all surfaces of plug and shell with lint-free

tissue or rinse with acetone.

8.3.3 Firmly seat the plug into the shell by rotating the p

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.