ASTM C1678-07

(Practice)Standard Practice for Fractographic Analysis of Fracture Mirror Sizes in Ceramics and Glasses

Standard Practice for Fractographic Analysis of Fracture Mirror Sizes in Ceramics and Glasses

SIGNIFICANCE AND USE

Fracture mirror size analysis is a powerful tool for analyzing glass and ceramic fractures. Fracture mirrors are telltale fractographic markings in brittle materials that surround a fracture origin as discussed in Practices C 1256 and C 1322. Fig. 1 shows a schematic with key features identified. Fig. 2 shows an example in glass. The fracture mirror region is very smooth and highly reflective in glasses, hence the name “fracture mirror.” In fact, high magnification microscopy reveals that, even within the mirror region in glasses, there are very fine features and escalating roughness as the crack advances away from the origin. These are submicrometer in size and hence are not discernable with an optical microscope. Early investigators interpreted fracture mirrors as having discrete boundaries including a “mirror-mist” boundary and also a “mist-hackle” boundary in glasses. These were also termed “inner mirror” or “outer mirror” boundaries, respectively. It is now known that there are no discrete boundaries corresponding to specific changes in the fractographic features. Surface roughness increases gradually from well within the fracture mirror to beyond the apparent boundaries. The boundaries were a matter of interpretation, the resolving power of the microscope, and the mode of viewing. In very weak specimens, the mirror may be larger than the specimen or component and the boundaries will not be present.

Figs. 3-5 show examples in ceramics. In polycrystalline ceramics, the qualifier “relatively” as in “relatively smooth” must be used, since there is an inherent roughness from the microstructure even in the area immediately surrounding the origin. In coarse-grained or porous ceramics, it may be impossible to identify a mirror boundary. In polycrystalline ceramics, it is highly unlikely that a mirror-mist boundary can be detected due to the inherent roughness created by the crack-microstructure interactions, even within the mirror. The word “systematic” in the defin...

SCOPE

1.1 This practice pertains to the analysis and interpretation of fracture mirror sizes in brittle materials. Fracture mirrors (Fig. 1) are telltale fractographic markings that surround a fracture origin in brittle materials. The fracture mirror size may be used with known fracture mirror constants to estimate the stress in a fractured component. Alternatively, the fracture mirror size may be used in conjunction with known stresses in test specimens to calculate fracture mirror constants. The practice is applicable to glasses and polycrystalline ceramic laboratory test specimens as well as fractured components. The analysis and interpretation procedures for glasses and ceramics are similar, but they are not identical. Different optical microscopy examination techniques are listed and described, including observation angles, illumination methods, appropriate magnification, and measurement protocols. Guidance is given for calculating a fracture mirror constant and for interpreting the fracture mirror size and shape for both circular and noncircular mirrors including stress gradients, geometrical effects, and/or residual stresses. The practice provides figures and micrographs illustrating the different types of features commonly observed in and measurement techniques used for the fracture mirrors of glasses and polycrystalline ceramics.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1678–07

Standard Practice for

Fractographic Analysis of Fracture Mirror Sizes in Ceramics

and Glasses

This standard is issued under the fixed designation C 1678; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C 1256 Practice for Interpreting Glass Fracture Surface

Features

1.1 This practice pertains to the analysis and interpretation

C 1322 Practice for Fractography and Characterization of

of fracture mirror sizes in brittle materials. Fracture mirrors

Fracture Origins in Advanced Ceramics

(Fig. 1) are telltale fractographic markings that surround a

fractureorigininbrittlematerials.Thefracturemirrorsizemay

3. Terminology

be used with known fracture mirror constants to estimate the

3.1 Definitions: (See Fig. 1)

stress in a fractured component. Alternatively, the fracture

3.1.1 fracture mirror, n—as used in fractography of brittle

mirror size may be used in conjunction with known stresses in

materials, a relatively smooth region in the immediate vicinity

test specimens to calculate fracture mirror constants. The

of and surrounding the fracture origin C 1145, C 1322

practice is applicable to glasses and polycrystalline ceramic

3.1.2 fracture origin, n—the source from which brittle

laboratory test specimens as well as fractured components.The

fracture commences. C 1145, C 1322

analysis and interpretation procedures for glasses and ceramics

3.1.3 hackle, n—as used in fractography of brittle materials,

are similar, but they are not identical. Different optical micros-

alineorlinesonthecracksurfacerunninginthelocaldirection

copy examination techniques are listed and described, includ-

of cracking, separating parallel but noncoplanar portions of the

ing observation angles, illumination methods, appropriate

crack surface. C 1145, C 1322

magnification, and measurement protocols. Guidance is given

3.1.4 mist, n—as used in fractography of brittle materials,

for calculating a fracture mirror constant and for interpreting

markings on the surface of an accelerating crack close to its

the fracture mirror size and shape for both circular and

effective terminal velocity, observable first as a misty appear-

noncircular mirrors including stress gradients, geometrical

ance and with increasing velocity reveals a fibrous texture,

effects, and/or residual stresses. The practice provides figures

elongated in the direction of crack propagation. C 1145,

and micrographs illustrating the different types of features

C 1322

commonly observed in and measurement techniques used for

3.2 Definitions of Terms Specific to This Standard:

the fracture mirrors of glasses and polycrystalline ceramics.

(See Fig. 1)

1.2 This standard does not purport to address all of the

3.2.1 mirror-mist boundary in glasses, n—the periphery

safety concerns, if any, associated with its use. It is the

where one can discern the onset of mist around a glass fracture

responsibility of the user of this standard to establish appro-

mirror. This boundary corresponds to A, the inner mirror

i

priate safety and health practices and determine the applica-

constant.

bility of regulatory limitations prior to use.

3.2.2 mist-hackle boundary in glasses, n—the periphery

2. Referenced Documents where one can discern the onset of systematic hackle around a

glass fracture mirror. This boundary corresponds to A , the

o

2.1 ASTM Standards:

outer mirror constant.

C 1145 Terminology of Advanced Ceramics

3.2.3 mirror-hackle boundary in polycrystalline ceramics,,

n—theperipherywhereonecandiscerntheonsetofsystematic

This practice is under the jurisdiction of ASTM Committee C28 on Advanced

new hackle and there is an obvious roughness change relative

Ceramics and is the direct responsibility of Subcommittee C28.03 on Physical

to that inside a ceramic fracture mirror region. This boundary

Properties and Non-Destructive Evaluation.

corresponds toA , the outer mirror constant. Ignore premature

Current edition approved Oct. 15, 2007. Published February 2008.

o

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

hackle and/or isolated steps from microstructural irregularities

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in the mirror or irregularities at the origin.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1678–07

NOTE—The initial flaw may grow stably to size a prior to unstable fracture when the stress intensity reaches K . The mirror-mist radius is R, the

c Ic i

mist-hackle radius is R , and the branching distance is R . These transitions correspond to the mirror constants, A,A , and A , respectively.

o b i o b

FIG. 1 Schematic of a Fracture Mirror Centered on a Surface Flaw of Initial Size (a).

-3/2

3.2.4 fracture mirror constant, n—(Fl ) an empirical ma- Early investigators interpreted fracture mirrors as having

terial constant that relates the fracture stress to the mirror discrete boundaries including a “mirror-mist” boundary and

radius in glasses and ceramics. also a “mist-hackle” boundary in glasses. These were also

termed “inner mirror” or “outer mirror” boundaries, respec-

4. Summary of Practice

tively. It is now known that there are no discrete boundaries

corresponding to specific changes in the fractographic features.

4.1 This practice provides guidance on the measurement

Surface roughness increases gradually from well within the

and interpretation of fracture mirror sizes in laboratory test

fracture mirror to beyond the apparent boundaries. The bound-

specimens as well as in fractured components. Microscopy

aries were a matter of interpretation, the resolving power of the

examination techniques are listed. The procedures for glasses

microscope,andthemodeofviewing.Inveryweakspecimens,

and ceramics are similar, but they are not identical. Guidance

is given for interpreting the fracture mirror size and shape. the mirror may be larger than the specimen or component and

the boundaries will not be present.

Guidance is given on how to interpret noncircular mirrors due

to stress gradients, geometrical effects, or residual stresses.

5.2 Figs. 3-5 show examples in ceramics. In polycrystalline

4.2 Thestressattheorigininacomponentmaybeestimated

ceramics, the qualifier “relatively” as in “relatively smooth”

from the mirror size.

must be used, since there is an inherent roughness from the

4.3 Fracture mirror constants may be estimated from

microstructure even in the area immediately surrounding the

matched sets of fracture stresses and mirror sizes.

origin. In coarse-grained or porous ceramics, it may be

impossible to identify a mirror boundary. In polycrystalline

5. Significance and Use

ceramics, it is highly unlikely that a mirror-mist boundary can

5.1 Fracture mirror size analysis is a powerful tool for be detected due to the inherent roughness created by the

analyzing glass and ceramic fractures. Fracture mirrors are crack-microstructure interactions, even within the mirror. The

telltalefractographicmarkingsinbrittlematerialsthatsurround word “systematic” in the definition for “mirror-hackle bound-

a fracture origin as discussed in Practices C 1256 and C 1322. ary in polycrystalline ceramics” requires some elaboration.

Fig. 1 shows a schematic with key features identified. Fig. 2 Mirror boundary hackle lines are velocity hackle lines created

shows an example in glass. The fracture mirror region is very after the radiating crack reaches terminal velocity. However,

smooth and highly reflective in glasses, hence the name premature, isolated hackle can in some instances be generated

“fracture mirror.” In fact, high magnification microscopy well within a ceramic fracture mirror. It should be disregarded

reveals that, even within the mirror region in glasses, there are when judging the mirror boundary. Wake hackle from an

very fine features and escalating roughness as the crack isolated obstacle inside the mirror (such as a large grain or

advances away from the origin. These are submicrometer in agglomerate) can trigger early “premature” hackle lines. Steps

size and hence are not discernable with an optical microscope. in scratches or grinding flaws can trigger hackle lines that

C1678–07

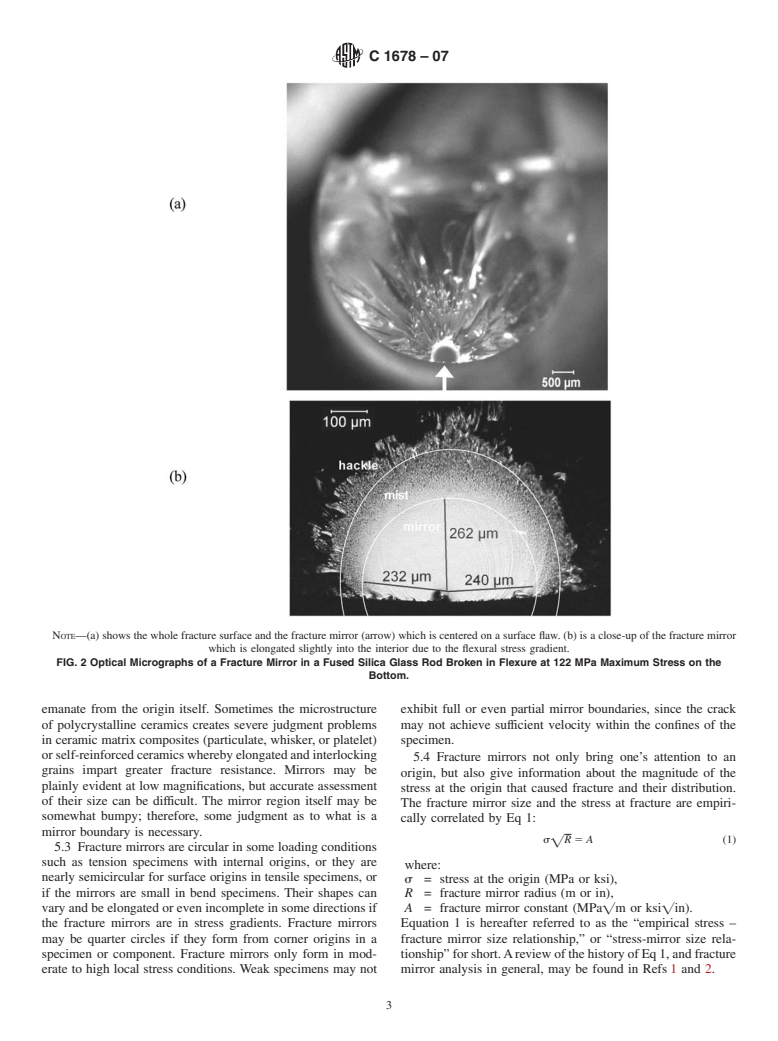

NOTE—(a) shows the whole fracture surface and the fracture mirror (arrow) which is centered on a surface flaw. (b) is a close-up of the fracture mirror

which is elongated slightly into the interior due to the flexural stress gradient.

FIG. 2 Optical Micrographs of a Fracture Mirror in a Fused Silica Glass Rod Broken in Flexure at 122 MPa Maximum Stress on the

Bottom.

emanate from the origin itself. Sometimes the microstructure exhibit full or even partial mirror boundaries, since the crack

of polycrystalline ceramics creates severe judgment problems may not achieve sufficient velocity within the confines of the

in ceramic matrix composites (particulate, whisker, or platelet) specimen.

orself-reinforcedceramicswherebyelongatedandinterlocking

5.4 Fracture mirrors not only bring one’s attention to an

grains impart greater fracture resistance. Mirrors may be

origin, but also give information about the magnitude of the

plainly evident at low magnifications, but accurate assessment

stress at the origin that caused fracture and their distribution.

of their size can be difficult. The mirror region itself may be

The fracture mirror size and the stress at fracture are empiri-

somewhat bumpy; therefore, some judgment as to what is a

cally correlated by Eq 1:

mirror boundary is necessary.

s R 5 A (1)

=

5.3 Fracture mirrors are circular in some loading conditions

such as tension specimens with internal origins, or they are

where:

nearly semicircular for surface origins in tensile specimens, or

s = stress at the origin (MPa or ksi),

if the mirrors are small in bend specimens. Their shapes can R = fracture mirror radius (m or in),

vary and be elongated or even incomplete in some directions if A = fracture mirror constant (MPa=morksi=in).

the fracture mirrors are in stress gradients. Fracture mirrors Equation 1 is hereafter referred to as the “empirical stress –

may be quarter circles if they form from corner origins in a fracture mirror size relationship,” or “stress-mirror size rela-

specimen or component. Fracture mirrors only form in mod- tionship”forshort.AreviewofthehistoryofEq1,andfracture

erate to high local stress conditions. Weak specimens may not mirror analysis in general, may be found in Refs 1 and 2.

C1678–07

NOTE—Notice how clear the mirror is in the low power images in (a) and (b).The mirror boundary (arrows in c) is where systematic new hackle forms

and there is an obvious roughness difference compared to the roughness inside the mirror region.

FIG. 3 Silicon Carbide Tension Strength Specimen (371 MPa) with a Mirror Centered on a Compositional Inhomogeneity Flaw.

5.5 A, the “fracture mirror constant” (sometimes also boundaries between them in glasses. Each has a corresponding

known as the “mirror constant”) has units of stress intensity mirrorconstant,A.Themostcommonnotationistorefertothe

(MPa=morksi=in) and is considered by many to be a mirror-mist boundary as the inner mirror boundary, and its

material property. As shown in Figs. 1 and 2, it is possible to mirror constant is designated A. The mist-hackle boundary is

i

discern separate mist and hackle regions and the apparent referredtoastheoutermirrorboundary,anditsmirrorconstant

C1678–07

NOTE— The mirror boundary is difficult to delineate in this material. (a) shows the uncoated fracture surface of a 2.8 mm thick flexural strength

specimen that fractured at 486 MPa. Vicinal illumination brings out the markings. (b) shows a mirror-hackle boundary where systematic new hackle is

detected (small white arrows) as compared to the roughness inside the mirror. The marked circle is elongated somewhat into the depth due to the stress

gradient. The radius in the direction along the bottom surface (a region of constant stress) was 345 mm.

FIG. 4 A Fracture Mirror in a Fine-Grained 3 Mol % Yttria-Stabilized Tetragonal Zirconia Polycrystal (3Y-TZP).

is designated A . The mirror-mist boundary is usually not estimate the stress in the component at the origin. Practice

o

perceivable in polycrystalline ceramics. Usually, only the C 1322 has a comprehensive list of fracture mirror constants

mirror-hackle boundary is measured and only an A for the for a variety of ceramics and glasses.

o

mirror-hackle boundary is calculated. A more fundamental

6. Procedure

relationship than Eq 1 may be based on the stress intensity

6.1 Use an optical microscope whenever possible.

factors (K ) at the mirror-mist or mist-hackle boundaries, but

I

Eq 1 is more practical and simpler to use. 6.1.1 For glasses, use a compound optical microscope in

bright field mode with reflected light illumination. A scanning

5.6 The size predictions based on Eq 1 and theAvalues, or

alternatively stress intensity factors, match very closely for the electron microscope may be used if optical microscopy is not

limiting cases of small mirrors in tension specimens. This is feasible.

also true for small semicircular mirrors centered on surface 6.1.2 Forceramics,useastereoopticalmicroscopewithlow

flaws in strong flexure specimens. So, at least for some special angle grazing (vicinal) illumination. A scanning electron mi-

mirror cases,Ashould be directly related to a more fundamen- croscope may be used if optical microscopy is not feasible

tal parameter based on stress intensity factors. 6.1.3 Differential interference contrast (DIC, also known as

5.7 The size of the fracture mirrors in laboratory test Nomarski) mode viewing with a research compound micro-

specimen fractures may be used in conjunction with known scope is not recommended for either glasses or ceramics. It is

fracture mirror constants to verify the stress at fracture was as not suitable for rough ceramic fracture surfaces. It also creates

expected. The fracture mirror sizes and known stresses from complicationswithglassfracturesurfaces.Thereisnoquestion

laboratorytestspecimensmayalsobeusedtocomputefracture that DIC mode viewing can discern very subtle mist features in

mirror constants, A. glasses, but the threshold of mist detectability is highly

5.8 The size of the fracture mirrors in components ma

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.