ASTM F2148-07(2012)

(Practice)Standard Practice for Evaluation of Delayed Contact Hypersensitivity Using the Murine Local Lymph Node Assay (LLNA)

Standard Practice for Evaluation of Delayed Contact Hypersensitivity Using the Murine Local Lymph Node Assay (LLNA)

SIGNIFICANCE AND USE

5.1 The propensity of a material to stimulate delayed contact hypersensitivity must be assessed before clinical application of devices containing this material. Delayed hypersensitivity may occur anywhere in the body. Systemic delayed hypersensitivity may have a complex set of reactions and consequences depending on the actual tissue/organ site of reaction. Although the reactions are seldom life-threatening, severe tissue and organ damage my result over time. Skin is the usual test site to determine the propensity of a material to cause delayed hypersensitivity.

5.2 The standard historical test methods have involved the use of guinea pigs with a cutaneous application and observation of the reaction site. The use of the murine local lymph node assay results in a numerical quantitation of stimulation, rather than subjective evaluation and could be used to determine dose responses.

5.3 This practice may not be predictive of events occurring during all types of implant applications. The user is cautioned to consider the appropriateness of the method in view of the materials being tested, their potential applications, and the recommendations contained in Practice F748.

SCOPE

1.1 This practice provides a methodology to use an in-situ procedure for the evaluation of delayed contact hypersensitivity reactions.

1.2 This practice is intended to provide an alternative to the use of guinea pigs for evaluation of the ability of a device material to stimulate delayed contact hypersensitivity reactions. This alternative is particularly applicable for materials used in devices that contact only intact skin. However, the guinea pig maximization test is still the recommended method when assessing the delayed hypersensitivity response to metals or when testing substances that do not penetrate the skin but are used in devices that contact deep tissues or breached surfaces. The guinea pig maximization test should be used for these substances.

1.3 This practice consists of a protocol for assessing an increase in lymphocyte proliferation within the nodes draining the site of administration on the ears of mice.

1.4 The LLNA has been validated only for low-molecular-weight chemicals that can penetrate the skin. The absorbed chemical or metabolite must bind to macromolecules, such as proteins, to form immunogenic conjugates.

1.5 This practice is one of several developed for the assessment of the biocompatibility of materials. Practice F748 may provide guidance for the selection of appropriate methods for testing materials for a specific application.

1.6 Identification of a supplier of materials or reagents is for the convenience of the user and does not imply a single source. Appropriate materials and reagents may be obtained from many commercial supply houses.

1.7 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2148 − 07(Reapproved 2012)

Standard Practice for

Evaluation of Delayed Contact Hypersensitivity Using the

Murine Local Lymph Node Assay (LLNA)

This standard is issued under the fixed designation F2148; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.8 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This practice provides a methodology to use an in-situ

responsibility of the user of this standard to establish appro-

procedure for the evaluation of delayed contact hypersensitiv-

priate safety and health practices and determine the applica-

ity reactions.

bility of regulatory limitations prior to use.

1.2 This practice is intended to provide an alternative to the

2. Referenced Documents

use of guinea pigs for evaluation of the ability of a device

material to stimulate delayed contact hypersensitivity reac- 2

2.1 ASTM Standards:

tions. This alternative is particularly applicable for materials

F619 Practice for Extraction of Medical Plastics

used in devices that contact only intact skin. However, the

F720 PracticeforTestingGuineaPigsforContactAllergens:

guinea pig maximization test is still the recommended method

Guinea Pig Maximization Test

when assessing the delayed hypersensitivity response to metals

F748 PracticeforSelectingGenericBiologicalTestMethods

orwhentestingsubstancesthatdonotpenetratetheskinbutare

for Materials and Devices

used in devices that contact deep tissues or breached surfaces.

F750 Practice for Evaluating Material Extracts by Systemic

The guinea pig maximization test should be used for these

Injection in the Mouse

substances.

2.2 Other Document:

ICCVAM NIH Publication No: 99-4494 The Murine Local

1.3 This practice consists of a protocol for assessing an

increase in lymphocyte proliferation within the nodes draining Lymph Node Assay, 1999

the site of administration on the ears of mice.

3. Terminology

1.4 The LLNA has been validated only for low-molecular-

3.1 Definitions:

weight chemicals that can penetrate the skin. The absorbed

3.1.1 AOO, n—acetone olive oil solution (4:1 v/v) is a

chemical or metabolite must bind to macromolecules, such as

suitable nonpolar solvent.

proteins, to form immunogenic conjugates.

3.1.2 aqueous solvent, n—in this assay refers to the polar

1.5 This practice is one of several developed for the

solvent, saline.

assessment of the biocompatibility of materials. Practice F748

3.1.3 DMSO, n—dimethylsulfoxide (nonaqueous, suitable

may provide guidance for the selection of appropriate methods

organic solvent).

for testing materials for a specific application.

3.1.4 DNCB, n—2,4-dinitrochlorobenzene.

1.6 Identification of a supplier of materials or reagents is for

3.1.5 formalin, n—a ⁄10 dilution of 37 to 39 % formalde-

the convenience of the user and does not imply a single source.

hyde solution (formaldehyde) in PBS.

Appropriate materials and reagents may be obtained from

many commercial supply houses.

3.1.6 ICCVAM, n—Interagency Coordinating Committee on

the Validation of Alternative Methods.

1.7 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this 3.1.7 nonaqueous solvent, n—in this assay refers to the

standard.

organic or nonpolar solvent, which shall be dimethylsulfoxide

(DMSO) or acetone olive oil (AOO).

1 2

ThispracticeisunderthejurisdictionofASTMCommitteeF04onMedicaland For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Surgical Materials and Devices and is the direct responsibility of Subcommittee contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

F04.16 on Biocompatibility Test Methods. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Oct. 1, 2012. Published October 2012. Originally the ASTM website.

ε1 3

approved in 2001. Last previous edition approved in 2007 as F2148 – 07 . DOI: Available from NICEATM, NIEHS, 79 Alexander Dr., Mail Drop EC-17,

10.1520/F2148-07R12. Research Triangle Park, NC 27709.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2148 − 07 (2012)

3.1.8 PBS, n—phosphate buffered saline, pH 7.2. hydroxyethyl cellulose to each 10 mL of the aqueous vehicle

control and test solutions to aid in holding the solution to the

3.1.9 positive control, n—a substance capable of consis-

ear.

tently stimulating lymphocyte proliferation.

6.4 The final specimen to be extracted should be prepared

3.1.10 saline, n—0.9 % sodium chloride (aqueous, polar

with a surface finish consistent with end-use application.

solvent).

6.5 The specimen shall be sterilized by the method to be

3.1.11 TCA, n—5 % trichloroacetic acid.

H3 used for the final product.

3.1.12 tritiated thymidine, n— methyl thymidine, specific

activity 2 Ci/mM (in PBS) I IUDR-radioactive uridine. 6.6 Care should be taken that the specimens do not become

contaminated during preparation and aseptic technique is

3.1.13 vehicle controls, n—an aqueous, polar solvent and a

recommended.

non-aqueous, nonpolar solvent.

7. Preparation of Positive Controls

4. Summary of Practice

7.1 Nonaqueous Positive Control—Weigh0.025gofDNCB

4.1 Test and control substances or extracts are applied to the

and place in a flask. Add enough DMSO to dissolve all of the

ears of test mice. The draining lymph nodes are harvested and

DNCB.Add more DMSO to bring the level up to 10 mL. Cap

lymphocyte proliferation evaluated. Comparisons are made

and shake the flask until a homogeneous solution is obtained.

with the control and test specimens tested under identical

The dose level of the positive control should not produce

conditions.

systemic toxicity as evidenced by clinical observations.

7.2 Aqueous Positive Control—Neutral buffered formalin is

5. Significance and Use

commercially available. (Or dilute formaldehyde ⁄10 in PBS.

5.1 The propensity of a material to stimulate delayed

Place 1 mL of formaldehyde in a 10-mL flask. Add enough

contact hypersensitivity must be assessed before clinical ap-

PBS to mix the two solutions.Add more PBS to bring the level

plication of devices containing this material. Delayed hyper-

up to 10 mL. Cap and shake the flask until a homogeneous

sensitivity may occur anywhere in the body. Systemic delayed

solution is obtained.)

hypersensitivity may have a complex set of reactions and

7.3 Aqueous solutions are not suitable for application to the

consequences depending on the actual tissue/organ site of

ear. Therefore, for use in the assay, add 0.05 g of hydroxyethyl

reaction. Although the reactions are seldom life-threatening,

cellulose to each 10 mLof the aqueous positive control to aid

severetissueandorgandamagemyresultovertime.Skinisthe

in holding the solution to the ear until absorbed.

usualtestsitetodeterminethepropensityofamaterialtocause

delayed hypersensitivity.

7.4 For all specimens requiring extractions, prepare an

aqueous and non-aqueous extract (DMSO or AOO are recom-

5.2 The standard historical test methods have involved the

mended but other permissible extractants are listed in the

use of guinea pigs with a cutaneous application and observa-

ICCVAM document) following the procedures described in

tion of the reaction site. The use of the murine local lymph

Practice F619.

node assay results in a numerical quantitation of stimulation,

rather than subjective evaluation and could be used to deter-

8. Dosing of the Animals

mine dose responses.

8.1 Healthy, non-pregnant female CBA/Ca or CBA/j mice

5.3 This practice may not be predictive of events occurring

that are seven to twelve weeks of age shall be used. House the

during all types of implant applications. The user is cautioned

animals according to treatment group with five animals per

to consider the appropriateness of the method in view of the

cage.

materials being tested, their potential applications, and the

8.2 Day One—Uniquelyidentifyeachmouse(eartagsorear

recommendations contained in Practice F748.

notches may not be used). Weigh each mouse to the nearest

whole gram.

6. Preparation of Test Specimens

8.3 Aminimum of five mice shall be used for each positive

6.1 Specimens should be prepared in accordance with Prac-

andnegativecontrolandeachtestsample.Theyshallbetreated

tice F619. All solid materials shall be extracted. Extractions

dailyforthreeconsecutivedaysbytopicalapplicationof25µL

shall be done with an aqueous (polar) solvent and a nonaque-

of one of the solutions to the dorsal surface of both ears. For

ous (nonpolar or organic) solvent, either DMSO or AOO.

the aqueous groups only, the dorsal surface should be wiped

6.2 Liquid test articles and gels shall be used directly if they

with acetone just before treating to aid in absorption of the

are not irritants.Aliquid that is an irritant shall be diluted with

aqueous solution, although it will not be completely absorbed.

an aqueous or nonaqueous solvent based on solubility of the

liquid test article until the solution is non-irritating.

“Final Report on the Safety Assessment of Hydroxyethylcellulose,

6.3 Wholly aqueous solutions are not suitable for applica-

Hydroxypropylcellulose, Methylcellulose, Hydroxypropyl Methylcellulose, and

tion to the ear. Therefore, for use in the assay, add 0.05 g of Cellulose Gum,” J. Amer Coll Tox., Vol 5, No. 3, 1986, pp. 1-59.

F2148 − 07 (2012)

8.3.1 For testing, other than liquid test articles, the groups cpm

5 dpm

shall include: aqueous and nonaqueous positive controls, decimal counter efficiency

aqueous and nonaqueous vehicle controls, aqueous extract of

For verification of the working tritiated thymidine solution,

the test sample, and nonaqueous extract of test sample.

determinetheclosenessoftheconcentrationto80µCi/mL.The

8.3.2 For testing of liquid test articles, the groups shall

final diluted solution contains 0.032 µCi. Since 1.0

include: aqueous and nonaqueous positive controls, the liquid

µCi = 2 220 000 dpm, then 0.032 µCi = 71 040 dpm. There-

test sample, and either an aqueous or a nonaqueous vehicle

fore:

control appropriate for the nature of the liquid sample.

mean dpm

8.3.3 The extract shall be used within 24 h of preparation.

the µCi of the working solution 5 380 µCi/mL

71040 dpm

The extract should be stored in a stoppered container at room

temperature. The applications shall be performed at 24 62h

Make adjustments to the solution as needed. Make similar

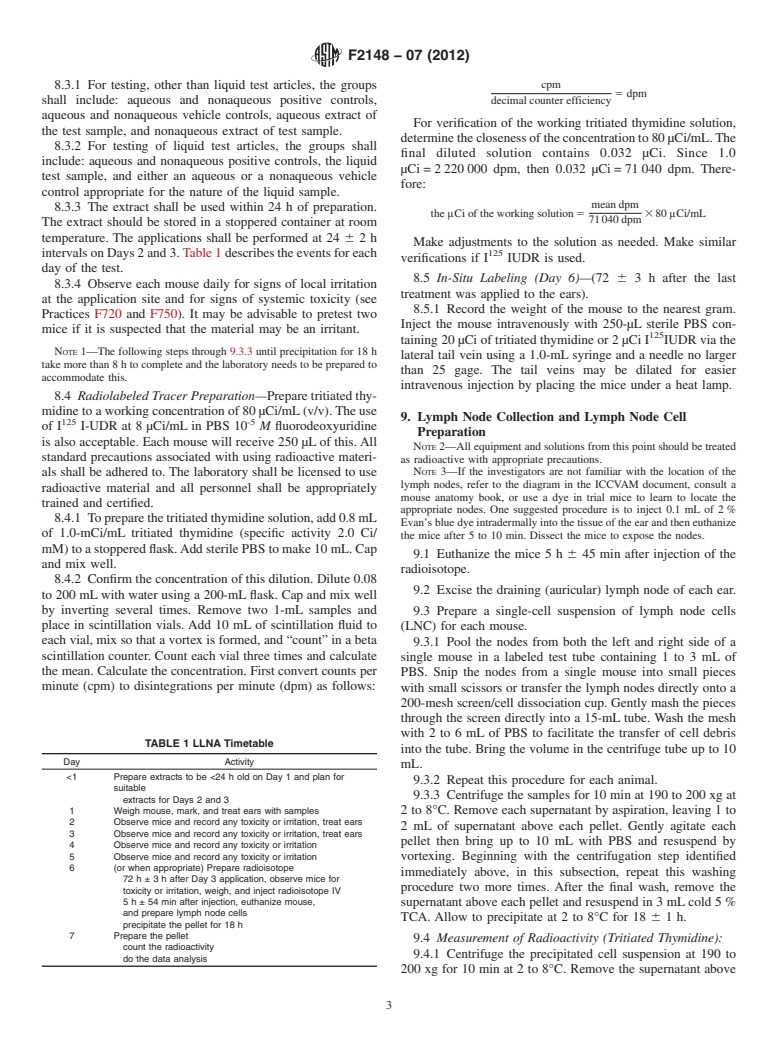

intervalsonDays2and3.Table1describestheeventsforeach

verifications if I IUDR is used.

day of the test.

8.5 In-Situ Labeling (Day 6)—(72 6 3 h after the last

8.3.4 Observe each mouse daily for signs of local irritation

treatment was applied to the ears).

at the application site and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.