ASTM C1252-23

(Test Method)Standard Test Methods for Uncompacted Void Content of Fine Aggregate (as Influenced by Particle Shape, Surface Texture, and Grading)

Standard Test Methods for Uncompacted Void Content of Fine Aggregate (as Influenced by Particle Shape, Surface Texture, and Grading)

SIGNIFICANCE AND USE

5.1 Test Methods A and B provide percent void content determined under standardized conditions which depend on the particle shape and texture of a fine aggregate. An increase in void content by these procedures indicates greater angularity, less sphericity, rougher surface texture, or combinations thereof. A decrease in void content results is associated with more rounded, spherical, or smooth-surfaced fine aggregate, or a combination thereof.

5.2 Test Method C measures the uncompacted void content of the minus 4.75 mm (No. 4) portion of the as-received material. This void content depends on grading as well as particle shape and texture.

5.3 The void content determined on the standard graded sample (Test Method A) is not directly comparable with the average void content of the three individual size fractions from the same sample tested separately (Test Method B). A sample consisting of single-size particles will have a higher void content than a graded sample. Therefore, use either one method or the other as a comparative measure of shape and texture, and identify which test method has been used to obtain the reported data. Test Method C does not provide an indication of shape and texture directly if the grading from sample to sample changes.

5.3.1 The standard graded sample (Test Method A) is most useful as a quick test which indicates the particle shape properties of a graded fine aggregate. Typically, the material used to make up the standard graded sample can be obtained from the remaining size fractions after performing a single sieve analysis of the fine aggregate.

5.3.2 Obtaining and testing individual size fractions (Test Method B) are more time consuming and require a larger initial sample than using the graded sample. However, Test Method B provides additional information concerning the shape and texture characteristics of individual sizes.

5.3.3 Testing samples in the as-received grading (Test Method C) may be useful in selecting proportio...

SCOPE

1.1 These test methods cover the determination of the loose, uncompacted void content of a sample of fine aggregate. When measured on any aggregate of a known grading, void content provides an indication of that aggregate's angularity, sphericity, and surface texture compared with other fine aggregates tested in the same grading. When void content is measured on an as-received fine-aggregate grading, it can be an indicator of the effect of the fine aggregate on the workability of a mixture in which it may be used.

1.2 Three procedures are included for the measurement of void content. Two use graded fine aggregate (standard grading or as-received grading), and the other uses several individual size fractions for void content determinations:

1.2.1 Standard Graded Sample (Test Method A)—This test method uses a standard fine aggregate grading that is obtained by combining individual sieve fractions from a typical fine aggregate sieve analysis. See the Section 9 for the grading.

1.2.2 Individual Size Fractions (Test Method B)—This test method uses each of three fine aggregate size fractions: (a) 2.36 mm (No. 8) to 1.18 mm (No. 16); (b) 1.18 mm (No. 16) to 600 μm (No. 30); and (c) 600 μm (No. 30) to 300 μm (No. 50). For this test method, each size is tested separately.

1.2.3 As-Received Grading (Test Method C)—This test method uses that portion of the fine aggregate finer than a 4.75 mm (No. 4) sieve.

1.2.4 See the section on Significance and Use for guidance on the method to be used.

1.3 The values stated in SI units shall be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accor...

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C1252 − 23

Standard Test Methods for

Uncompacted Void Content of Fine Aggregate (as

Influenced by Particle Shape, Surface Texture, and

1

Grading)

This standard is issued under the fixed designation C1252; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

1.1 These test methods cover the determination of the loose,

1.5 This international standard was developed in accor-

uncompacted void content of a sample of fine aggregate. When

dance with internationally recognized principles on standard-

measured on any aggregate of a known grading, void content

ization established in the Decision on Principles for the

provides an indication of that aggregate’s angularity,

Development of International Standards, Guides and Recom-

sphericity, and surface texture compared with other fine aggre-

mendations issued by the World Trade Organization Technical

gates tested in the same grading. When void content is

measured on an as-received fine-aggregate grading, it can be an Barriers to Trade (TBT) Committee.

indicator of the effect of the fine aggregate on the workability

of a mixture in which it may be used. 2. Referenced Documents

2

1.2 Three procedures are included for the measurement of

2.1 ASTM Standards:

void content. Two use graded fine aggregate (standard grading

B88 Specification for Seamless Copper Water Tube

or as-received grading), and the other uses several individual

B88M Specification for Seamless Copper Water Tube (Met-

size fractions for void content determinations:

ric)

1.2.1 Standard Graded Sample (Test Method A)—This test

C29/C29M Test Method for Bulk Density (“Unit Weight”)

method uses a standard fine aggregate grading that is obtained

and Voids in Aggregate

by combining individual sieve fractions from a typical fine

C117 Test Method for Materials Finer than 75-μm (No. 200)

aggregate sieve analysis. See the Section 9 for the grading.

Sieve in Mineral Aggregates by Washing

1.2.2 Individual Size Fractions (Test Method B)—This test

C125 Terminology Relating to Concrete and Concrete Ag-

method uses each of three fine aggregate size fractions: (a)

gregates

2.36 mm (No. 8) to 1.18 mm (No. 16); (b) 1.18 mm (No. 16)

C128 Test Method for Relative Density (Specific Gravity)

to 600 μm (No. 30); and (c) 600 μm (No. 30) to 300 μm (No.

and Absorption of Fine Aggregate

50). For this test method, each size is tested separately.

C136/C136M Test Method for Sieve Analysis of Fine and

1.2.3 As-Received Grading (Test Method C)—This test

Coarse Aggregates

method uses that portion of the fine aggregate finer than a 4.75

C670 Practice for Preparing Precision and Bias Statements

mm (No. 4) sieve.

for Test Methods for Construction Materials

1.2.4 See the section on Significance and Use for guidance

C702/C702M Practice for Reducing Samples of Aggregate

on the method to be used.

to Testing Size

1.3 The values stated in SI units shall be regarded as the

C778 Specification for Standard Sand

standard.

D75/D75M Practice for Sampling Aggregates

1.4 This standard does not purport to address all of the

3. Terminology

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.1 Terms used in these test methods are defined in Termi-

nology C125.

1

These test methods are under the jurisdiction of ASTM Committee D04 on

Road and Paving Materials and are the direct responsibility of Subcommittee

2

D04.51 on Aggregate Tests. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved June 1, 2023. Published June 2023. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1993. Last previous edition approved in 2017 as C1252 – 17. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/C1252-23. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1252 − 23

4. Summary of Test Method content suggests that the material could be improved by

providing additional fines in the fine aggregate or more

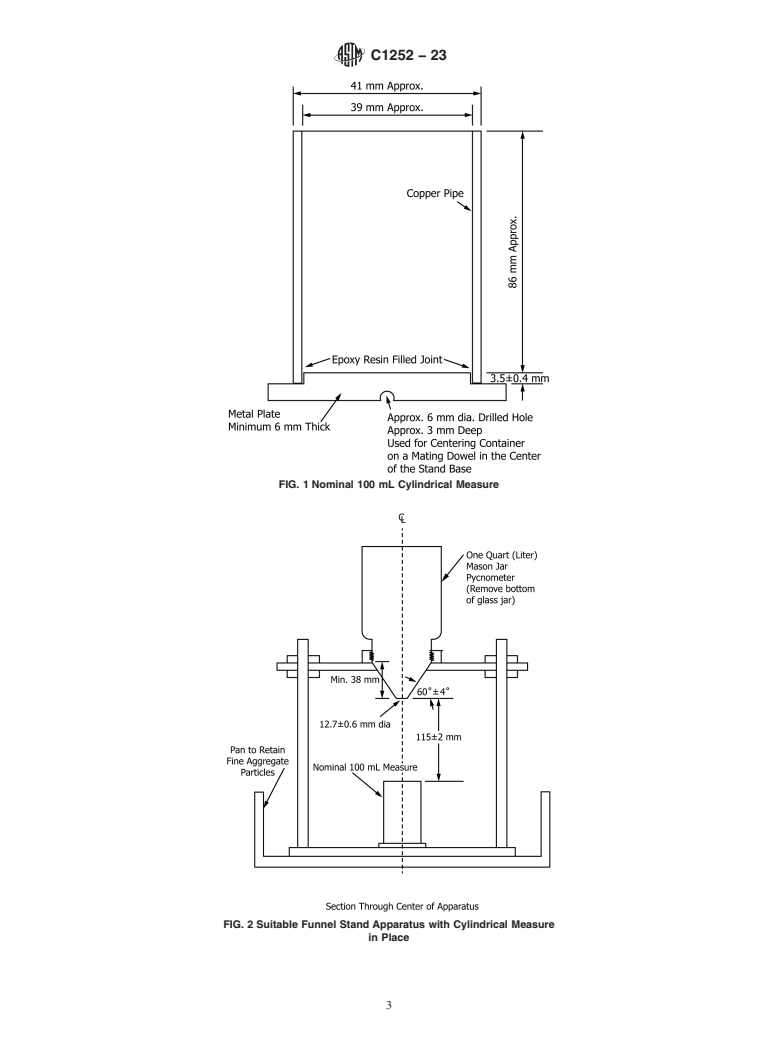

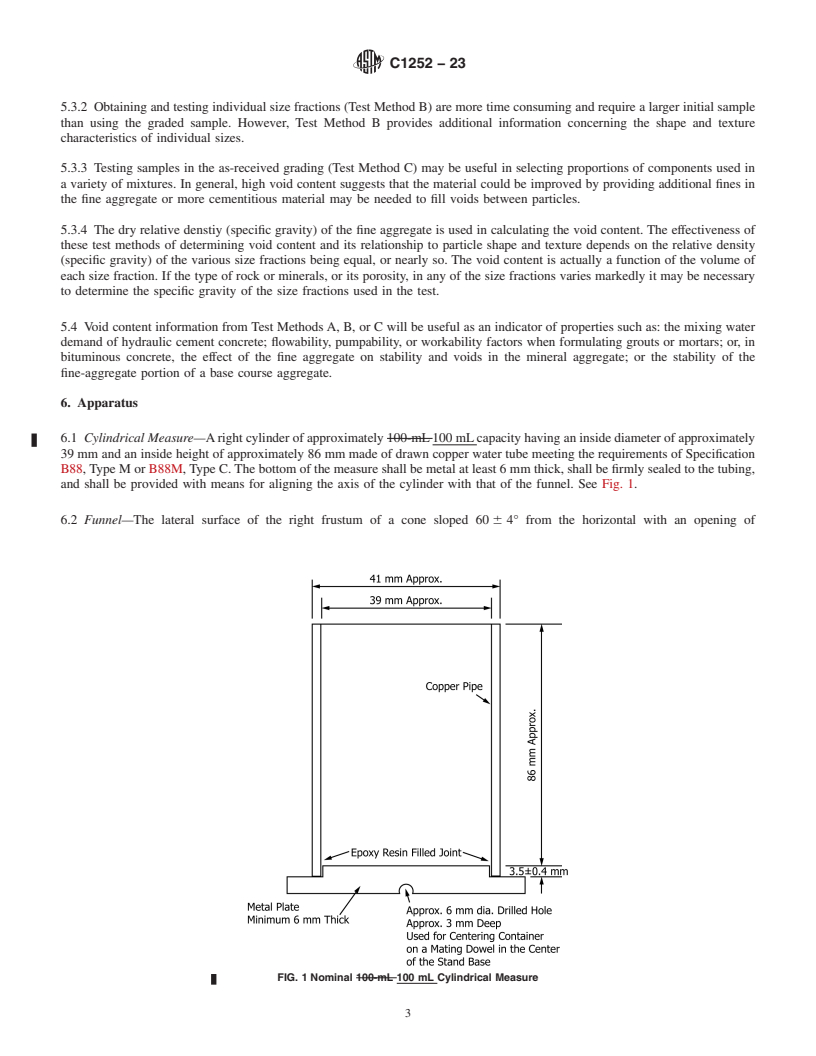

4.1 A nominal 100 mL calibrated cylindrical measure is

cementitious material may be n

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1252 − 17 C1252 − 23

Standard Test Methods for

Uncompacted Void Content of Fine Aggregate (as

Influenced by Particle Shape, Surface Texture, and

1

Grading)

This standard is issued under the fixed designation C1252; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 These test methods cover the determination of the loose, uncompacted void content of a sample of fine aggregate. When

measured on any aggregate of a known grading, void content provides an indication of that aggregate’s angularity, sphericity, and

surface texture compared with other fine aggregates tested in the same grading. When void content is measured on an as-received

fine-aggregate grading, it can be an indicator of the effect of the fine aggregate on the workability of a mixture in which it may

be used.

1.2 Three procedures are included for the measurement of void content. Two use graded fine aggregate (standard grading or

as-received grading), and the other uses several individual size fractions for void content determinations:

1.2.1 Standard Graded Sample (Test Method A)—This test method uses a standard fine aggregate grading that is obtained by

combining individual sieve fractions from a typical fine aggregate sieve analysis. See the Section 9 for the grading.

1.2.2 Individual Size Fractions (Test Method B)—This test method uses each of three fine aggregate size fractions: (a) 2.36 mm

(No. 8) to 1.18 mm (No. 16); (b) 1.18 mm (No. 16) to 600 μm (No. 30); and (c) 600 μm (No. 30) to 300 μm (No. 50). For this

test method, each size is tested separately.

1.2.3 As-Received Grading (Test Method C)—This test method uses that portion of the fine aggregate finer than a 4.75-mm 4.75

mm (No. 4) sieve.

1.2.4 See the section on Significance and Use for guidance on the method to be used.

1.3 The values stated in SI units shall be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and healthsafety, health, and environmental practices and determine

the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

1

These test methods are under the jurisdiction of ASTM Committee D04 on Road and Paving Materials and are the direct responsibility of Subcommittee D04.51 on

Aggregate Tests.

Current edition approved May 1, 2017June 1, 2023. Published May 2017June 2023. Originally approved in 1993. Last previous edition approved in 20062017 as

C1252 – 06C1252 – 17. which was withdrawn January 2015 and reinstated May 2017. DOI: 10.1520/C1252-17.DOI: 10.1520/C1252-23.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1252 − 23

2. Referenced Documents

2

2.1 ASTM Standards:

B88 Specification for Seamless Copper Water Tube

B88M Specification for Seamless Copper Water Tube (Metric)

C29/C29M Test Method for Bulk Density (“Unit Weight”) and Voids in Aggregate

C117 Test Method for Materials Finer than 75-μm (No. 200) Sieve in Mineral Aggregates by Washing

C125 Terminology Relating to Concrete and Concrete Aggregates

C128 Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate

C136C136/C136M Test Method for Sieve Analysis of Fine and Coarse Aggregates

C670 Practice for Preparing Precision and Bias Statements for Test Methods for Construction Materials

C702C702/C702M Practice for Reducing Samples of Aggregate to Testing Size

C778 Specification for Standard Sand

D75D75/D75M Practice for Sampling Aggregates

2.2 ACI Document:

3

ACI 116R Cement and Concrete Terminology

3. Terminology

3.1 Terms used in these test methods are defined in Terminology C125 or ACI 116R.

4. Summary of Test Method

4.1 A nominal 100-mL 100 mL calibrated cylindrical measure is filled with fine aggregate of prescrib

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.