ASTM D8021-20

(Guide)Standard Guide for Blast Furnace and Steel Furnace Slag as Produced During the Manufacture of Iron and Steel

Standard Guide for Blast Furnace and Steel Furnace Slag as Produced During the Manufacture of Iron and Steel

SIGNIFICANCE AND USE

4.1 This guide provides guidance as to the appropriate/typical mineralogy observed when iron and steel slag is produced during a variety of processes in the manufacture of iron and steel.

4.2 Slag can be considered a product based on the mineralogy of samples that are tested using X-ray diffraction, phase recognition and characterization, powdered XRD-Rietveld analysis, and SEM-PARC results, using this guide.

SCOPE

1.1 This standard is intended to provide guidance as to the appropriate/typical mineralogy observed when iron and steel slag, produced during the manufacture of iron and steel, is designated as a product. The included information covers the mineral properties of blast furnace slag and steel slag when they are manufactured in conjunction with the production of iron or steel, or both (Note 1).

Note 1: This guide is not intended to be used to determine the applicability of iron or steel slag, or both, for various applications. Terminology D8 designates steel slag as a product, while Terminology C125 designates blast furnace slag as a product. Its sole intent is to provide guidance as to the typical mineralogy when the iron or steel slag, or both, is designated as a product.

1.2 The values stated in SI units are to be regarded as standard. No other units are utilized in this standard.

1.3 The text of this standard references notes and footnotes that provide explanatory material. These notes and footnotes (excluding those in tables and figures) should not be considered as requirements of the specification.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D8021 − 20

Standard Guide for

Blast Furnace and Steel Furnace Slag as Produced During

1

the Manufacture of Iron and Steel

This standard is issued under the fixed designation D8021; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 This standard is intended to provide guidance as to the 2.1 ASTM Standards:

appropriate/typical mineralogy observed when iron and steel C125 Terminology Relating to Concrete and Concrete Ag-

slag, produced during the manufacture of iron and steel, is gregates

designated as a product. The included information covers the C702/C702M Practice for Reducing Samples of Aggregate

mineral properties of blast furnace slag and steel slag when to Testing Size

they are manufactured in conjunction with the production of C989/C989M Specification for Slag Cement for Use in

iron or steel, or both (Note 1). Concrete and Mortars

D8 Terminology Relating to Materials for Roads and Pave-

NOTE 1—This guide is not intended to be used to determine the

ments

applicability of iron or steel slag, or both, for various applications.

D75/D75M Practice for Sampling Aggregates

Terminology D8 designates steel slag as a product, while Terminology

C125 designates blast furnace slag as a product. Its sole intent is to

3. Terminology

provide guidance as to the typical mineralogy when the iron or steel slag,

or both, is designated as a product.

3.1 Definitions—For the definitions of terms used in this

1.2 The values stated in SI units are to be regarded as

standard, refer to Terminology D8.

standard. No other units are utilized in this standard.

3.2 Definitions of Terms Specific to This Standard:

1.3 The text of this standard references notes and footnotes

3.2.1 blast furnace slag, n—see Terminology C125.

that provide explanatory material. These notes and footnotes

3.2.1.1 Discussion—Slag, ferrous metal, blast furnace

(excludingthoseintablesandfigures)shouldnotbeconsidered

(granulated, GBS or air-cooled,ABFS orABF)—Blast furnace

as requirements of the specification.

slag is formed in a continuous process by the fusion of

1.4 This standard does not purport to address all of the limestone (or dolomite, or a combination thereof) and other

fluxes with the residues from the carbon source and the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- non-metallic components of the iron-bearing materials (for

example, iron ore, iron sinter). Blast furnace slag is generated

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use. at temperatures above 1500 °C. Dependent on the manner of

cooling of the liquid slag, it can be distinguished between

1.5 This international standard was developed in accor-

dance with internationally recognized principles on standard- crystalline, air-cooled blast furnace slag and glassy, granulated

blast furnace slag. Various cooling processes are defined in

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom- Terminology C125.

mendations issued by the World Trade Organization Technical

3.2.2 slag, steelmaking, n—steelmaking slags (SMS) are

Barriers to Trade (TBT) Committee.

generated as products during the refining/modification of steel

in the production process.

1

This guide is under the jurisdiction of ASTM Committee D04 on Road and

2

Paving Materials and is the direct responsibility of Subcommittee D04.99 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Sustainable Asphalt Pavement Materials and Construction. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Nov. 1, 2020. Published November 2020. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D8021-20. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D8021 − 20

3.2.2.1 Discussion—Steelmaking slag is formed (for 5. Classification

example, from the conversion of hot metal to steel) from the

5.1 Slag, ferrous metal, blast furnace (granulated, GBS or

melting of scrap in an electric arc furnace or from the

air-cooled, ABFS).

subsequent treatments of various refinements/modifications of

5.2 Slag,

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D8021 − 20

Standard Guide for

Blast Furnace and Steel Furnace Slag as Produced During

1

the Manufacture of Iron and Steel

This standard is issued under the fixed designation D8021; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 This standard is intended to provide guidance as to the 2.1 ASTM Standards:

appropriate/typical mineralogy observed when iron and steel C125 Terminology Relating to Concrete and Concrete Ag-

slag, produced during the manufacture of iron and steel, is gregates

designated as a product. The included information covers the C702/C702M Practice for Reducing Samples of Aggregate

mineral properties of blast furnace slag and steel slag when to Testing Size

they are manufactured in conjunction with the production of C989/C989M Specification for Slag Cement for Use in

iron or steel, or both (Note 1). Concrete and Mortars

D8 Terminology Relating to Materials for Roads and Pave-

NOTE 1—This guide is not intended to be used to determine the

ments

applicability of iron or steel slag, or both, for various applications.

D75/D75M Practice for Sampling Aggregates

Terminology D8 designates steel slag as a product, while Terminology

C125 designates blast furnace slag as a product. Its sole intent is to

3. Terminology

provide guidance as to the typical mineralogy when the iron or steel slag,

or both, is designated as a product.

3.1 Definitions—For the definitions of terms used in this

1.2 The values stated in SI units are to be regarded as

standard, refer to Terminology D8.

standard. No other units are utilized in this standard.

3.2 Definitions of Terms Specific to This Standard:

1.3 The text of this standard references notes and footnotes

3.2.1 blast furnace slag, n—see Terminology C125.

that provide explanatory material. These notes and footnotes

3.2.1.1 Discussion—Slag, ferrous metal, blast furnace

(excluding those in tables and figures) should not be considered

(granulated, GBS or air-cooled, ABFS or ABF)—Blast furnace

as requirements of the specification.

slag is formed in a continuous process by the fusion of

limestone (or dolomite, or a combination thereof) and other

1.4 This standard does not purport to address all of the

fluxes with the residues from the carbon source and the

safety concerns, if any, associated with its use. It is the

non-metallic components of the iron-bearing materials (for

responsibility of the user of this standard to establish appro-

example, iron ore, iron sinter). Blast furnace slag is generated

priate safety, health, and environmental practices and deter-

at temperatures above 1500 °C. Dependent on the manner of

mine the applicability of regulatory limitations prior to use.

cooling of the liquid slag, it can be distinguished between

1.5 This international standard was developed in accor-

crystalline, air-cooled blast furnace slag and glassy, granulated

dance with internationally recognized principles on standard-

blast furnace slag. Various cooling processes are defined in

ization established in the Decision on Principles for the

Terminology C125.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

3.2.2 slag, steelmaking, n—steelmaking slags (SMS) are

Barriers to Trade (TBT) Committee.

generated as products during the refining/modification of steel

in the production process.

1

This guide is under the jurisdiction of ASTM Committee D04 on Road and

2

Paving Materials and is the direct responsibility of Subcommittee D04.99 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Sustainable Asphalt Pavement Materials and Construction. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Nov. 1, 2020. Published November 2020. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D8021-20. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D8021 − 20

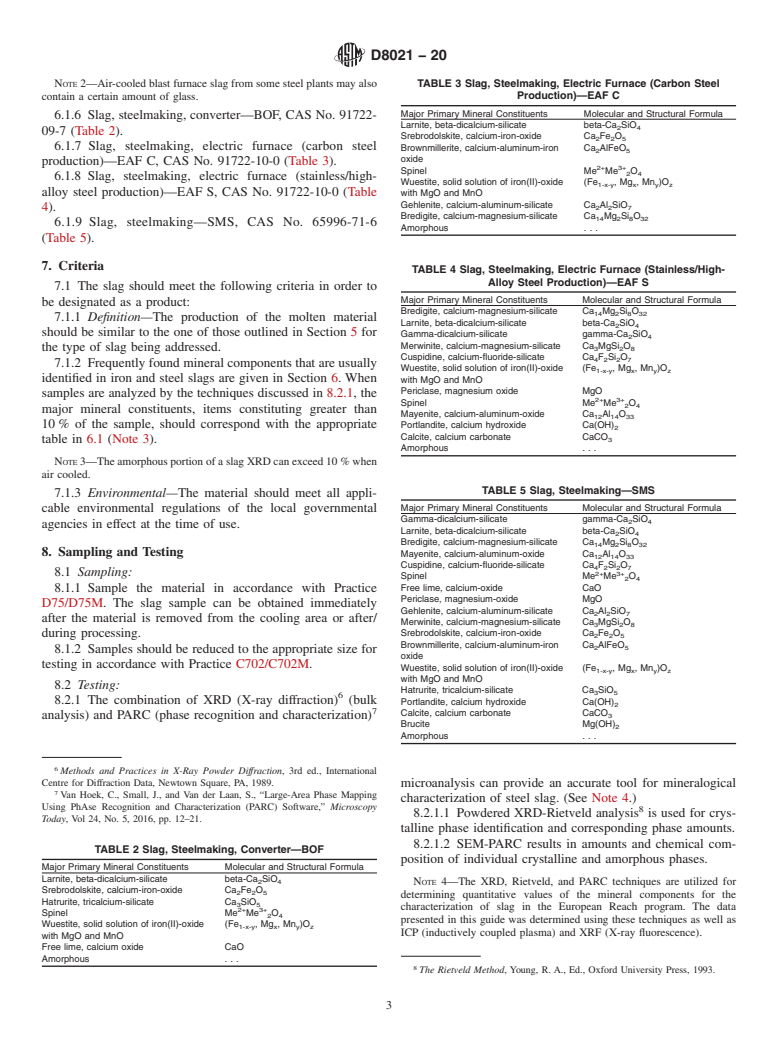

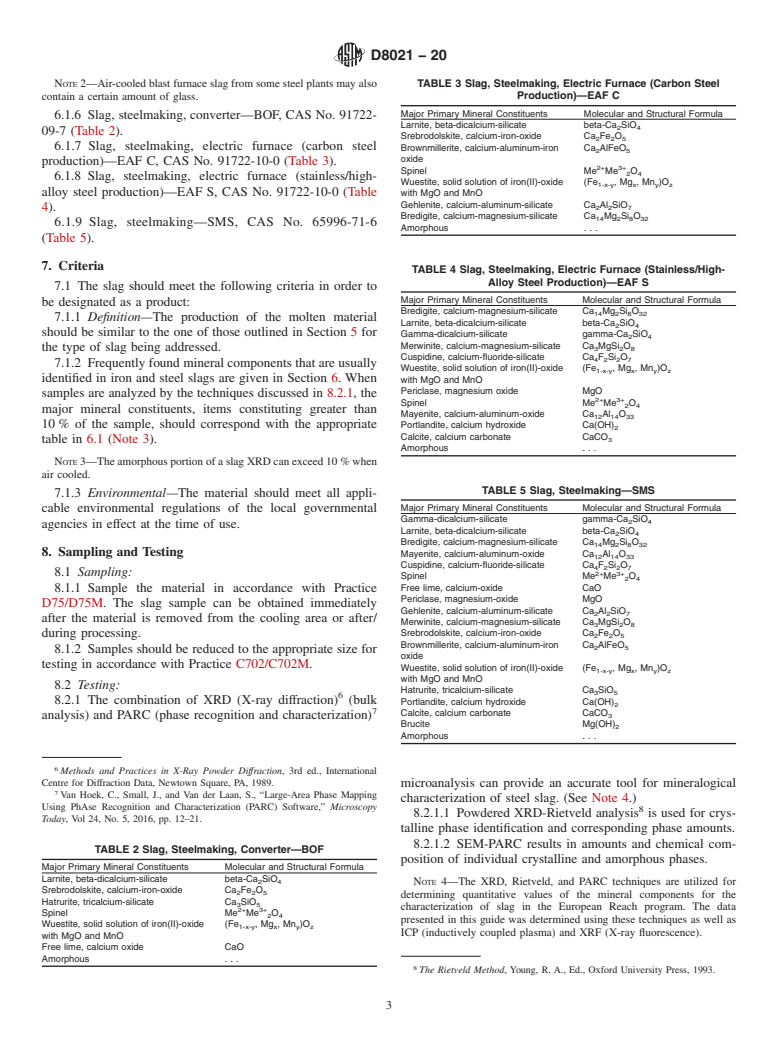

3.2.2.1 Discussion—Steelmaking slag is formed (for 5. Classification

example, from the conversion of hot metal to steel) from the

5.1 Slag, ferrous metal, blast furnace (granulated, GBS or

melting of scrap in an electric arc furnace or from the

air-cooled, ABFS).

subsequent treatments of various refinements/modifications of

5.2 Slag, steelmaking, and converter—BOF.

the crude steel, or both. The composition of the slags varies

depending on the process step in whi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.