ASTM F2731-11

(Test Method)Standard Test Method for Measuring the Transmitted and Stored Energy of Firefighter Protective Clothing Systems

Standard Test Method for Measuring the Transmitted and Stored Energy of Firefighter Protective Clothing Systems

SIGNIFICANCE AND USE

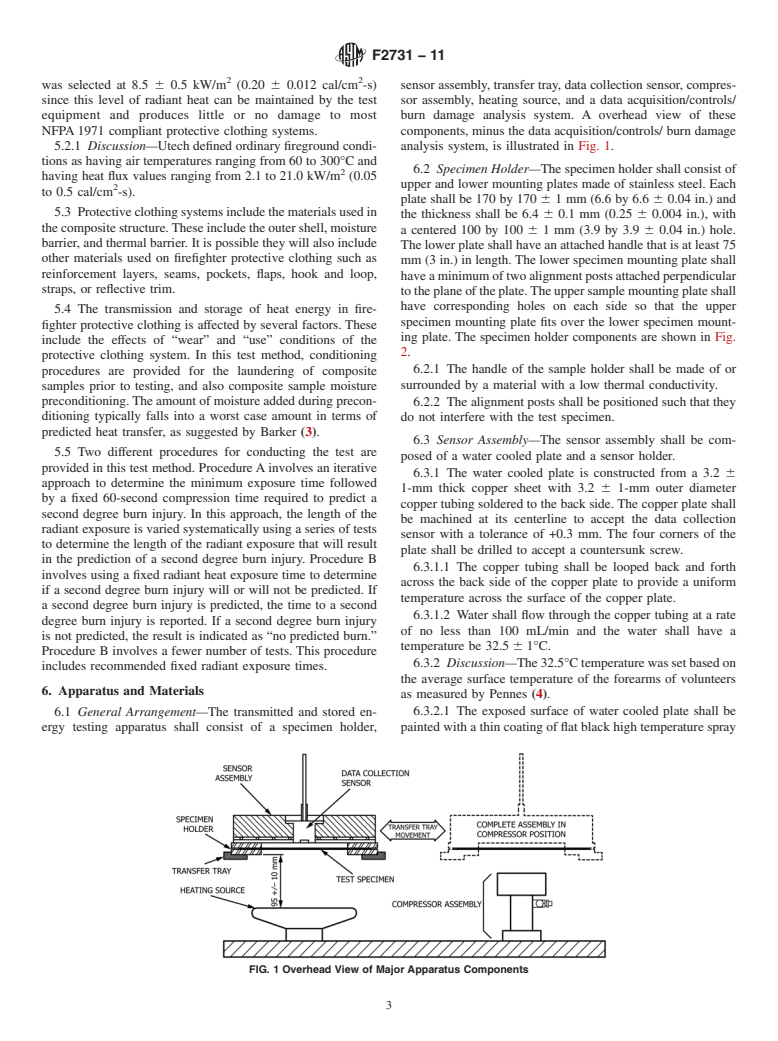

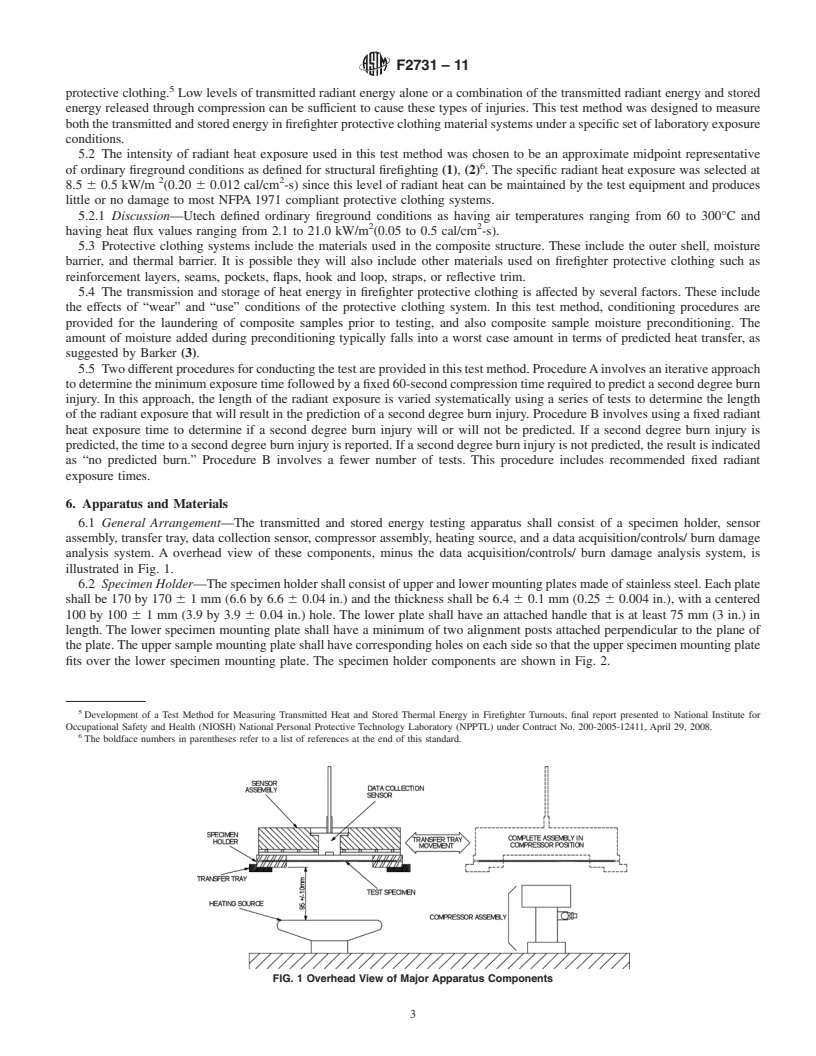

Firefighters are routinely exposed to radiant heat in the course of their fireground activities. In some cases, firefighters have reported burn injuries under clothing where there is no evidence of damage to the exterior or interior layers of the firefighter protective clothing. Low levels of transmitted radiant energy alone or a combination of the transmitted radiant energy and stored energy released through compression can be sufficient to cause these types of injuries. This test method was designed to measure both the transmitted and stored energy in firefighter protective clothing material systems under a specific set of laboratory exposure conditions.

The intensity of radiant heat exposure used in this test method was chosen to be an approximate midpoint representative of ordinary fireground conditions as defined for structural firefighting (1), (2) . The specific radiant heat exposure was selected at 8.5 ± 0.5 kW/m2 (0.20 ± 0.012 cal/cm2-s) since this level of radiant heat can be maintained by the test equipment and produces little or no damage to most NFPA 1971 compliant protective clothing systems.

5.2.1 DiscussionUtech defined ordinary fireground conditions as having air temperatures ranging from 60 to 300°C and having heat flux values ranging from 2.1 to 21.0 kW/m2 (0.05 to 0.5 cal/cm2-s).

Protective clothing systems include the materials used in the composite structure. These include the outer shell, moisture barrier, and thermal barrier. It is possible they will also include other materials used on firefighter protective clothing such as reinforcement layers, seams, pockets, flaps, hook and loop, straps, or reflective trim.

The transmission and storage of heat energy in firefighter protective clothing is affected by several factors. These include the effects of “wear” and “use” conditions of the protective clothing system. In this test method, conditioning procedures are provided for the laundering of composite samples prior to testing, and also...

SCOPE

1.1 This test method provides procedures for measuring the combination of transmitted and stored energy that occurs in firefighter protective clothing material systems as the result of exposure to prolonged, relatively low levels of radiant heat.

1.1.1 This test method applies a predetermined compressive load to a preheated specimen to simulate conductive heat transfer.

1.1.2 This test method is not applicable to protective clothing systems that are not flame resistant.

1.1.3 DiscussionFlame resistance of the material system shall be determined prior to testing according to the applicable performance and/or specification standard for the material’s end-use.

1.2 This test method establishes procedures for moisture preconditioning of firefighter protective clothing material systems.

1.3 The second-degree burn injury used in this standard is based on a limited number of experiments on forearms of human subjects.

1.3.1 DiscussionThe length of exposures needed to generate a second-degree burn injury in this test method exceeds the exposures times found in the limited number of experiments on human forearms.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are mathematical conversions to English units or other units commonly used for thermal testing.

1.5 This standard is used to measure and describe the properties of materials, products, or assemblies in response to radiant heat under controlled laboratory conditions but does not by itself incorporate all factors required for fire-hazard or fire-risk assessment of the materials, products, or assemblies under actual fire conditions.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior ...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2731 −11

Standard Test Method for

Measuring the Transmitted and Stored Energy of Firefighter

1

Protective Clothing Systems

This standard is issued under the fixed designation F2731; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method provides procedures for measuring the

responsibility of the user of this standard to establish appro-

combination of transmitted and stored energy that occurs in

priate safety and health practices and determine the applica-

firefighter protective clothing material systems as the result of

bility of regulatory limitations prior to use. Specific precau-

exposure to prolonged, relatively low levels of radiant heat.

tionary information is found in Section 7.

1.1.1 Thistestmethodappliesapredeterminedcompressive

load to a preheated specimen to simulate conductive heat

2. Referenced Documents

transfer.

2

2.1 ASTM Standards:

1.1.2 This test method is not applicable to protective cloth-

D123Terminology Relating to Textiles

ing systems that are not flame resistant.

D1777Test Method for Thickness of Textile Materials

1.1.3 Discussion—Flame resistance of the material system

D3776Test Methods for Mass Per Unit Area (Weight) of

shall be determined prior to testing according to the applicable

Fabric

performance and/or specification standard for the material’s

F1494Terminology Relating to Protective Clothing

end-use.

F1930TestMethodforEvaluationofFlameResistantCloth-

1.2 This test method establishes procedures for moisture

ing for Protection Against Fire Simulations Using an

preconditioning of firefighter protective clothing material sys-

Instrumented Manikin

tems. 3

2.2 AATCC Test Methods:

1.3 The second-degree burn injury used in this standard is

AATCC70Test Method for Water Repellency: Tumble Jar

based on a limited number of experiments on forearms of Dynamic Absorption Test

human subjects.

AATCC135 Dimensional Changes in Automatic Home

1.3.1 Discussion—The length of exposures needed to gen-

Laundering of Durable Press Woven or Knit Fabrics

4

erate a second-degree burn injury in this test method exceeds

2.3 NFPA Standard:

the exposures times found in the limited number of experi-

NFPA1971StandardonProtectiveEnsemblesforStructural

ments on human forearms.

Fire Fighting and Proximity Fire Fighting

1.4 The values stated in SI units are to be regarded as the

3. Terminology

standard. The values given in parentheses are mathematical

3.1 Definitions:

conversions to English units or other units commonly used for

3.1.1 break-open, n—intestingthermalprotectivematerials,

thermal testing.

a material response evidence by the formation of a hole in the

1.5 This standard is used to measure and describe the

test specimen.

properties of materials, products, or assemblies in response to

3.1.1.1 Discussion—The specimen is considered to exhibit

radiant heat under controlled laboratory conditions but does

break-open when a hole is produced as a result of the thermal

not by itself incorporate all factors required for fire-hazard or

2 2

exposurethatisatleast3.2cm (0.25in. )inareaoratleast2.5

fire-risk assessment of the materials, products, or assemblies

under actual fire conditions.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

1

ThistestmethodisunderthejurisdictionofASTMCommitteeF23onPersonal the ASTM website.

3

ProtectiveClothingandEquipmentandisthedirectresponsibilityofSubcommittee Available from American Association of Textile Chemists and Colorists

F23.80 on Flame and Thermal. (AATCC), P.O. Box 12215, Research Triangle Park, NC 27709, http://

CurrenteditionapprovedJuly1,2011.PublishedJuly2011.Originallyapproved www.aatcc.org.

4

in 2010. Last previous edition approved in 2010 as F2731-10. DOI: 10.1520/ Available from National Fire Protection Association (NFPA), 1 Batterymarch

F2731-11. Park, Quincy, MA 02169-7471, http://www.nfpa.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2731−11

cm (1.0 in.) in any dimension. Single threads across the 4.2 During the time of radiant heat exposure, a data collec-

opening or hole do not reduce the size of the hole for purposes tionsensor,positioned6.4 60.1mm(0.25 60.004in.)behind

of this test method. and parallel to

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:F2731–10 Designation: F2731 – 11

Standard Test Method for

Measuring the Transmitted and Stored Energy of Firefighter

1

Protective Clothing Systems

This standard is issued under the fixed designation F2731; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method provides procedures for measuring the combination of transmitted and stored energy that occurs in

firefighter protective clothing material systems as the result of exposure to prolonged, relatively low levels of radiant heat.

1.1.1 This test method applies a predetermined compressive load to a preheated specimen to simulate conductive heat transfer.

1.1.2 This test method is not applicable to protective clothing systems that are not flame resistant.

1.1.3 Discussion—Flame resistance of the material system shall be determined prior to testing according to the applicable

performance and/or specification standard for the material’s end-use.

1.2 This test method establishes procedures for moisture preconditioning of firefighter protective clothing material systems.

1.3 The second-degree burn injury used in this standard is based on a limited number of experiments on forearms of human

subjects.

1.3.1 Discussion—The length of exposures needed to generate a second-degree burn injury in this test method exceeds the

exposures times found in the limited number of experiments on human forearms.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are mathematical

conversions to English units or other units commonly used for thermal testing.

1.5 This standard is used to measure and describe the properties of materials, products, or assemblies in response to radiant

heat under controlled laboratory conditions but does not by itself incorporate all factors required for fire-hazard or fire-risk

assessment of the materials, products, or assemblies under actual fire conditions.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Specific precautionary information is found in Section 7.

2. Referenced Documents

2

2.1 ASTM Standards:

D123 Terminology Relating to Textiles

D1777 Test Method for Thickness of Textile Materials

D3776 Test Methods for Mass Per Unit Area (Weight) of Fabric

F1494 Terminology Relating to Protective Clothing

F1930 Test Method for Evaluation of Flame Resistant Clothing for Protection Against Flash Fire Simulations Using an

Instrumented Manikin

3

2.2 AATCC Test Methods:

AATCC 70 Test Method for Water Repellency: Tumble Jar Dynamic Absorption Test

AATCC 135 Dimensional Changes in Automatic Home Laundering of Durable Press Woven or Knit Fabrics

4

2.3 NFPA Standard:

NFPA 1971 Standard on Protective Ensembles for Structural Fire Fighting and Proximity Fire Fighting

3. Terminology

3.1 Definitions:

1

This test method is under the jurisdiction of ASTM Committee F23 on Personal Protective Clothing and Equipment and is the direct responsibility of Subcommittee

F23.80 on Flame and Thermal.

Current edition approved Feb. 15, 2010. Published March 2010. DOI: 10.1520/F2731-10.

Current edition approved July 1, 2011. Published July 2011. Originally approved in 2010. Last previous edition approved in 2010 as F2731 - 10. DOI: 10.1520/F2731-11.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American Association of Textile Chemists and Colorists (AATCC), P.O. Box 12215, Research Triangle Park, NC 27709, http://www.aatcc.org.

4

Available from National Fire Protection Association (NFPA), 1 Batterymarch Park, Quincy, MA 02169-7471, http://www.nfpa.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F2731 – 11

3.1.1 break-open, n—in testing thermal protective materials, a material response evidence by the formation of a hole in the test

specimen.

3.1.1.1 D

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.