ASTM B49-15

(Specification)Standard Specification for Copper Rod for Electrical Purposes

Standard Specification for Copper Rod for Electrical Purposes

ABSTRACT

This specification covers the requirements for rod drawing stock produced from electrolytic tough-pitch or oxygen-free coppers and is suitable for further fabrication into electrical conductors. The rod shall be fabricated from copper of such quality and purity. Copper of special qualities, forms, or types, as agreed upon between the manufacturer and the purchaser and that will conform to the requirements prescribed in this specification may also be used. The specimen shall have the following chemical composition: tellurium, selenium, bismuth, antimony, arsenic, tin, lead, iron, nickel, sulfur, silver, oxygen, cadmium, phosphorus, zinc, and manganese. Embrittlement test shall be performed on the specimen to reflect propensity towards hydrogen embrittlement and shall be performed only on oxygen-free copper. The rod shall be free of defects, but blemishes of a nature that do not interfere with the intended application are acceptable.

SCOPE

1.1 This specification covers the requirements for rod in diameters from 1/4 to 13/8 in. (6.4 to 35 mm) produced from high conductivity coppers listed in Table 1, namely, electrolytic tough-pitch or oxygen-free coppers and are suitable for further fabrication into electrical conductors.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 The following safety hazards caveat pertains only to Section13. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B49 −15

StandardSpecification for

1

Copper Rod for Electrical Purposes

ThisstandardisissuedunderthefixeddesignationB49;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* B577TestMethodsforDetectionofCuprousOxide(Hydro-

gen Embrittlement Susceptibility) in Copper

1.1 This specification covers the requirements for rod in

B846Terminology for Copper and Copper Alloys

1 3

diameters from ⁄4to 1 ⁄8in. (6.4 to 35 mm) produced from

E8/E8MTest Methods for Tension Testing of Metallic Ma-

highconductivitycopperslistedinTable1,namely,electrolytic

terials

tough-pitch or oxygen-free coppers and are suitable for further

E18Test Methods for Rockwell Hardness of Metallic Ma-

fabrication into electrical conductors.

terials

1.2 Thevaluesstatedininch-poundunitsaretoberegarded

E29Practice for Using Significant Digits in Test Data to

as standard. The values given in parentheses are mathematical

Determine Conformance with Specifications

conversions to SI units that are provided for information only

E53Test Method for Determination of Copper in Unalloyed

and are not considered standard.

Copper by Gravimetry

1.3 The following safety hazards caveat pertains only to E478Test Methods for ChemicalAnalysis of CopperAlloys

Section13. This standard does not purport to address all of the

E1606Practice for Electromagnetic (Eddy-Current) Exami-

safety concerns, if any, associated with its use. It is the nation of Copper Redraw Rod for Electrical Purposes

responsibility of the user of this standard to establish appro-

E2575Test Method for Determination of Oxygen in Copper

priate safety and health practices and determine the applica- and Copper Alloys

3

bility of regulatory limitations prior to use.

2.3 Other Document:

NBS Handbook 100Copper Wire Tables

2. Referenced Documents

3. Terminology

2.1 The following documents in the current issue of the

3.1 For definitions of general terms relating to copper and

BookofStandardsformapartofthisspecificationtotheextent

copper alloys refer to Terminology B846.

referenced herein and define materials suitable for use in rod

manufacture:

4. Ordering Information

2

2.2 ASTM Standards:

4.1 Orders for rod under this specification shall include the

B5Specification for High ConductivityTough-Pitch Copper

following information:

Refinery Shapes

4.1.1 ASTM designation and year of issue,

B115Specification for Electrolytic Copper Cathode

4.1.2 Quantity of each size,

B170Specification for Oxygen-Free Electrolytic Copper—

4.1.3 UNS designation and requirements of copper (Sec-

Refinery Shapes

tions5–10),

B193Test Method for Resistivity of Electrical Conductor

4.1.4 Finish (Sections 9 and 10),

Materials

4.1.5 Package with or without joints (see 5.3),

B224Classification of Coppers

4.1.6 Rod diameter (see 9.2),

4.1.7 Inspection (Section 15),

4.1.8 Package size (see 19.1), and

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

4.1.9 Special package marking as agreed upon between the

and Copper Alloys and is the direct responsibility of Subcommittee B05.07 on

manufacturer and the purchaser (Section 19).

Refined Copper.

Current edition approved May 1, 2015. Published May 2015. Originally

4.2 The following requirements are optional and should be

approved in 1923. Last previous edition approved in 2010 as B49–10. DOI:

specified in the contract or purchase order when required.

10.1520/B0049-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from NationalTechnical Information Service (NTIS), 5301 Shawnee

the ASTM website. Rd., Alexandria, VA 22312, http://www.ntis.gov.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B49−15

A

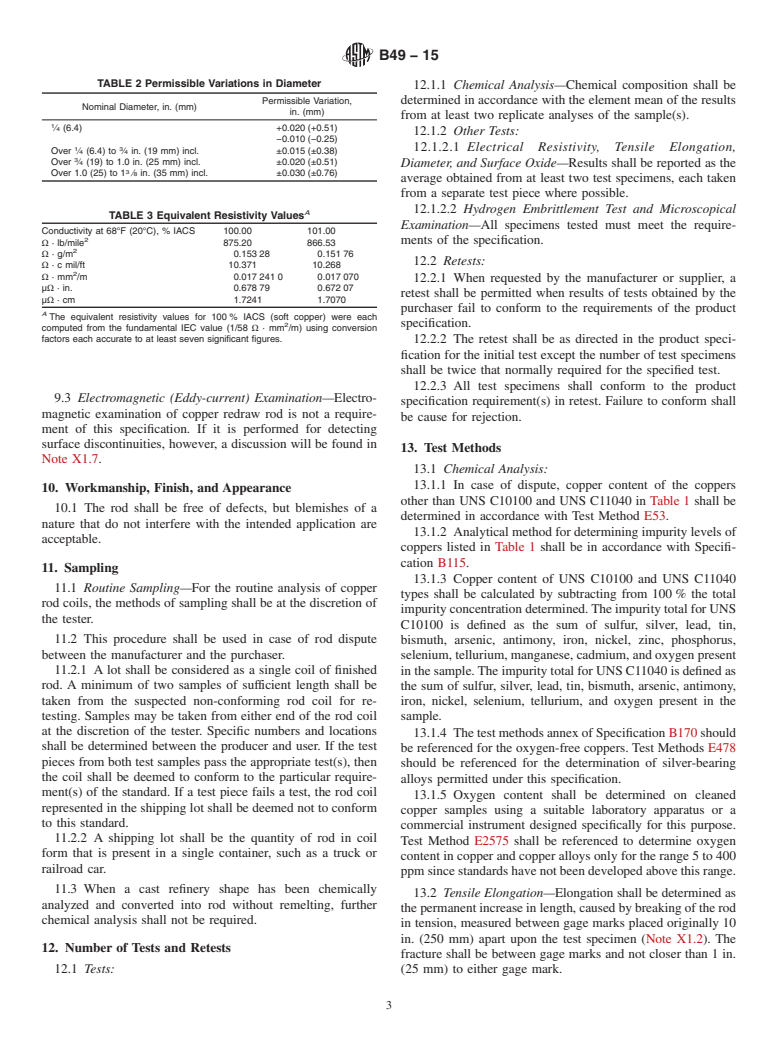

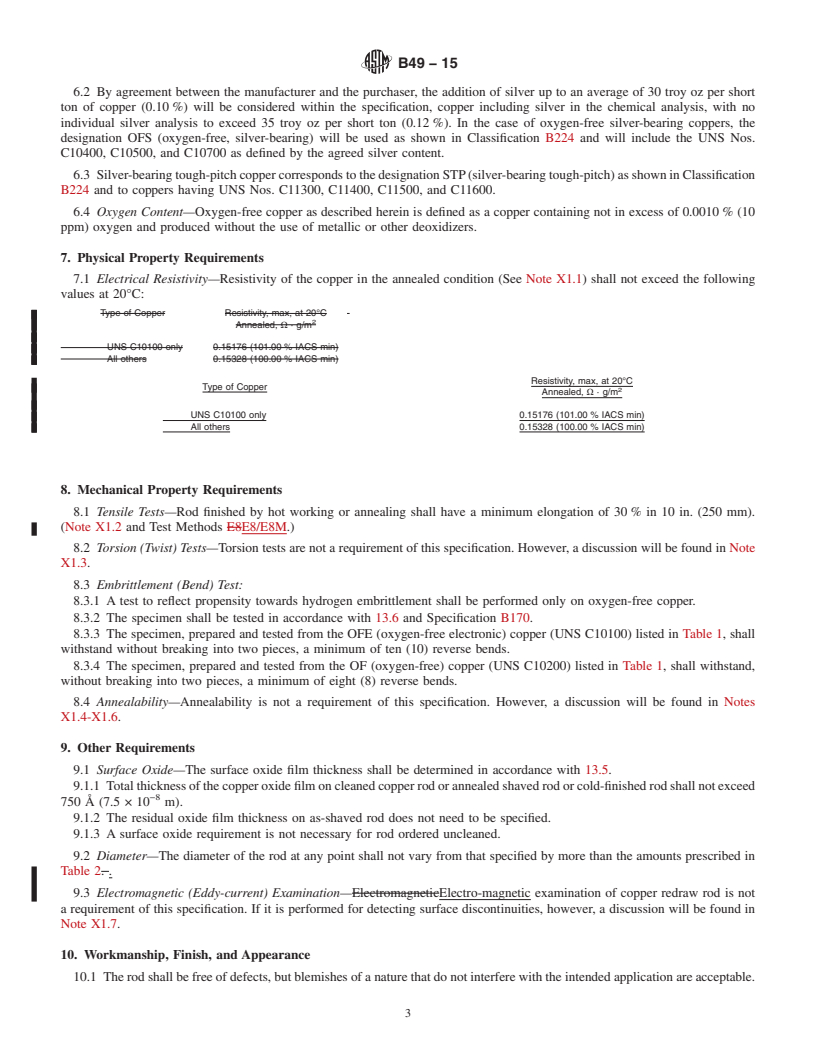

TABLE 1 Chemical Composition

6.3 Silver-bearing tough-pitch copper corresponds to the

UNS Number C11040 C10100 C10200 C11000

designation STP (silver-bearing tough-pitch) as shown in

B C

Copper Type ETP OFE OF ETP

Classification B224 and to coppers having UNS Nos. C11300,

D D E E

Copper, min 99.90 % 99.99 % 99.95 % 99.90 %

C11400, C11500, and C11600.

incl silver incl silver

ppm ppm ppm ppm

6.4 Oxygen Content—Oxygen-free copper as described

Tellurium, max 2 2 . . . . . .

herein is defined as a copper containing not in excess of

Selenium, max 2 3 . . . . .

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B49 − 10 B49 − 15

Standard Specification for

1

Copper Rod Drawing Stock for Electrical Purposes

This standard is issued under the fixed designation B49; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1 3

1.1 This specification covers the requirements for rod drawing stock in diameters from ⁄4 to 1 ⁄8 in. (6.4 to 35 mm) produced

from high conductivity coppers listed in Table 1, namely, electrolytic tough-pitch or oxygen-free coppers and are suitable for

further fabrication into electrical conductors.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 The following safety hazards caveat pertains only to Section13. This standard does not purport to address all of the safety

concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2.1 The following documents in the current issue of the Book of Standards form a part of this specification to the extent

referenced herein and define materials suitable for use in rod manufacture:

2

2.2 ASTM Standards:

B5 Specification for High Conductivity Tough-Pitch Copper Refinery Shapes

B115 Specification for Electrolytic Copper Cathode

B170 Specification for Oxygen-Free Electrolytic Copper—Refinery Shapes

B193 Test Method for Resistivity of Electrical Conductor Materials

B224 Classification of Coppers

B577 Test Methods for Detection of Cuprous Oxide (Hydrogen Embrittlement Susceptibility) in Copper

B846 Terminology for Copper and Copper Alloys

E8E8/E8M Test Methods for Tension Testing of Metallic Materials

E18 Test Methods for Rockwell Hardness of Metallic Materials

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E53 Test Method for Determination of Copper in Unalloyed Copper by Gravimetry

E478 Test Methods for Chemical Analysis of Copper Alloys

E1606 Practice for Electromagnetic (Eddy-Current) Examination of Copper Redraw Rod for Electrical Purposes

E2575 Test Method for Determination of Oxygen in Copper and Copper Alloys

3

2.3 Other Document:

NBS Handbook 100 Copper Wire Tables

3. Terminology

3.1 For definitions of general terms relating to copper and copper alloys refer to Terminology B846.

1

This specification is under the jurisdiction of ASTM Committee B05 on Copper and Copper Alloys and is the direct responsibility of Subcommittee B05.07 on Refined

Copper.

Current edition approved Oct. 1, 2010May 1, 2015. Published November 2010May 2015. Originally approved in 1923. Last previous edition approved in 20092010 as

B49 – 09.B49 – 10. DOI: 10.1520/B0049-10.10.1520/B0049-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from National Technical Information Service (NTIS), 5285 Port Royal Rd., Springfield, VA 22161,5301 Shawnee Rd., Alexandria, VA 22312,

http://www.ntis.gov.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B49 − 15

4. Ordering Information

4.1 Orders for rod under this specification shall include the following information:

4.1.1 ASTM designation and year of issue,

4.1.2 Quantity of each size,

4.1.3 UNS designation and requirements of copper (Sections 5 – 10),

4.1.4 Finish (Sections 9 and 10),

4.1.5 Package with or without joints (see 5.3),

4.1.6 Rod diameter (see 9.2),

4.1.7 Inspection (Section 15),

4.1.8 Package size (see 19.1), and

4.1.9 Special package marking as agreed upon between the manufacturer and the purchaser (Section 19).

4.2 The following requirements are optional and should be specified in the contract or purchase order when required.

4.2.1 Certification (Section 17) and

4.2.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.