ASTM D3493-04

(Test Method)Standard Test Method for Carbon Black—Oil Absorption Number of Compressed Sample (COAN)

Standard Test Method for Carbon Black—Oil Absorption Number of Compressed Sample (COAN)

SCOPE

1.1 This test method covers the procedure for the mechanical compression of a carbon black sample and the determination of the oil absorption number of the compressed sample.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 3493 – 04

Standard Test Method for

Carbon Black—Oil Absorption Number of Compressed

1

Sample (COAN)

This standard is issued under the fixed designation D 3493; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 n -Dibutyl phthalate or paraffin oil is added by means of

a constant-rate buret to the compressed sample of carbon black

1.1 This test method covers the procedure for the mechani-

in the mixer chamber of an absorptometer. As the sample

cal compression of a carbon black sample and the determina-

absorbs the oil, the mixture changes from a free-flowing state

tion of the oil absorption number of the compressed sample.

to one of a semiplastic agglomeration, with an accompanying

1.2 The values stated in SI units are to be regarded as the

increase in viscosity. This increased viscosity is transmitted to

standard. The values given in parentheses are for information

the torque-sensing system of the absorptometer. When the

only.

viscosity of the mixture reaches a predetermined torque level,

1.3 This standard does not purport to address all of the

the absorptometer and buret will simultaneously shut off. The

safety concerns, if any, associated with its use. It is the

volume of oil added is read from the direct reading buret. The

responsibility of the user of this standard to establish appro-

volume of oil per unit mass of carbon black is the oil

priate safety and health practices and determine the applica-

absorption number. Either DBP or paraffin oil is acceptable for

bility of regulatory limitations prior to use.

use with many standard pelleted grades of N-series carbon

2. Referenced Documents blacks found in Classification D 1765. COAN testing using

2

paraffin oil on some carbon black products may result in

2.1 ASTM Standards:

unacceptable differences as compared to OAN testing using

D 1799 Practice for Carbon Black—Sampling Packaged

DBP oil. Referee testing between suppliers and users should

Shipments

use DBP oil until such time that precision data is available for

D 1900 Practice for Carbon Black—Sampling Bulk Ship-

paraffin oil.

ments

D 2414 Test Method for Carbon Black—Oil Absorption

4. Significance and Use

Number

4.1 The oil absorption number of a carbon black is related to

D 3324 Practice for Carbon Black—Improving Test Repro-

3

the processing and vulcanizate properties of rubber compounds

ducibility Using ASTM Standard Reference Blacks

containing the carbon black.

D 4821 Guide for Carbon Black—Validation of Test

4.2 The difference between the regular oil absorption num-

Method Precision and Bias

ber and the oil absorption number of compressed sample is

D 4483 Practice for Determining Precision for Test Method

some measure of the stability of the structure of the carbon

Standards in the Rubber and Carbon Black Industries

black.

3. Summary of Test Method

4

5. Apparatus

3.1 A sample of carbon black is compressed four times in a

5.1 Balance, analytical, 0.01-g sensitivity.

compression cylinder at a pressure of 165 MPa (24 000 psi)

5.2 Oven, gravity-convection type, capable of maintaining

and then tested in an absorptometer to determine the oil

125° 6 5°C.

absorption number.

5.3 Carbon Black Press, capable of compressing a 25 g

5

sample to 165 MPa (24 000 psi).

1

This test method is under the jurisdiction of ASTM Committee D24 on Carbon

Black and is the direct responsibility of Subcommittee D24.11 on Absorptive

Properties of Carbon Black.

Current edition approved Jan. 1, 2004. Published February 2004. Originally

approved in 1976. Last previous edition approved in 2003 as D 3493-03.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or All apparatus is to be operated and maintained in accordance with the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM manufacturer’s directions for optimum performance.

5

Standards volume information, refer to the standard’s Document Summary page on Carbon black presses from the following companies have been found satisfac-

the ASTM website. tory for this test method: EG&G Engineering, P.O. Box 470710, Tulsa, OK

3

Withdrawn. 74147–0710 and Titan Specialties, Inc., P.O. Box 2316, Pampa, TX 79066-2316.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

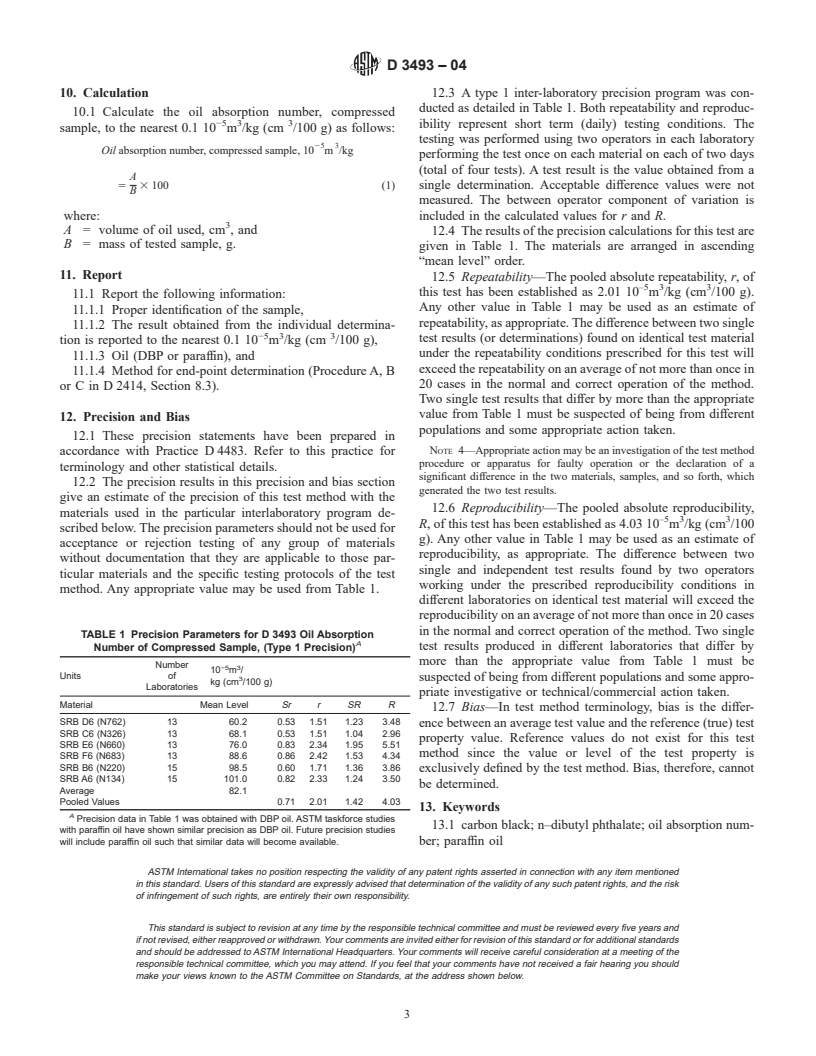

D3493–04

6

5.4 Absorptometer, equipped with a constant-rate buret 9.4.2 Place the carbon black sample in the compression

3 3

which delivers 67 6 0.4 mm /s (4 6 0.024 cm /min). cylinder and insert the piston with the nylon spac

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.